Artificial board surface defect detection method based on singular value decomposition

A singular value decomposition and defect detection technology, applied in the field of digital image processing, can solve the problems of workers' visual fatigue, false detection rate and high missed detection rate, and achieve the effect of simple calculation, high accuracy, and guaranteed accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

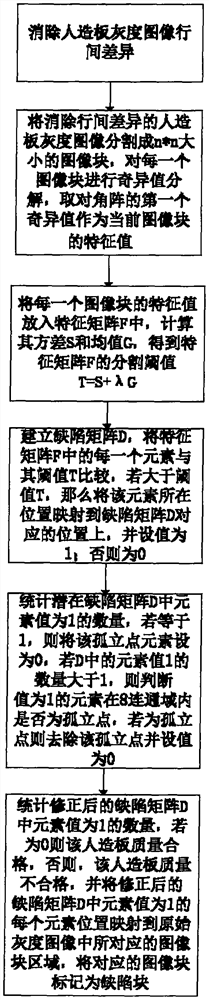

[0034] Taking the detection of a wood-based panel in actual production as an example, a method for detecting surface defects of a wood-based panel based on singular value decomposition provided by the present invention is adopted. The specific process is as follows figure 1 As shown, it specifically includes the following steps:

[0035] S1: The wood-based panel is photographed by a line-scan camera to obtain the original grayscale image I orig ,Such as figure 2 Shown; original grayscale image I orig The gray value of each pixel in minus the average value of the gray value of the row to obtain the gray image I that eliminates the difference between rows, such as image 3 Shown; The grayscale value I (i, j) of each pixel in the grayscale image I that eliminates the difference between lines satisfies the following formula:

[0036]

[0037] Where M, N are the original grayscale image I orig The horizontal and vertical coordinates of I orig (i, j) is the original graysca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com