A process optimization control method for steelmaking and continuous casting industry

An industrial process, optimization control technology, applied in steel manufacturing process, metal processing, process efficiency improvement, etc., to achieve the effect of improving optimization level and guaranteeing profits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

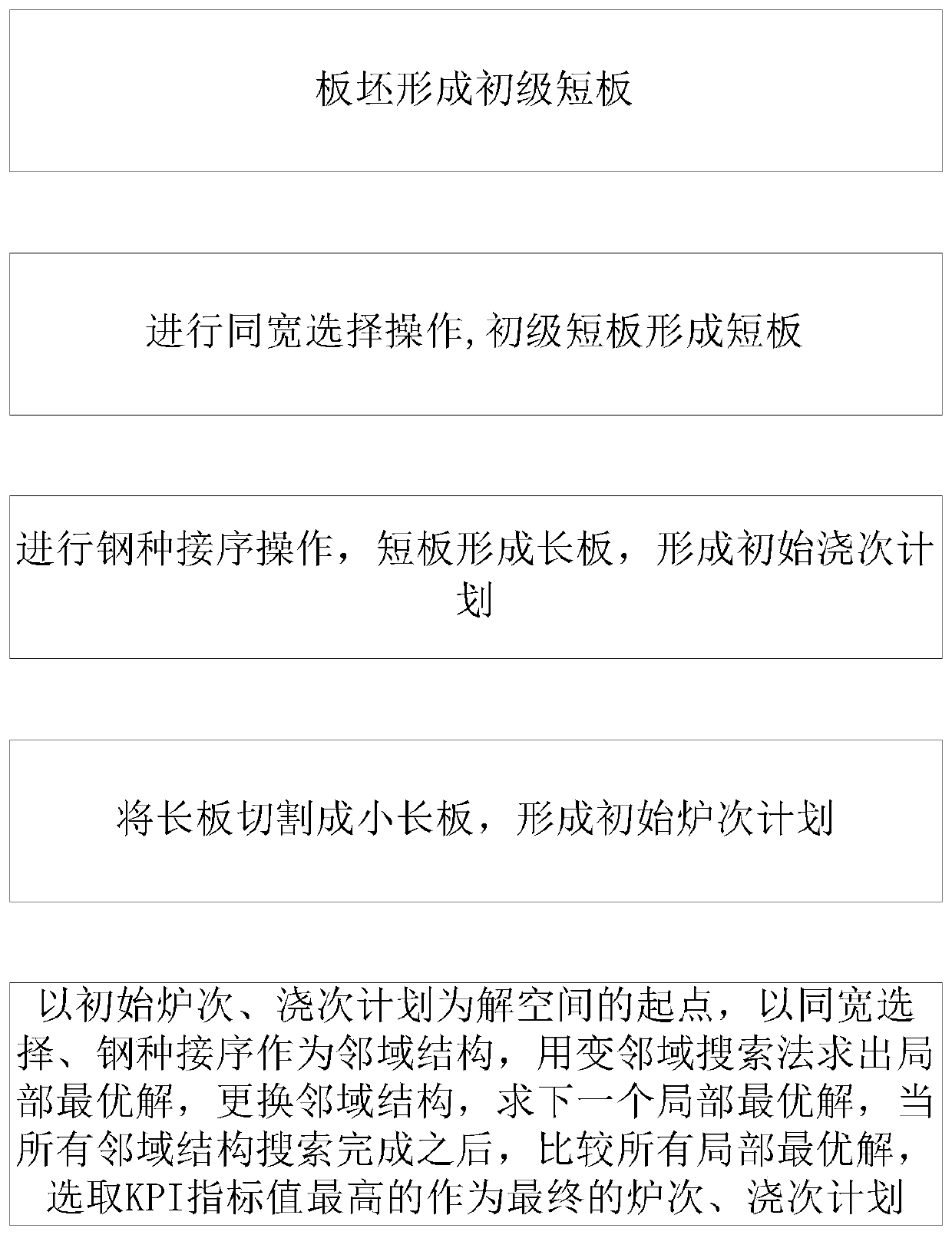

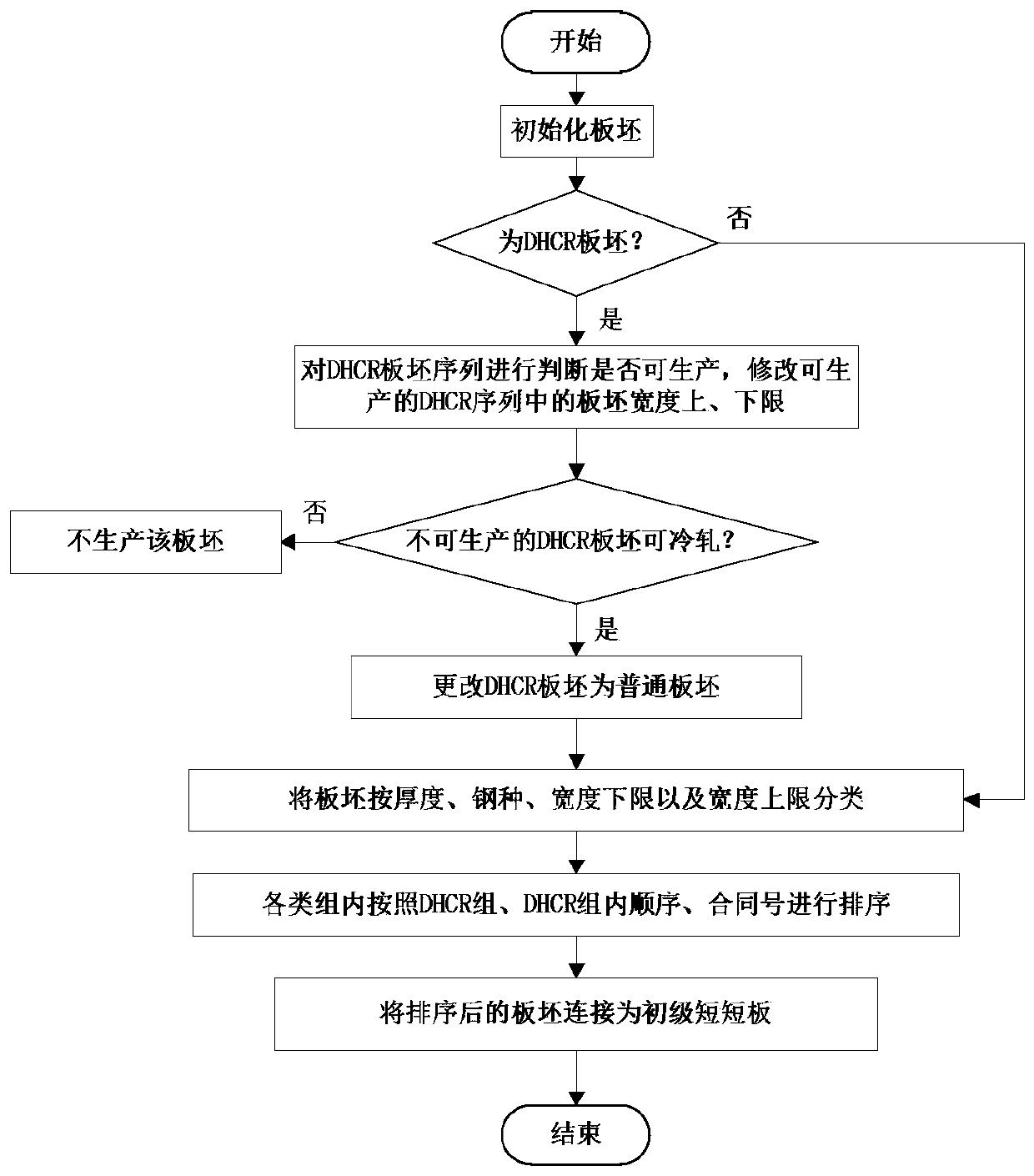

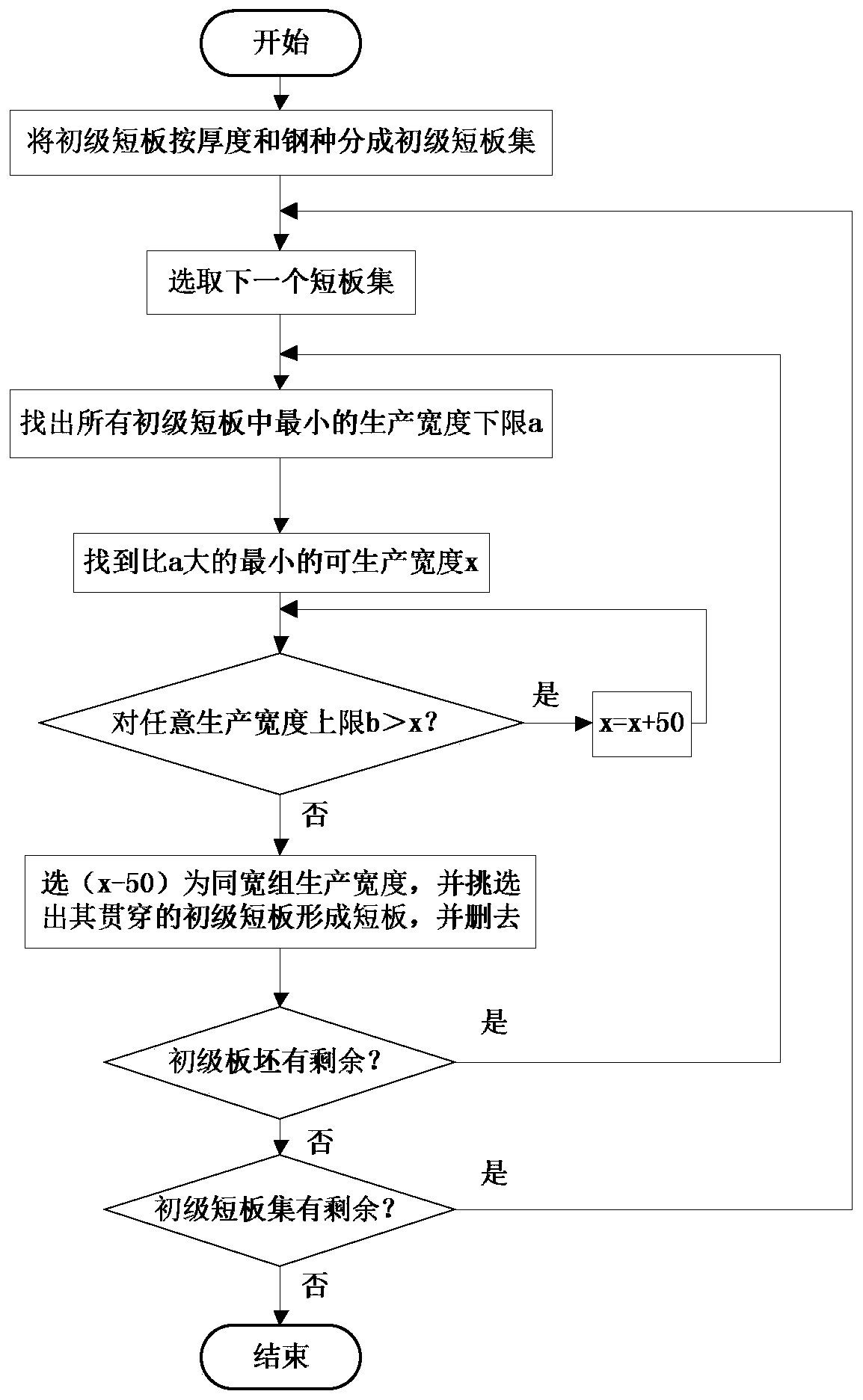

[0031] The steelmaking-continuous casting plan is due to the fact that the final contract (or converted production contract) demand is multi-variety and small batch, and the organization of production is based on a fixed batch (heat plan) and a certain amount of economical production to save adjustment time and save preparation costs. Batch (casting plan) is carried out, which requires the best combination of different contract requirements according to the limitations of the process. This type of problem belongs to the problem of production batch planning. Steelmaking-continuous casting plans are divided into two types: One is the furnace plan (Chargeplan); the other is the pouring plan (CAST plan).

[0032] 1. Heat plan

[0033] It belongs to the production batch plan of the steelmaking-continuous casting stage. In the steelmaking-continuous casting production stage, due to the demand of the intermediate contract (hot-rolled slab) or the final contract (such as hot-rolled st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com