Preparation method of drug-loaded nanofiber medical dressing

A nanofiber and drug technology, applied in medical science, bandages, absorbent pads, etc., can solve the problems of iatrogenic pollution, damage to new tissue, wound adhesion, etc., and achieve accelerated healing, good absorption, and conducive to growth and regeneration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] (1) The mixture of CS powder and PEO (its weight ratio is CS / PEO=3 / 7) is dissolved in the acetic acid solution of 95wt%, is made into the solution that the percentage by weight is 3wt%, then the solution is fully stirred, so that completely After dissolving, the solution was placed in ultrasonic for 1 hour so that all the bubbles were separated out to obtain a transparent CS electrospinning solution.

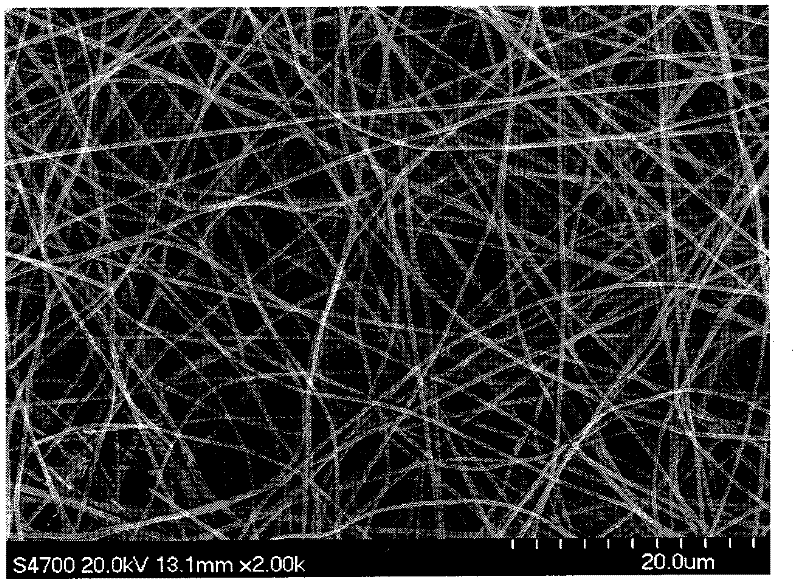

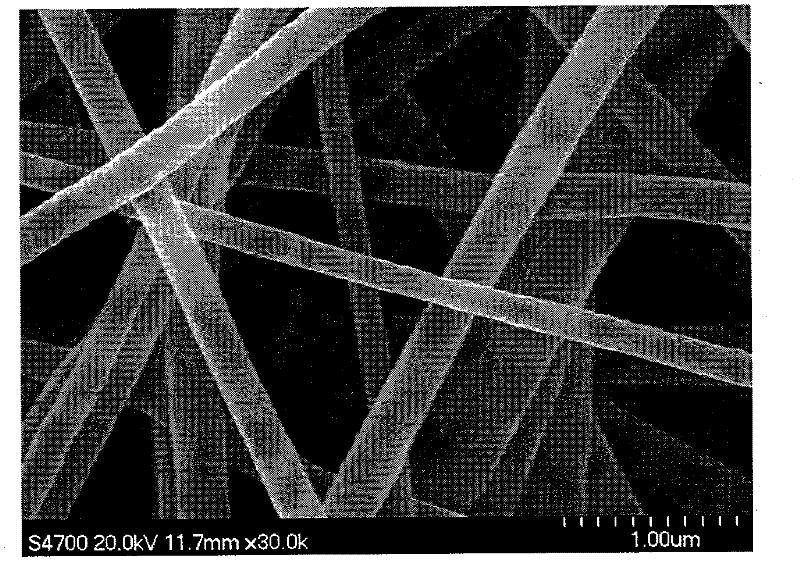

[0033](2) Add the CS electrospinning solution prepared in step (1) into the syringe pump, adjust the voltage to 20kV; the distance from the spinneret to the collecting plate is 12cm; the flow rate of the spinneret spinning solution is 0.5mL / h. The device was activated for electrospinning, and CS nanofibers (such as figure 1 ).

[0034] (3) Cross-link the CS nanofibers obtained in step (2) with glutaraldehyde for 2 hours, soak the cross-linked chitosan nanofibers in the solvent of the pore-forming agent, and selectively remove the pore-forming agent and excess cross-link...

Embodiment 2

[0037] (1) HA powder of Mw=1,000,000 and PVP (its weight ratio is HA / PVP=5 / 5) are dissolved in deionized water, formic acid and N, in the mixed solvent that N-dimethylformamide forms (deionized Water / formic acid / N, N-dimethylformamide=25 / 50 / 25), be made into the solution of 1wt% by weight percent, then the solution is fully stirred, so that dissolve completely, the solution is placed in ultrasonic for 2 hours to make All the bubbles are separated out to obtain a transparent HA solution.

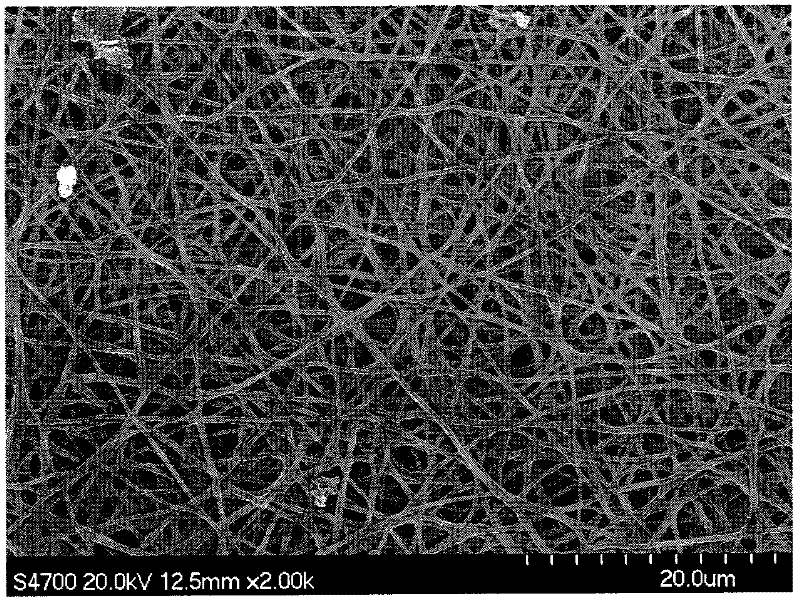

[0038] (2) Add the HA electrospinning solution prepared in step (1) to the syringe pump, adjust the voltage to 15kV; the distance from the spinneret to the collecting plate is 15cm; the flow rate of the spinneret spinning solution is 0.5mL / h; The spinning ambient temperature was 18°C. The device was activated for electrospinning of hyaluronic acid, and HA nanofibers (such as Figure 4 ).

[0039] (3) Cross-linking the hyaluronic acid nanofibers obtained in step (2) with divinyl sulfone for...

Embodiment 3

[0042] (1) The mixture of CS powder and PEG (its weight ratio is CS / PEG=9 / 1) is dissolved in the acetic acid solution of 10wt%, is made into the solution that weight percent is 8wt%, then fully stirs solution, so that completely Dissolved, the solution was placed in ultrasonic for 2 hours to make all the bubbles precipitate out to obtain a transparent CS electrospinning solution.

[0043] (2) Add the CS electrospinning solution prepared in step (1) into the syringe pump, adjust the voltage to 25kV; the distance from the spinneret to the collecting plate is 20cm; the flow rate of the spinneret spinning solution is 1mL / h. The device was activated for electrospinning, and CS nanofibers were obtained on the collecting plate.

[0044] (3) The CS nanofibers obtained in step (2) were crosslinked with genipin for 2 hours, and the crosslinked chitosan nanofibers were soaked in the solvent of the pore-forming agent to selectively remove the pore-forming agent and excess crosslinking ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com