Method for determining sodium chloride in industrial calcium chloride

A method of determination, the technology of calcium chloride, applied in the field of inspection and testing, can solve the problems of many factors affecting the accuracy, and achieve the effect of shortening the analysis cycle, reducing the cost of analysis, and reducing the amount of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] A kind of determination method of sodium chloride in industrial calcium chloride adopts the inductively coupled plasma atomic emission spectrometer to measure the content of sodium chloride in industrial calcium chloride, and realizes according to the following steps:

[0036] 1. Crucible drying: Dry a glass sand crucible with a filter plate pore size of 5 μm-15 μm in an oven at 105°C-110°C until the quality is constant;

[0037] 2. Prepare sample solution: Weigh 0.25 sample, put it in a 100ml beaker, add 20ml reverse osmosis pure water to dissolve, filter the solution with a sand crucible, collect the filtrate and put it in the beaker, and wash the crucible repeatedly with 10ml reverse osmosis pure water For insoluble matter, wash until there is no chloride ion in the filtrate; the determination method for washing until there is no chloride ion in the filtrate: take 5ml of washing liquid, add 5ml of silver nitrate solution with a concentration of 20g / L, mix well, and le...

Embodiment 2

[0058] A kind of determination method of sodium chloride in industrial calcium chloride adopts the inductively coupled plasma atomic emission spectrometer to measure the content of sodium chloride in industrial calcium chloride, and realizes according to the following steps:

[0059] 1. Crucible drying: Dry a glass sand crucible with a filter plate pore size of 5 μm-15 μm in an oven at 105°C-110°C until the quality is constant;

[0060] 2. Prepare sample solution: Weigh 0.25 sample, put it in a 100ml beaker, add 10ml (1:1) dilute nitric acid solution to dissolve the sample, then add 20ml reverse osmosis pure water to obtain a sample solution for the determination of chlorination sodium content;

[0061] 3. Preparation of blank solution: no sample is added, and the others are the same as in step 2 to obtain a blank solution;

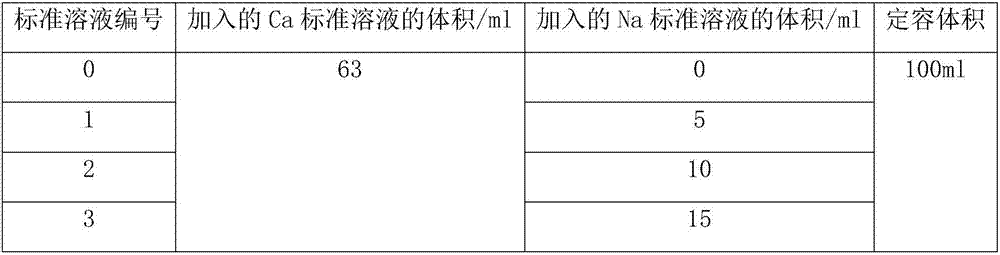

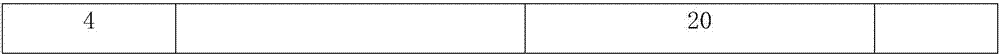

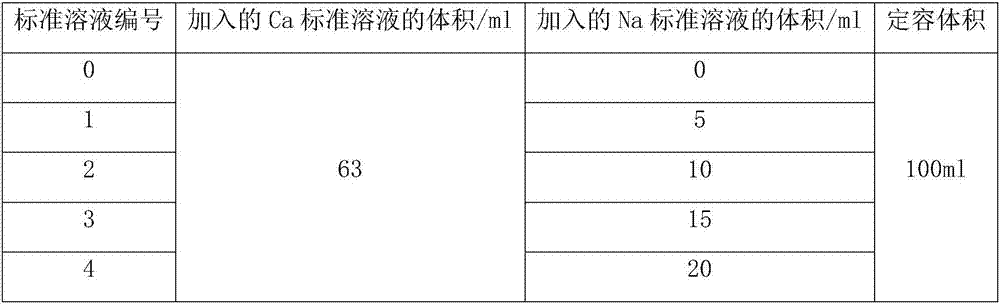

[0062] 4. Prepare standard series sample solutions:

[0063] (1) Prepare 1000 μg / ml sodium standard solution (outsourced national sodium standard solut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com