Cloth defect detection method using hierarchical gradient direction histogram and support vector machine

A support vector machine and gradient direction technology, applied in image enhancement, image analysis, image data processing, etc., can solve the problems of large sample demand, low detection efficiency, high false detection rate and missed detection rate, and improve the quality of cloth Control ability, reduce labor cost, and ensure the effect of accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

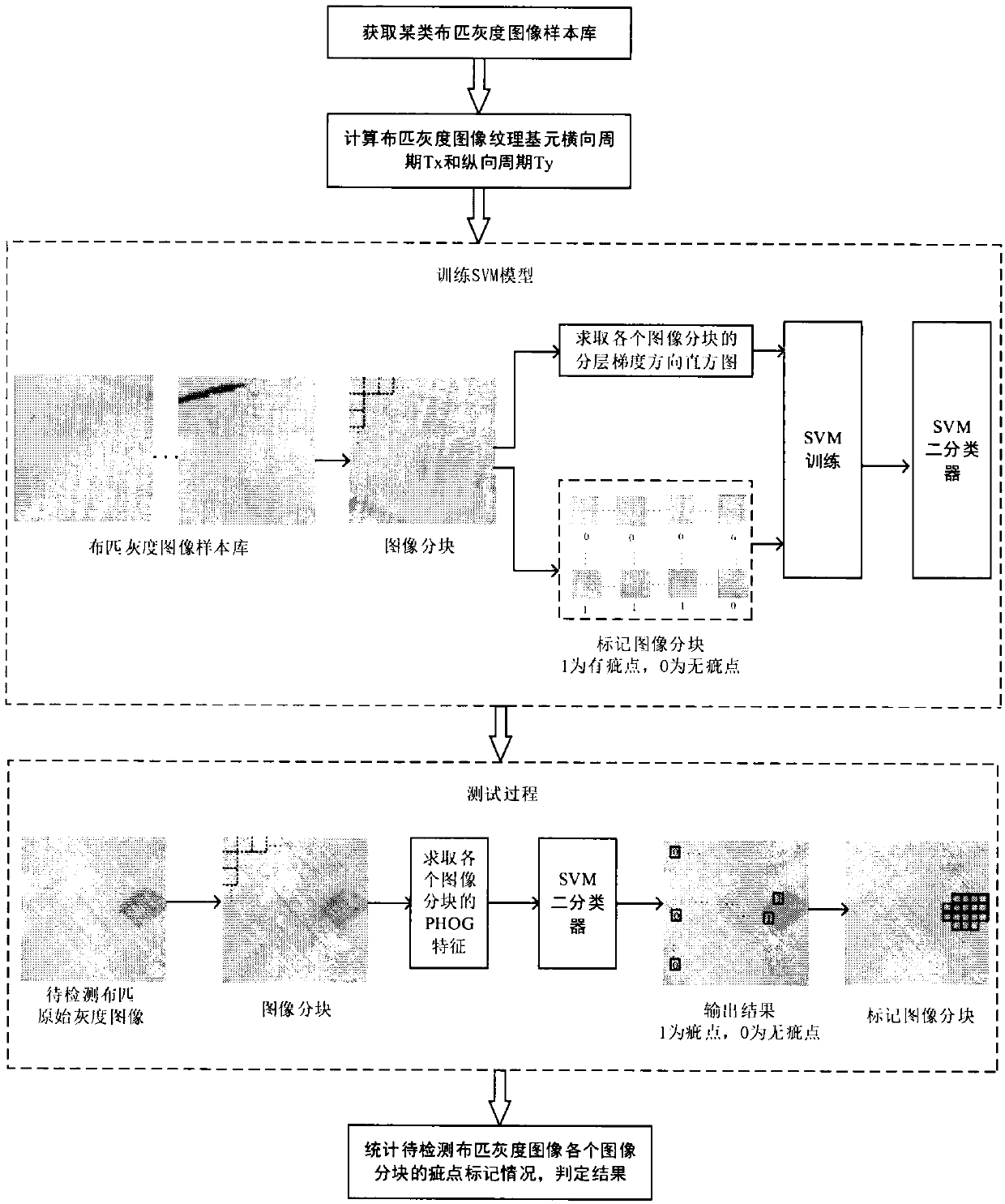

[0028] Such as figure 1 As shown, adopt a kind of cloth defect detection method that utilizes layered gradient orientation histogram and support vector machine that the present invention provides, comprise the following steps:

[0029] Taking the twill cloth image of the German TILDA cloth sample library as an example, a kind of cloth defect detection method utilizing a layered gradient direction histogram and a support vector machine provided by the present invention comprises the following steps:

[0030] S1: Obtain a certain type of cloth with defects and non-defective images and perform grayscale processing to form a sample library of grayscale images of defective and non-defective cloths;

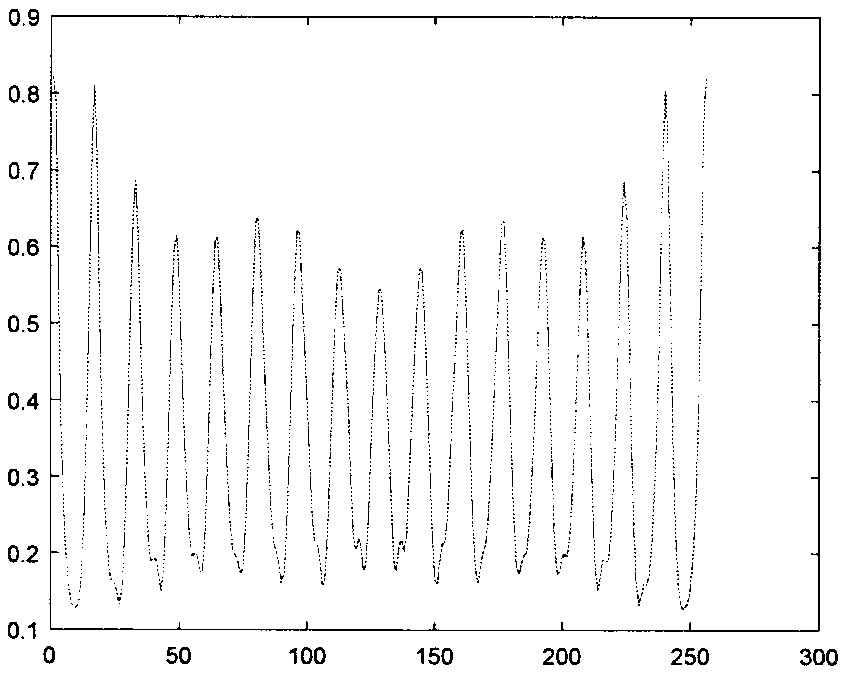

[0031] S2: Extract a non-defective cloth gray image from the cloth gray image sample library, and use the autocorrelation coefficient method to calculate the horizontal period Tx and longitudinal period Ty of the texture primitive of the cloth gray image;

[0032] S3: Divide all the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com