A kind of production method of flannelette special for powder puff

A production method and flannelette technology, applied in flannelette looms, fabric elongation, weaving, etc., can solve problems such as uncomfortable use, hard fluff, and poor stability of flocking powder puff fluff, and achieve reduced fabric weight and wear resistance Good performance, increase the effect of consolidation fastness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The production method of the flannelette special for powder puffs involved in this embodiment uses polyester filaments as raw materials, adopts W-type consolidation, uses double rapier looms to weave, and then undergoes finishing, and utilizes the characteristics of polyester filaments, after finishing, to make The suede is comfortable and soft, smooth and full.

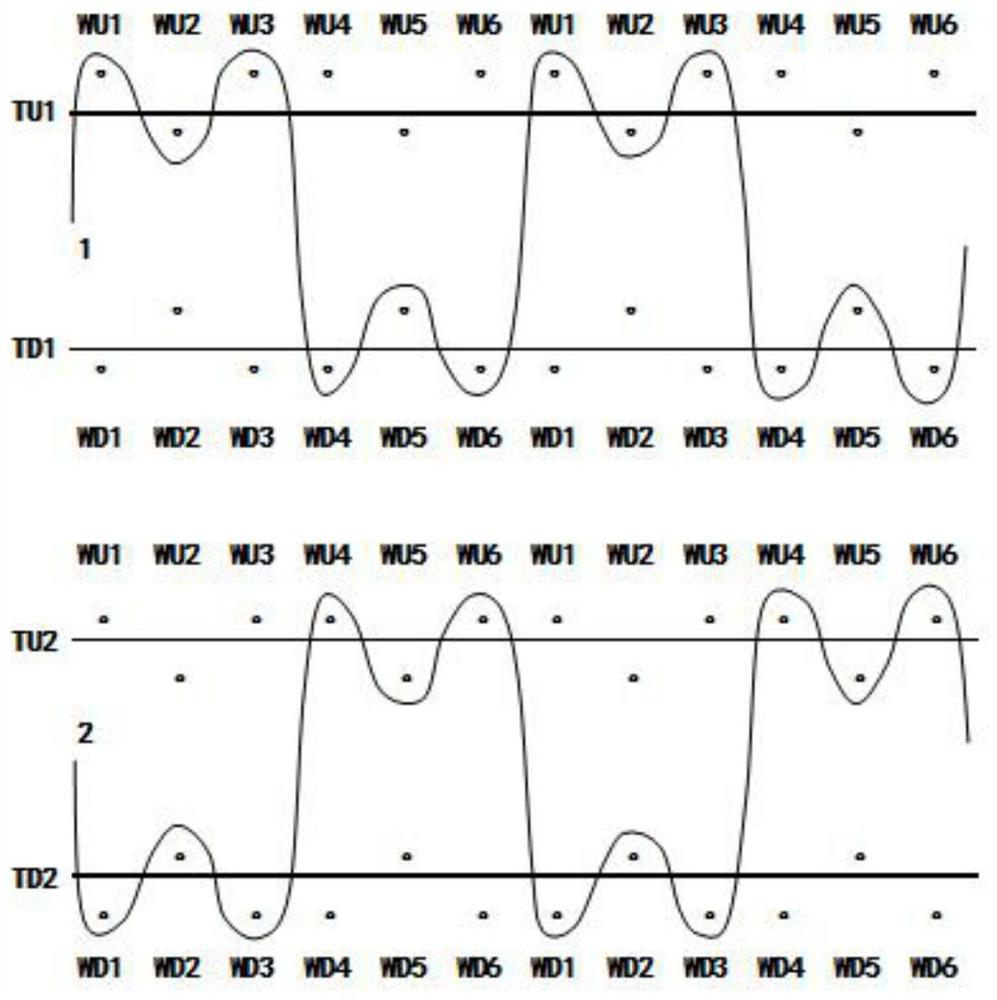

[0068] The warp of the weaving method is divided into ground warp and velvet warp. The ground warp adopts two ground warp heads. Weft yarn, the upper ground warp interweaves with the upper weft yarn to form the upper bottom, the lower ground warp interweaves with the lower weft yarn to form the lower bottom, the velvet warp and the weft yarn of the upper and lower layers interweave back and forth, and the velvet knife transmission mechanism drives the velvet knife to reciprocate, and the velvet warp Cut off and separate the upper and lower layers, then the surface of the cloth forms upright and dense fluff.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com