Patents

Literature

204results about How to "Appropriate flexibility" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

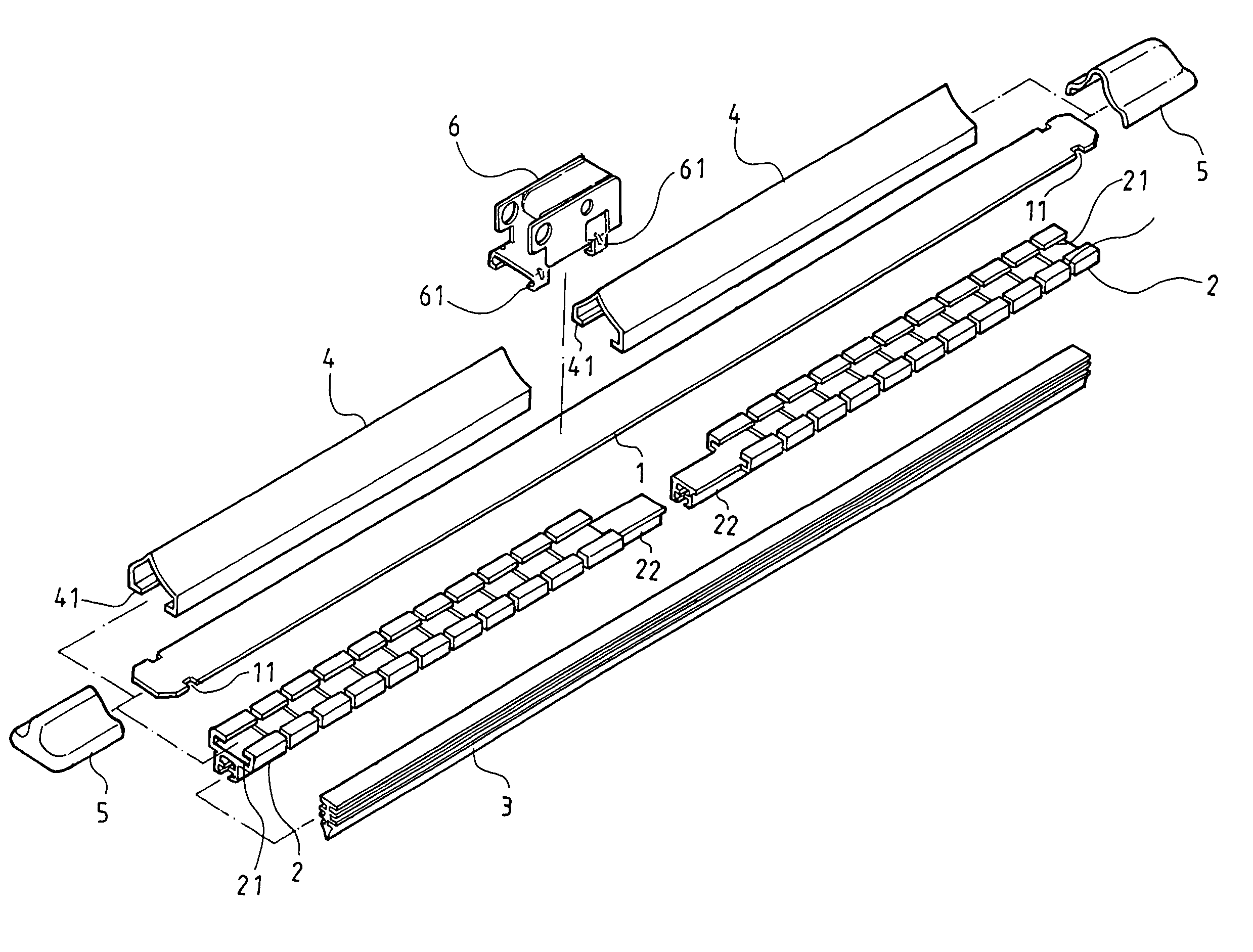

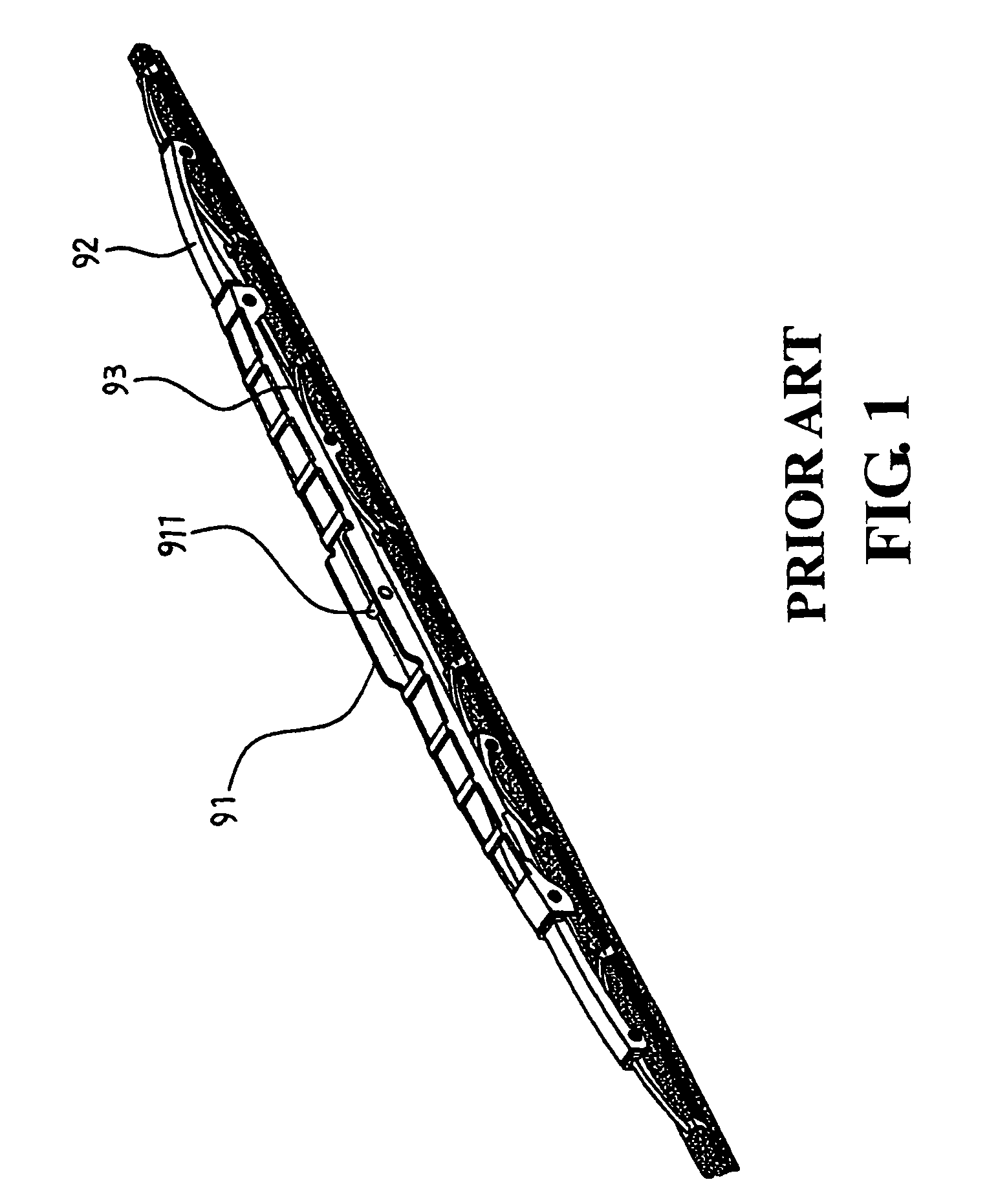

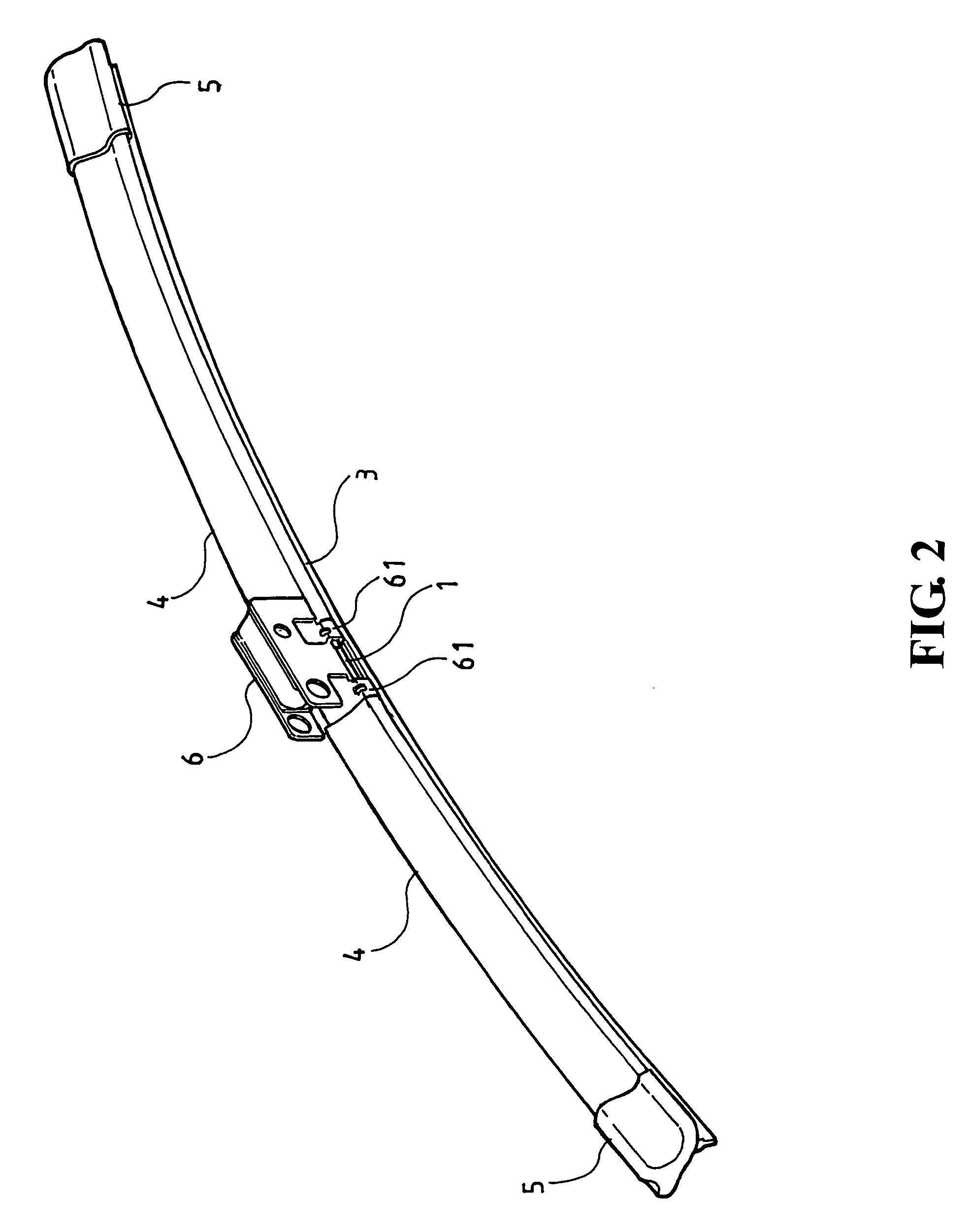

Flexible wiper with rubber cover

ActiveUS7370385B2Appropriate flexibilityWindow cleanersVehicle cleaningEngineeringMechanical engineering

Owner:FU GANG CO LTD

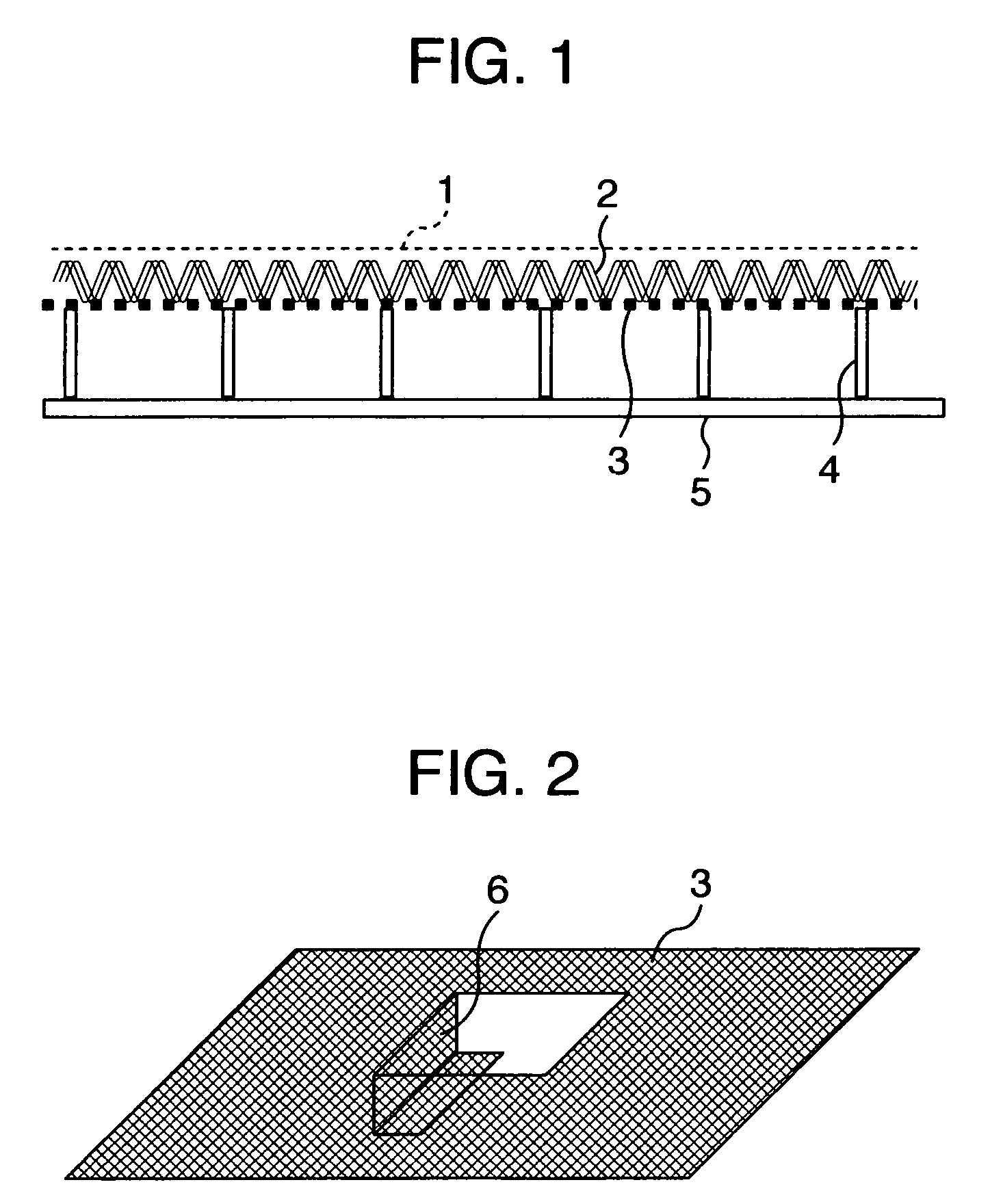

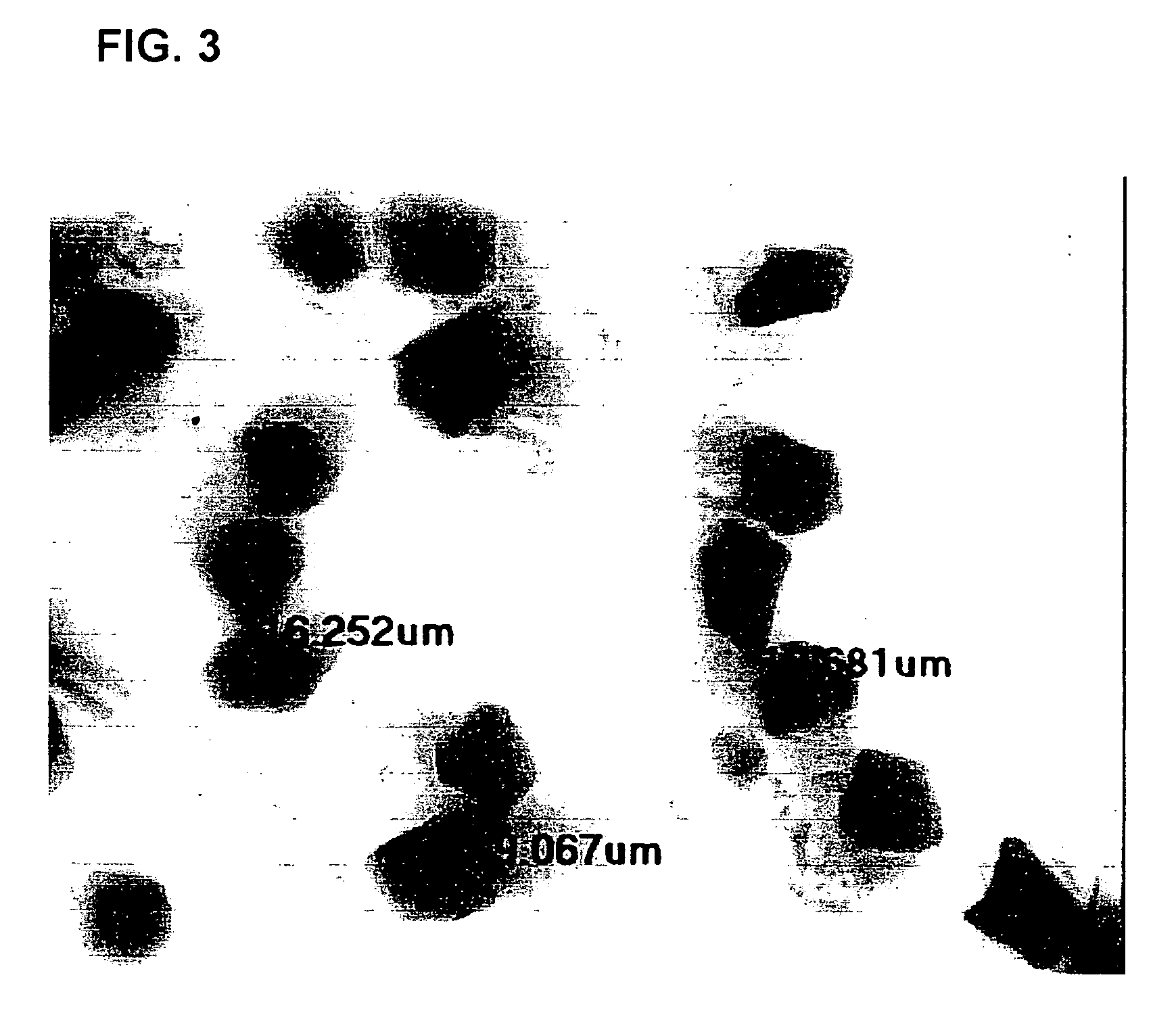

Preparation for carbon fiber paper used for gas diffusion layer of proton exchange membrane fuel cell

InactiveCN101591868ASimple methodLow costFinal product manufactureCell electrodesCarbon nanotubeCarbon black

The invention relates to a preparation for carbon fiber paper used for a gas diffusion layer of a proton exchange membrane fuel cell, which comprises the following steps: (1) carrying out water treatment on asphalt base carbon fiber, and carrying out activation treatment on PAN base pre-oxidized fiber; (2) chopping the fibers; (3) mixing the chopped fibers, and then carrying out wet papermaking forming to obtain raw paper; (4) dispersing carbon nano tubes and / or conductive carbon black grains in resin solution; (5) spraying the resin solution on the upper surface and the lower surface of the raw paper, drying the raw paper and then thermally pressing the raw paper into a semi-finished product; and (6) thermally treating the semi-finished product to obtain the carbon fiber paper. The preparation has simple process and low cost, and is suitable for industrialized production; and the carbon fiber paper has good electric conductivity, high porosity, smooth surface, compact structure and proper flexibility and rigidity.

Owner:DONGHUA UNIV

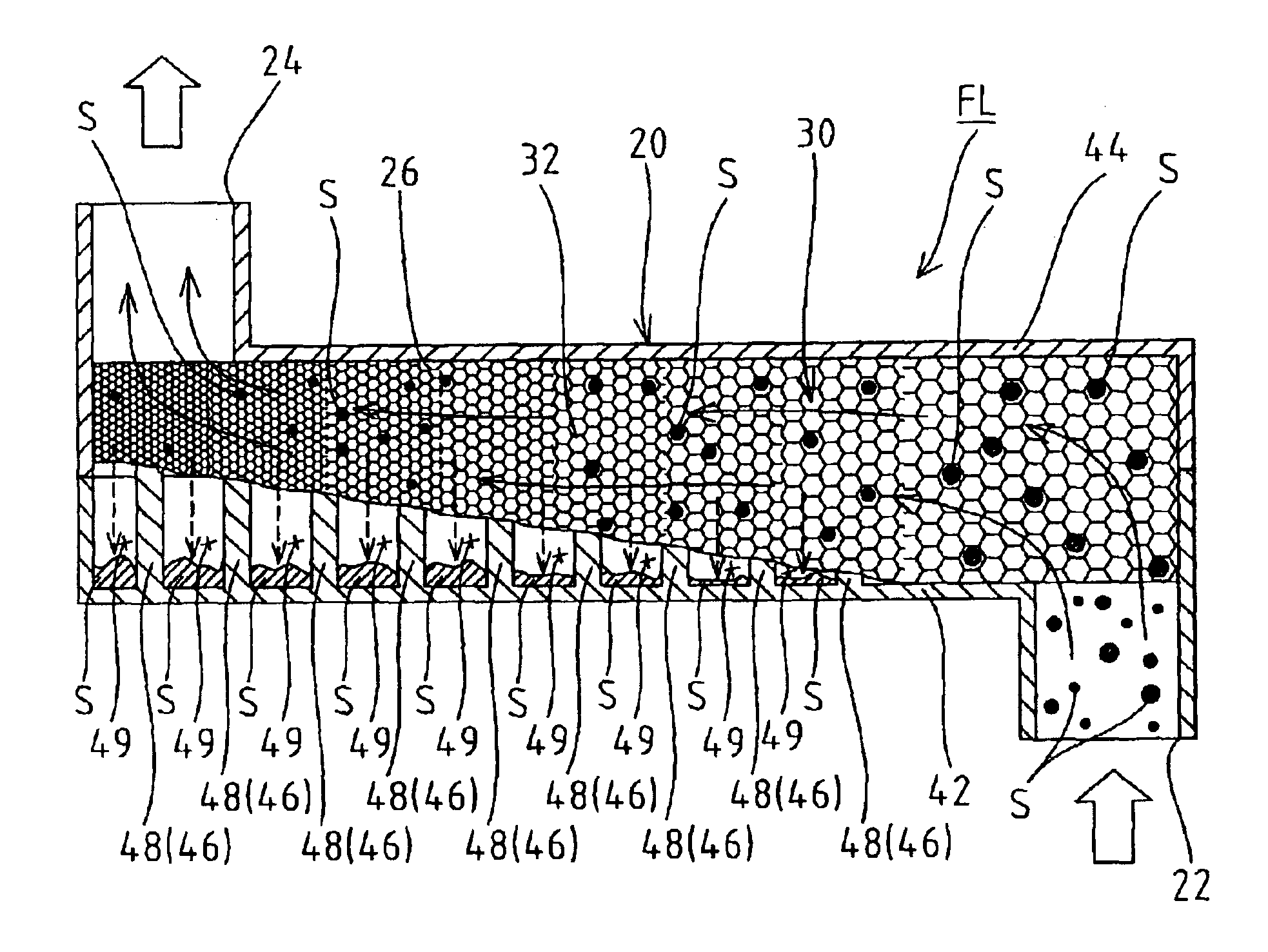

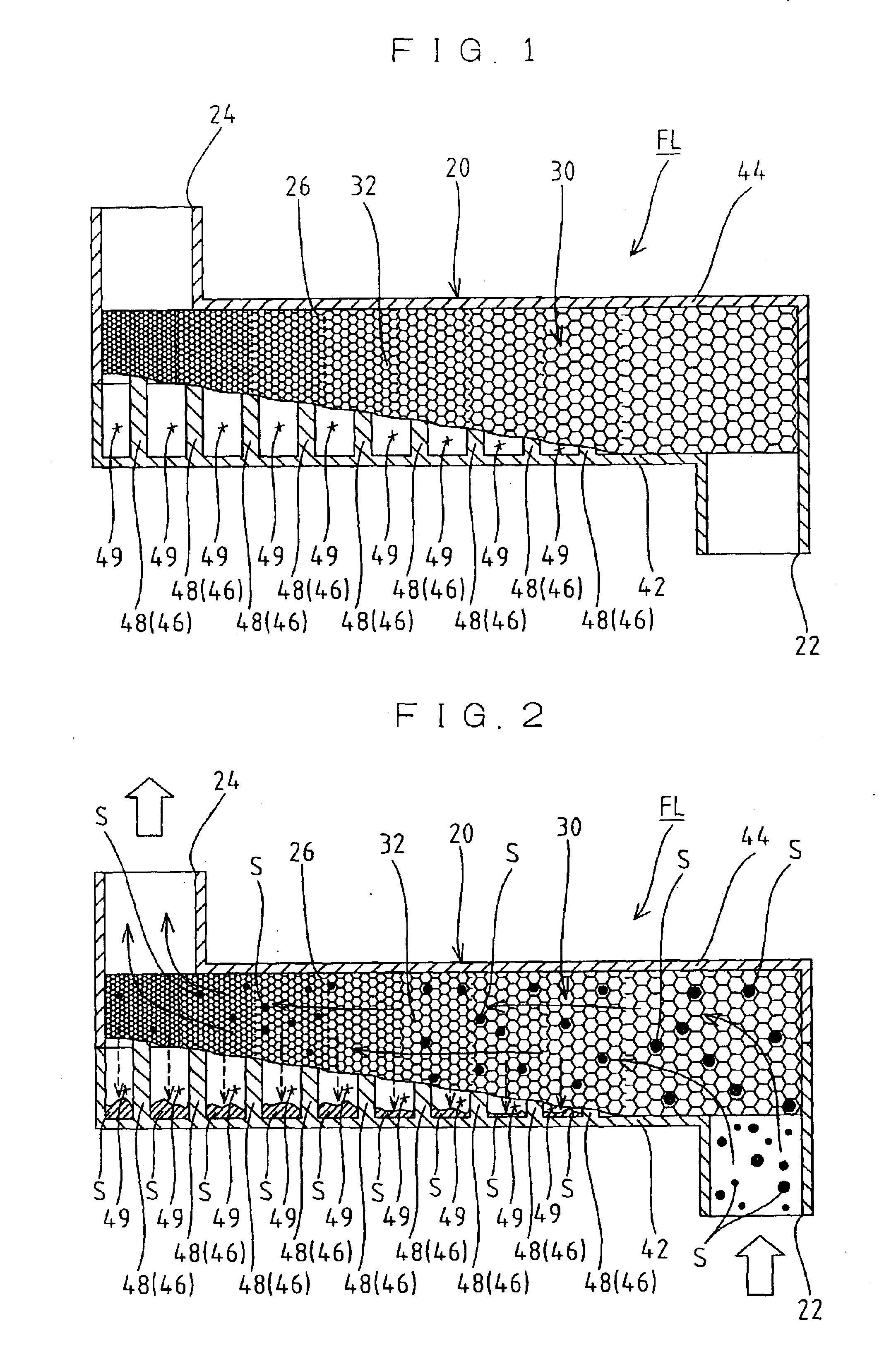

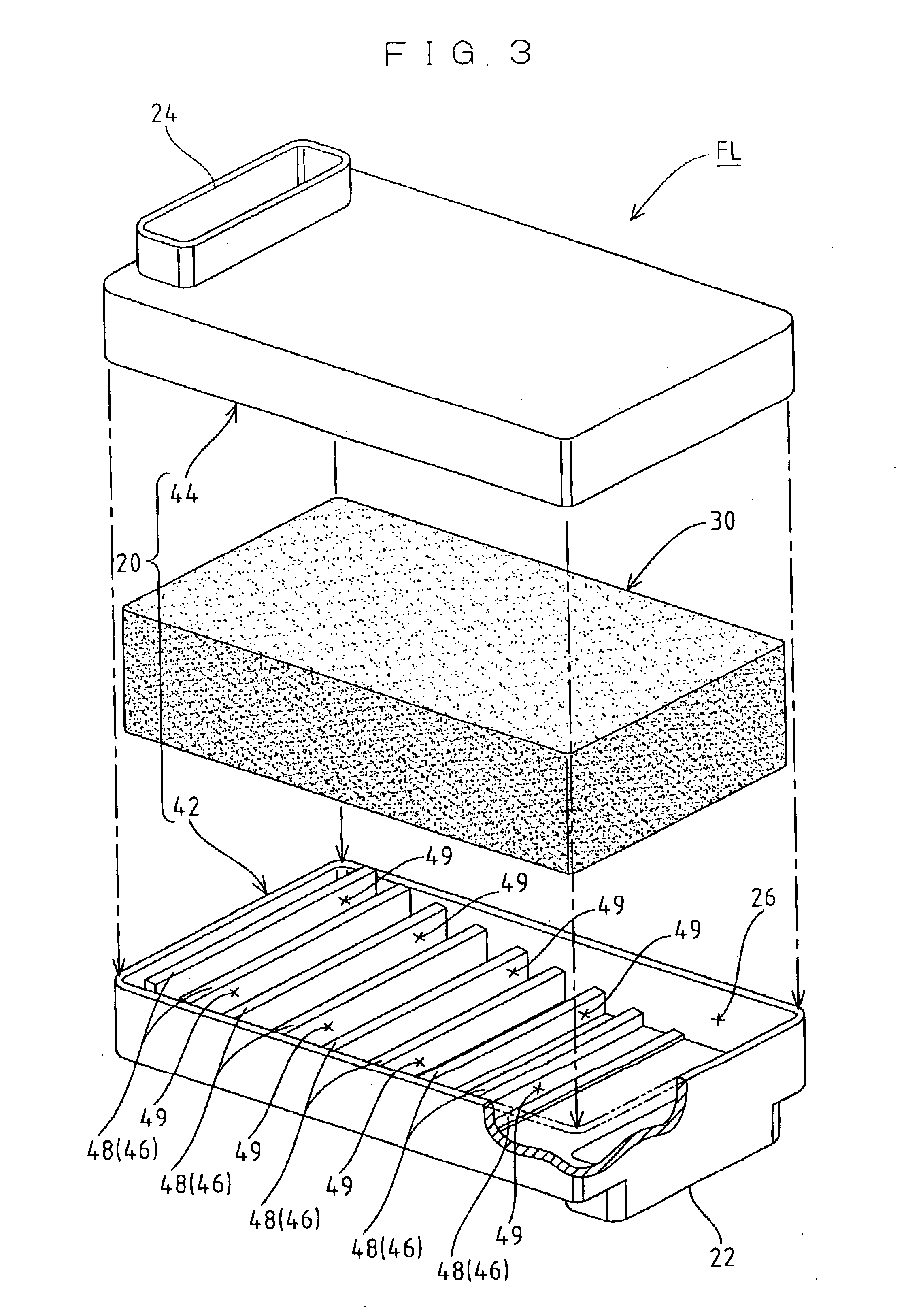

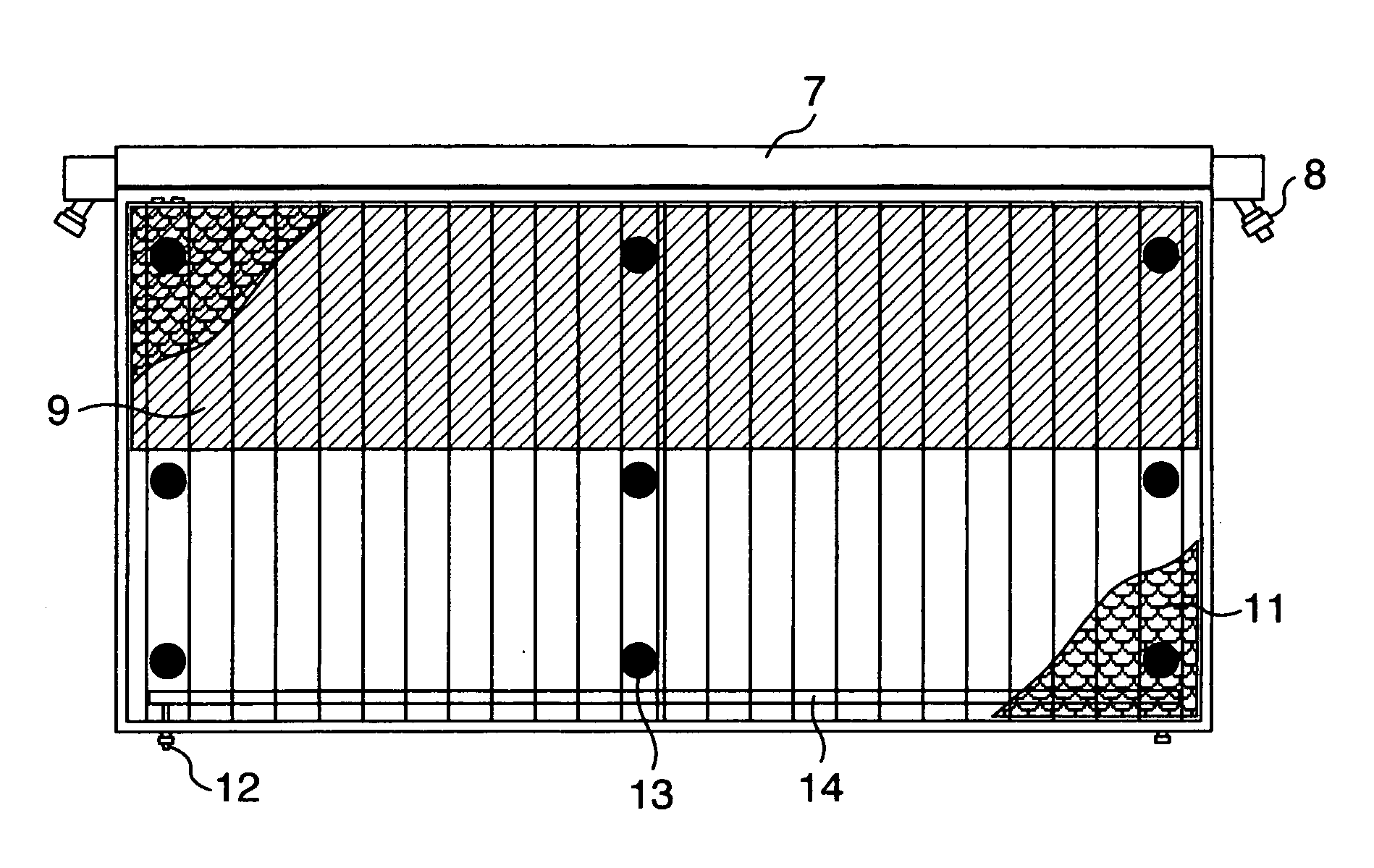

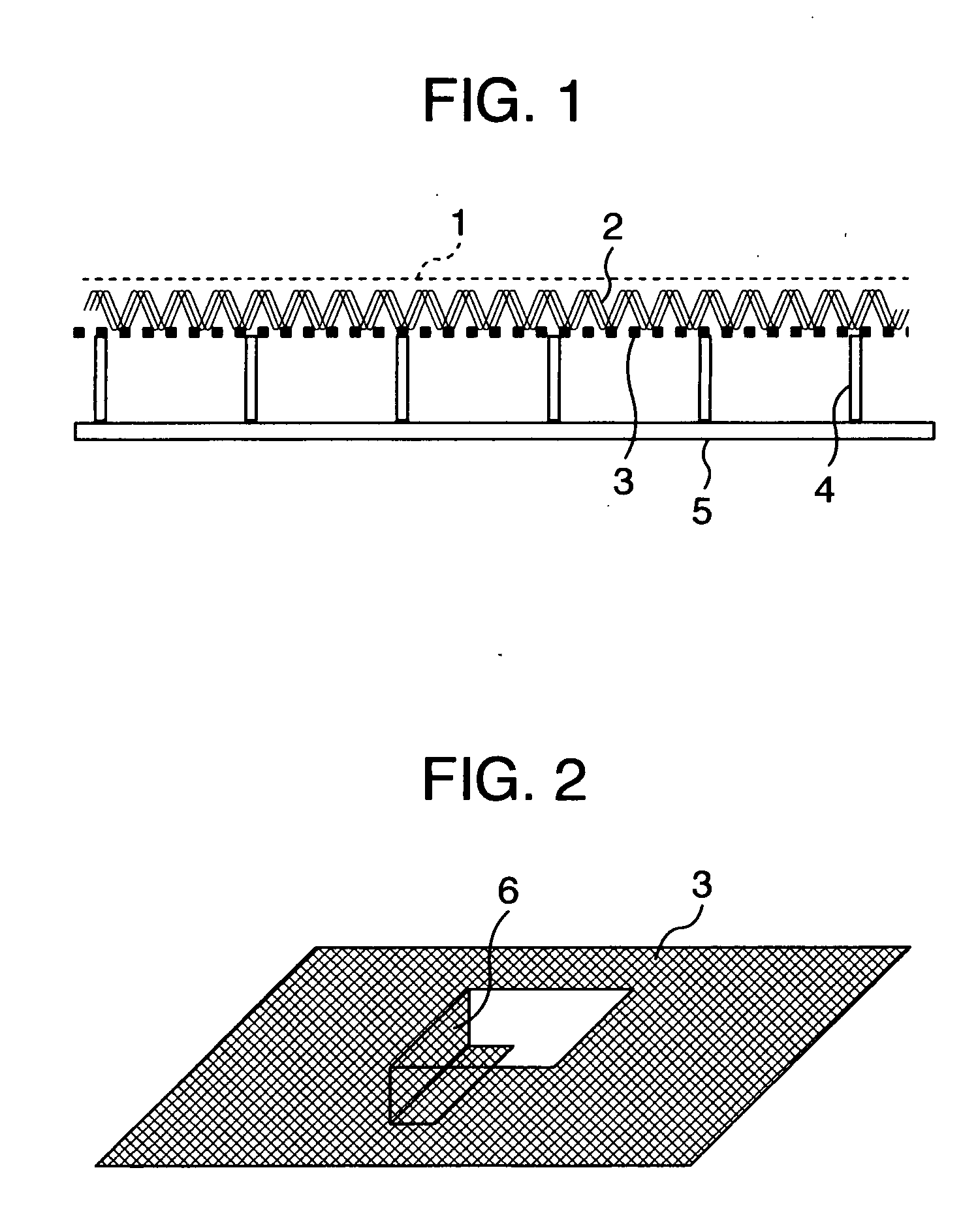

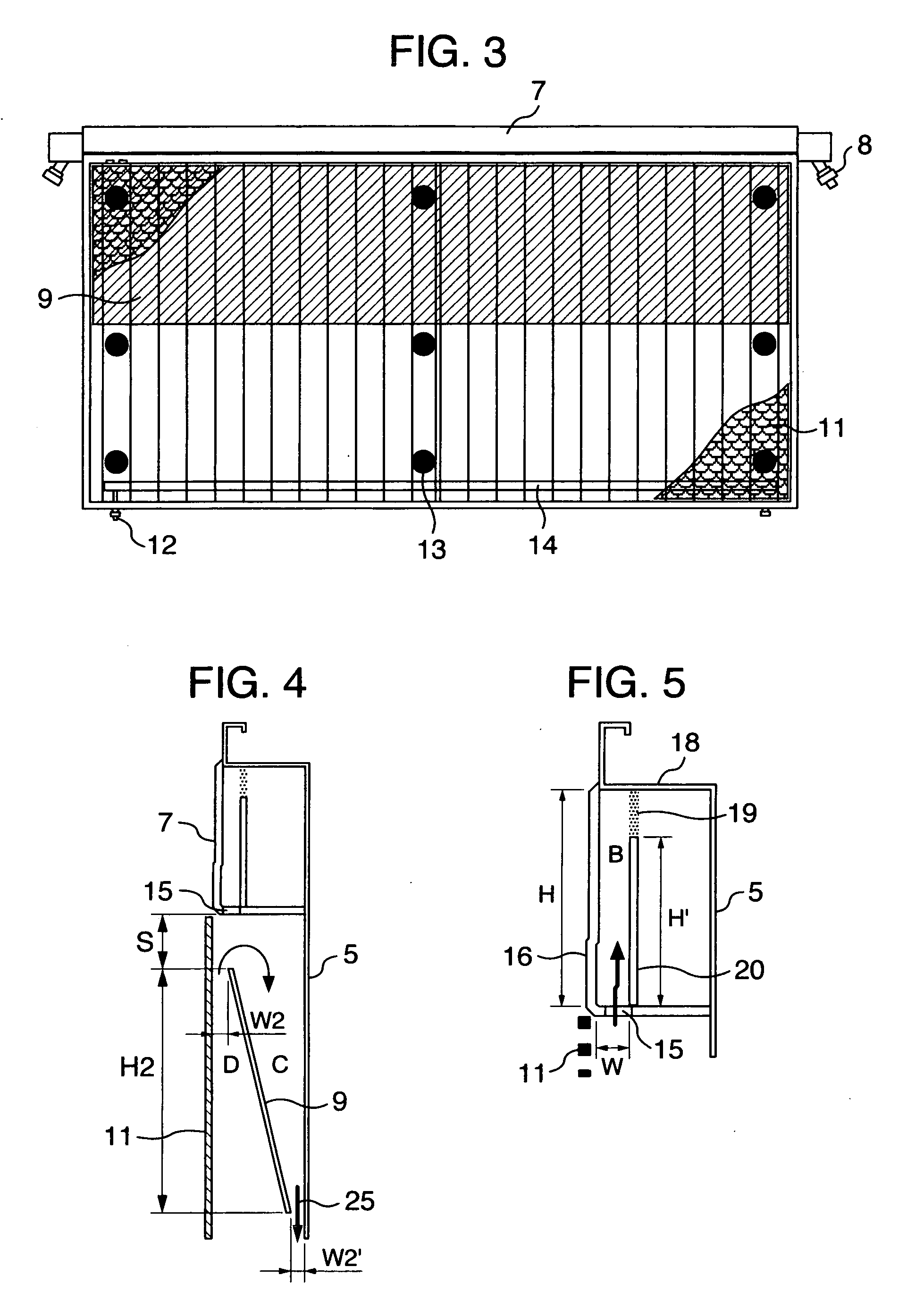

Fluid filter

InactiveUS6926828B2Low running costIncrease ratingsCombination devicesDispersed particle filtrationFilter mediaEngineering

Owner:INOAC CORP

Emulsification asphalt cement mortar for plate-type slag-free orbit and its preparing method and application

ActiveCN101033122AGood temperature adaptability and constructionExcellent durability and anti-vibration fatigue performanceSlagDefoaming Agents

This invention relates to a panel dreg-free emulsified asphalt-cement mortar used in orbits, its manufacturing method and an application including cement, mixed materials, emulsified asphalt, sand, water, polymer latex, defoaming agent, Al powder, an air entrainer and a regulator, which solves the problem of short working time, poor adaptability to temperature, easy separation, hard expansion after 24 hours of injection of the present emulsified asphalt-cement mortar and provides a panel dreg-free emulsified asphalt-cement mortar working long, well suitable to temperature, hard separated, easily expanding, low cost and raw materials are got easily.

Owner:CHINA ACADEMY OF RAILWAY SCI CORP LTD +1

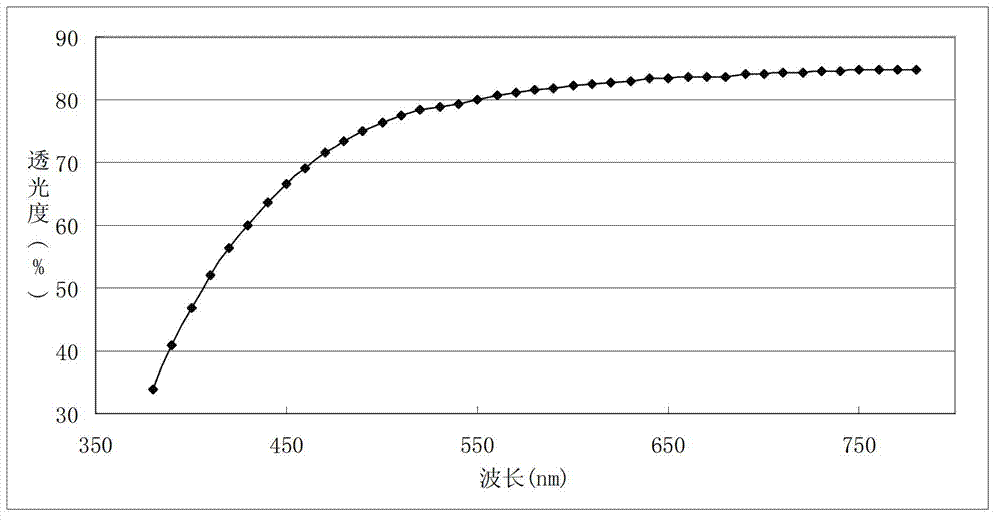

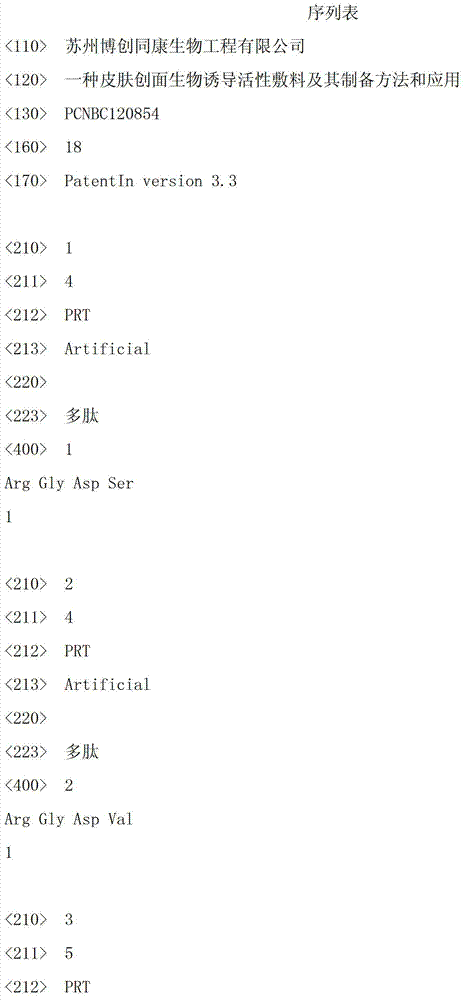

Skin wound biological induced active dressing, preparation method and application thereof

ActiveCN102772819AAppropriate mechanicsAppropriate flexibilityAbsorbent padsBandagesPolyurethane adhesiveHydrogen

The invention provides a medical dressing for protecting skin wounds and promoting repairing, an application of the medical dressing and a preparation method of the medical dressing. The medical dressing comprises a biological plural gel film dressing and a medical polyurethane adhesive film; the biological plural gel film dressing is composed of raw materials of a framework material synthesized by polyanion substances and polycation substances, hyaluronic acid, polypeptide and bonding polypeptide; and the potential of hydrogen (pH) value of the biological plural gel film dressing is 5.8-6.4. The medical dressing for protecting the skin wounds and promoting repairing of the skin wounds has the advantages of wound covering medical dressings, more importantly, by means of synergistic actions of the bonding polypeptide and the hyaluronic acid, the structural designs of medical dressing materials are optimized, and additional growth factors or living cells are not required for enabling the medical dressing materials to have functions of in-situ inducing tissue regeneration and repair.

Owner:SUZHOU BOCHUANG TONGKANG PHARM TECH CO LTD

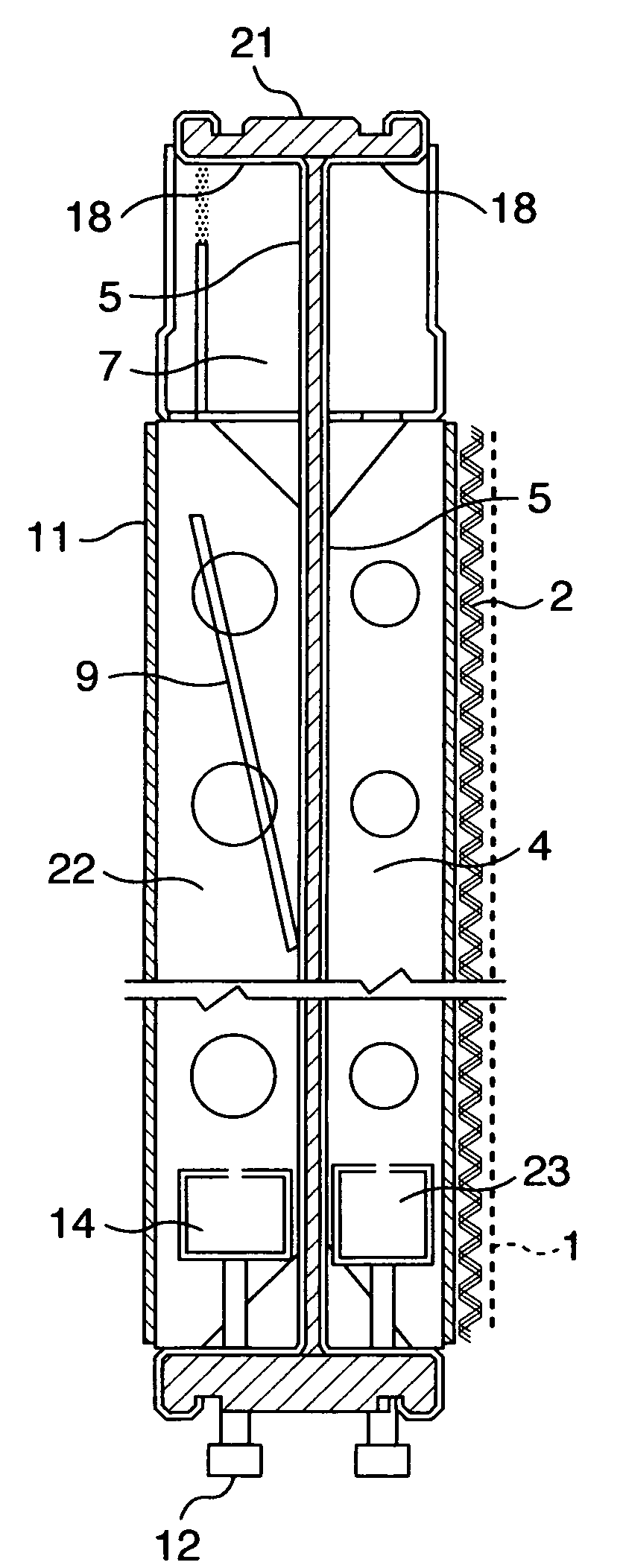

Bipolar zero-gap type electrolytic cell

ActiveUS20060042935A1Preventing gas vibrationStable electrolysisCellsElectrode shape/formsInternal pressureTitanium metal

A bipolar zero-gap electrolytic cell comprising an anode comprising an anode substrate constituted of a titanium expanded metal or titanium metal net of 25 to 70% opening ratio, which anode after coating the substrate with a catalyst has a surface of 5 to 50 μm unevenness difference maximum and has a thickness of 0.7 to 2.0 mm. In this electrolytic cell, the possibility of breakage of ion exchange membrane is low, and the anolyte and catholyte have a concentration distribution falling within given range. With this electrolytic cell, stable electrolysis can be performed for a prolonged period of time with less variation of cell internal pressure.

Owner:ASAHI KASEI KK

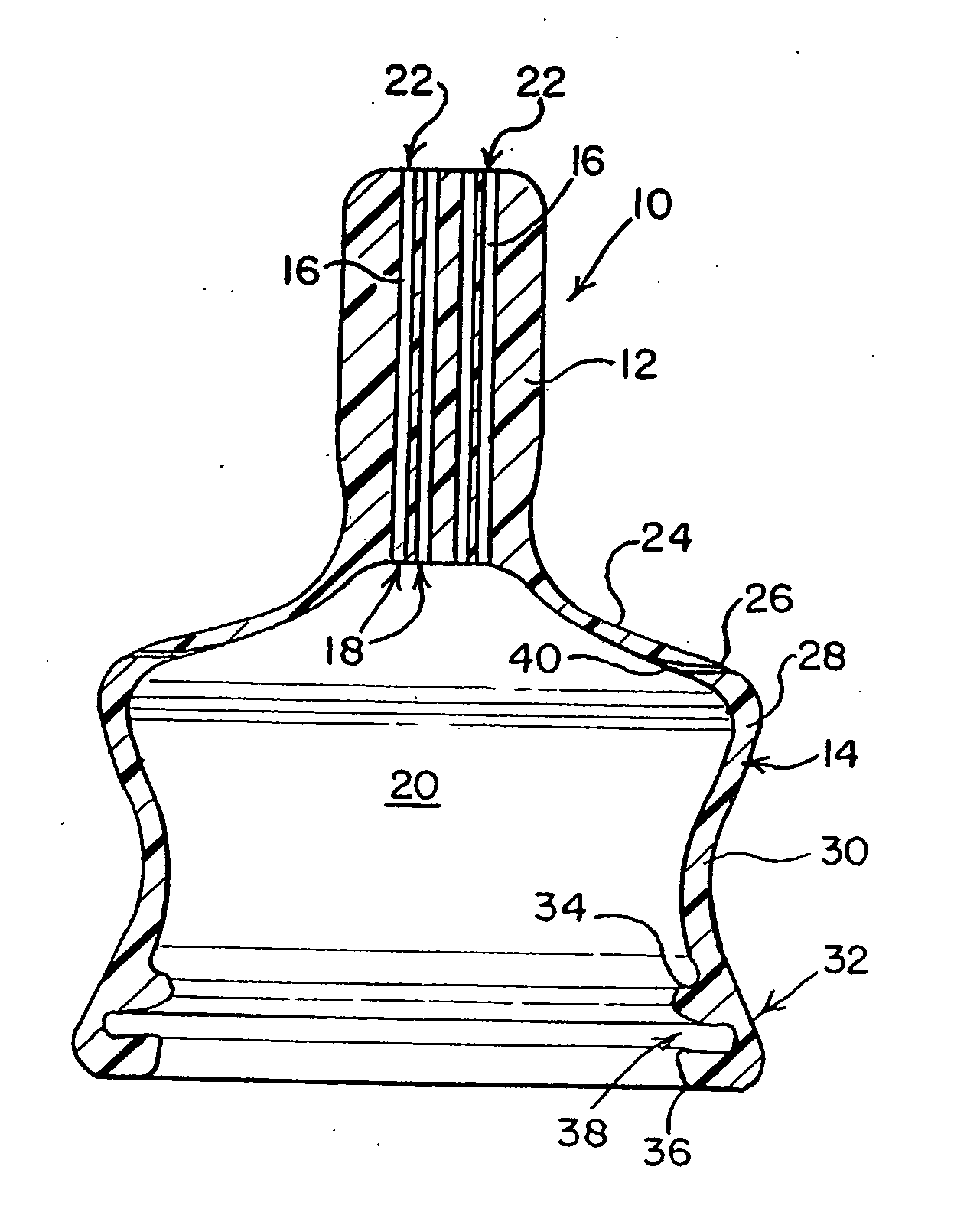

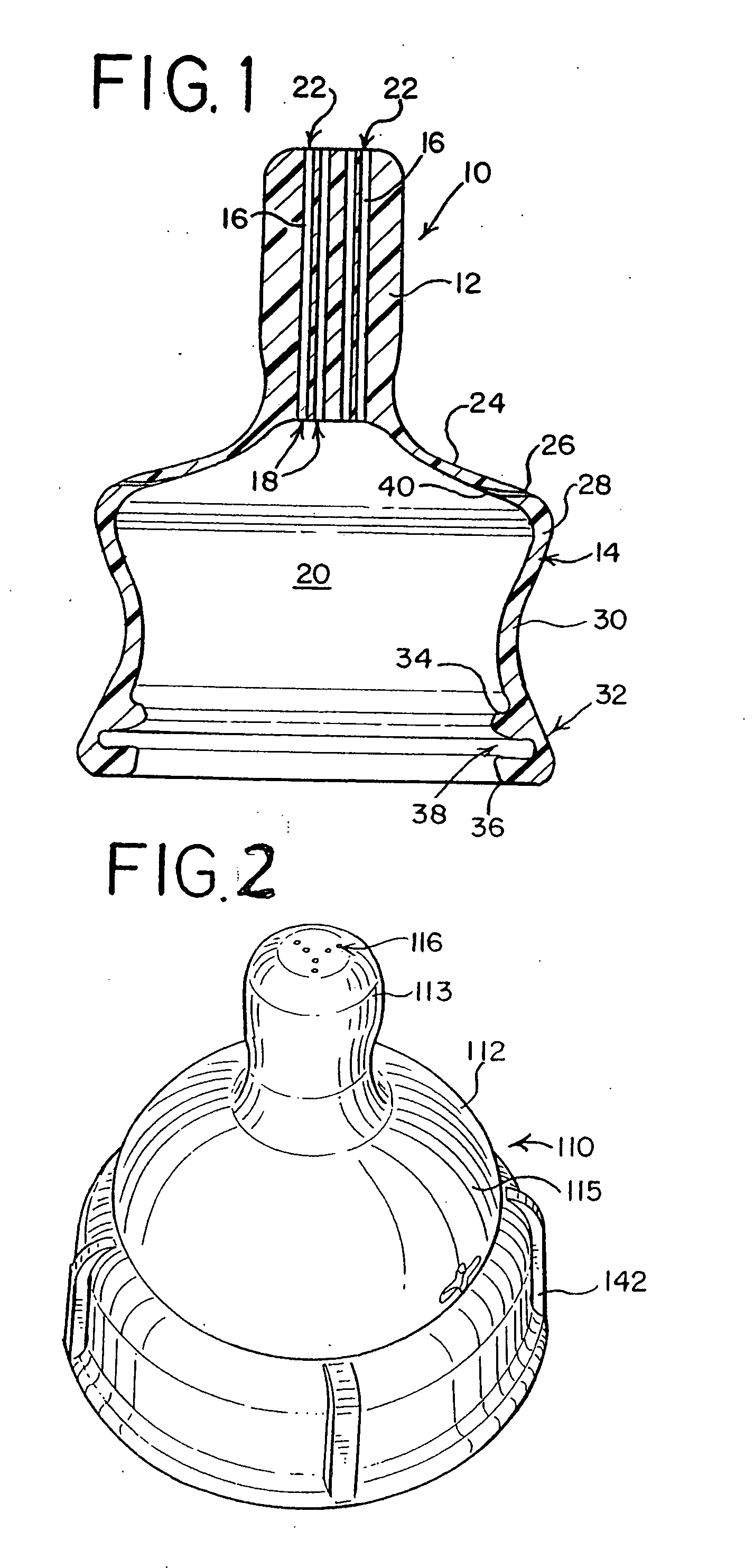

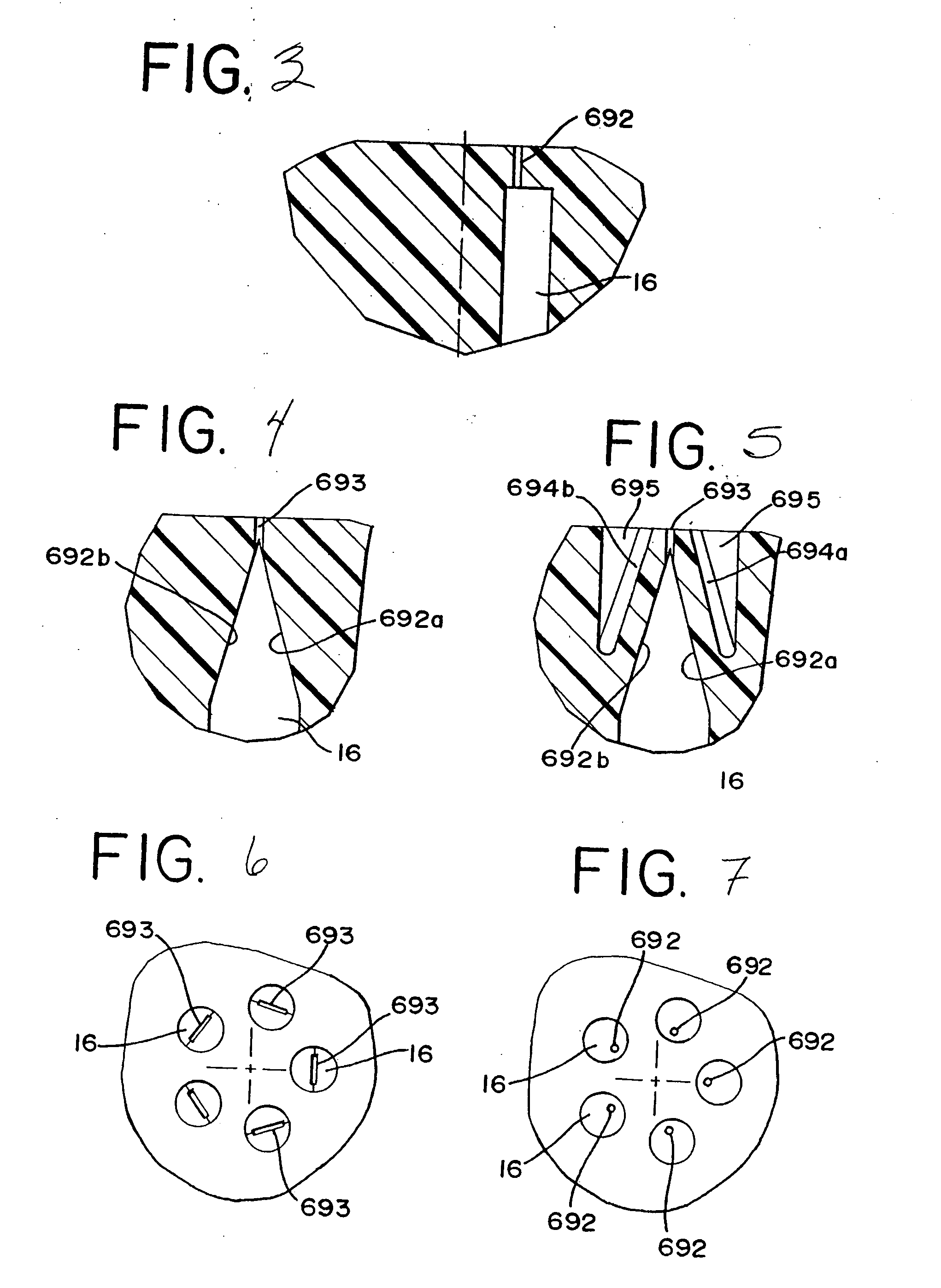

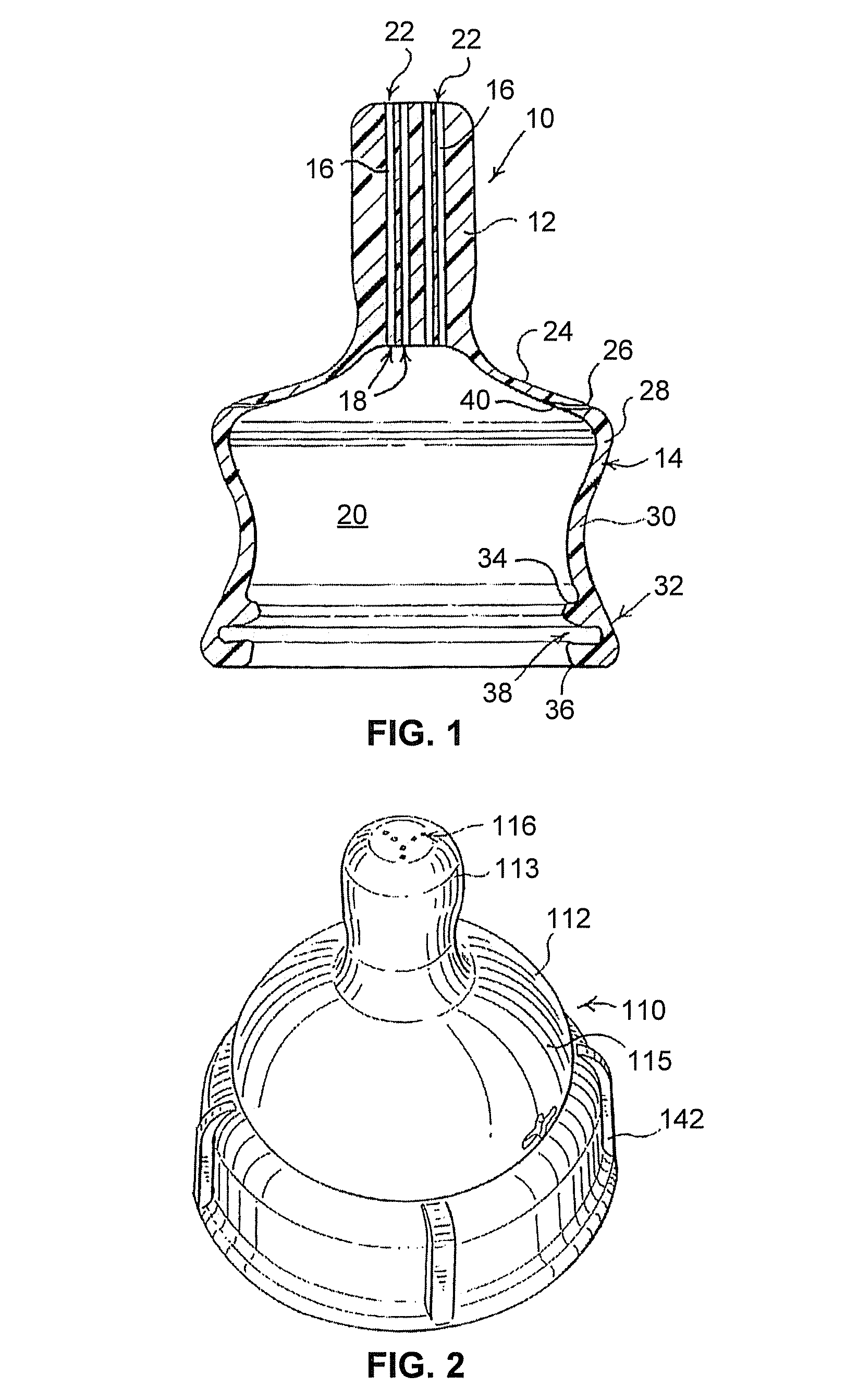

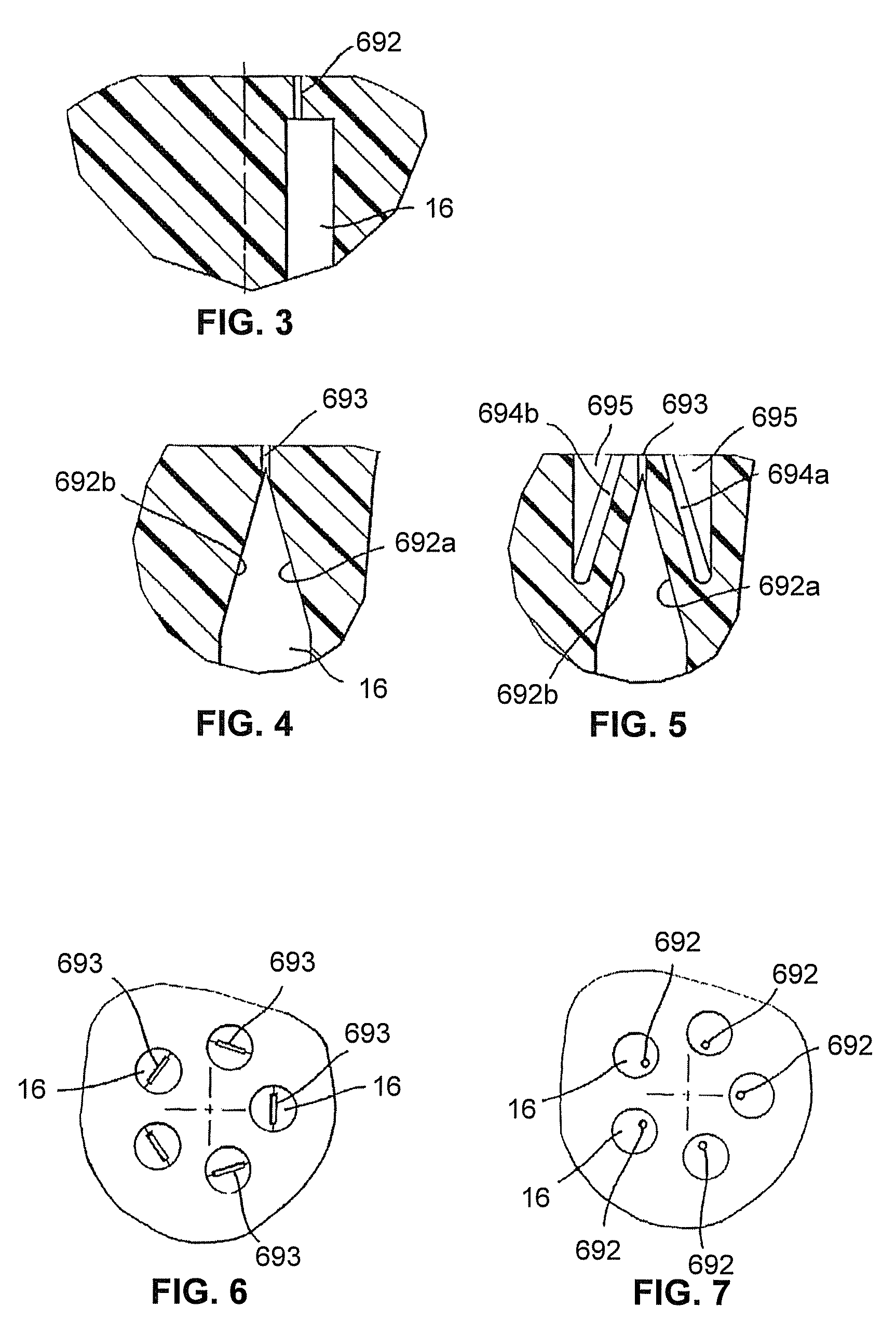

Artificial feeding nipple tip

InactiveUS20050258123A1Increase fluid velocityIncrease flow rateFeeding-bottlesTeatsEngineeringMechanical engineering

Owner:MEDELA HLDG AG

Aluminum soldering paste

InactiveCN102764938AEasy to apply and adhereAppropriate viscosityWelding/cutting media/materialsSoldering mediaOrganic solventSolder paste

The invention discloses an aluminum-based alloy soldering paste suitable for an aluminum-stainless steel and aluminum-aluminum alloy soldering connection batch production technology aiming at the requirement of high-efficiency soldering technology. The soldering paste consists of the following components by weight percent: 1) 50-65% of aluminum-based alloy soldering material powder, 2) 10-25% of fluoroaluminate soldering flux, 3) 3-10% of tackifier, 4) 2-10% of thickening agent, 5) 10-30% of organic solvent, and 6) 0.05-0.50% of stabilizing agent. The soldering paste provided by the invention has moderate viscosity and soldering flux which is in accurate proportion, and is extremely suitable for workpieces with irregular weld joint shapes and complex structures; the soldering paste can be very simply and conveniently coated on the part of a welding element, which is required for soldering joint; working procedures such as auxiliary positioning, soldering flux coating and brushing are not required like plate-shaped or silk-shaped soldering materials; the soldering production technology is simplified; the labor cost is lowered; and the product quality and production efficiency are improved.

Owner:江门市盈盛焊接材料科技有限公司

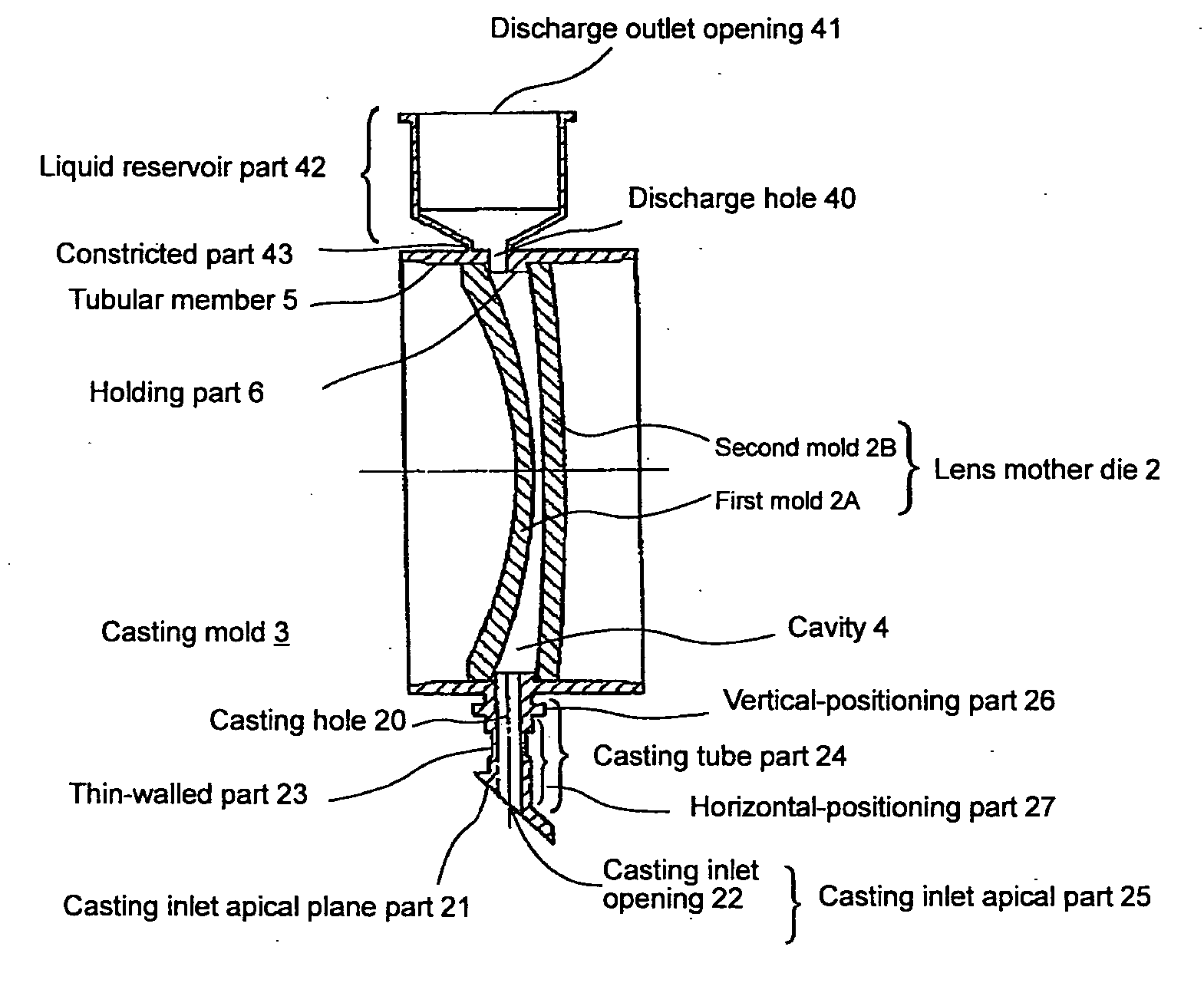

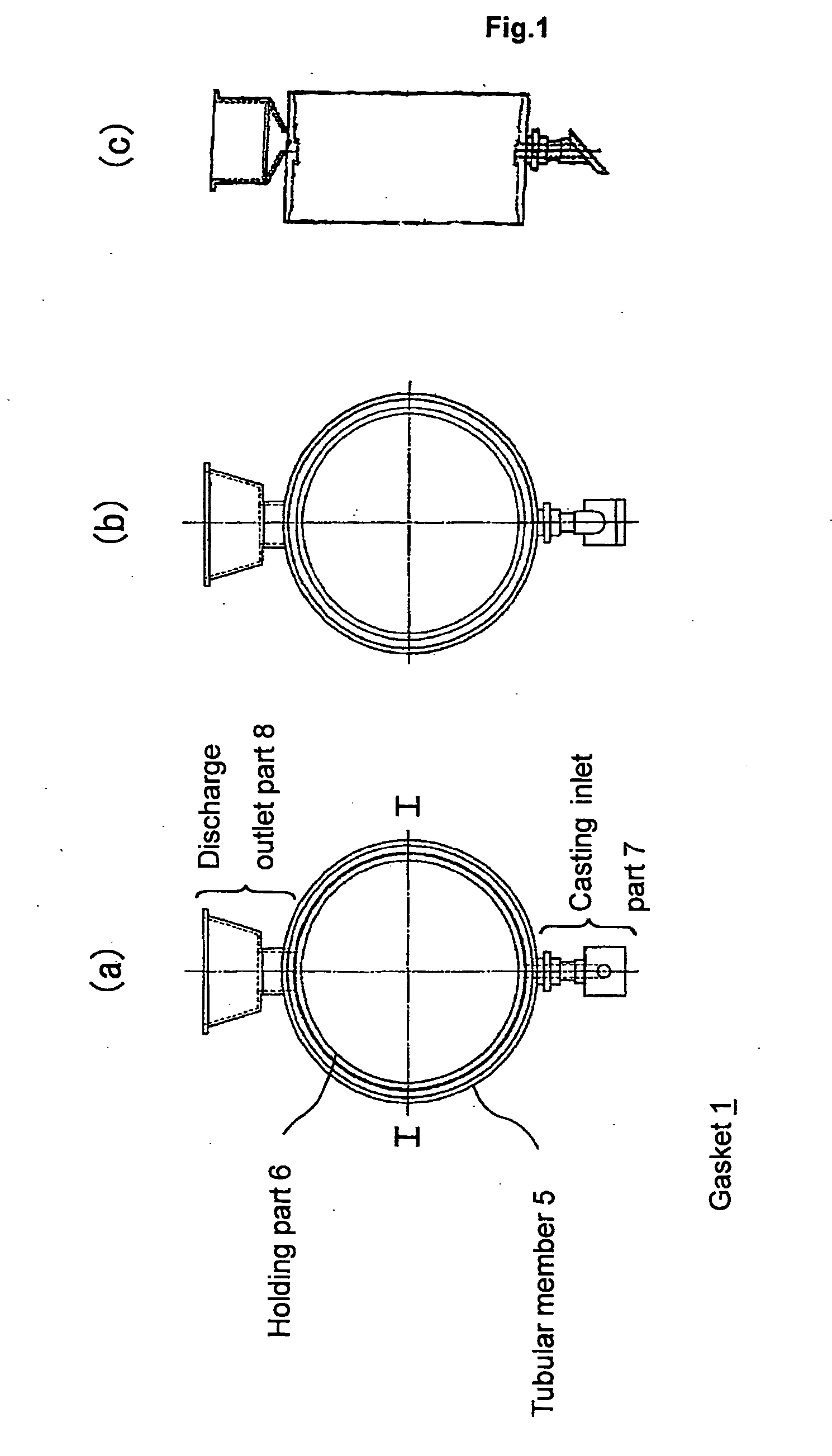

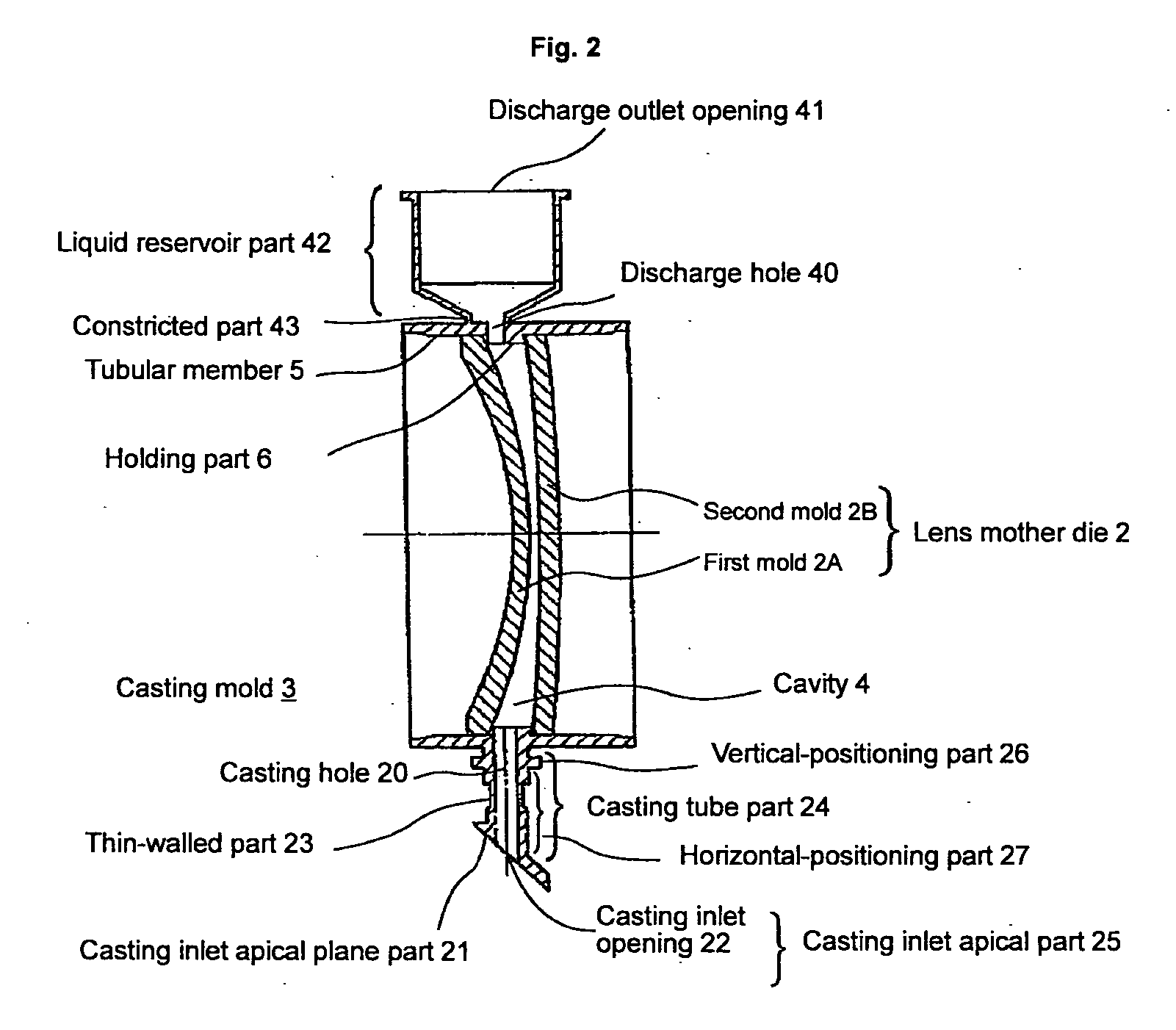

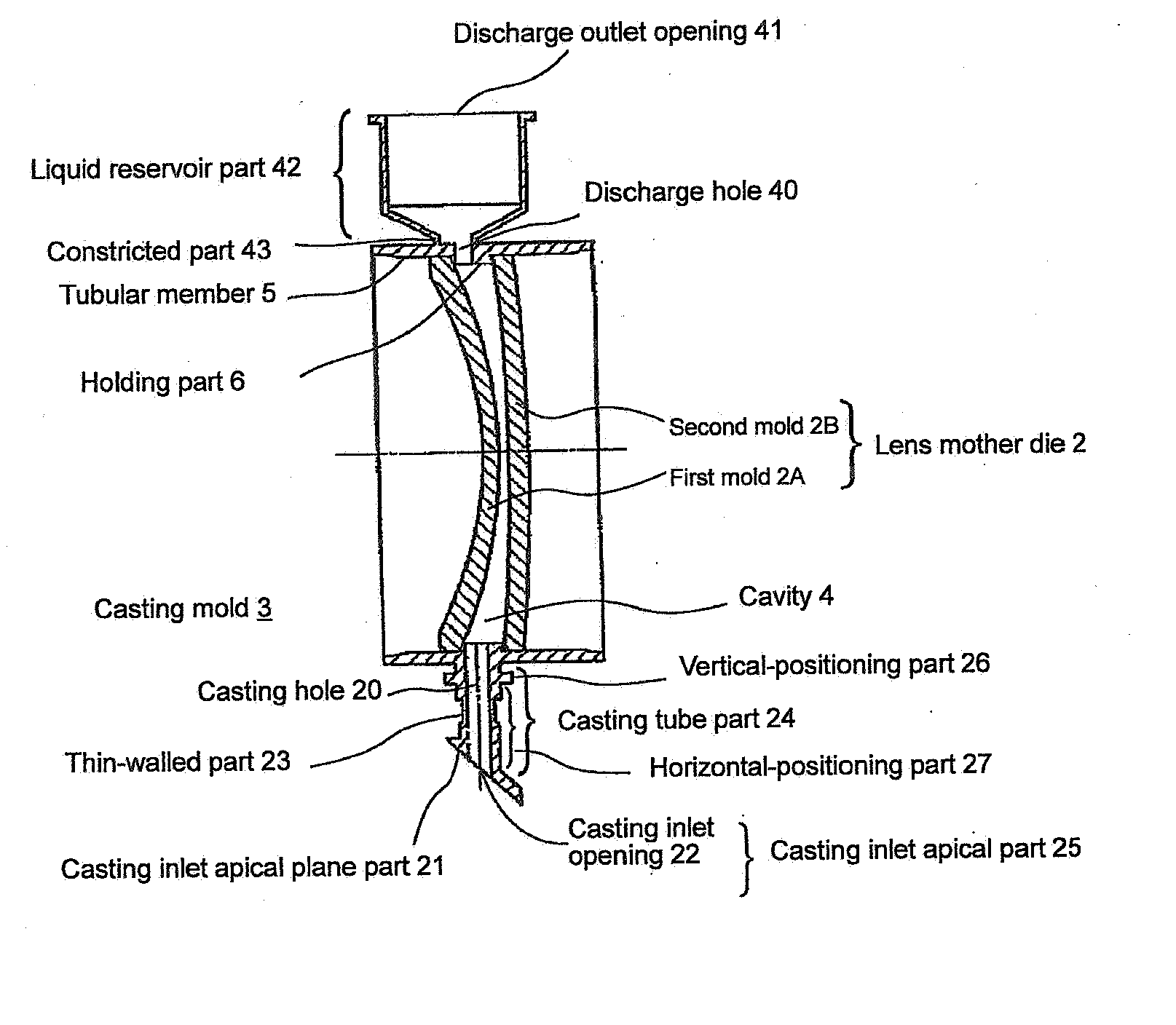

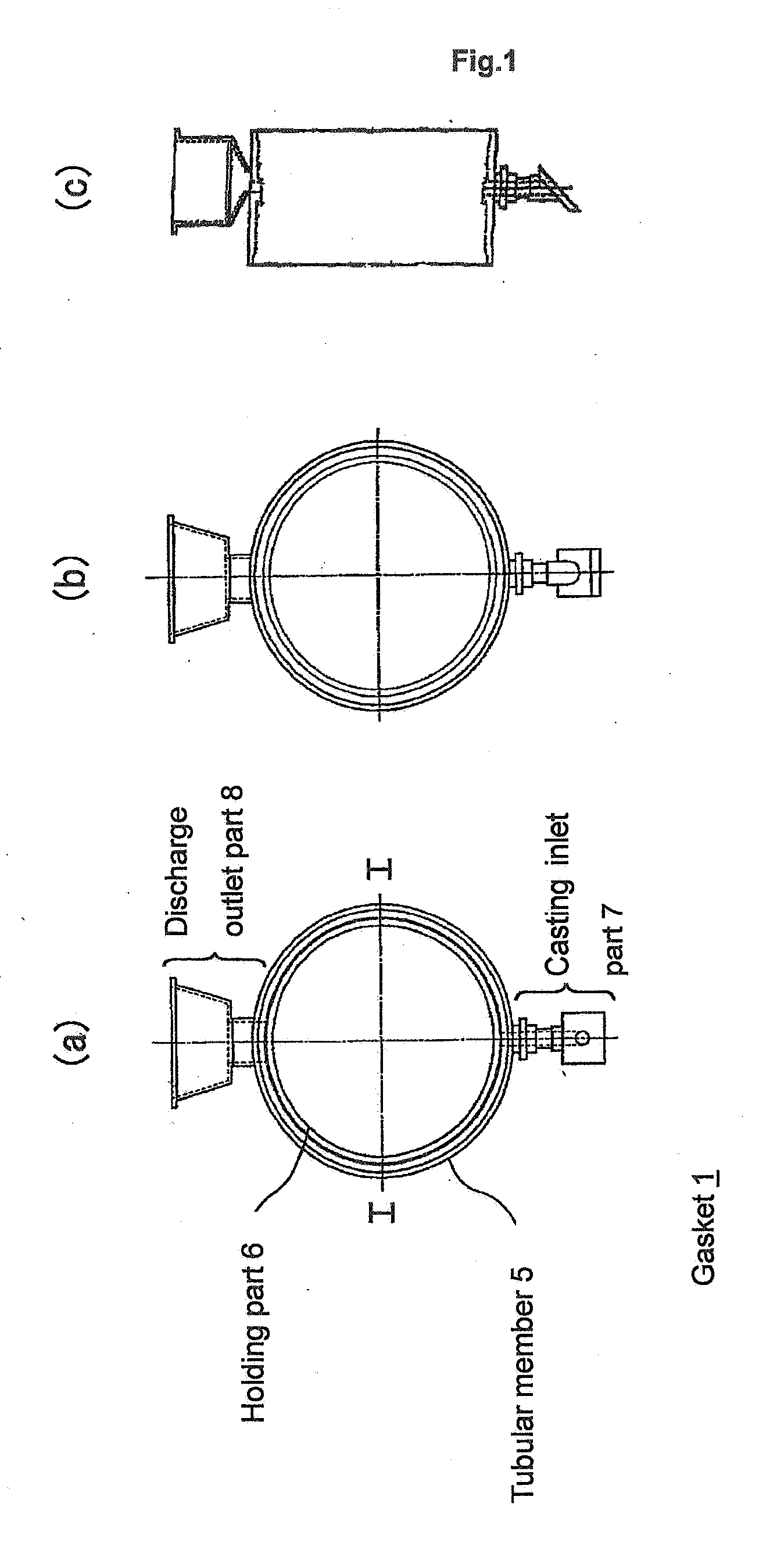

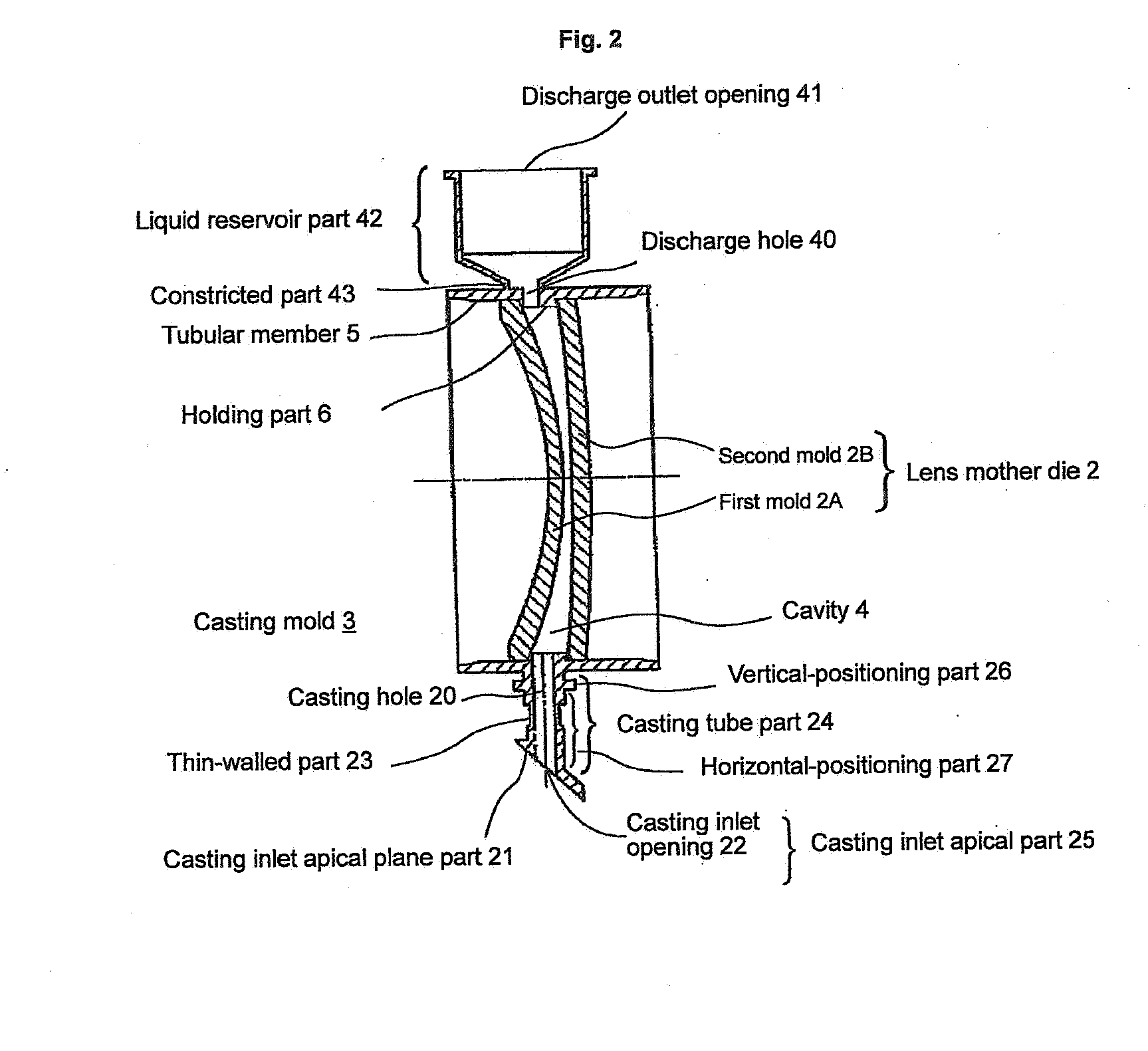

Method of manufacturing plastic lens, gasket for molding plastic lens, casting mold for molding plastic lens, casting jig for plastic lens starting material liquid, holding member for plastic lens casting mold, and plastic lens manufacturing apparatus

ActiveUS20080029914A1Reduced bubble and optical defectHigh viscosityConfectioneryOptical articlesNozzlePolymerization

A method of manufacturing a plastic lens by mixing plural polymerizable components, and immediately after mixing, casting a mixture into a casting mold and conducting polymerization to obtain a molded article. A method of manufacturing a plastic lens by casting a plastic lens starting material liquid flowing out of a casting jig opening into a casting mold and curing the above starting material liquid to form a molded article. A gasket for molding plastic lens comprised of a cylindrical member comprising openings for fitting by insertion two molds. A casting mold for molding plastic lens, wherein the above molds are detachably held in the above openings of the above gasket so that molding surfaces of the two molds are positioned opposite at a prescribed interval to form a cavity corresponding to a lens shape within the above cylindrical member. A casting jig for plastic lens starting material liquid equipped with a nozzle for casting a plastic lens starting material liquid into the casting mold. A method of manufacturing a plastic lens comprising casting of a plastic lens starting material liquid into a casting mold held by a holding member and curing the above starting material liquid to form a molded article. A holding member for plastic lens casting mold for holding a casting mold for molding a plastic lens.

Owner:HOYA CORP

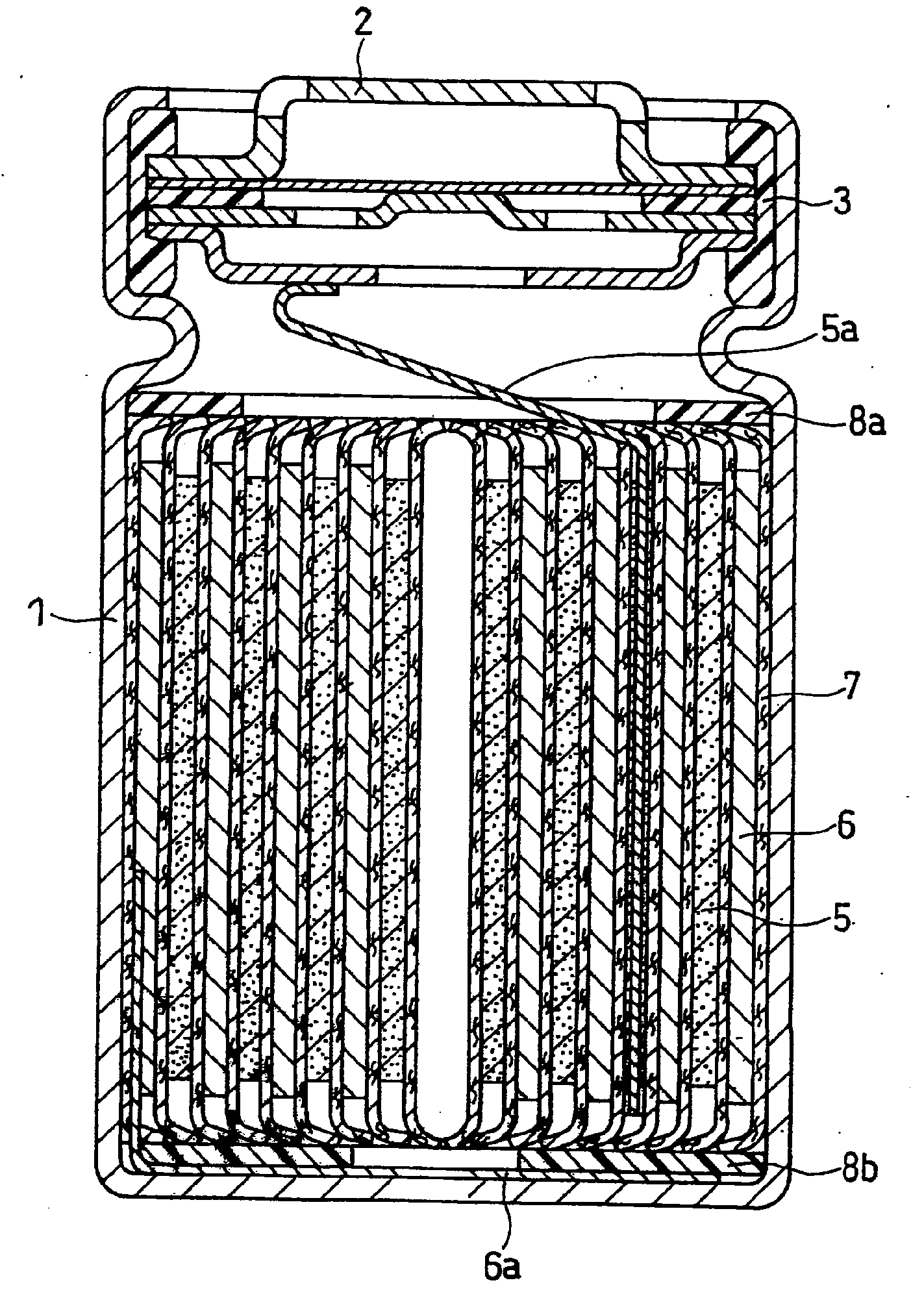

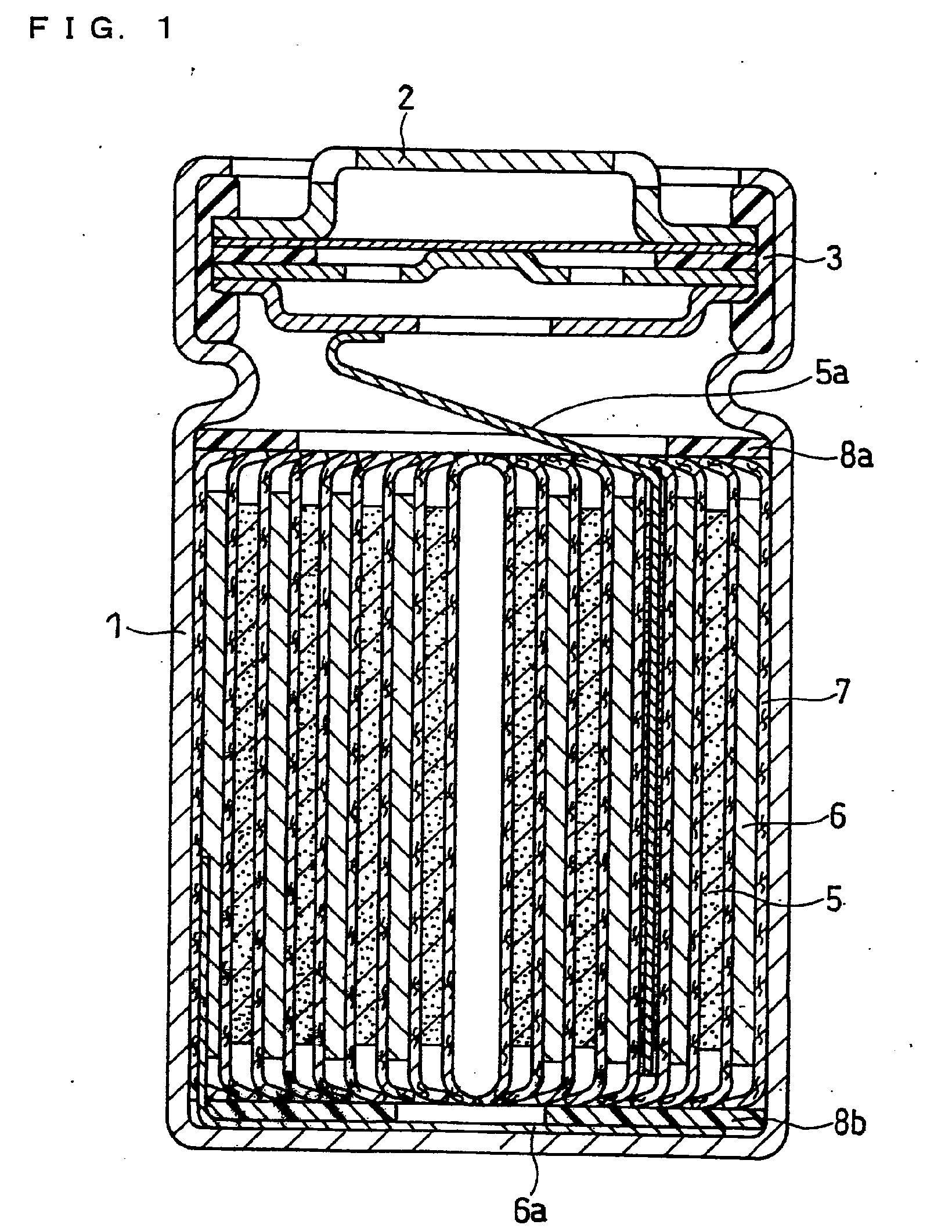

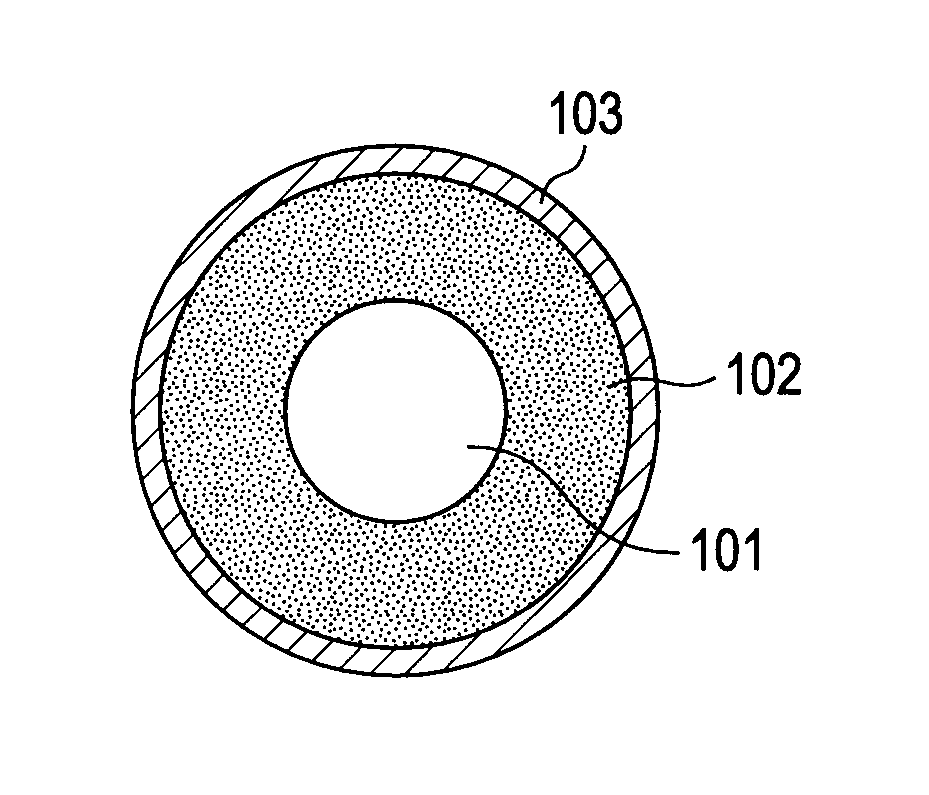

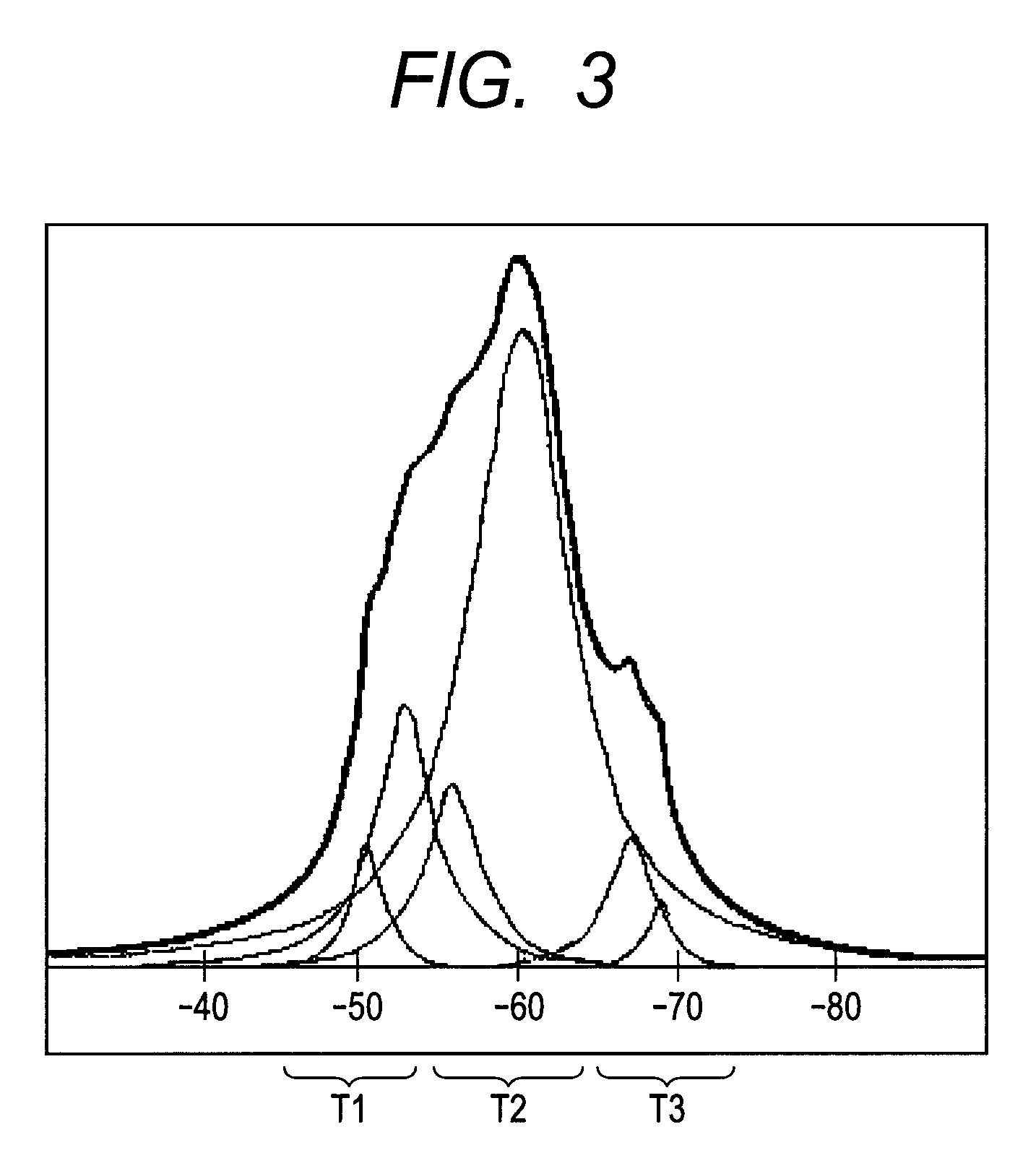

Separator and non-aqueous electrolyte secondary battery

ActiveUS20100151325A1Improve cycle performanceEasy to pressNegative electrodesPositive electrodesHeat deflection temperaturePolyolefin

In a non-aqueous electrolyte secondary battery, a separator in which its dynamic hardness DH obtained when the load to an indenter reaches 12 kgf / cm2 is 1000 or more is used. This separator includes at least one porous layer X including a polyolefin, and at least one porous layer Y including a heat resistant resin. The porosity of the porous layer X is 35% or more and 65% or less. In a pore size distribution of the porous layer X measured with a mercury porosimeter, a ratio of pores having a pore size of 0.02 μm or more and 0.2 μm or less is 40 vol % or more relative to a total pore volume. The thermal deformation temperature of the heat resistant resin is 160° C. or more.

Owner:PANASONIC CORP

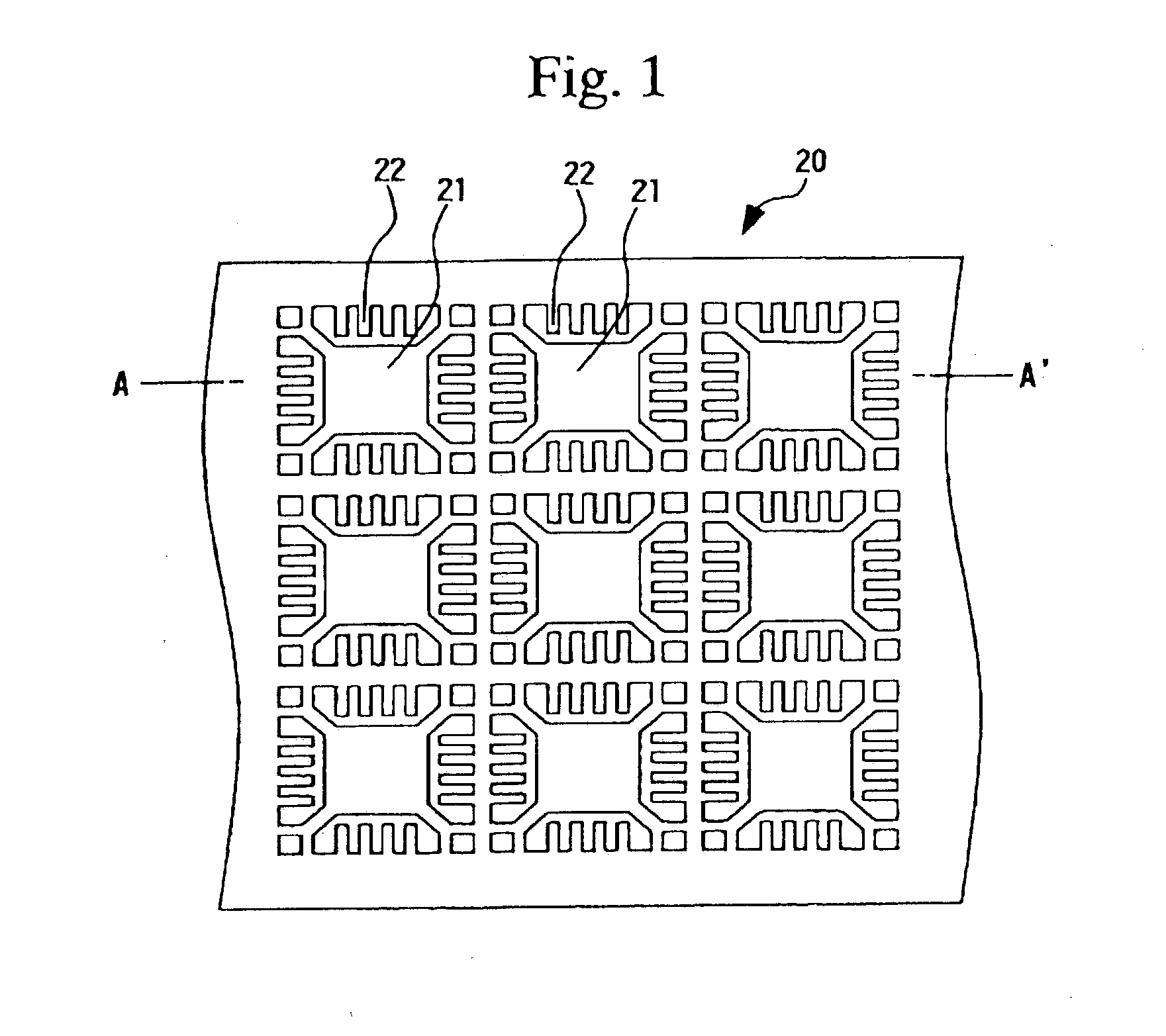

Adhesive sheet for producing semiconductor devices

InactiveUS20030190466A1Appropriate flexibilityHigh bonding strengthSemiconductor/solid-state device detailsSolid-state devicesEngineeringWire bonding

An adhesive sheet for producing semiconductor devices, such as QFNs, can prevent the generation both of wire-bonding defects and mold flashes, and can thereby prevent the production of defective semiconductor devices. The present invention provides an adhesive sheet for producing semiconductor devices which is detachably attached to a lead frame and which comprises a heat resistant substrate and an adhesive layer which is arranged on one surface of the heat resistant substrate, wherein the adhesive layer contains, a thermosetting resin component (a) and a thermoplastic resin component (b); and the weight ratio of the component (a) / the component (b) is 0.3 to 3.

Owner:TOMOEGAWA PAPER CO LTD

Sealing corrosion proof protection method of rope-suspension bridge cable system

ActiveCN101457364AGood weather resistanceIncrease elasticityHot-dipping/immersion processesLiquid surface applicatorsShock mountEngineering

The invention discloses a sealing and anti-corrosion protection method of a suspension bridge cable system, and belongs to an anti-corrosion protection method of a bridge cable. The method helps divide the whole cable system into 7 types of surfaces: an outer surface of a main cable of a wire wrapping section; the outer surface of the main cable of a non-wire wrapping section; the outer surface of a main cable saddle exposing a strand; the outer surfaces of a cable strand inside an anchor chamber, a sling wire rope, as well as a railing rope and a side rope of a maintaining roadway; the outer surfaces of a cable clamp, a cable saddle (sleeve) and a saddle, and exposed surfaces of bolts and nuts; the outer surfaces of an anchor cup, a sling clamp, a sling shock mount, and columns and brackets of the maintaining roadway; and gap sealing surfaces of the cable clamp, a cable jacket girth seam, an abutted seam and a top saddle opening. The 7 types of the surfaces are treated by different methods, and the sealing and anti-corrosion method is complete. In the method, novel sealing materials and anti-corrosion paints are used, which has good sealing performance, long anti-corrosion service life and high strength, and ensures the durability of the suspension bridge cable system.

Owner:JIANGSU CUMT DAZHENG SURFACE ENG TECH

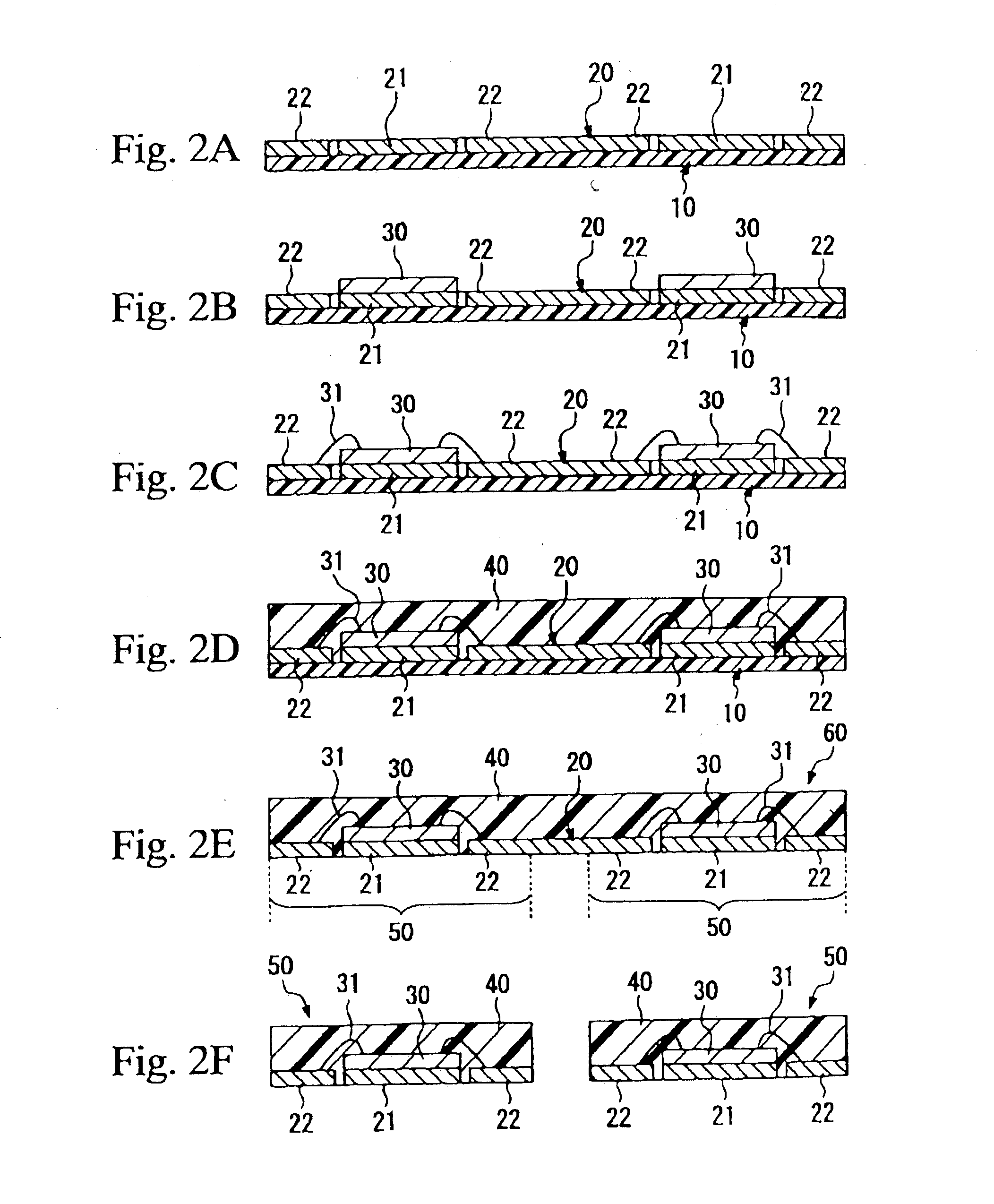

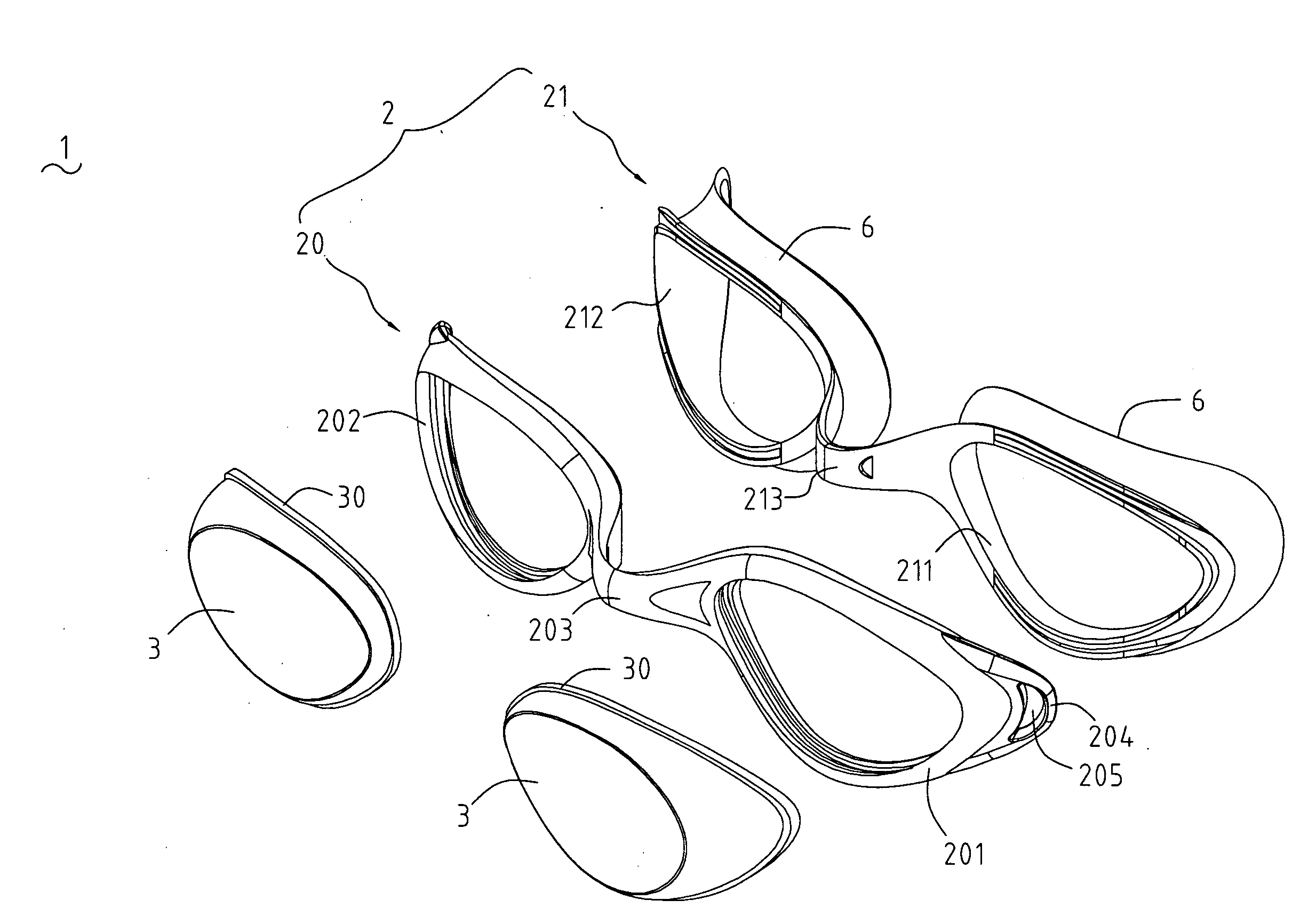

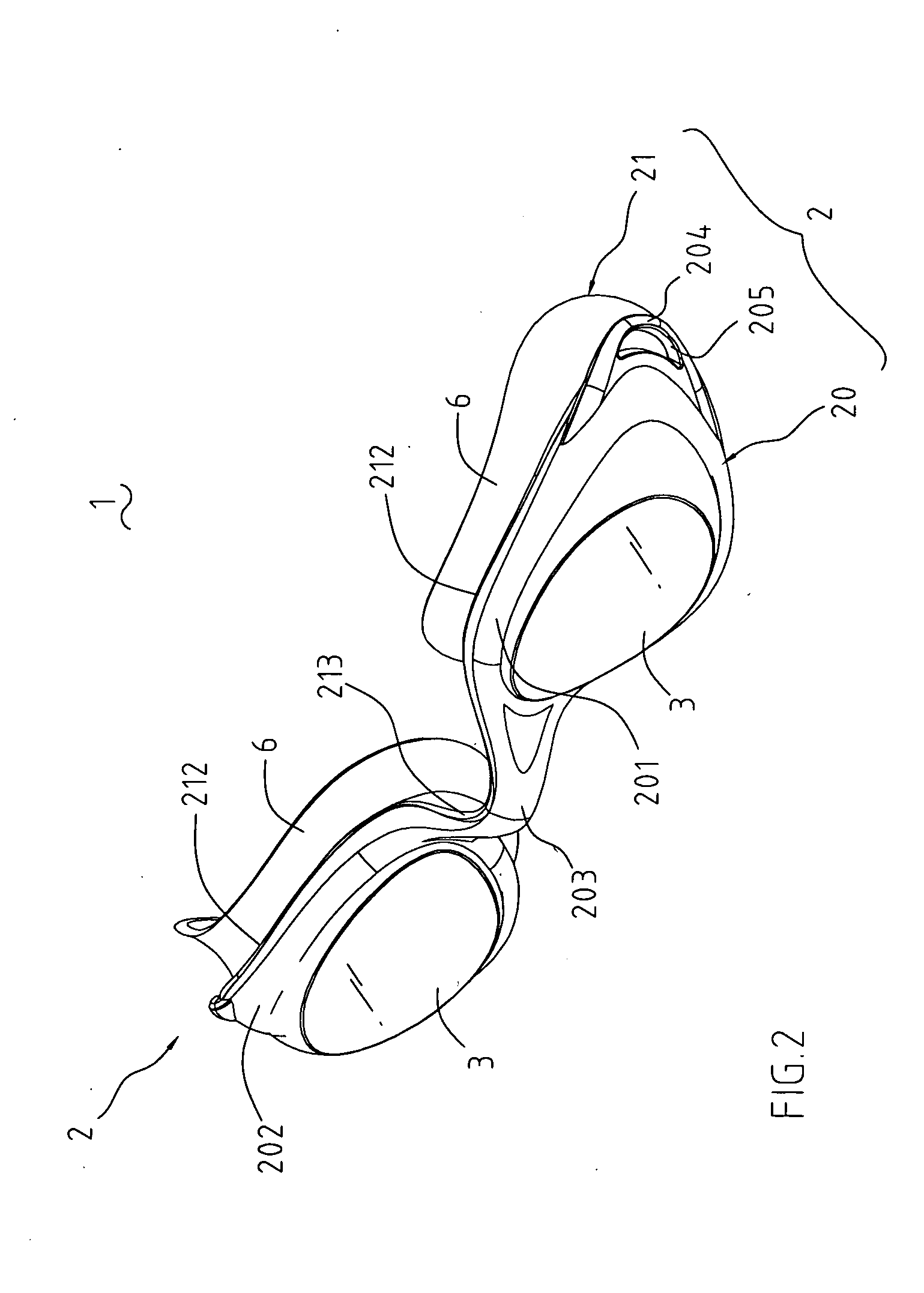

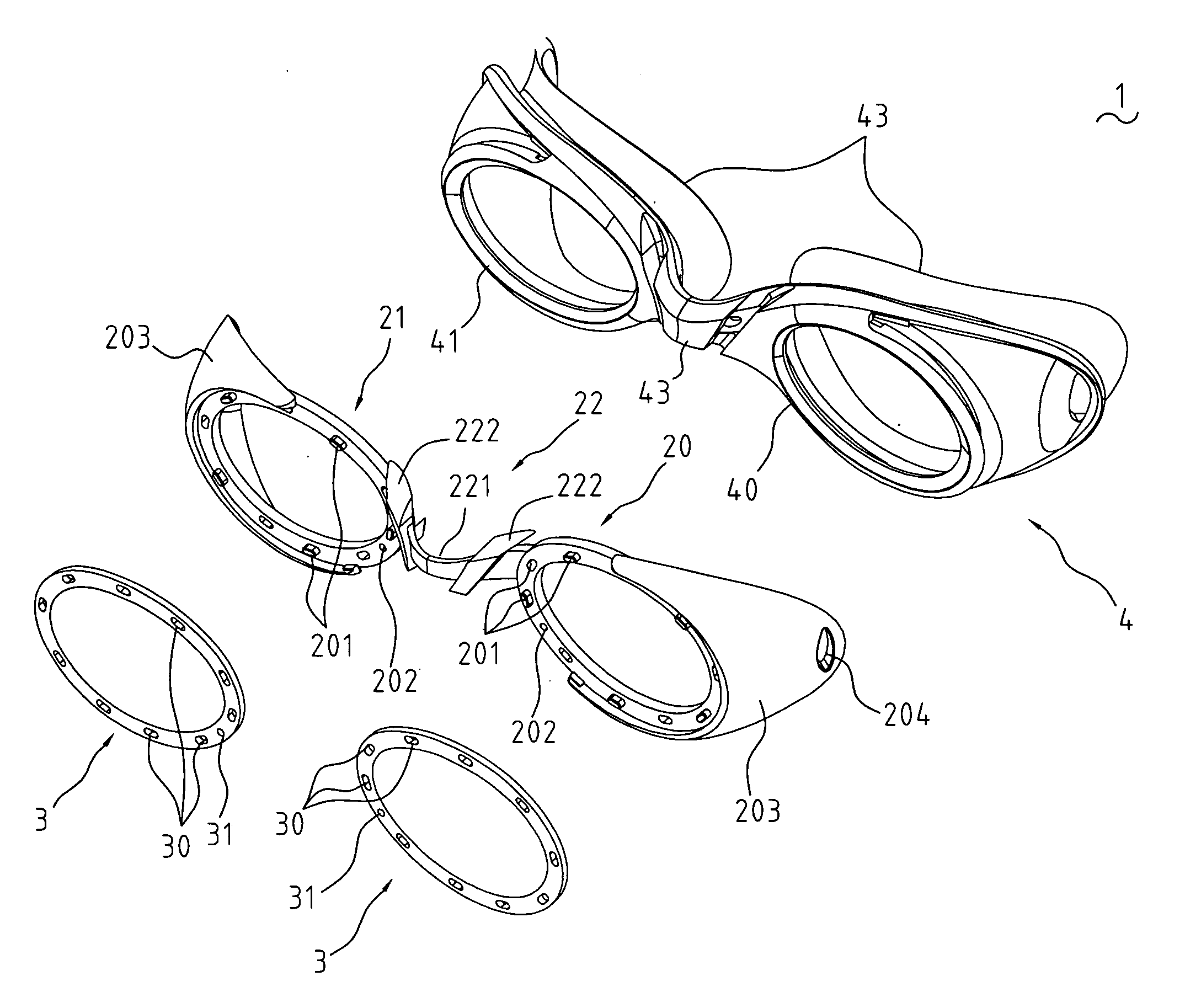

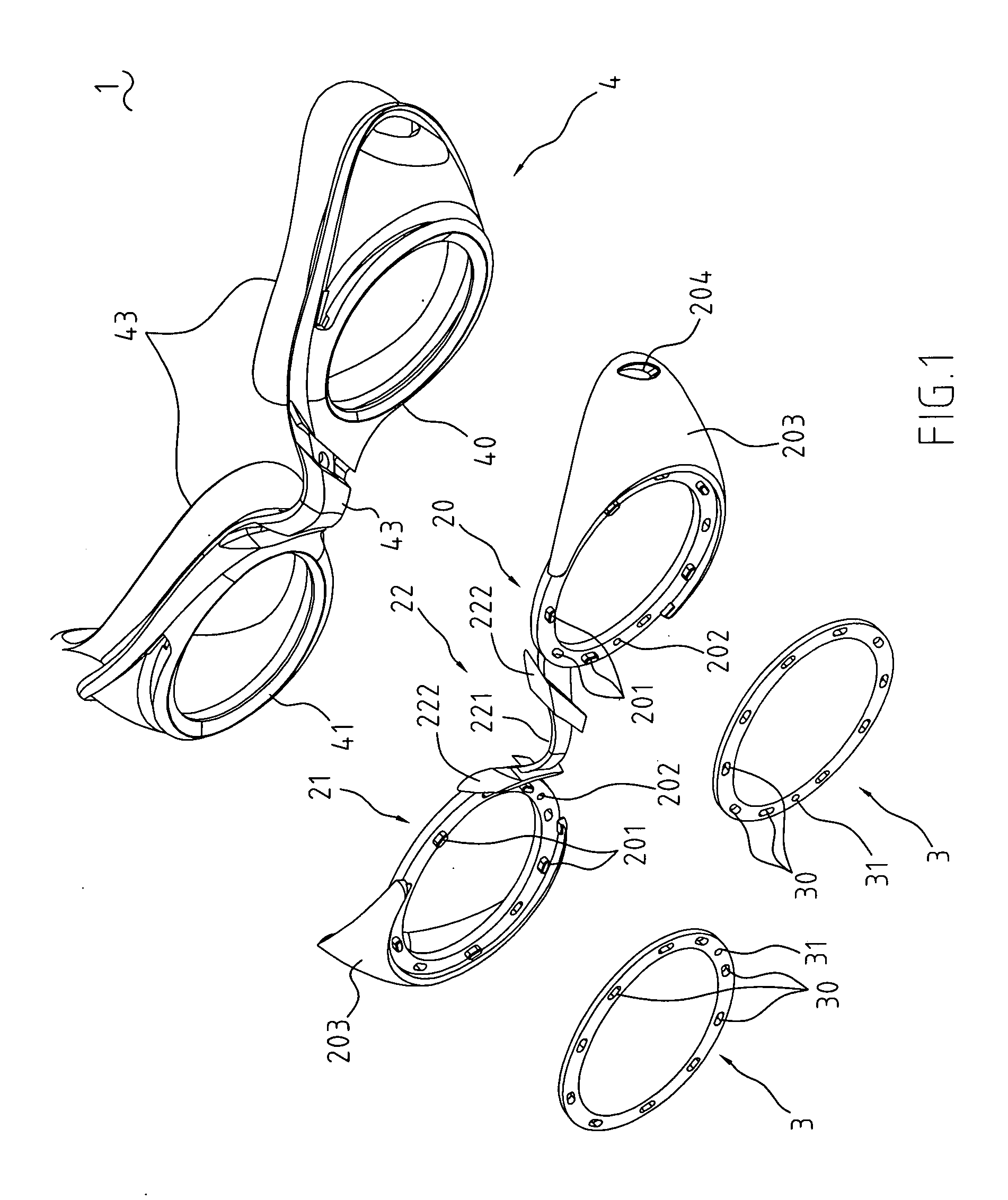

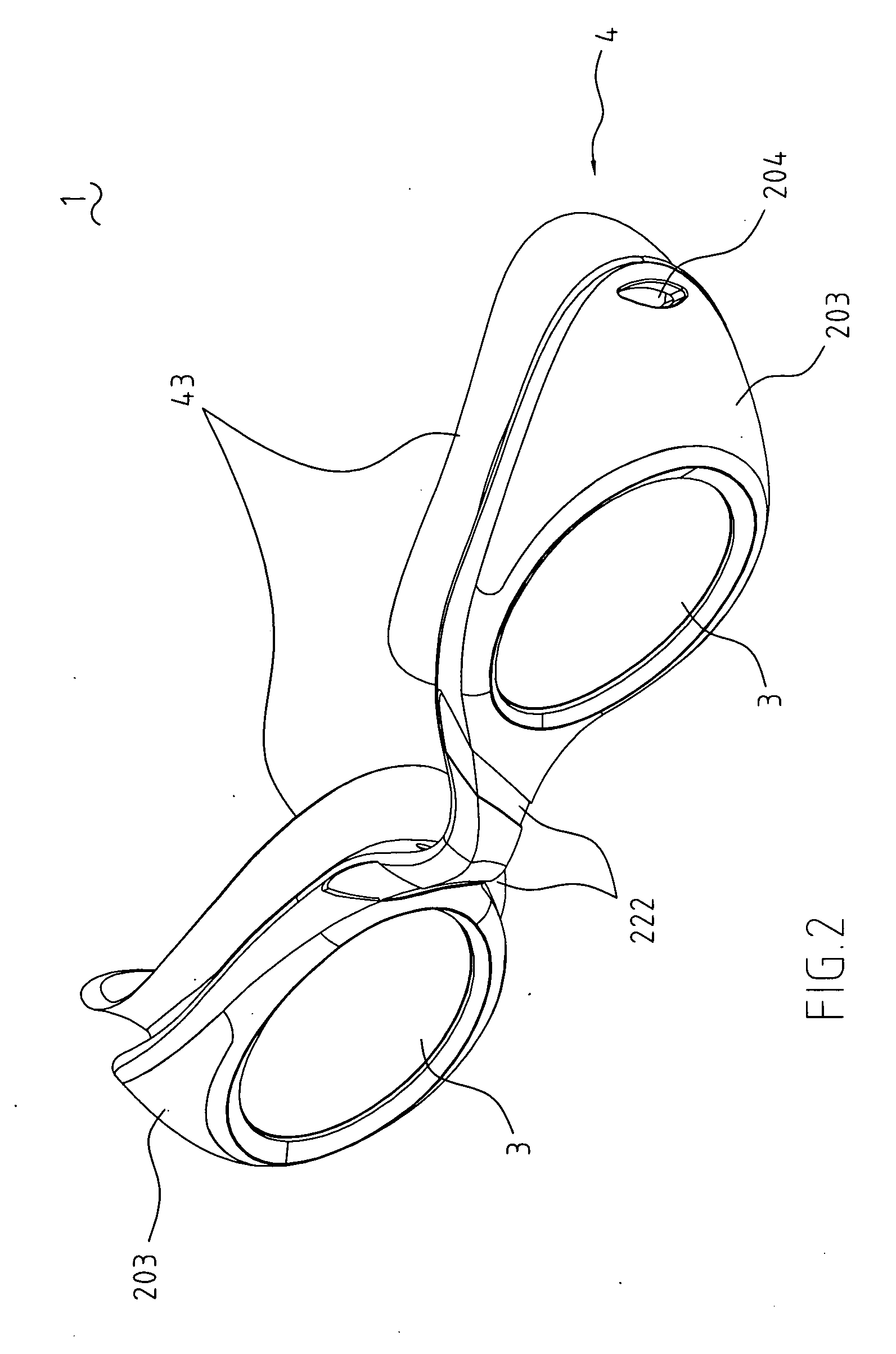

Swimming goggles

InactiveUS20090300828A1Appropriate flexibilityFeel comfortableGogglesSwim gogglesSoft materialsEngineering

Swimming goggles are provided which include an integral left and right frames and nose bridge. The integral left and right frames and nose bridge include an outer frame and an inner frame. The outer frame includes front sections of the left and right frames, and a front section of the nose bridge. The inner frame includes rear sections of the left and right frames, and a rear section of the nose bridge. Lenses are received in the left and right frames of the outer frame and the inner frame. Pads are made of soft material and are assembled on the rear sections of the left and right frames. The outer frame and the inner frame are made of different material or of the same material with different rigidity.

Owner:CHIANG HERMAN

Bipolar zero-gap type electrolytic cell

ActiveUS7323090B2Stable electrolysisHigh densityCellsElectrode shape/formsInternal pressureTitanium metal

A bipolar zero-gap electrolytic cell comprising an anode comprising an anode substrate constituted of a titanium expanded metal or titanium metal net of 25 to 70% opening ratio, which anode after coating the substrate with a catalyst has a surface of 5 to 50 μm unevenness difference maximum and has a thickness of 0.7 to 2.0 mm. In this electrolytic cell, the possibility of breakage of ion exchange membrane is low, and the anolyte and catholyte have a concentration distribution falling within given range. With this electrolytic cell, stable electrolysis can be performed for a prolonged period of time with less variation of cell internal pressure.

Owner:ASAHI KASEI KK

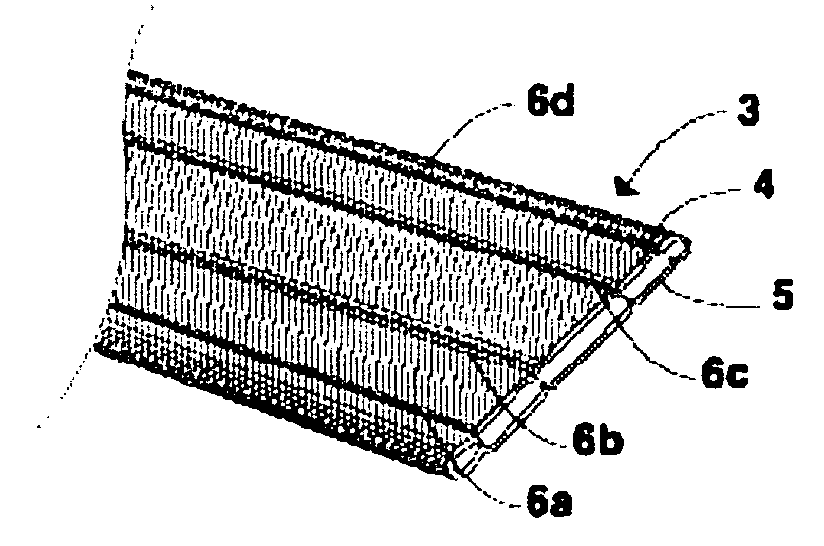

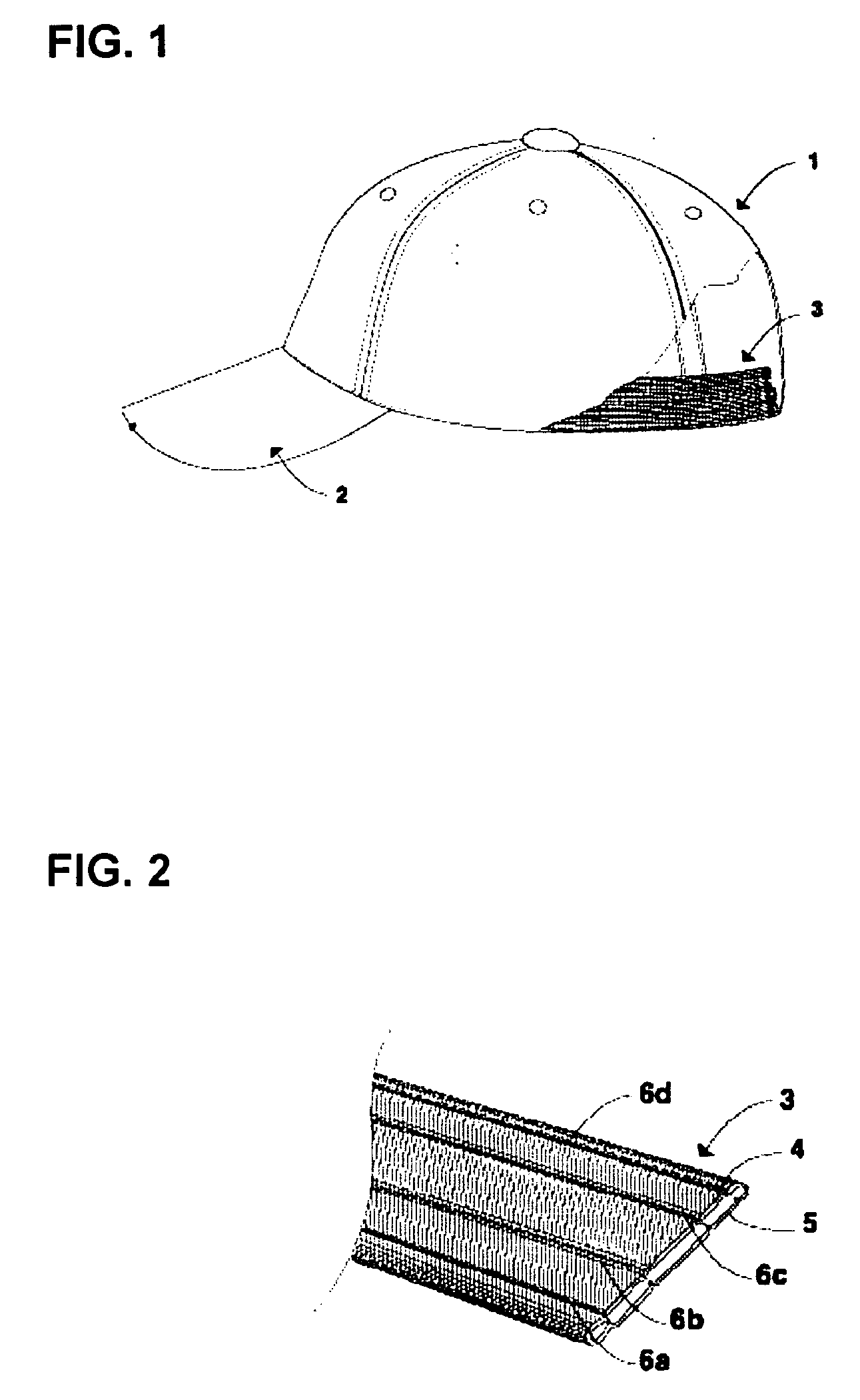

Sweatband using micro fiber yarn for a cap

A sweatband using micro fiber yarn for headwear that is made to 0.5˜1.05 denier thickness of micro fiber yarn and woven of 100% polyester wrap-way and weft-way, made to single or two-ply without any polyurethane and additional stitched portion. The resulting sweatband, which preferably provides excellent sweat absorbing capability, and having high dryness factor, anti-static electricity function and the highly washable function, and exhibits good elasticity through the structure of the textile without imposing undue pressure on the wearer, with the result that the sweatband may be worn comfortably for long periods of time. The yarn used to produce the sweatband is processed by high temperature and piece dyeing methods and has twist per each certain length.

Owner:DADA CO LTD

Swimming goggles

Swimming goggles include a left bracket, a right bracket, a hard nose support between the left bracket and the right bracket, lenses respectively assembled on the left bracket and the right bracket, soft integral assembly of frame, nose bridge and pad, and a head strap. The left bracket and the right bracket are made of rigid material, and form a plurality of latch portions and define injection orifices thereon. Strap assembling blocks are formed on outward sides of the left bracket and the right bracket for assembling with the head strap. Through holes are defined in the lenses for corresponding to the injection orifices. Soft integral frame, nose bridge and pad is made in such a way that during shaping, the left bracket, the right bracket and the hard nose support are covered along peripherals of the lenses with the strap assembling blocks being exposed outward.

Owner:CHIANG HERMAN

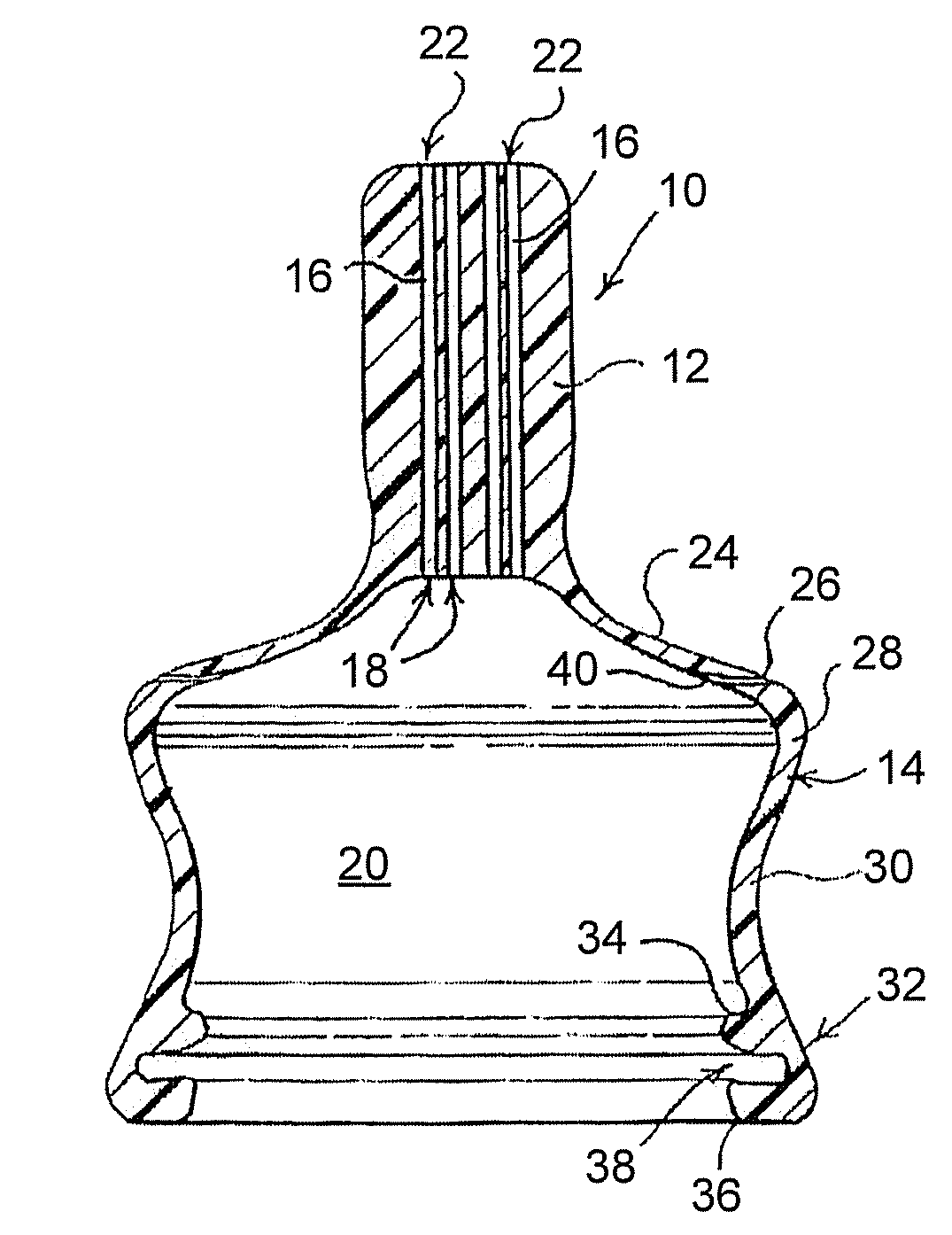

Artificial feeding nipple tip with variable flow construction

InactiveUS7540388B2Appropriate flexibilityIncrease flow rateFeeding-bottlesTeatsMechanical engineeringArtificial feeds

Owner:MEDELA HLDG AG

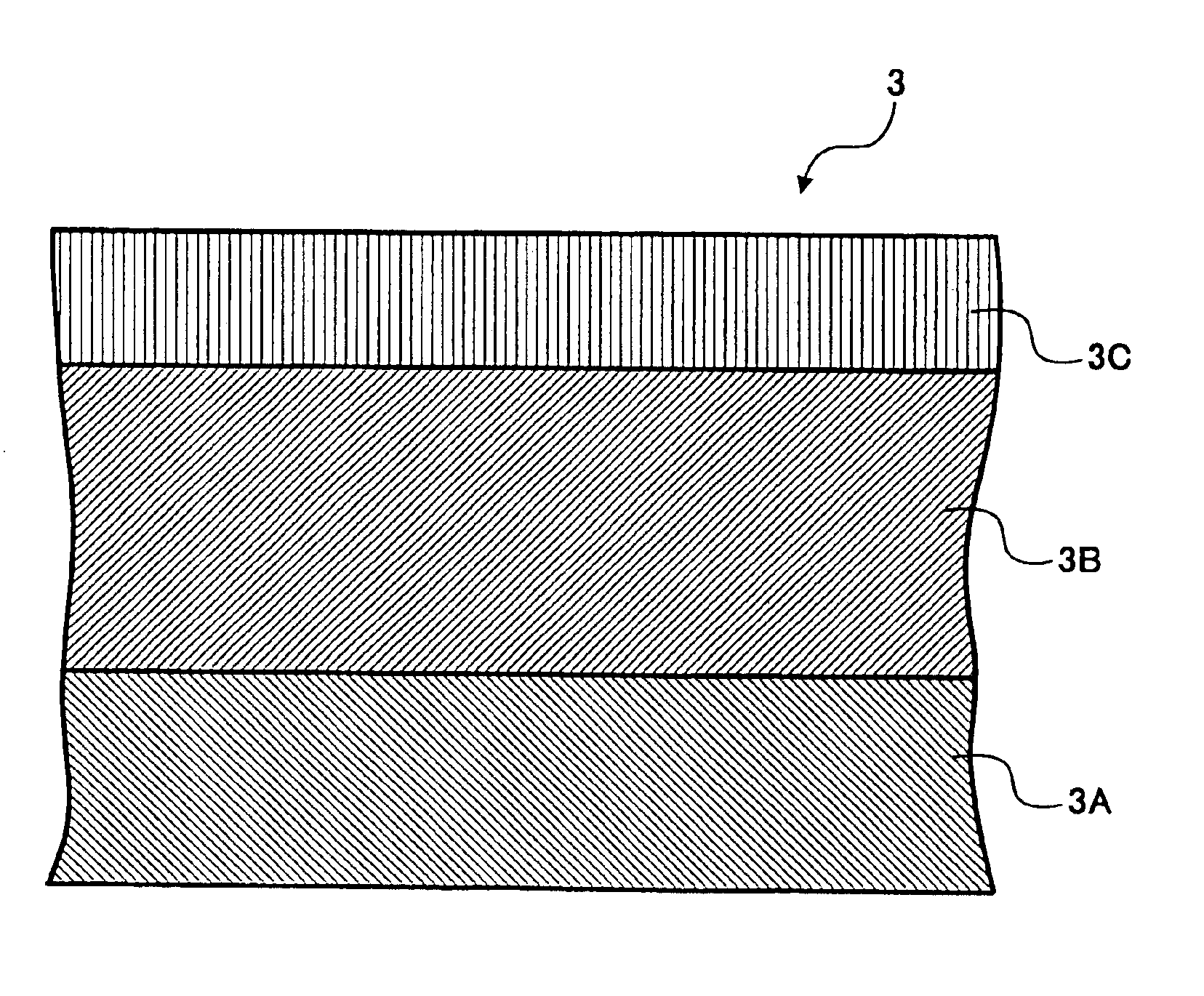

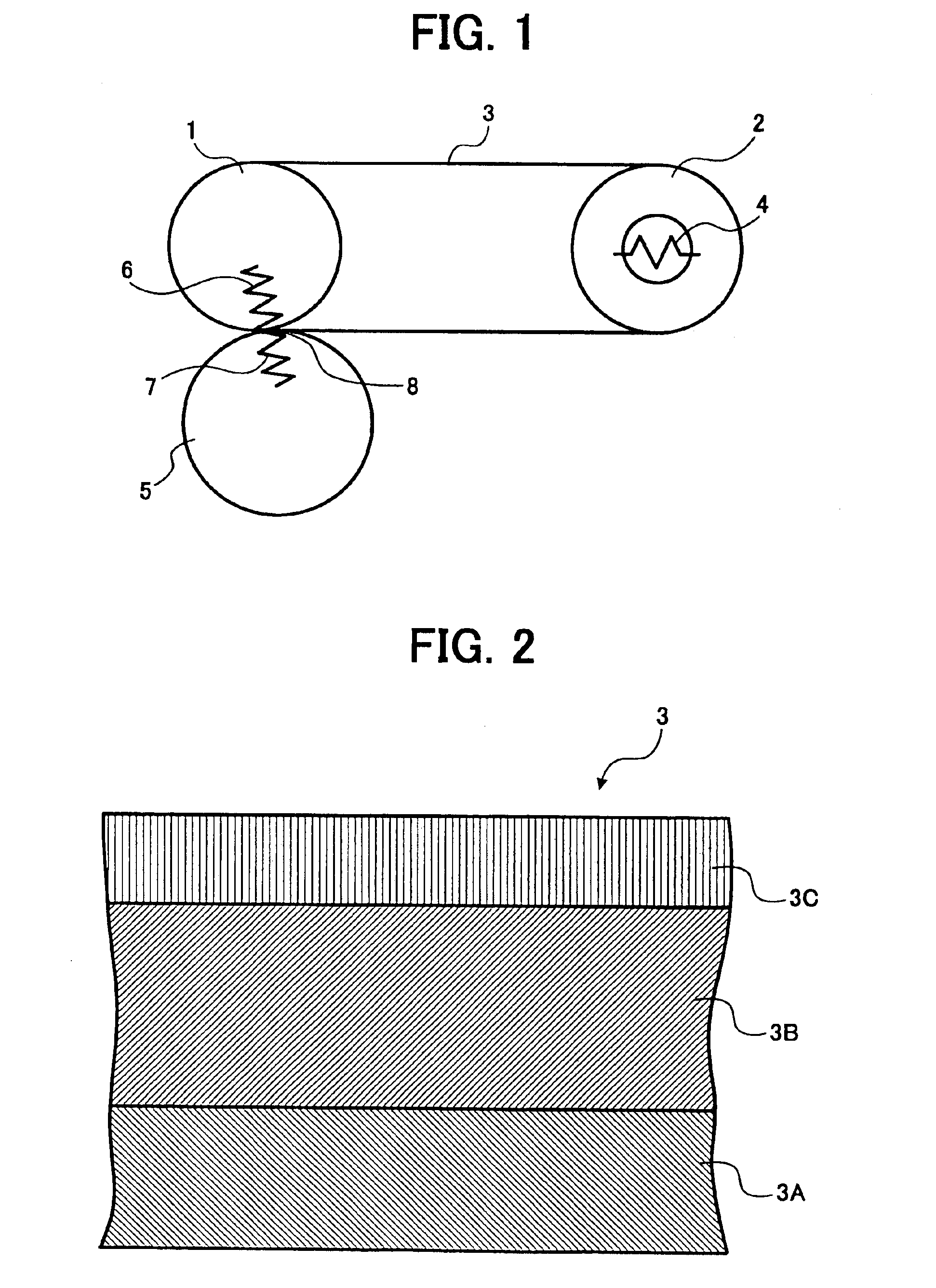

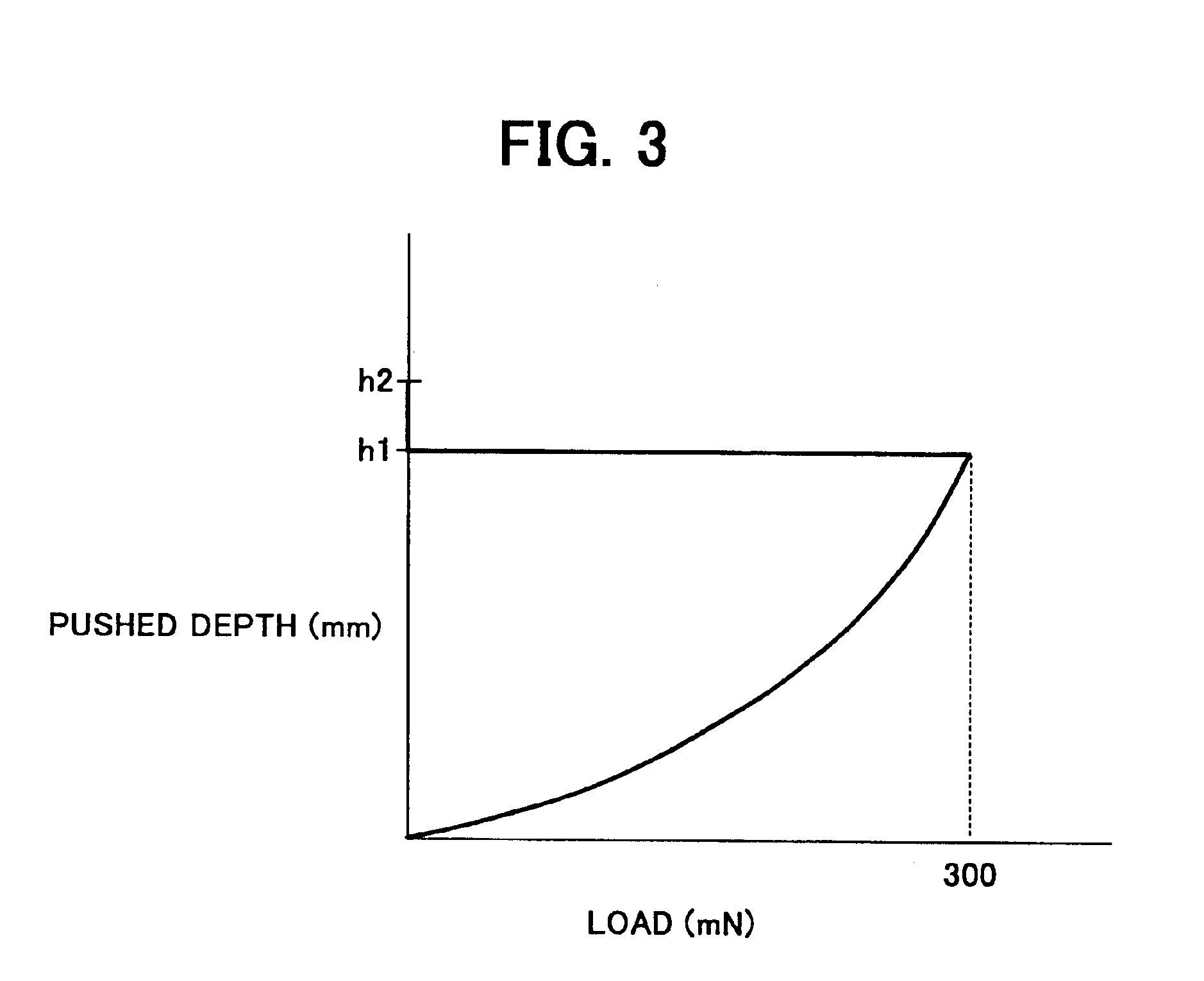

Fixing belt and method for evaluating it

InactiveUS6861124B2Avoid wrinklesAvoid it happening againLamination ancillary operationsCellulosic plastic layered productsEngineeringHardness

Disclosed are a fixing belt and a method for evaluating it in which an occurrence of crumple can be prevented by means of accurate evaluation whether a surface of the fixing belt has a appropriate flexibility or not.In this method for evaluating, a universal hardness test is achieved for the fixing belt in which an elastic layer and a mold releasing layer are laminated on a substrate, the fixing belt is judged as an acceptable product if a creep value CHU is included within a range of 0.40≦CHU≦3.50(%) when a creep value CHU which is measured from the mold releasing layer side is defined by a formula below.CHU=(h2−h1) / h1×100(%)where h1 is a pushed depth (mm) when a test load reaches a predetermined value which is kept for a predetermined period of time, andh2 is a pushed depth (mm) when a predetermined period of time is elapsed after the test load is removed.

Owner:RICOH KK

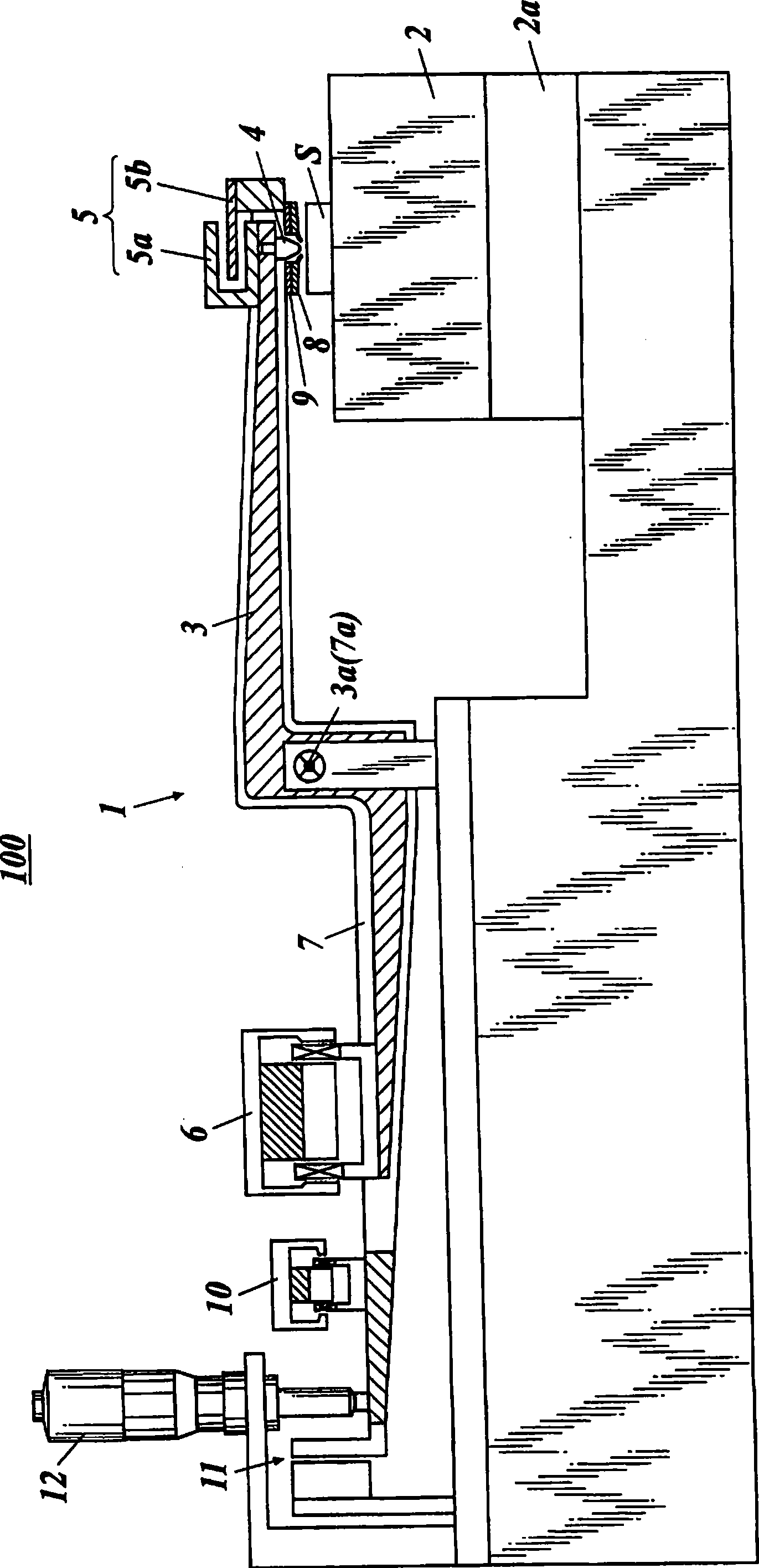

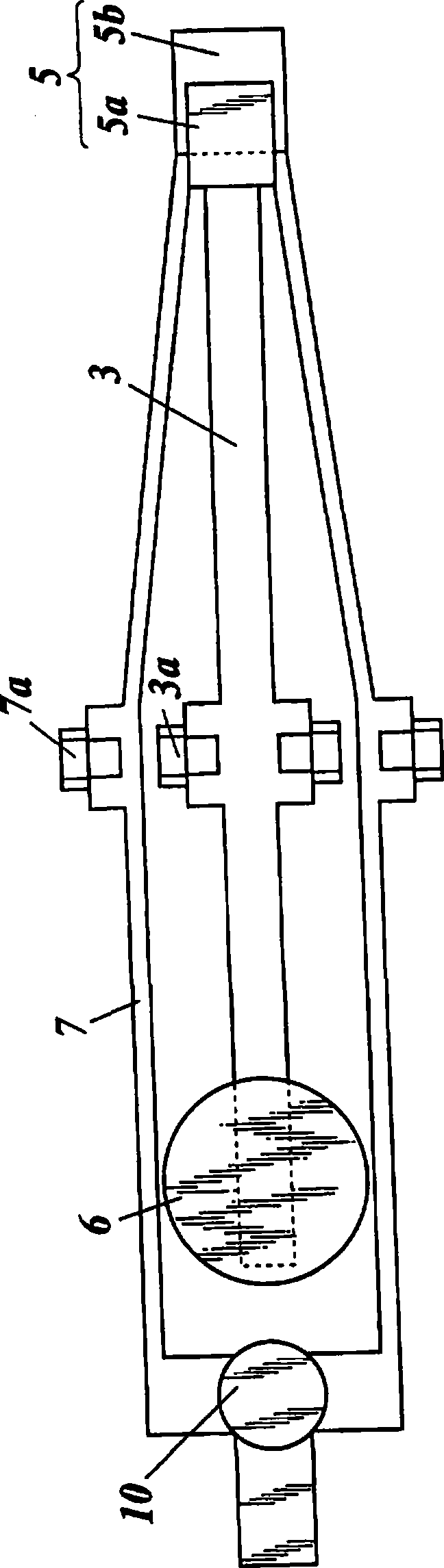

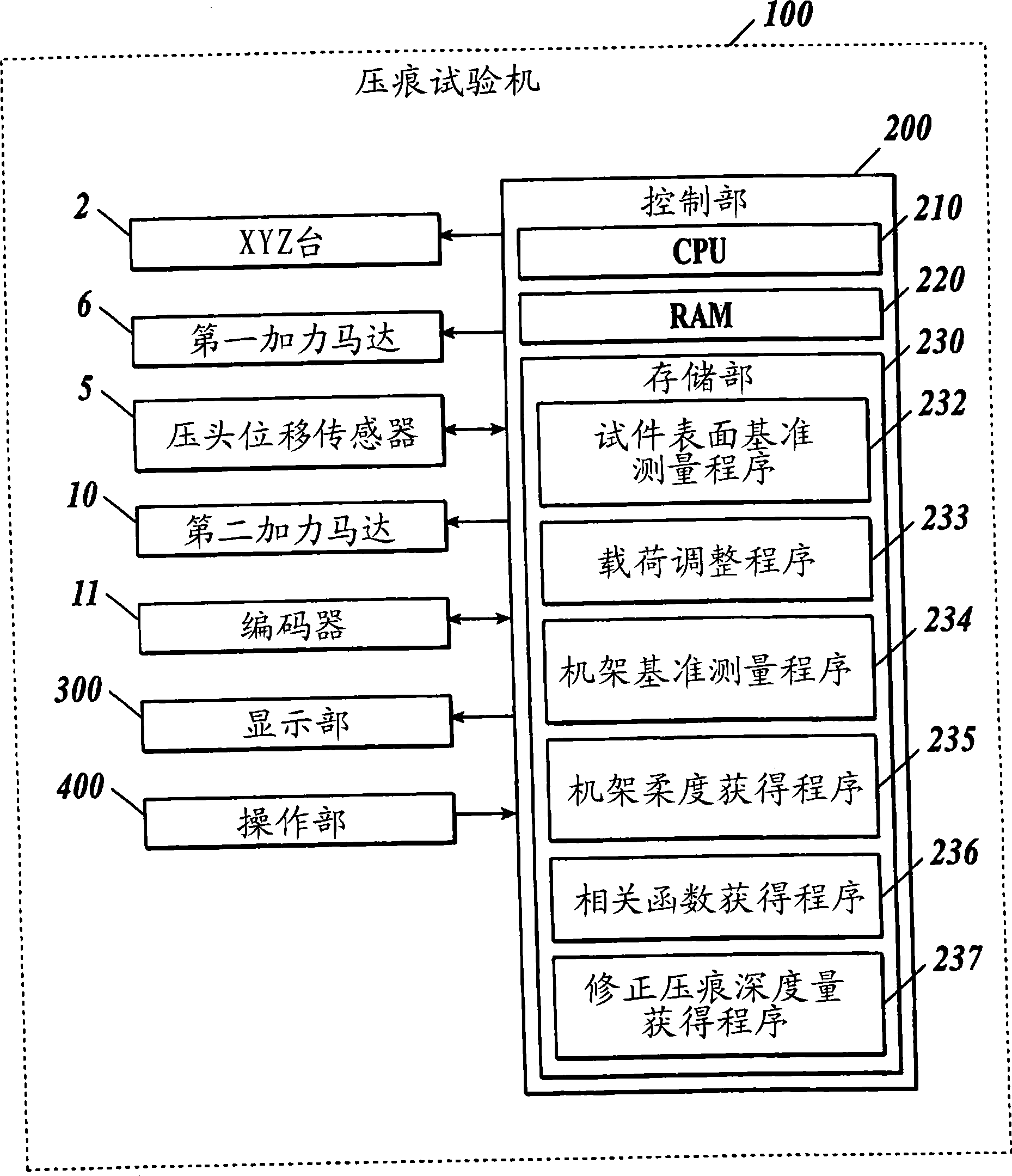

Indentation testing instrument and indentation testing method

ActiveCN101470061AAppropriate flexibilityAccurate measurementInvestigating material hardnessIndentation testingEngineering

Disclosed an indentation testing instrument including: a loading lever supported pivotally; an indenter provided on the loading lever; an indenter linkage section; a loading lever driving section; a reference lever supported pivotally having a same shaft center as the loading lever; an indenter reference section provided on the reference lever as a positional reference of a tip portion of the indenter; an indenter position detection section; a reference lever driving section; a stopper to stop the reference lever; a specimen surface reference measurement member to turn the loading lever from the state that the indenter reference section touches the specimen surface, and to measure a first indentation depth amount; and a machine frame reference measurement member to turn the loading lever from the state that the reference lever touches the stopper and the indenter reference section is spaced apart from the specimen surface, and to measure a second indentation depth amount.

Owner:MITUTOYO CORP

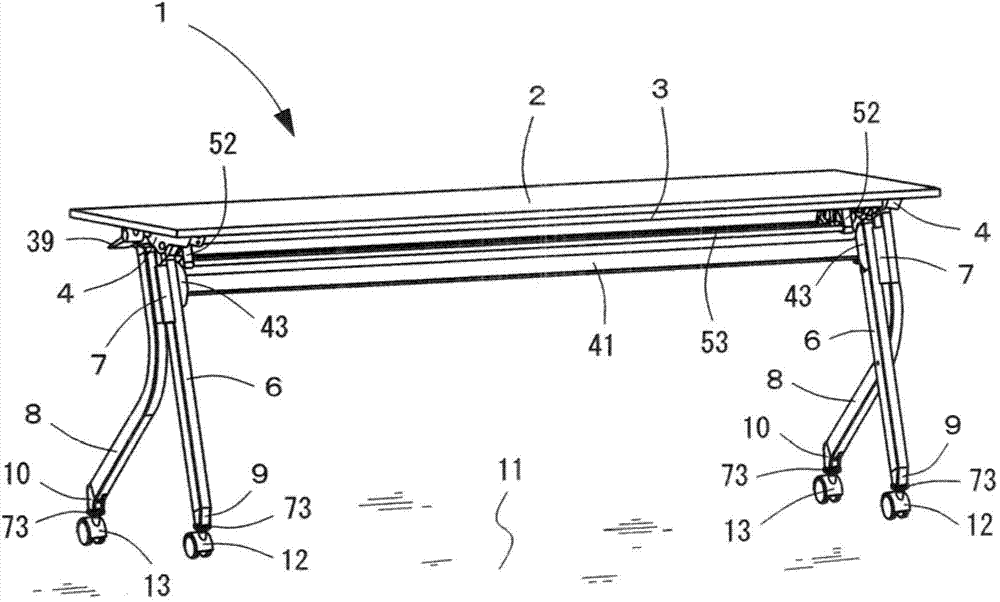

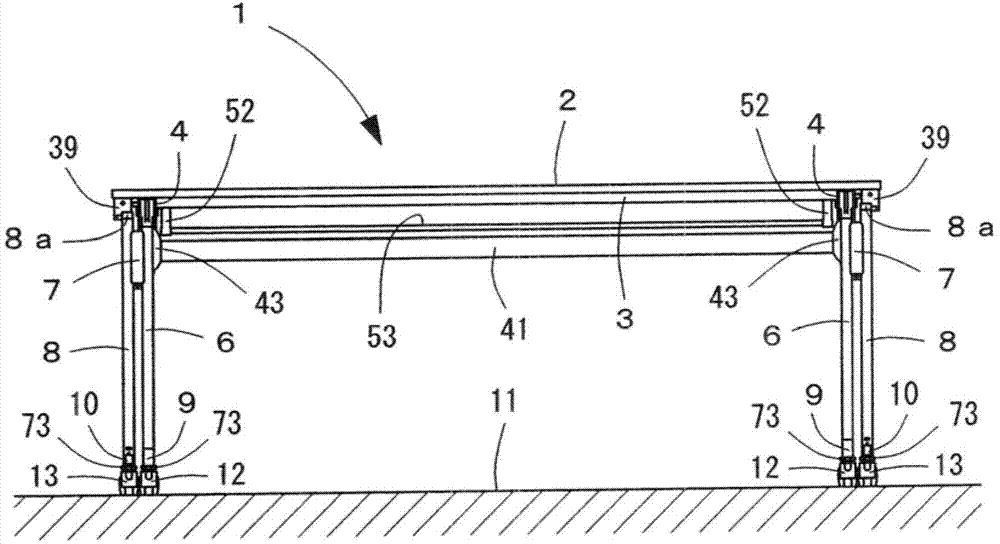

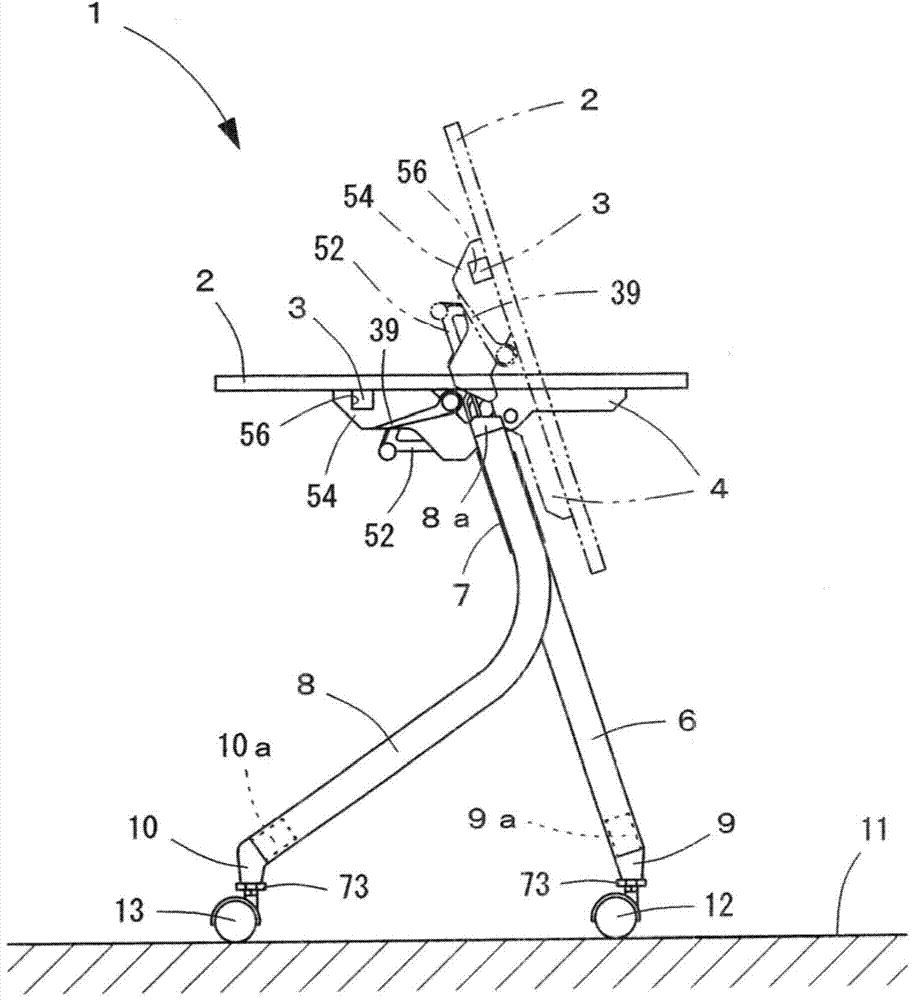

Folding table

ActiveCN103156384AAchieve compactnessConducive to lightweightFoldable tablesStowable tablesMechanical engineeringGround level

The invention provides a folding table, which comprises a height regulation device capable of easily and reliably regulating height from a leg or a top plate to the ground, while the folding table obtains reliable and stable using and folding states to the top plate. A locking connecting rod is arranged, and the locking connecting rod comprises a clamping part clamping or unclamping in a clamping groove. The clamping part of the locking connecting rod forms a plate on a same plane with the locking connecting rod. A peripheral surface on an upper end of a connection component is configured a same plane of a rotation area of the clamping part.

Owner:HUIBIES FURNITURE

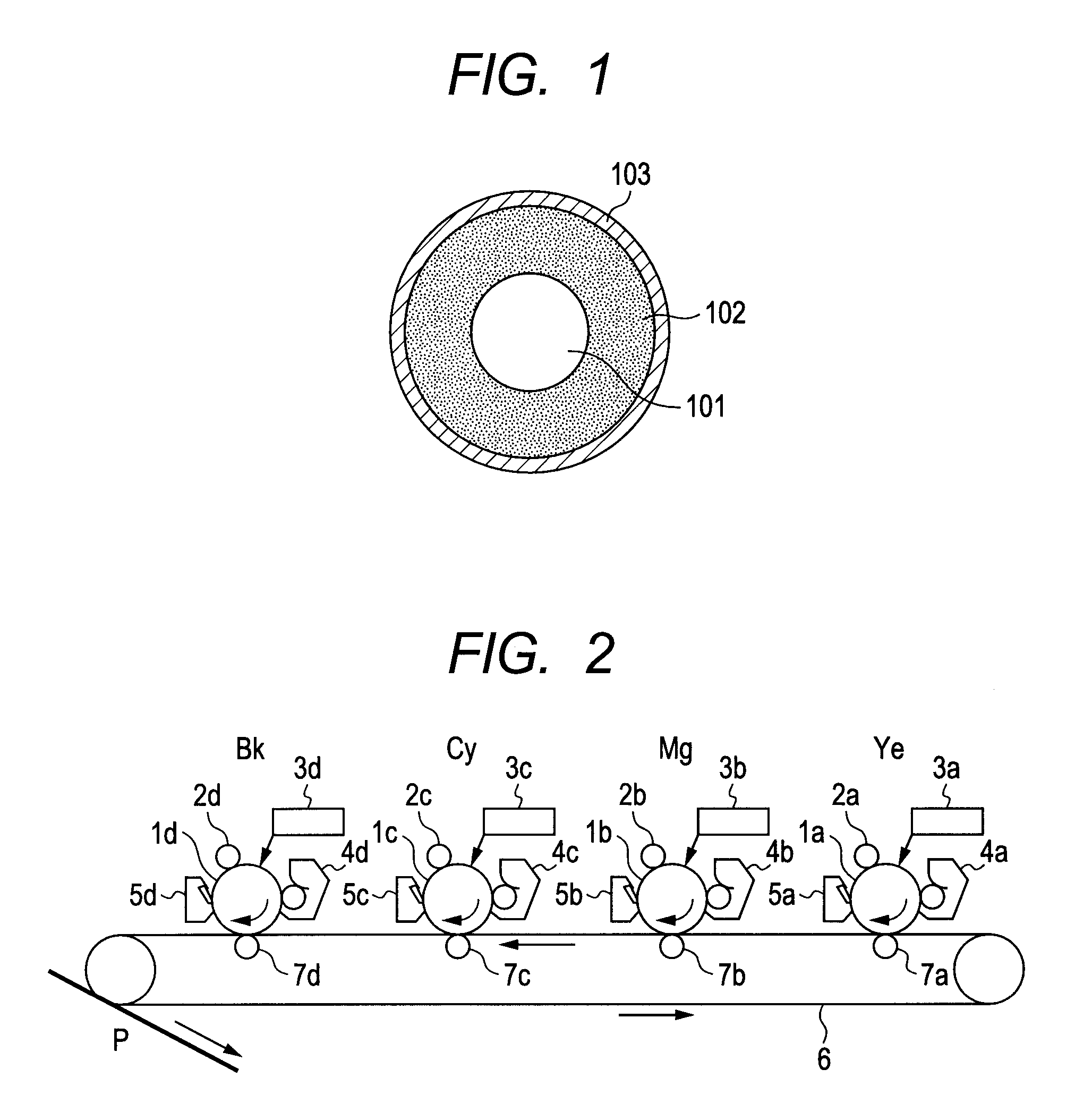

Charging member, process cartridge and electrophotographic apparatus

ActiveUS8755714B2Improve wear resistanceNot easy to wearElectrographic process apparatusCorona dischargeSurface layerStructural unit

A charging member is provided with a surface layer that can not easily wear even due to its contact with a photosensitive member and also has an appropriate elasticity contributing to the formation of an appropriate nip between it and the photosensitive member. The charging member has a substrate, an elastic layer and a surface layer; the surface layer containing a high-molecular compound having an Si—O—Hf linkage and having a constitutional unit represented by the formula (1) and a constitutional unit represented by the formula (2):

Owner:CANON KK

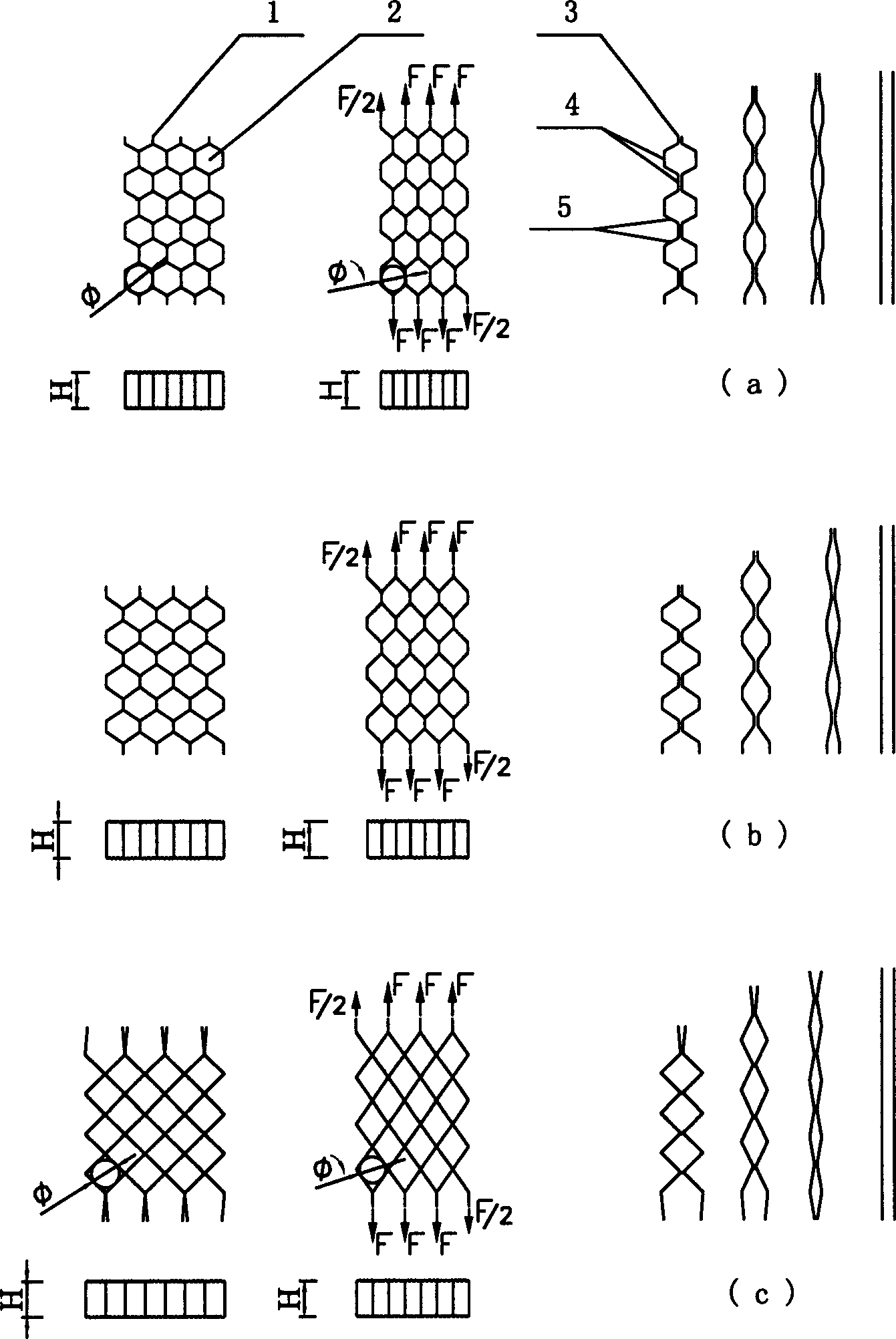

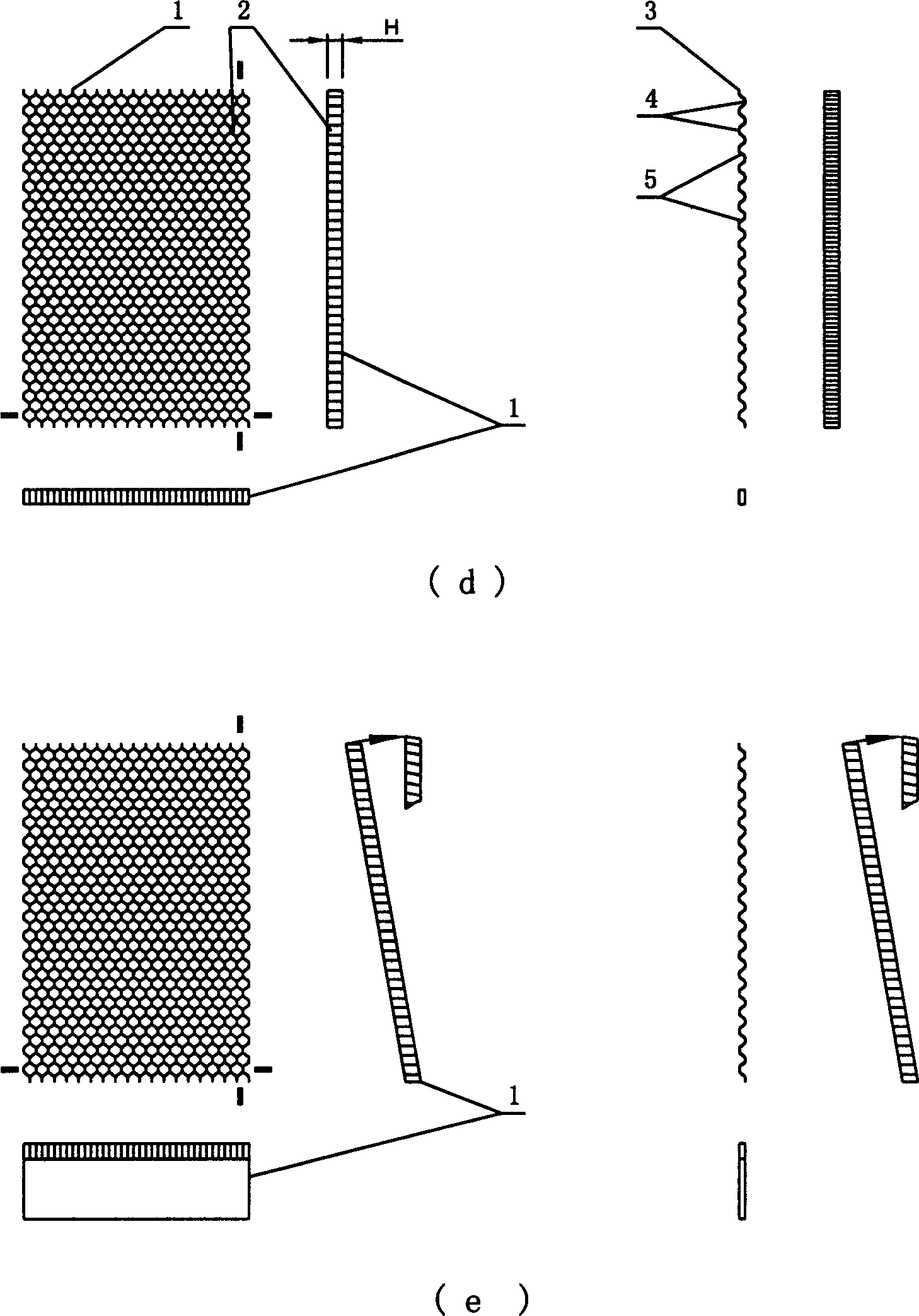

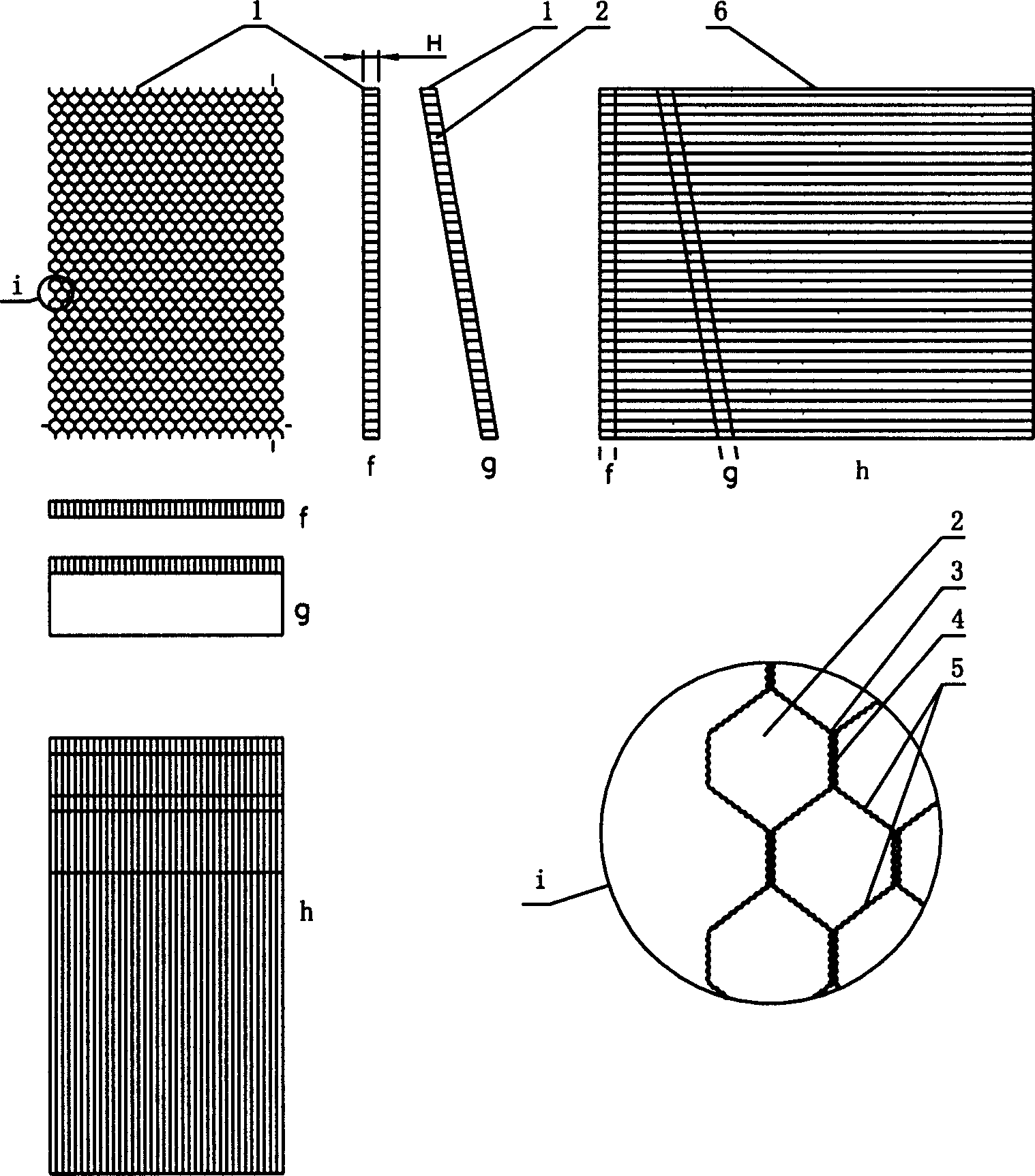

Multipurpose plastic honeycomb bundle

InactiveCN1596634ASignificant comprehensive benefitsRemarkable effectAnimal husbandryAquatic animalAquatic product

A multi-purpose plastic cellular bundle for raising silkworms, storage of grains, culture of aquatic animals, etc is made up of non-toxic plastics or composite material.

Owner:黄海芳

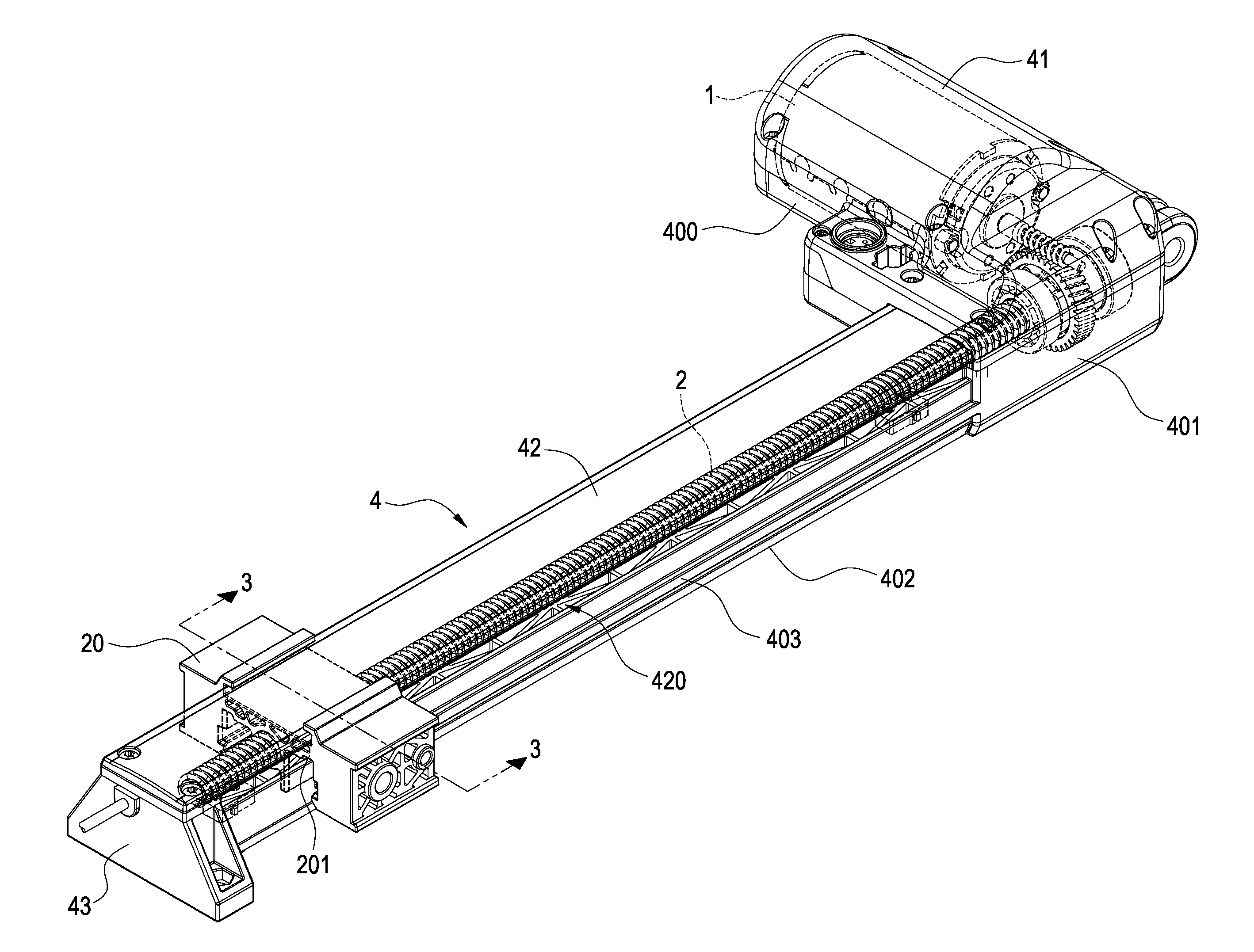

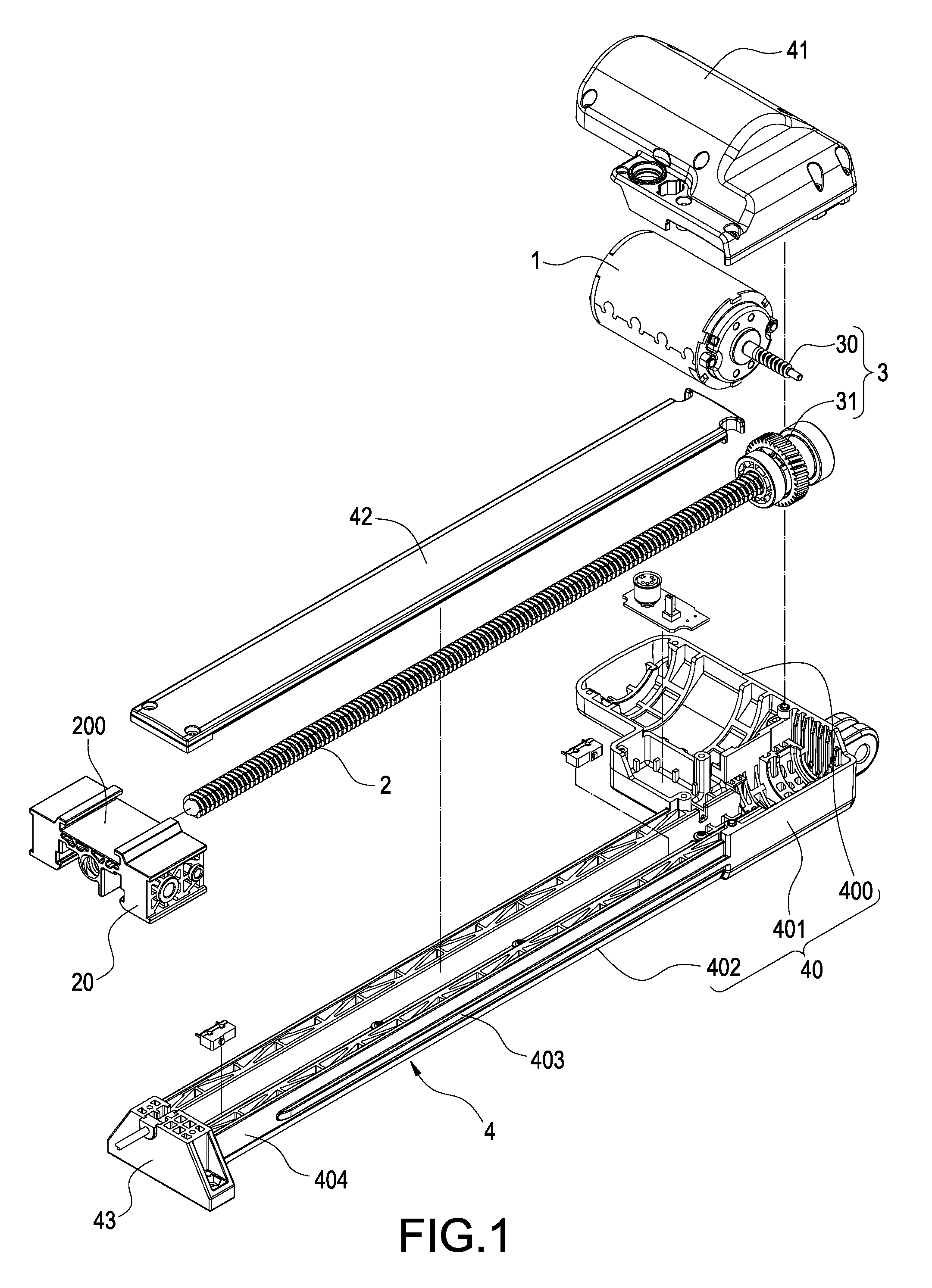

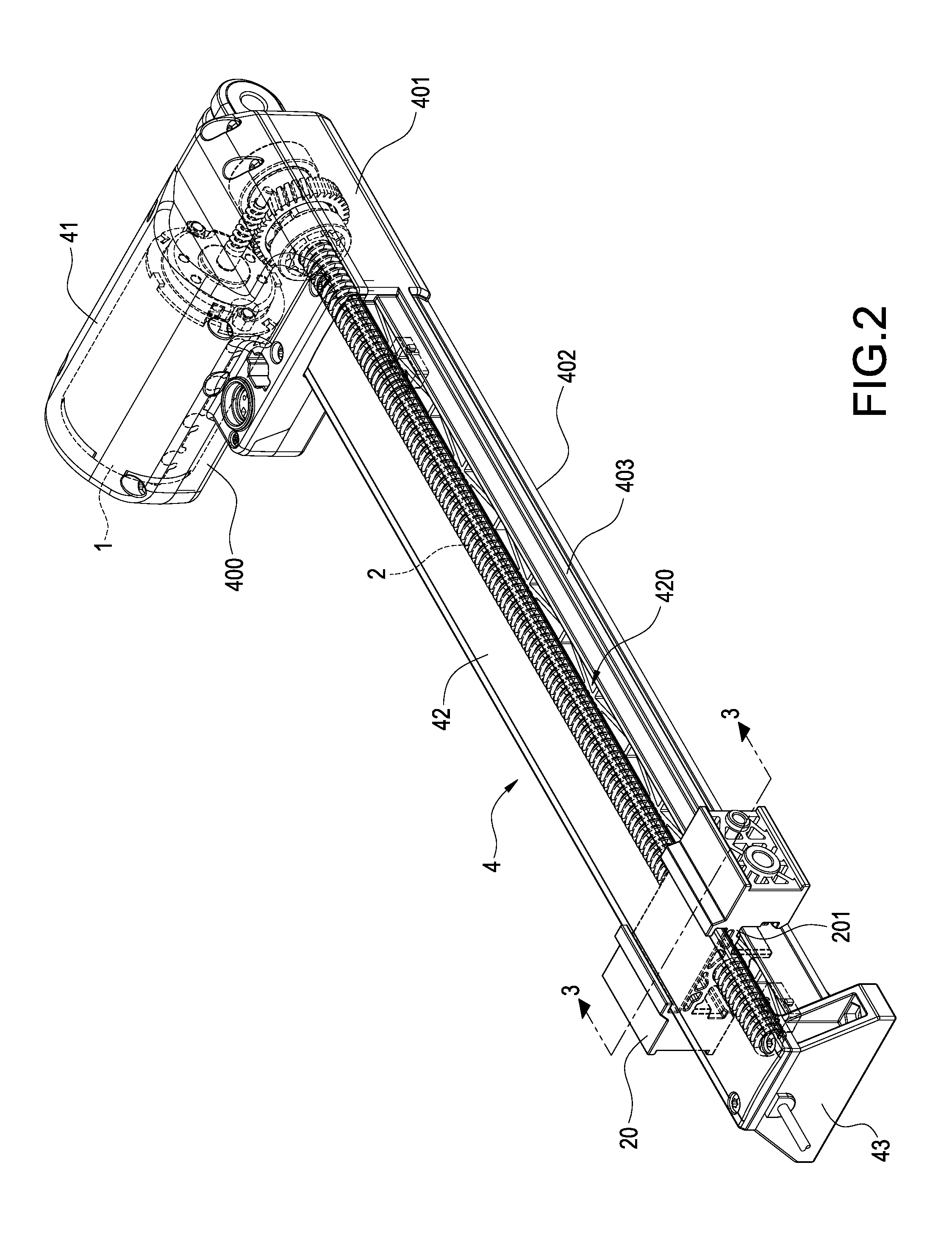

Linear actuator

ActiveUS20140196555A1Simple designSmall thicknessLinear bearingsToothed gearingsEngineeringLinear actuator

A linear actuator includes a driver (1), a transmission rod assembly (2), a mechanical motion conversion assembly (3) linked between the driver (1) and the transmission rod assembly (2), and a housing (4) covered onto the driver (1), the transmission rod assembly (2), and the mechanical motion conversion assembly (3). The housing (4) includes a lower part (40) and an upper part (41), and the lower part (40) sequentially includes a first containing portion (400) for receiving and installing the driver (1), a second containing portion (401) for receiving and installing the mechanical motion conversion assembly (3), and a third containing portion (402) for receiving and installing the transmission rod assembly (2), and the upper part (41) is covered on top of the first and second containing portions (401, 402), and the first, second and third containing portions (401, 402, 403) are integrally formed as a whole.

Owner:TIMOTION TECH CO LTD

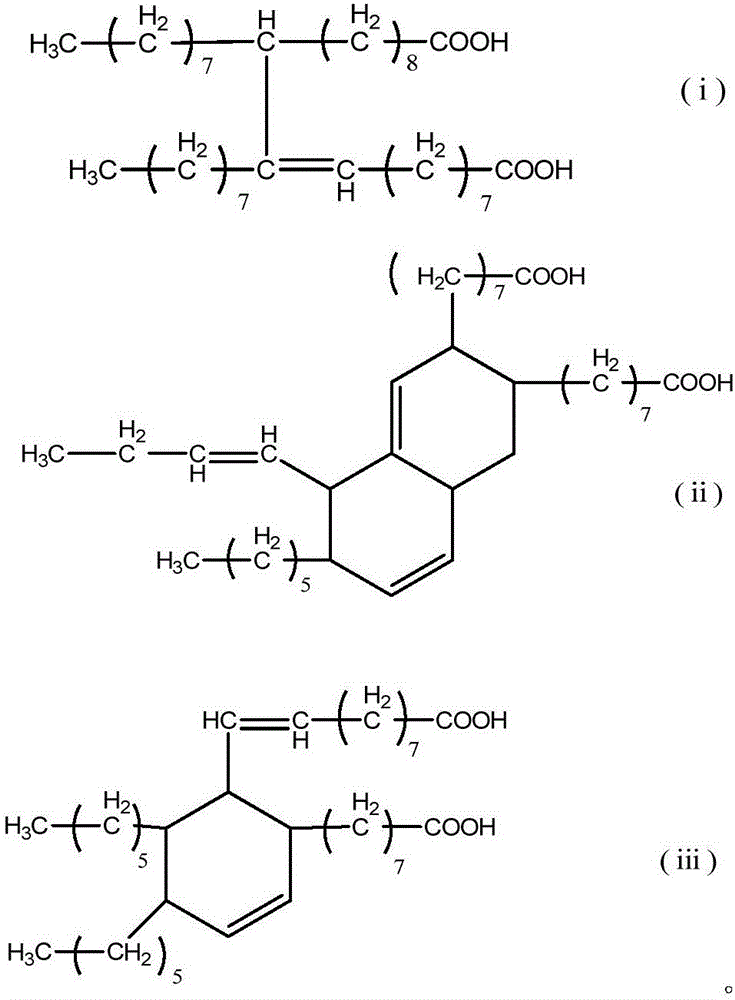

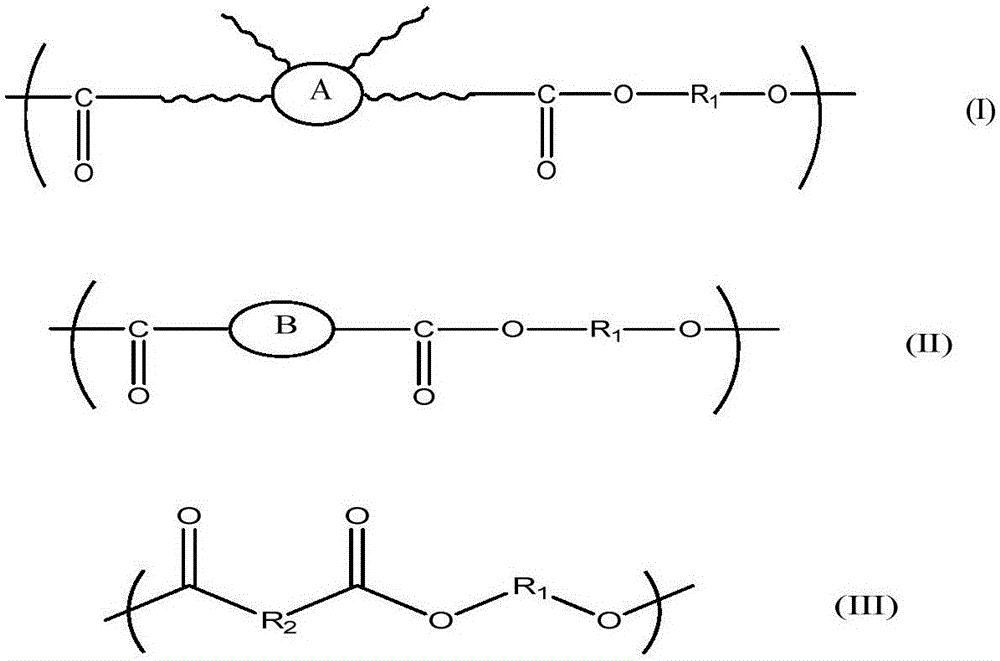

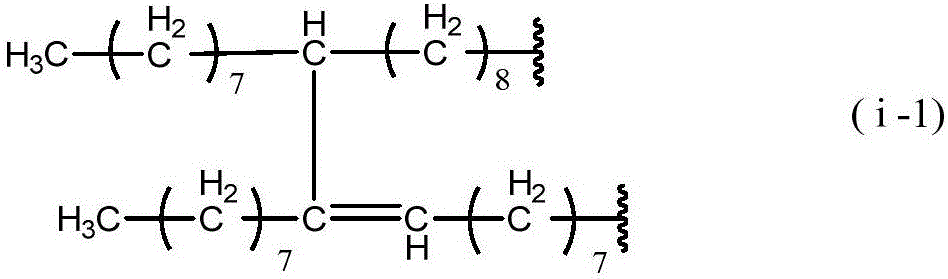

Bio-based biodegradable tri-block and multi-block copolymer with dimer acid polyester chain segment, preparation method of copolymer and application of copolymer

The invention discloses bio-based biodegradable tri-block and multi-block copolymer with a dimer acid polyester chain segment, a preparation method of the copolymer and an application of the copolymer. The tri-block copolymer is of an A-B-A type, a chain segment B is polyester containing dimer acid, a chain segment A is a homopolymer or copolymer, one or more cyclic monomers E are polymerized in a ring opening manner to obtain the homopolymer or copolymer, and the tri-block copolymer, an optional polymer D and a chain extender react to form A-B-A-type multi-block copolymer and / or A-B-A-D-type multi-block copolymer. The tri-block and multi-block copolymer has high biological carbon content, good biodegradability and family composting performance and excellent mechanical performance and machining performance, belongs to environmental-friendly materials and can be widely used for fields such as packaging, agriculture, biological medicines and medical treatment.

Owner:王肖桦

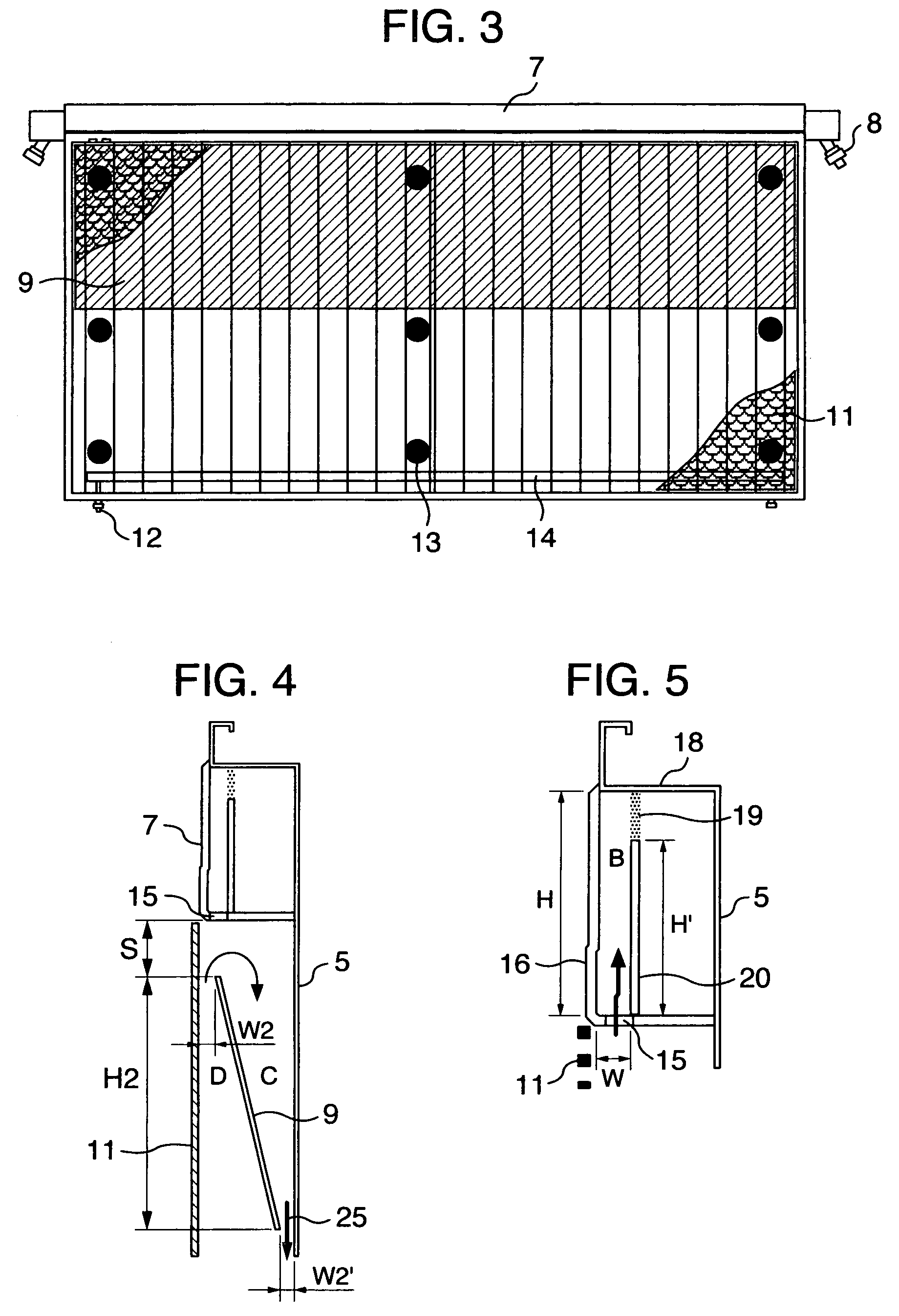

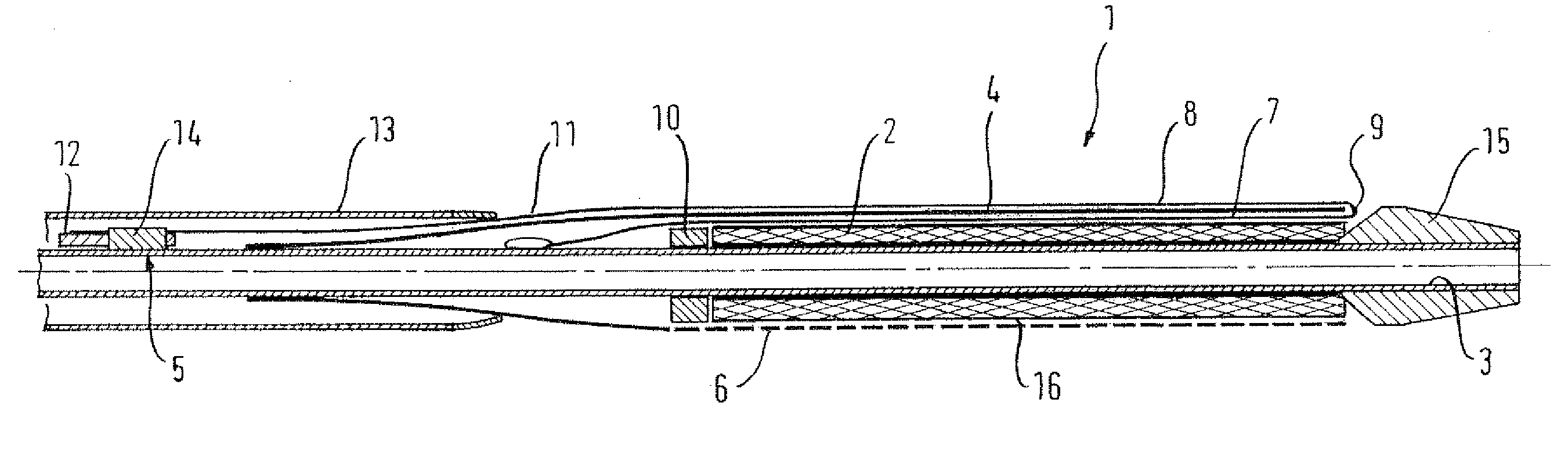

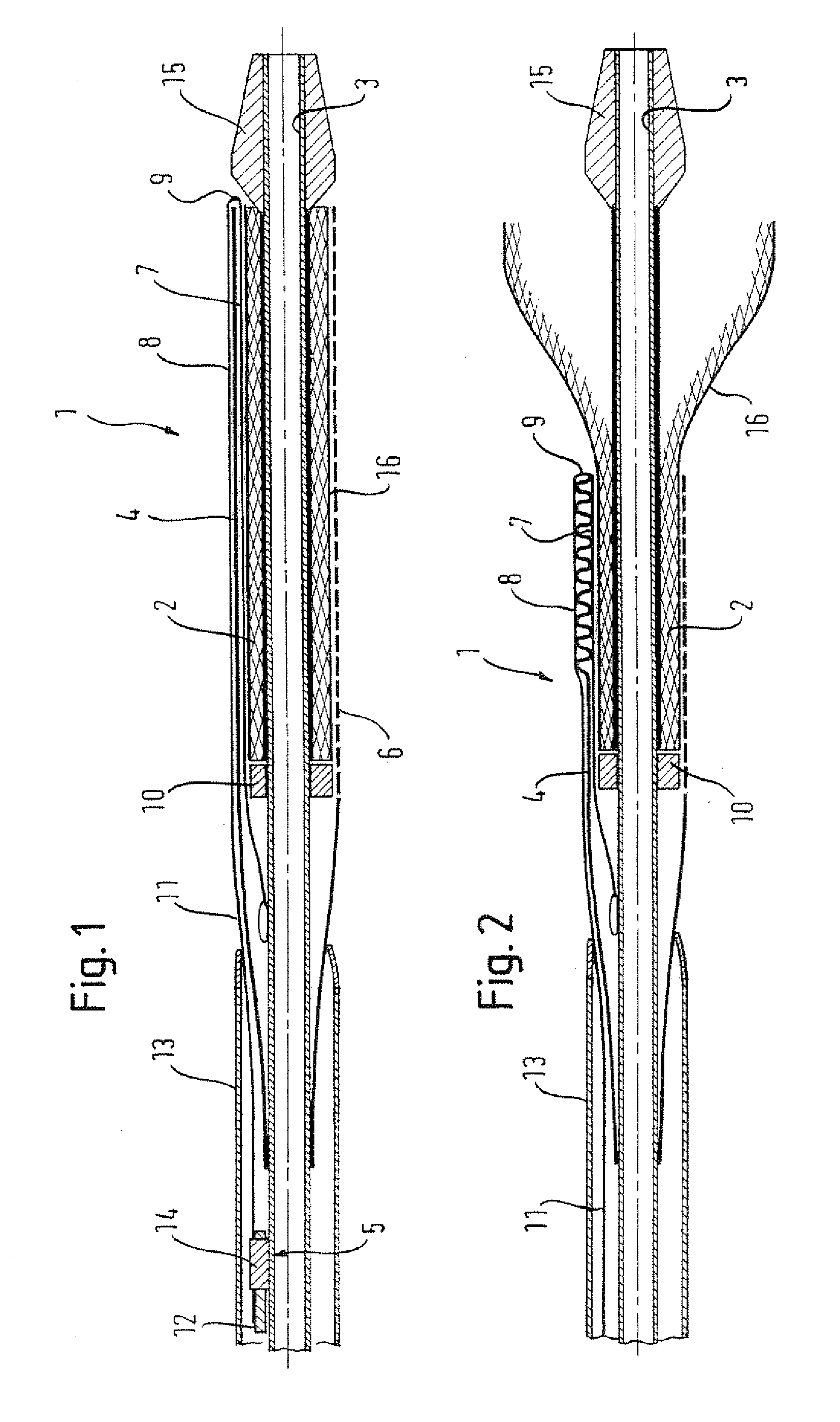

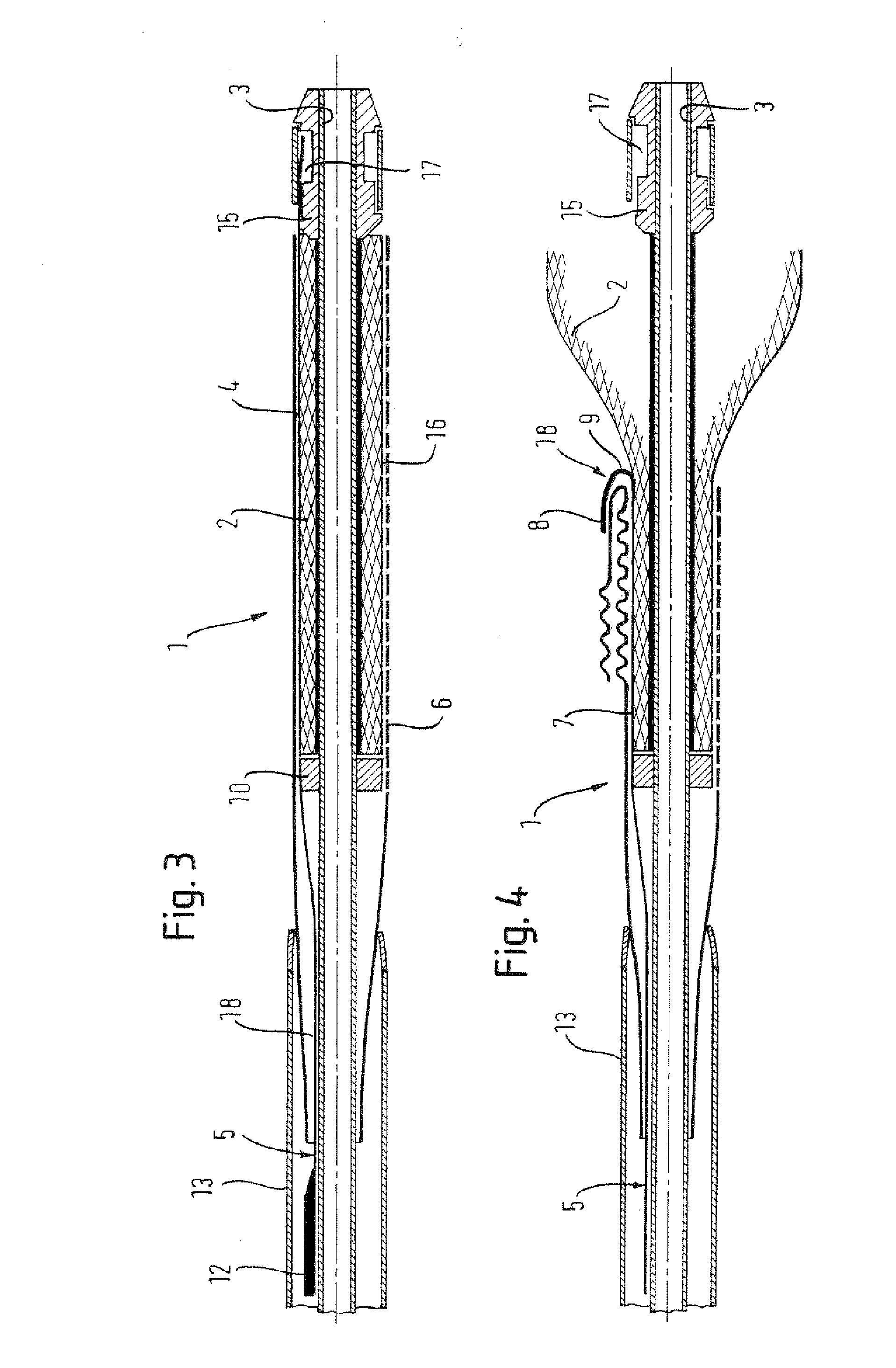

Stent Delivery Device

ActiveUS20110301689A1Reduced profile constructionAppropriate flexibilityStentsBlood vesselsWeaknessBiomedical engineering

A delivery device is provided for delivering a stent device. The stent device (2) is radially expandable from a radially reduced, delivery configuration to a radially expanded, deployment configuration. A restraining sheath (4) is mounted coaxially over the stent device for maintaining the stent device in the delivery configuration. The restraining sheath has a line of weakness (6) extending axially therealong. A pull member is provided, which is to be pulled so as to split the restraining sheath at the line of weakness and withdraw the restraining sheath from over the stent device. The pull member and the line of weakness are located on opposing sides of the restraining sheath. The pull member (5) is wrapped around a distal end of the restraining sheath. The wrap around portion may be formed by a hook of a metal pull member. The wrap around portion may be formed by an open loop of polymer thread. Both ends of the open loop may extend proximally from the restraining sheath and the stent device with one of the ends being fixed to the delivery device and the other being moveable to provide a pull end.

Owner:CR BARD INC

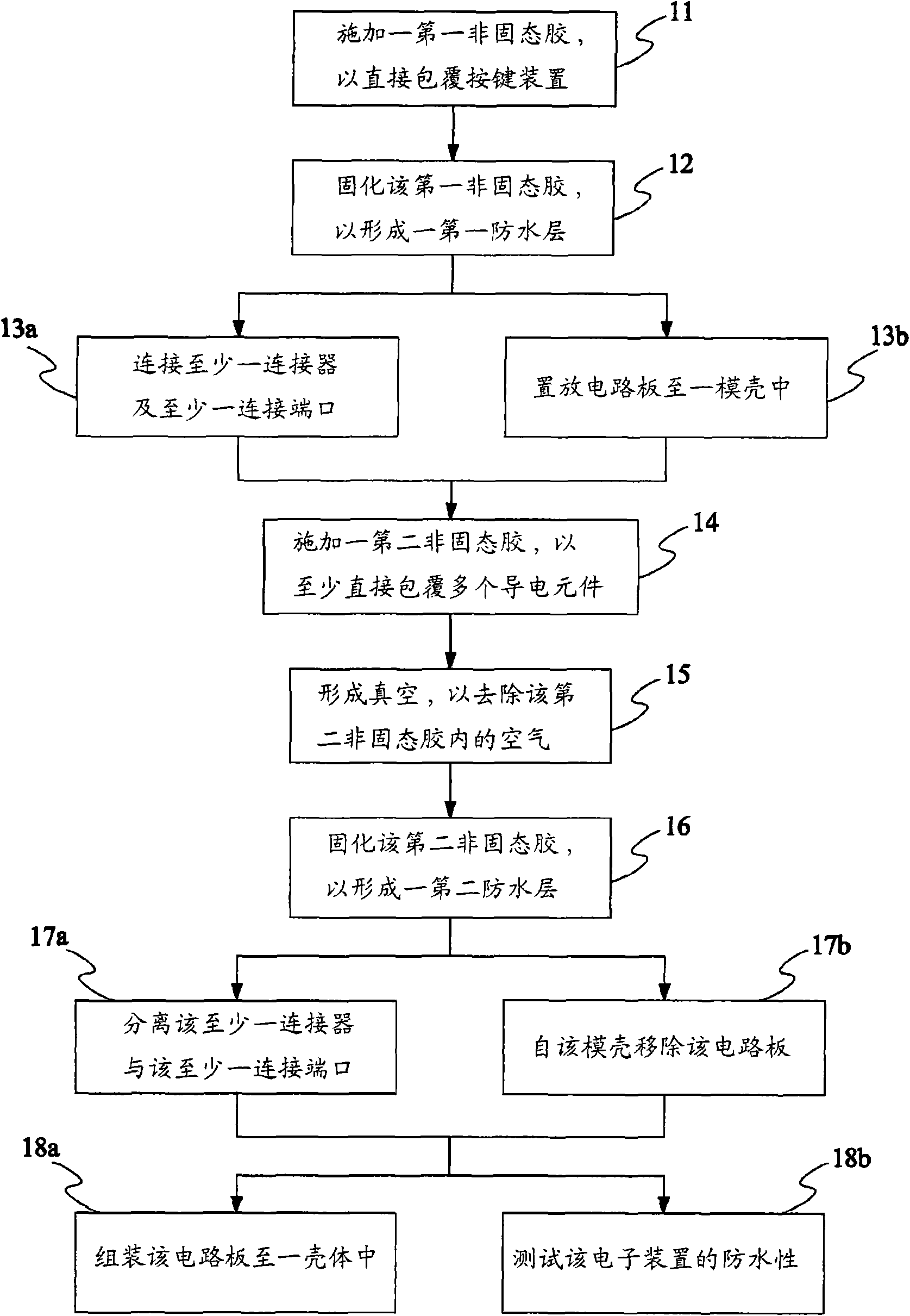

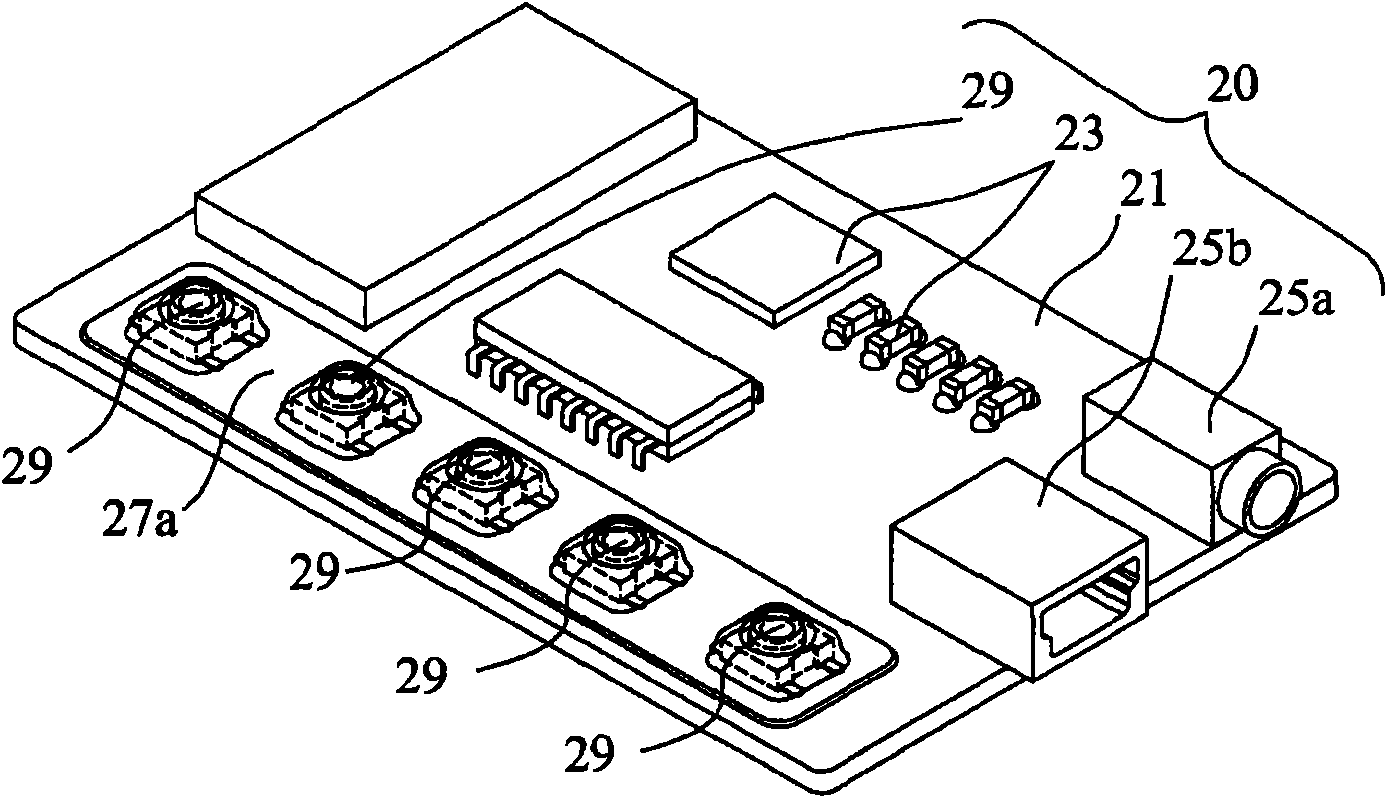

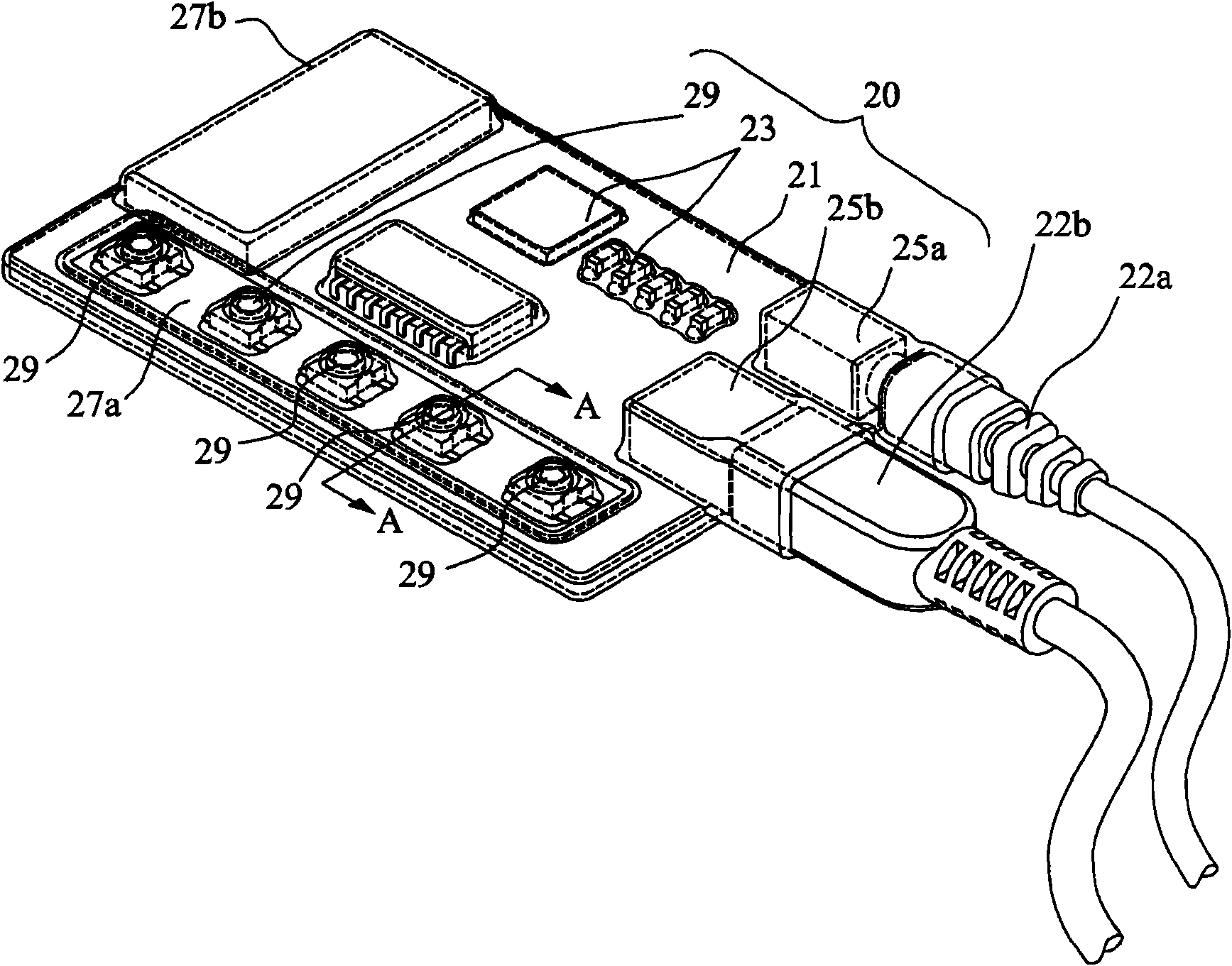

Waterproof method for electronic device and waterproof electronic device

InactiveCN101583247AEffective waterproofReduce volumeHermetically-sealed casingsNon-metallic protective coating applicationEngineering

The invention discloses a waterproof method for an electronic device and a waterproof electronic device. The electronic device comprises a circuit board; the circuit board comprises a board body, a plurality of conducting elements and a key device. The waterproof method comprises the following steps of: applying first non-solid glue to directly coat the key device, solidifying the first non-solid glue to form a first waterproof layer, applying second non-solid glue to at least directly coat the conducting elements, and solidifying the second non-solid glue to form a second waterproof layer. Finally, the circuit board, on which a plurality of waterproof layers are coated, is assembled in a casing body so as to form the waterproof electronic device.

Owner:QBAS CO LTD

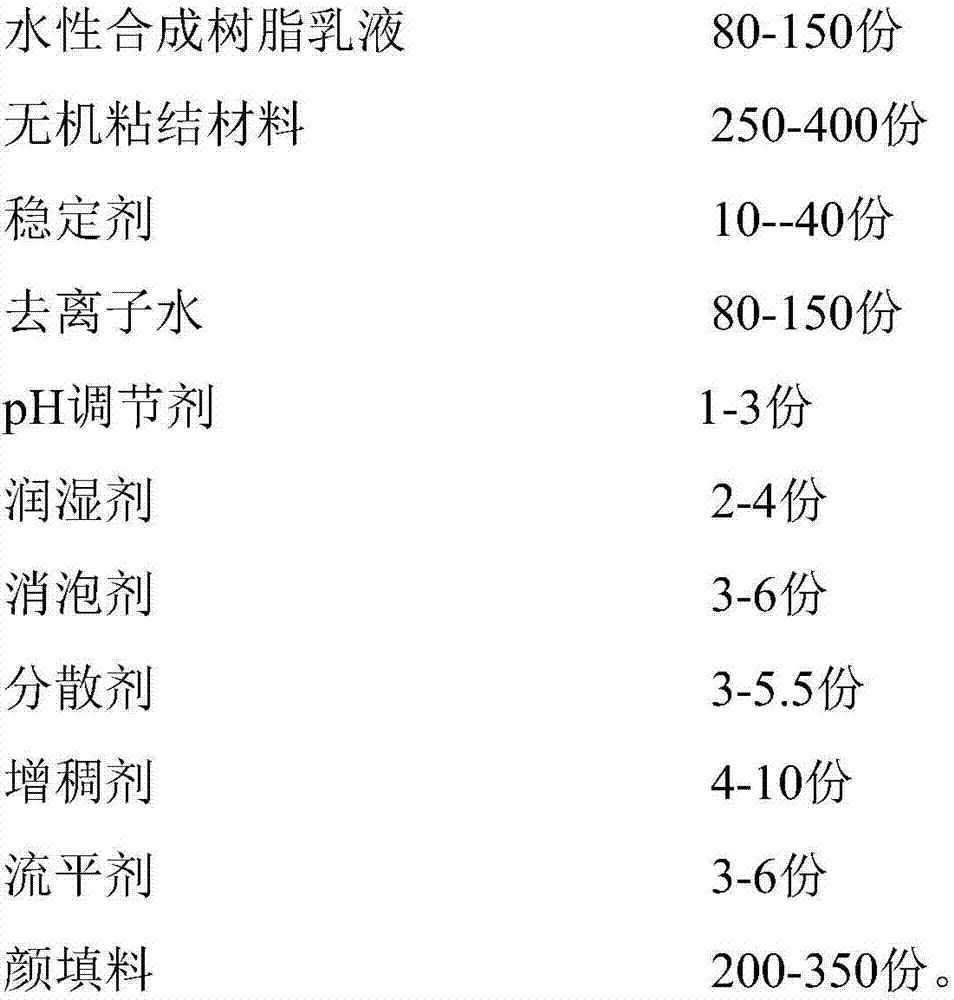

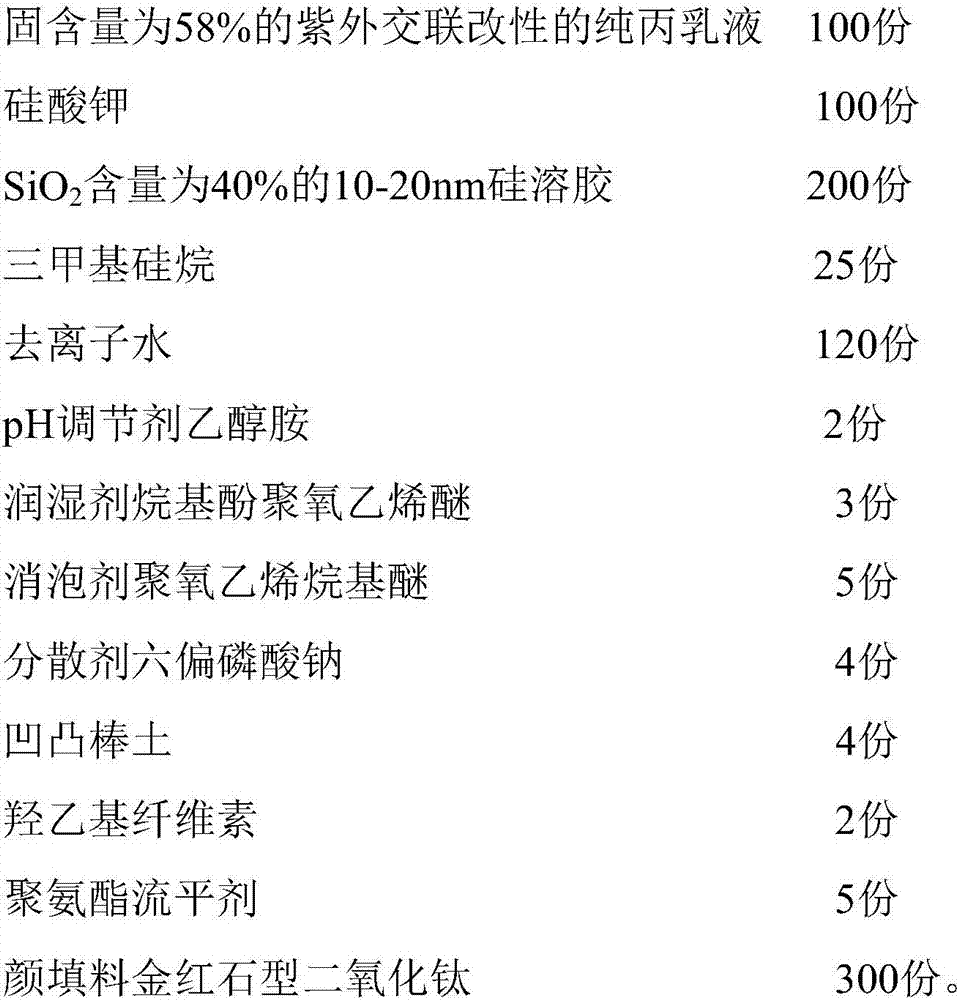

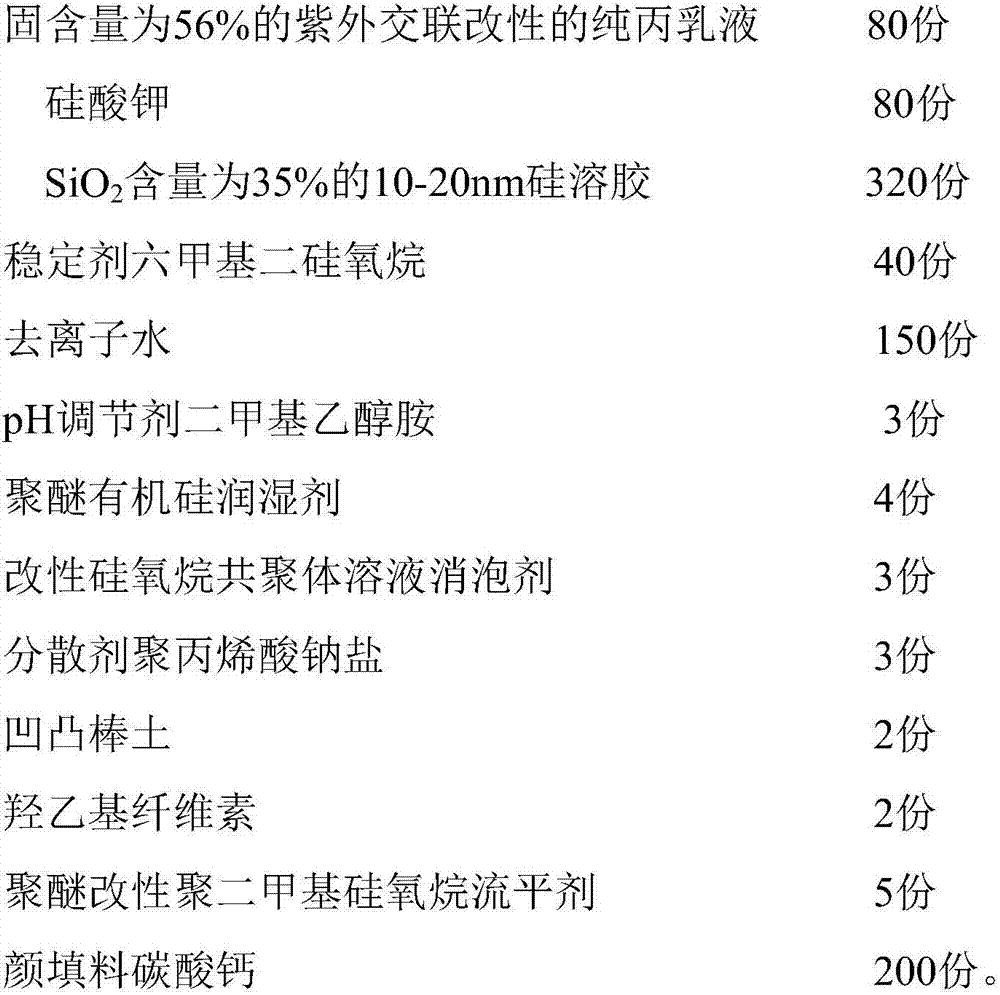

Organic and inorganic compound waterborne paint for exterior walls and preparation method thereof

ActiveCN107083135AGood film forming effectAppropriate flexibilityAlkali metal silicate coatingsEmulsionOrganic inorganic

The invention provides organic and inorganic compound waterborne paint for exterior walls and a preparation method thereof. The paint comprises waterborne synthetic resin, an inorganic cementitious material, a stabilizing agent, an auxiliary agent, a pigment and filler, and water, wherein the waterborne synthetic resin is pure acrylic emulsion modified by ultraviolet crosslinking, the inorganic cementitious material is a mixer of silicate and silica sol, and the stabilizing agent is siloxane. The organic and inorganic compound waterborne paint for exterior walls has good film forming effects, appropriate flexibility, extremely good adhesive force for surface of an object, good stability, as well as extremely good weatherability, wear resistance, and moisture and heat resistance; and the paint can satisfy demands of multiple respects.

Owner:HEBEI CHENYANG INDAL & TRADE GROUP CO LTD

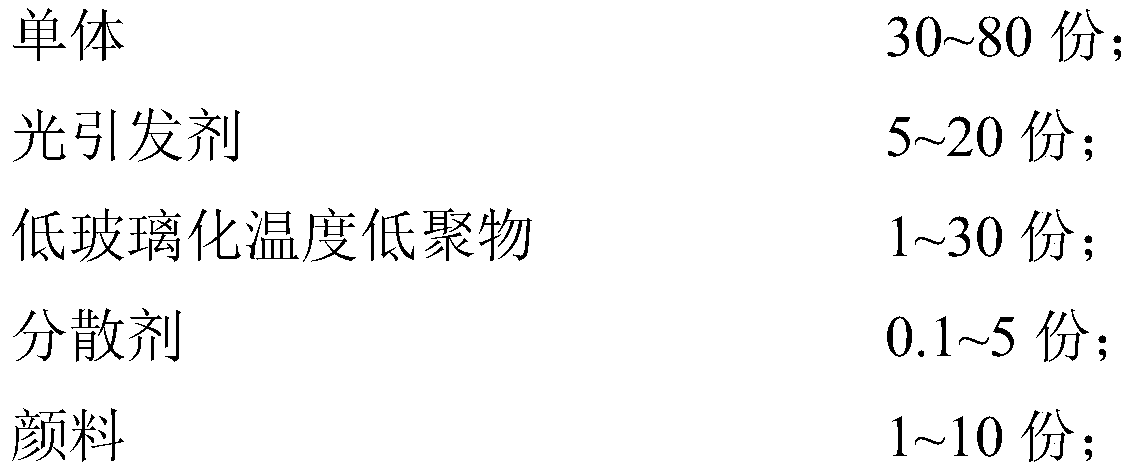

UV inkjet ink and preparation method thereof

The invention provides an UV inkjet ink and a preparation method thereof, and relates to the technical field of inkjet inks. The UV inkjet ink comprises the following components in parts by mass: 30-80 parts of a monomer, 5-20 parts of a photo initiator, 1-30 parts of an oligomer, 0.1-5 parts of a dispersant, and 1-10 parts of a pigment. The embodiment results show that the coating formed by the UV inkjet ink has relatively good flexibility at room temperature and low temperature and relatively good ductility.

Owner:TRENDVISION TECH(ZHUHAI) CO LTD

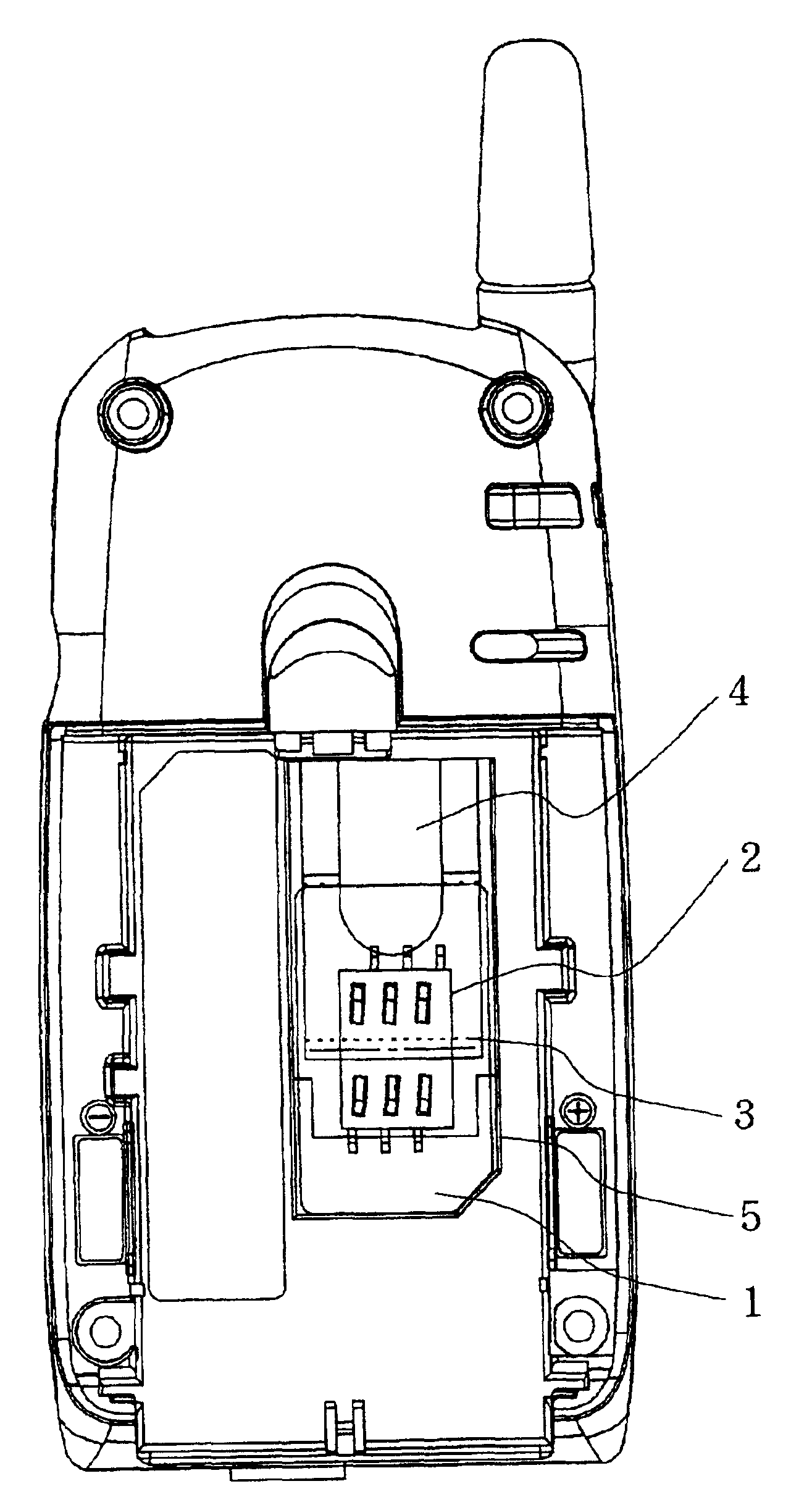

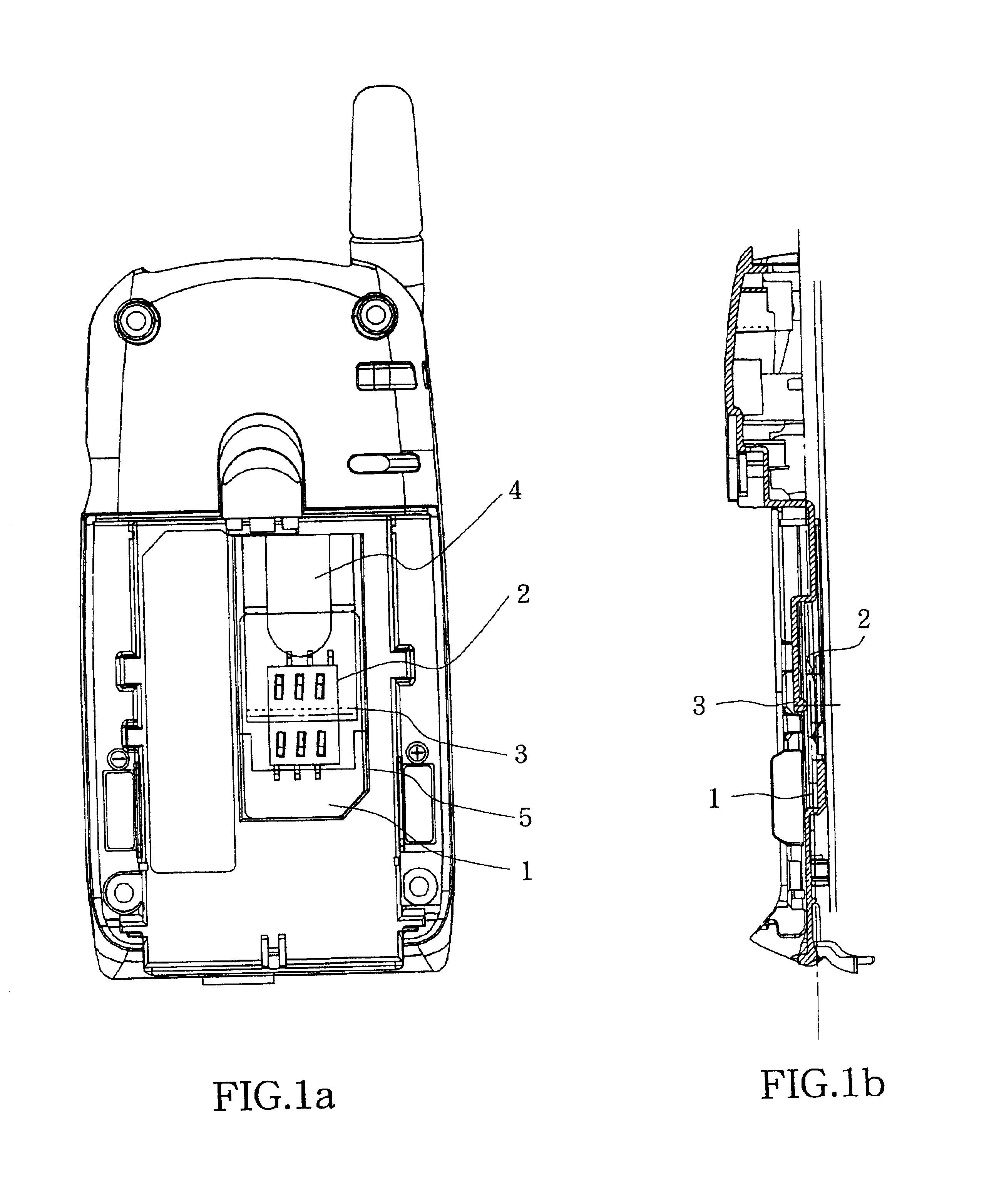

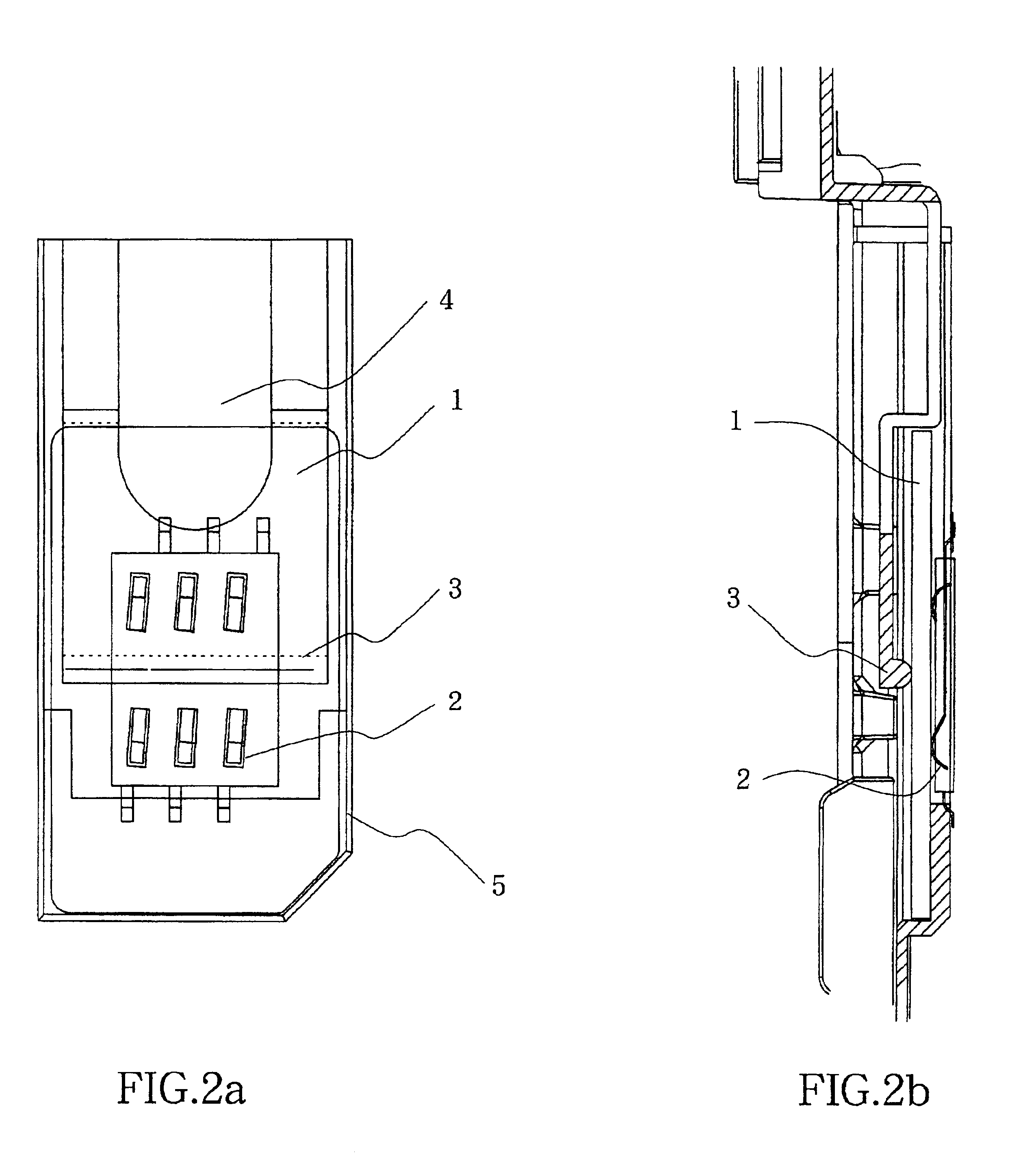

Sim card mounting structure of mobile phone

InactiveUS6892078B2Easy to operateEasy stateInterconnection arrangementsIncorrect coupling preventionEngineeringMobile phone

A SIM card mounting structure of a mobile phone includes a SIM card receiving recess 5 provided in a rear surface portion of a front side casing of the mobile phone for fittingly receiving a SIM card 1 therein, a pressing portion 3 formed of an elastic material and having one end integrally formed with the rear surface portion of the front side casing and the other end positioned over the SIM card receiving recess to elastically press the SIM card 1 and electrode terminals 2 for connecting electrodes of the SIM card 1 to a battery. The electrode terminals 2 are formed of an elastic material and arranged on a bottom of the recess 5 in an opposing relation to electrodes of the SIM card 1. The one end of the pressing portion is formed integrally on an end portion of the SIM card receiving recess 5 in a longitudinal direction of the mobile phone such that the pressing portion functions as a longitudinal leaf spring. The pressing portion 3 has a notch 4 for setting elasticity of the pressing portion appropriately and facilitating a handling operation of a SIM card.

Owner:NEC CORP

Method Of Manufacturing Plastic Lens, Gasket For Molding Plastic Lens, Casting Mold For Molding Plastic Lens, Casting Jig For Plastic Lens Starting Material Liquid, Holding Member For Plastic Lens Casting Mold, And Plastic Lens Manufacturing Apparatus

InactiveUS20080018005A1Reduce bubblingReduced optical defectOptical articlesCasting moldPolymerization

A method of manufacturing a plastic lens by mixing plural polymerizable components, and immediately after mixing, casting a mixture into a casting mold and conducting polymerization to obtain a molded article. A method of manufacturing a plastic lens by casting a plastic lens starting material liquid flowing out of a casting jig opening into a casting mold and curing the above starting material liquid to form a molded article. A gasket for molding plastic lens comprised of a cylindrical member comprising openings for fitting by insertion two molds. A casting mold for molding plastic lens, wherein the above molds are detachably held in the above openings of the above gasket so that molding surfaces of the two molds are positioned opposite at a prescribed interval to form a cavity corresponding to a lens shape within the above cylindrical member. A casting jig for plastic lens starting material liquid equipped with a nozzle for casting a plastic lens starting material liquid into the casting mold. A method of manufacturing a plastic lens comprising casting of a plastic lens starting material liquid into a casting mold held by a holding member and curing the above starting material liquid to form a molded article. A holding member for plastic lens casting mold for holding a casting mold for molding a plastic lens.

Owner:HOYA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com