Method for online real-time single cigarette quality data one-by-one synchronization method during cigarette rolling process

A real-time data, cigarette rolling technology, applied in the direction of electrical program control, comprehensive factory control, etc., can solve the problems of long lag, unable to reflect whether the production process is "normal" or not, and does not have real-time synchronization one by one, to achieve Improve the level of optimization, shorten the design cycle, improve the effect of quality control capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

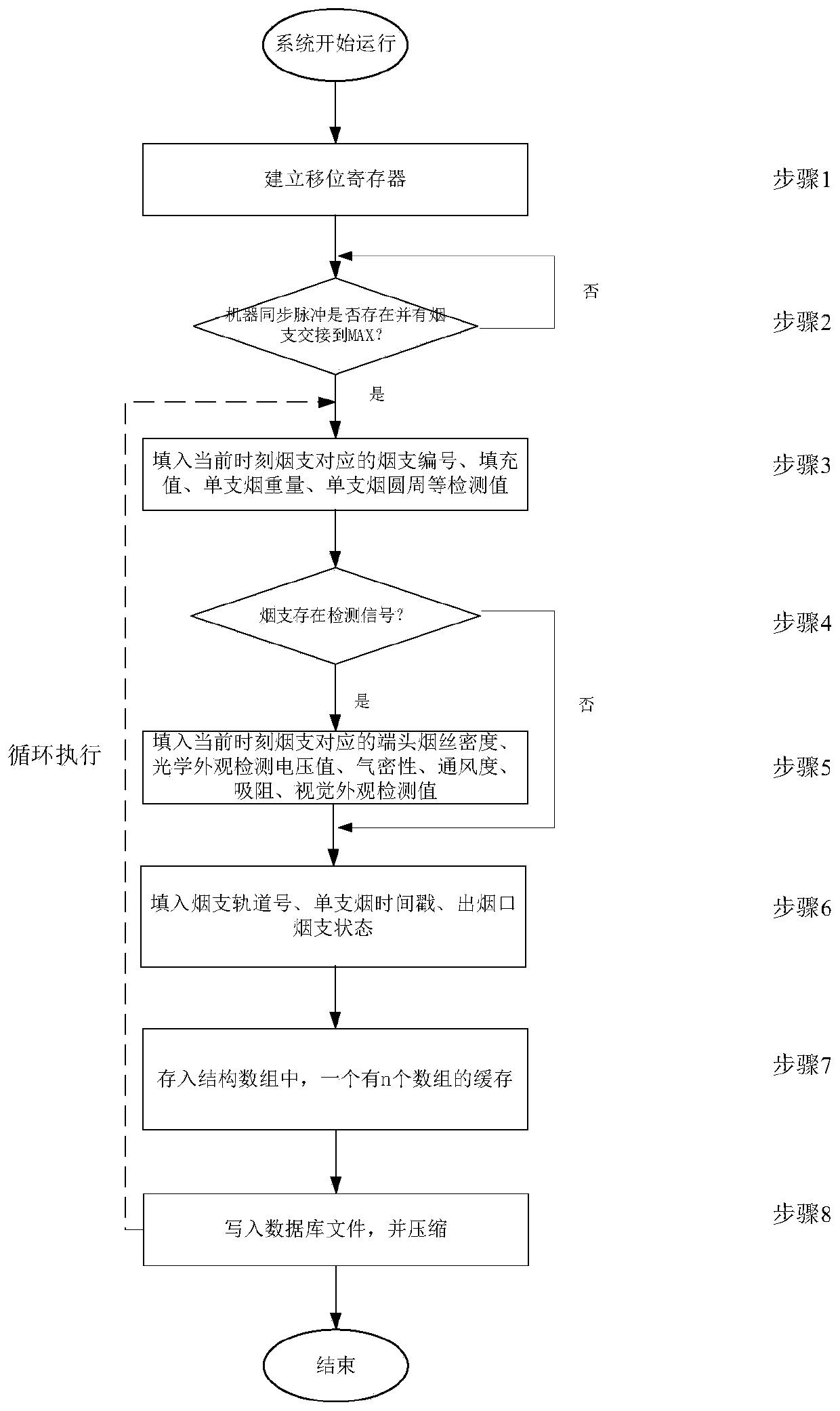

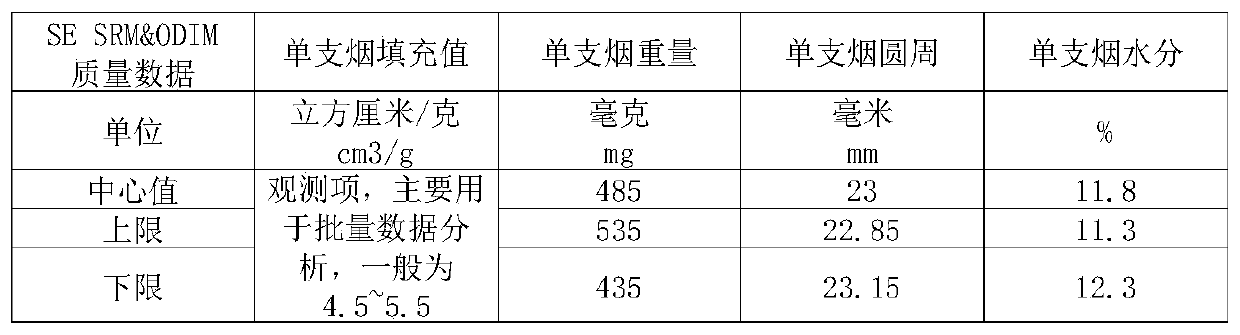

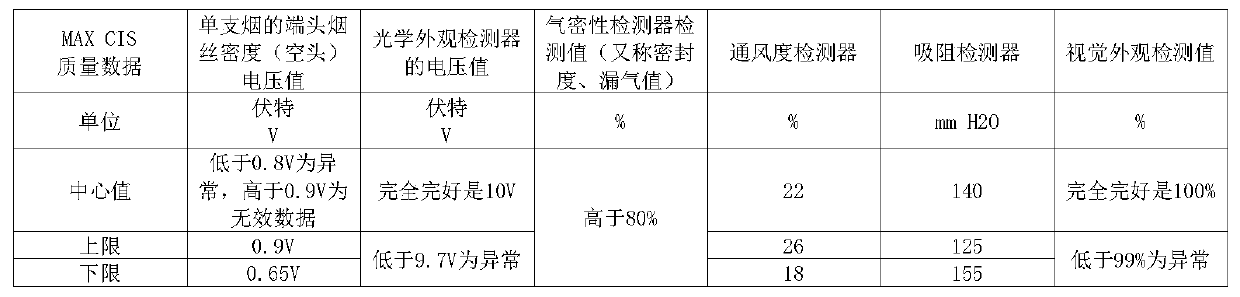

[0038] In order to better understand the technical solution and purpose of the present invention, the implementation of the present invention will be further described below in conjunction with the accompanying drawings. "SE" of the present invention refers to "cut tobacco rod forming machine", and MAX refers to "filter tip and tobacco rod joining machine".

[0039]This embodiment is a method for synchronizing online single cigarette quality real-time data of the cigarette rolling process of the ZJ17E cigarette rolling machine produced by Changde Tobacco Machinery Co., Ltd. one by one. This model is currently produced by Changde Company and equipped with a fast control core (Beckhoff IPC controller, the control period can reach the microsecond level, which can meet the basic technical requirements of the present invention: the production speed of the ZJ17E coiler is 7000 pieces / minute , that is, the cycle of each cigarette is 60000ms / 7000 = 8.6ms / , even if the current world's ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com