Manual broad tufted carpet cutting machine

A technology for tufted carpets and pile cutting machines, which is applied to the field of manual wide-width tufted carpet cutting machines, can solve the problems of low labor efficiency and product quality control ability, so as to improve quality control ability, improve pile cutting efficiency, reduce The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

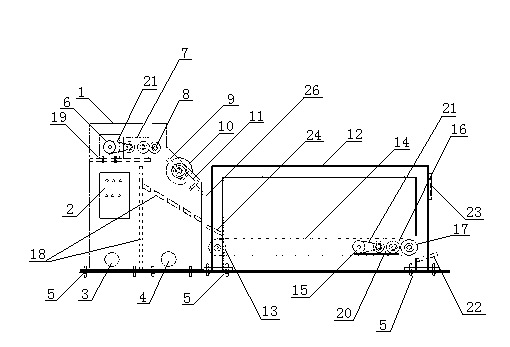

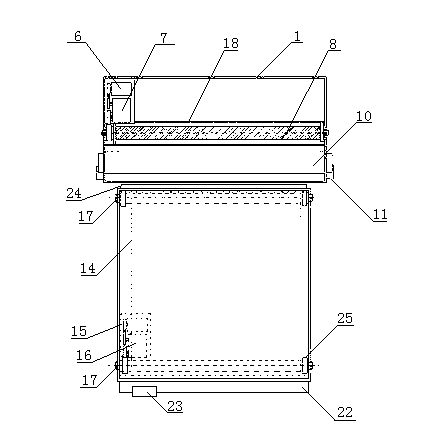

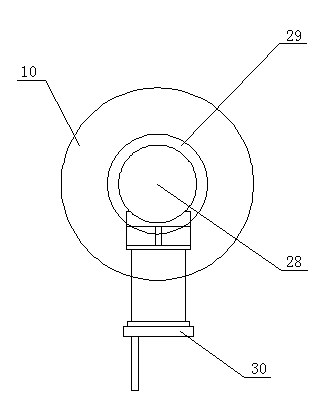

[0022] Such as figure 1 , 2 , 3, 4, and 5, a manual wide-width tufted carpet cutting machine includes a cutting machine casing 1, a cutting machine control switch 2, a cylinder pressure regulating device, a cutting motor 6, and a cutting gear box 7 , Carpet cutting velvet support roller 10, support roll lifting cylinder 11, fluff partition 18, anti-fall baffle 22 and cycle guide belt motor switch 23, support roller lifting cylinder 11 is placed obliquely; velvet cutting machine control switch 2 controls the velvet cutting The rotating speed of motor 6, and then adjust the output speed of cutting velvet gearbox 7, and finally adjust the rotating speed of cutting velvet hob 8; the cutting velvet machine control switch 2 controls the rotating speed of circulation conduction belt motor 15, and then adjusts circulation conduction belt gearbox 16 output Speed finally adjusts the transmission speed of the carpet loop nylon guide belt 14. The cylinder pressure regulating device is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com