UV inkjet ink and preparation method thereof

An inkjet ink and ink technology, which is applied in the field of UV inkjet ink and its preparation, can solve the problems of desorption, tortuous cracks, and extension of exposed undercoating, etc., and achieves improved folding endurance, good ambient temperature flexibility, and improved flexibility. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

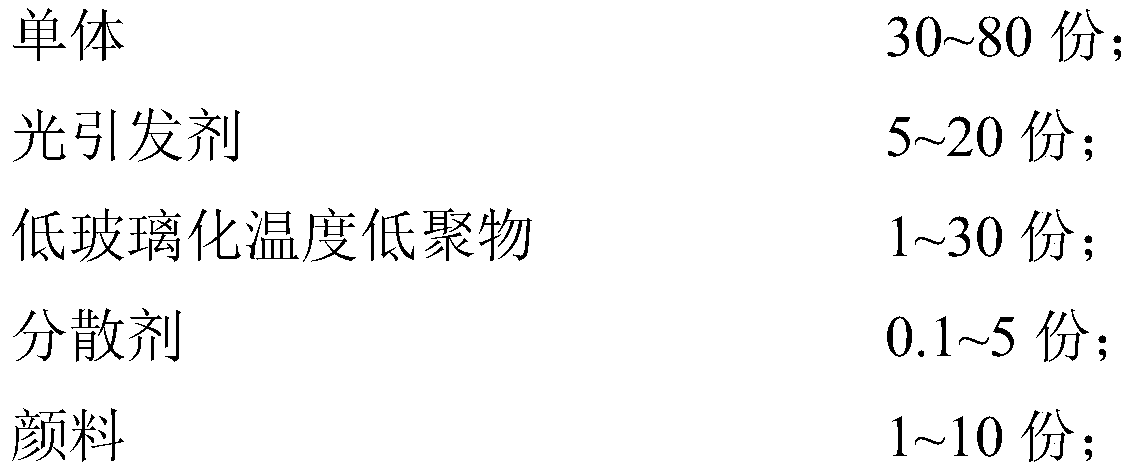

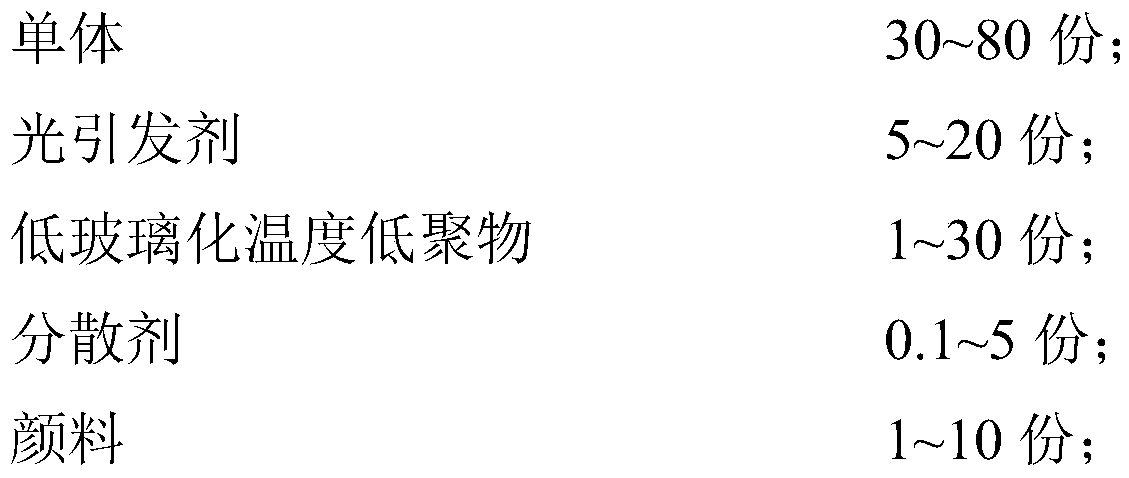

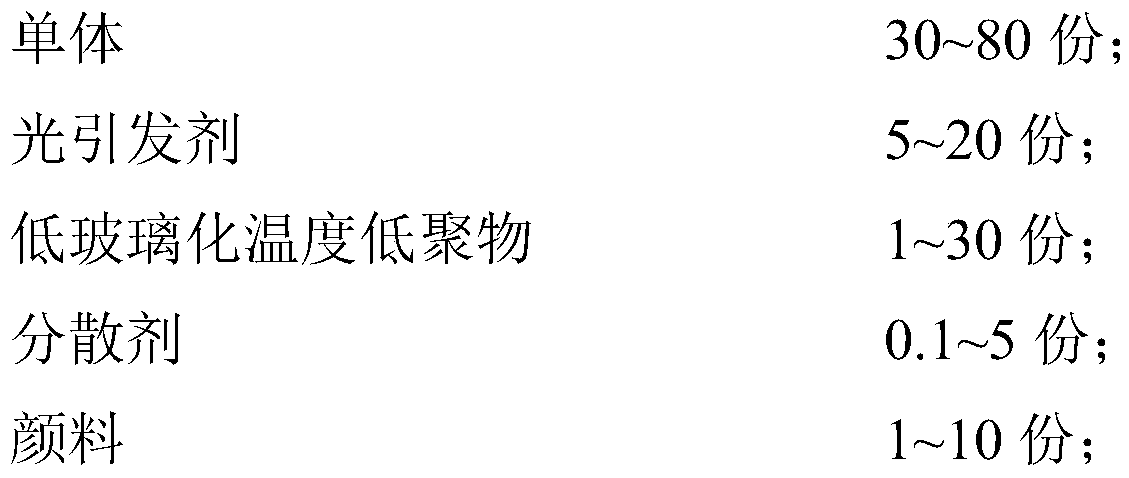

[0045] The present invention also provides a preparation method of the UV inkjet ink described in the above technical solution, comprising the following steps:

[0046] (1) After mixing monomers, photoinitiators, low glass transition temperature oligomers, dispersants and pigments, add grinding beads, and perform shock treatment to obtain a mixed material liquid;

[0047] (2) Filtrating the mixture liquid obtained in the step (1) to obtain UV inkjet ink.

[0048]In the invention, after mixing the monomer, photoinitiator, oligomer with low glass transition temperature, dispersant and pigment, adding grinding beads and performing shock treatment to obtain the mixed material liquid. The present invention has no special requirements on the specific implementation of the mixing, and the mixing methods well known to those skilled in the art can be used. In the present invention, the particle size of the grinding beads is preferably 0.2-0.4 mm, more preferably 0.3 mm. In the presen...

Embodiment 1

[0055] The UV inkjet ink consists of: tetrahydrofurfuryl acrylate 38.2%, isooctyl acrylate 15%, 1,6-hexanediol diacrylate 5%, epoxy acrylate 2253 6.0%, polyurethane Acrylate C2 12%, 2,4,6-trimethylbenzoyldiphenylphosphine oxide 10%, BYK-337 0.5%, GENORAD 16 0.7%, BYK-9151 0.6%, white pigment titanium dioxide 12%.

[0056] The preparation method of UV inkjet ink is: grinding beads with 4 times the weight of raw materials, tetrahydrofurfuryl acrylate, isooctyl acrylate, 1,6-hexanediol diacrylate, 2,4,6-trimethyl Benzoyl diphenyl phosphine oxide, epoxy acrylate 2253, polyurethane acrylate C2, BYK-337, GENORAD 16, BYK-9151 and white pigment titanium dioxide were poured into a shock bottle and sealed, and the shock bottle was placed in Shake in a shaker for 16 hours, and then filter through 0.7 μm glass fiber and 0.5 μm PP membrane to obtain UV inkjet ink.

[0057] Adopt identical method to carry out embodiment 2~12 and comparative example, wherein the raw material of embodiment 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com