Method for measuring content of manganese in silicon-vanadium alloy

A technology of silicon vanadium alloy and manganese content, applied in the field of chemical detection, can solve the problems of high cost and long time, and achieve the effects of less reagents, convenient operation and low analysis cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

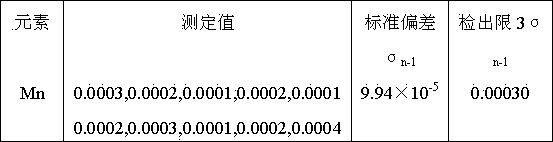

[0018] 1) According to the preparation method of the sample solution in step A, prepare 6 blank sample solutions and transfer them into volumetric flasks;

[0019] 2) Precisely weigh 0.1000g of pure manganese with a purity greater than 99.9%, dissolve it with 30ml of 1+1 hydrochloric acid, transfer it into a 100ml volumetric flask, and dilute with distilled water or secondary deionized water to obtain a manganese standard stock solution;

[0020] 3) Add 0ml, 1.00ml, 3.00ml, 5.00ml, 7.00ml and 10.00ml of manganese standard stock solutions into the volumetric flasks of the aforementioned 6 blank sample solutions, add distilled water or secondary deionized water to constant volume to obtain Manganese standard solution;

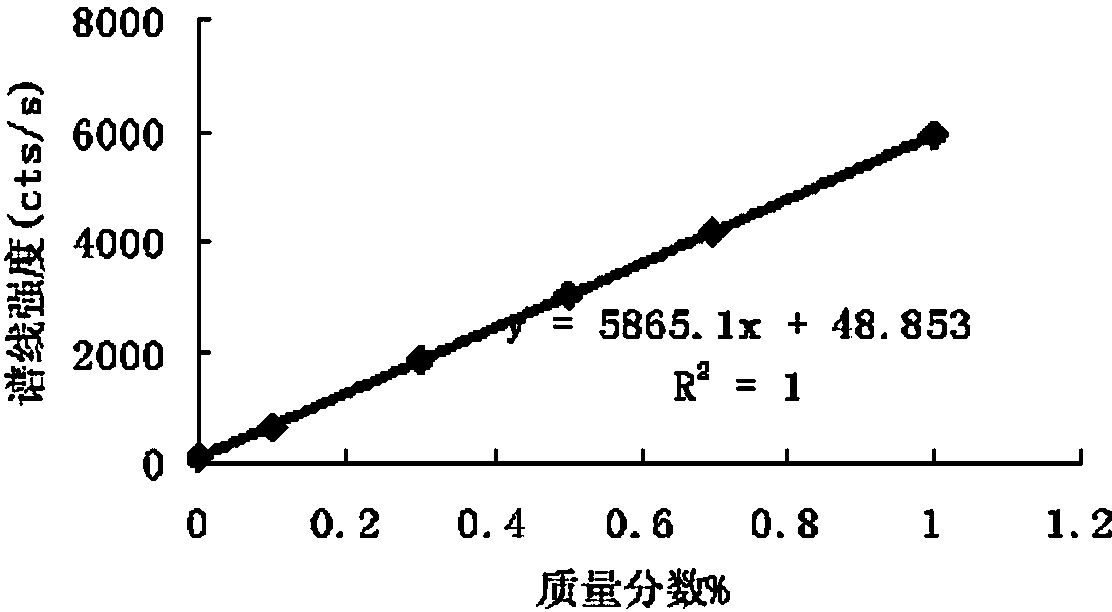

[0021] C. Determination: Determination is performed by plasma atomic emission spectrometry.

[0022] The concentrated nitric acid concentration described in A step is 60~80%, preferably 70%.

[0023] The hydrofluoric acid concentration described in A step is 30...

Embodiment 1

[0046] Reagent used in the present invention and preparation thereof:

[0047] 1. Nitric acid (ρ1.42g / mL);

[0048] 2. Hydrofluoric acid (ρ1.15g / mL);

[0049] 3. Perchloric acid (ρ1.67g / mL);

[0050] 4. The above reagents nitric acid, hydrofluoric acid and perchloric acid are analytical reagents, and water is secondary deionized water.

Embodiment 2

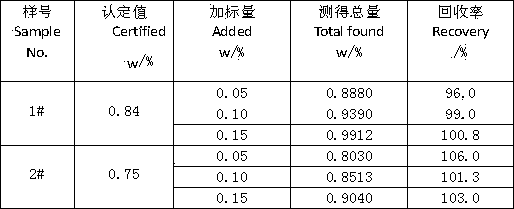

[0052] 1. The preparation of the standard stock solution used in the working curve:

[0053] A. Weigh 0.1000g manganese metal (﹥99.9%) into a 100mL beaker, add 30mL hydrochloric acid (1+1), heat to dissolve completely, after cooling, transfer to a 1000mL volumetric flask, dilute to the mark with water, and mix well. 1 mL of this solution contains 100 μg manganese.

[0054] 2. Preparation of standard solution for working curve

[0055]2A. Add 8mL of concentrated nitric acid, 2.5mL of hydrofluoric acid, and 5mL of perchloric acid to six 100mL volumetric flasks, heat to emit perchloric acid fumes for 15 minutes, remove and cool, and add 10mL of distilled water.

[0056] 2B. Add 0mL, 1.00mL, 3.00mL, 5.00mL, 7.00mL, 10.00mL of the A standard stock solution in step 2 to the 6 solutions obtained in step A, add distilled water to a 100mL volumetric flask and shake well .

[0057] 2C, the working conditions of the instrument are shown in Table 1, the wavelength and series of element...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com