Organic and inorganic compound waterborne paint for exterior walls and preparation method thereof

A water-based paint, inorganic technology, applied in the direction of alkali metal silicate paint, coating, etc., can solve the problems of poor stability, poor decoration, aging, etc., and achieve excellent wear resistance and moisture resistance, good stability, The effect of appropriate flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

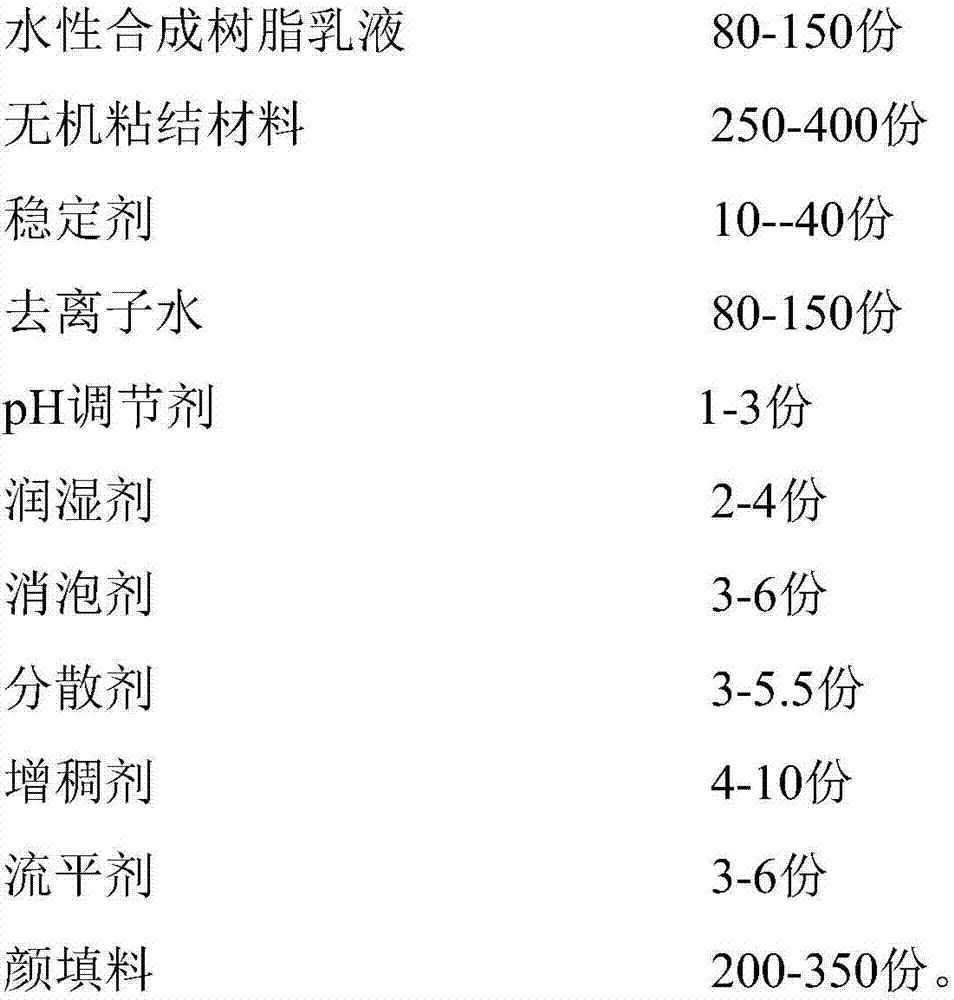

[0049] Materials and contents used in the present embodiment are as follows:

[0050]

[0051] Preparation of inorganic bonding solution: Add silica sol into cylinder A according to the formula, stir at a speed of 500r / min and heat up to 35°C, then add stabilizer, stir at a speed of 500r / min for 20min, then add potassium silicate, Stir at a speed of 700r / min for 20min, and obtain an inorganic bonding solution in cylinder A for later use.

[0052] Preparation of paint slurry: Add pH adjuster, dispersant, wetting agent, defoamer, thickener and deionized water into cylinder B according to the formula amount, and stir at 1000r / min for 10min; then add pigments and fillers into cylinder B , disperse at 1400r / min for 30min, test the fineness of the millbase ≤ 50μm, and obtain the millbase,

[0053] Mixing steps: add the inorganic bonding solution in cylinder A to cylinder B, stir at a speed of 1100r / min for 10min, then add aqueous synthetic resin emulsion and leveling agent and s...

Embodiment 2

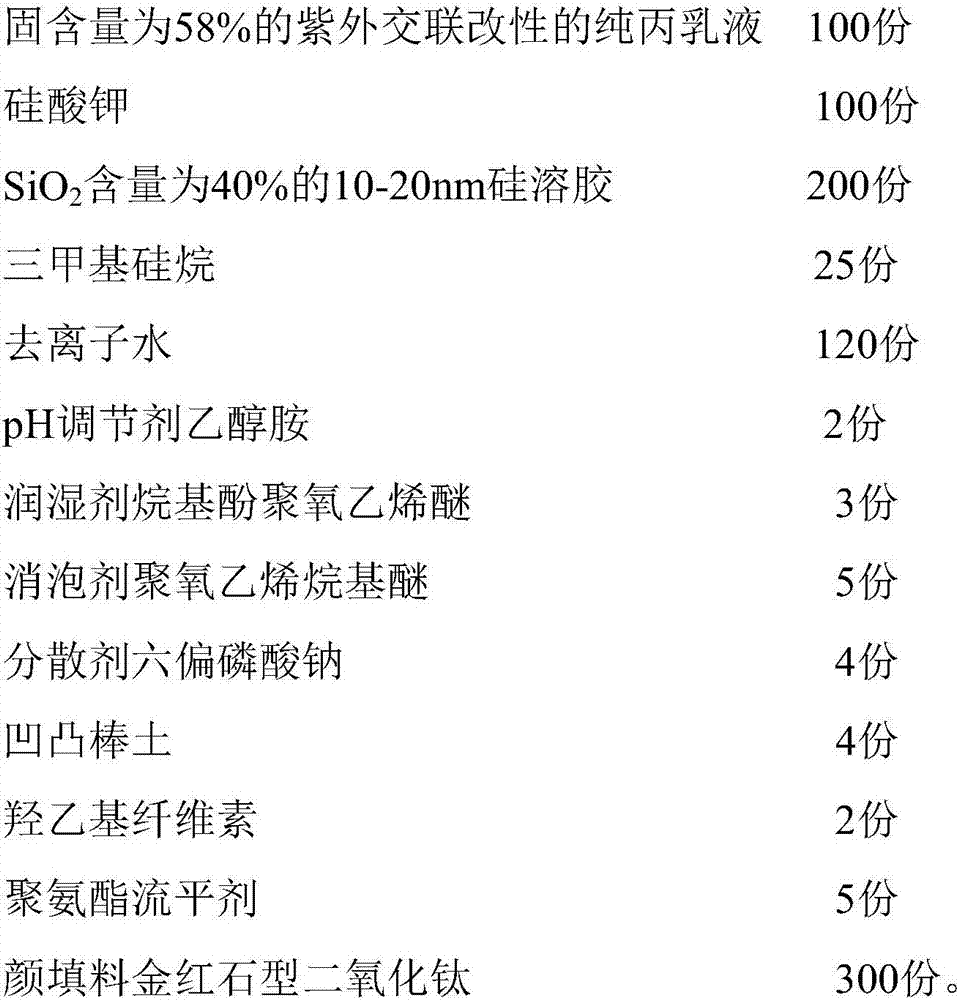

[0055] Materials and contents used in the present embodiment are as follows:

[0056]

[0057] Preparation of inorganic bonding solution: Add silica sol into cylinder A according to the formula, stir at a speed of 400r / min and heat up to 40°C, then add stabilizer, stir at a speed of 600r / min for 30min, then add potassium silicate, Stir at a speed of 600r / min for 10min, and obtain an inorganic bonding solution in cylinder A for later use.

[0058] Preparation of paint slurry: according to the formula, add pH regulator, dispersant, wetting agent, defoamer, thickener and deionized water into cylinder B, stir at 900r / min for 5min; then add pigments and fillers into cylinder B , disperse at 1300r / min for 40min, test the fineness of the millbase ≤ 50μm, and obtain the millbase,

[0059] Mixing steps: add the inorganic bonding solution in cylinder A to cylinder B, stir at a speed of 1000r / min for 5min, then add aqueous synthetic resin emulsion and leveling agent and stir at a spe...

Embodiment 3

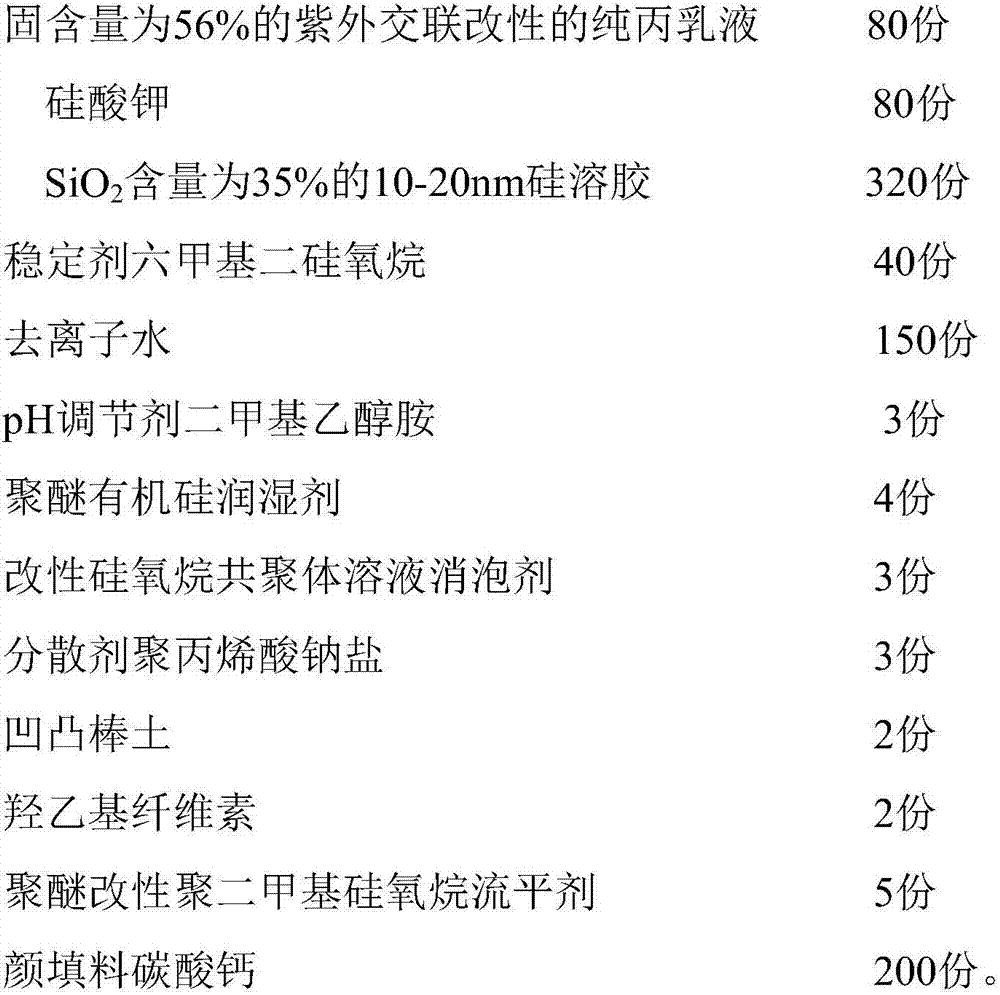

[0061] Materials and contents used in the present embodiment are as follows:

[0062]

[0063] Preparation of inorganic bonding solution: Add silica sol into cylinder A according to the formula, stir at a speed of 600r / min and heat up to 30°C, then add stabilizer, stir at a speed of 400r / min for 10min, then add sodium silicate, Stir at a speed of 800r / min for 30min, and obtain an inorganic bonding solution in cylinder A for later use.

[0064] Prepare the paint slurry: add pH adjuster, dispersant, wetting agent, defoamer, thickener and deionized water into cylinder B according to the formula amount, stir at 1100r / min for 10min; then add pigments and fillers into cylinder B , disperse at 1500r / min for 20min, test the fineness of the millbase ≤ 50μm, and obtain the millbase,

[0065] Mixing steps: add the inorganic bonding solution in cylinder A to cylinder B, stir at a speed of 1000-1200r / min for 10min, then add water-based synthetic resin emulsion, leveling agent and stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com