Protective agent applied to cyanide-free silver coating and preparation method thereof

A cyanide-free silver plating and protective agent technology, applied in coatings, metal material coating processes, anti-corrosion coatings, etc., can solve the problems of poor anti-tarnish performance, limited application, low electrical conductivity, etc., and achieve good corrosion resistance and Conductive properties, good gloss and corrosion resistance, effects of preventing discoloration due to chemical reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

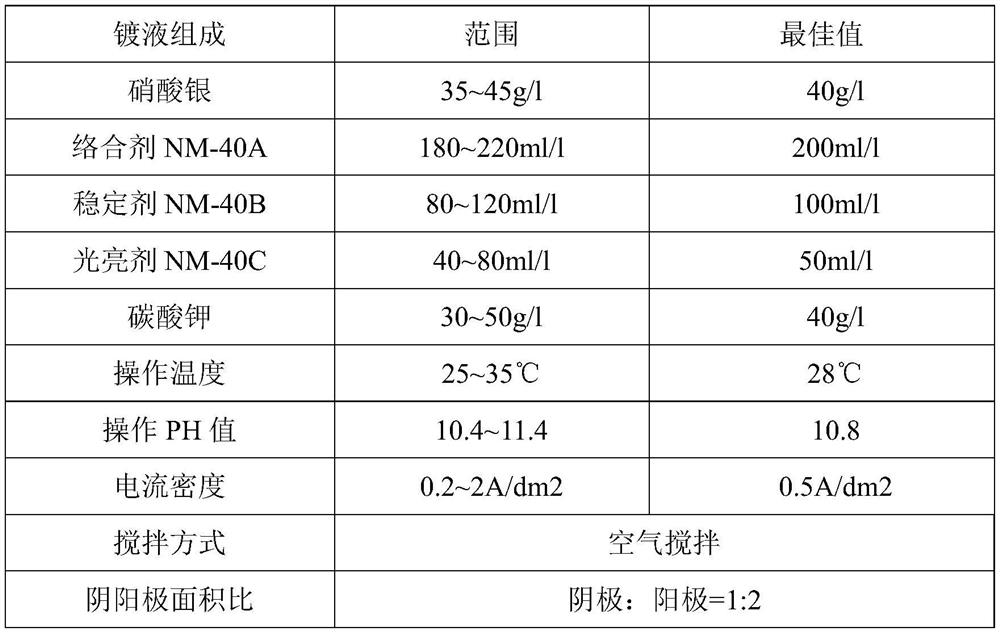

Image

Examples

preparation example Construction

[0026] The preparation method of the protective agent applied to the cyanide-free silver plating layer described in this embodiment comprises the following steps: film forming agent, cosolvent, poly(3,4-ethylenedioxythiophene)-poly(styrene Sulfonic acid), ammonium carbamate and 1-phenyl-5-mercaptotetrazolium are mixed evenly, and propanol solution is added and stirred evenly to obtain.

[0027] The method of using the protective agent applied to the cyanide-free silver plating layer prepared in this embodiment is as follows: immerse the silver-plated workpiece in the protective agent, keep the temperature at 35-40°C, and take it out after immersion for 1-3 minutes , Dry at 50-55°C for 5 minutes.

Embodiment 1

[0028] Embodiment 1, a kind of protective agent applied to cyanide-free silver plating layer

[0029] The protective agent applied to the cyanide-free silver plating layer comprises the following components and parts by weight thereof:

[0030] 30 parts of film-forming agent, 15 parts of co-solvent, 7 parts of poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonic acid), 15 parts of ammonium carbamate, 1-phenyl-5-mercapto tetra 10 parts of azoles, 50 parts of propanol.

[0031] The film-forming agent used in the protective agent for the cyanide-free silver plating layer is composed of dodecyl mercaptan, linoleic acid and polyphenol glycidyl ether epoxy resin in a mass ratio of 21:13:3.

[0032] The co-solvent used in the protective agent for the cyanide-free silver plating layer is composed of benzyl alcohol, propylene glycol phenyl ether and ethylene glycol butyl ether in a mass ratio of 15:7:12.

[0033] The particle size of poly(3,4-ethylenedioxythiophene)-poly(styrenesulf...

Embodiment 2

[0034] Embodiment 2, a kind of protective agent applied to cyanide-free silver plating layer

[0035] The protective agent applied to the cyanide-free silver plating layer comprises the following components and parts by weight thereof:

[0036] 37 parts of film-forming agent, 18 parts of co-solvent, 9 parts of poly(3,4-ethylenedioxythiophene)-poly(styrenesulfonic acid), 18 parts of ammonium carbamate, 1-phenyl-5-mercapto tetra 13 parts of azoles, 46 parts of propanol.

[0037] The film-forming agent used in the protective agent for the cyanide-free silver plating layer is composed of dodecyl mercaptan, linoleic acid and polyphenol glycidyl ether epoxy resin in a mass ratio of 23:14:5.

[0038] The co-solvent used in the protective agent for the cyanide-free silver plating layer is composed of benzyl alcohol, propylene glycol phenyl ether and propylene glycol butyl ether in a mass ratio of 17:8:11.

[0039] The particle diameter of poly(3,4-ethylenedioxythiophene)-poly(styren...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com