Optical filter coating method

A filter and substrate technology, which is applied in the production process of high-performance IR-CUT filters, can solve the problems of poor melting effect, affecting the yield rate, and long production time of products, so as to enhance quality control ability, improve the cleaning effect, and eliminate the effect of material perforation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention is further described below in conjunction with accompanying drawing:

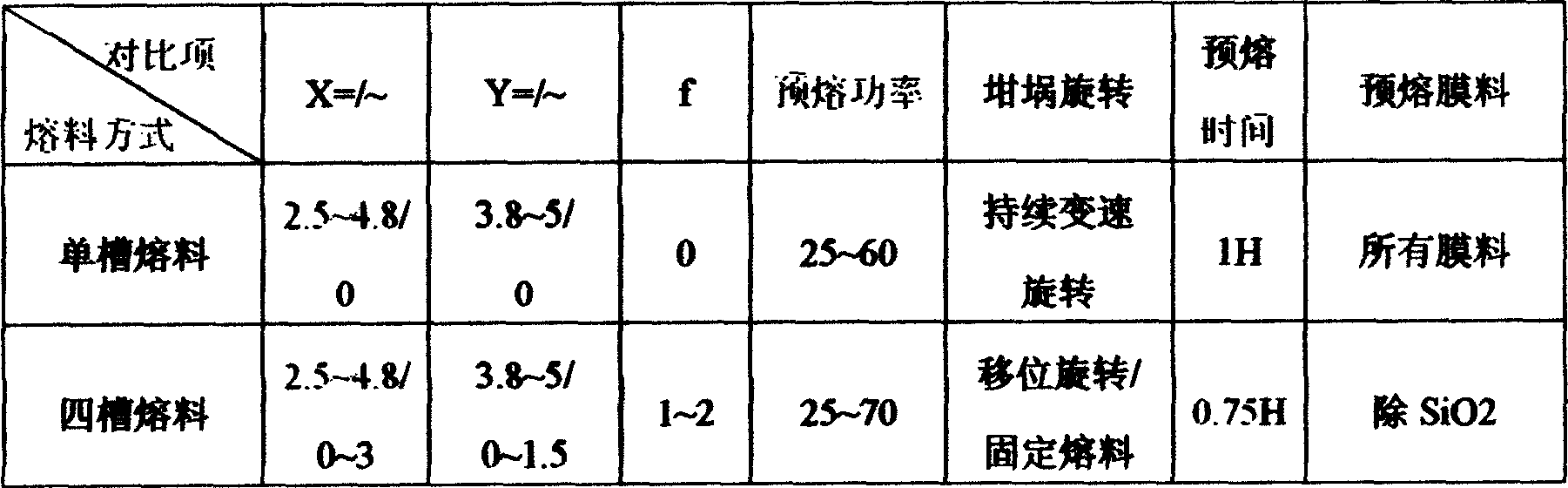

[0029] The production method of this technological process is perfect to complete the production of the product. In order to resolve the technical difficulties in the actual operation details. This process generally includes the following important links: substrate→polishing / cutting→ultrasonic cleaning before plating→plating of IR film→testing link→cutting→post-plating ultrasonic cleaning→inspection link→finished filter

[0030] The most core and key links are ultrasonic cleaning and IR film plating, which affect the final yield and product quality of the entire production process. In addition, ultrasonic cleaning before coating is added before coating, so that the substrate before coating is free from scratches, stains and dust; thus ensuring that the good product of the substrate before coating is close to 100%, greatly reducing the generation of bright spots under the coatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com