Feeding mechanism for solar silicon wafers

A technology of solar silicon wafers and feeding mechanisms, which is applied in the manufacture of conveyor objects, electrical components, semiconductors/solid-state devices, etc., can solve the problems of long travel, large mechanical loss, long time and low efficiency, and achieve simplified structure and easy control , Improve the effect of mechanical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

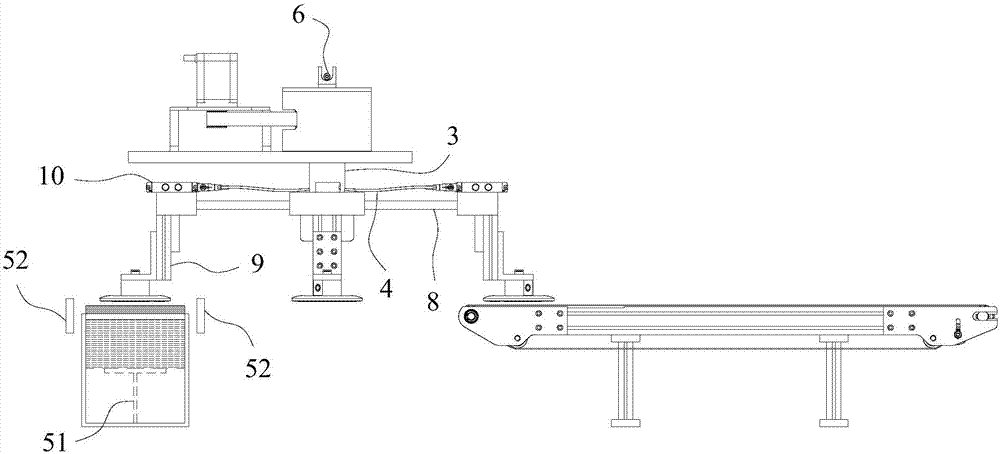

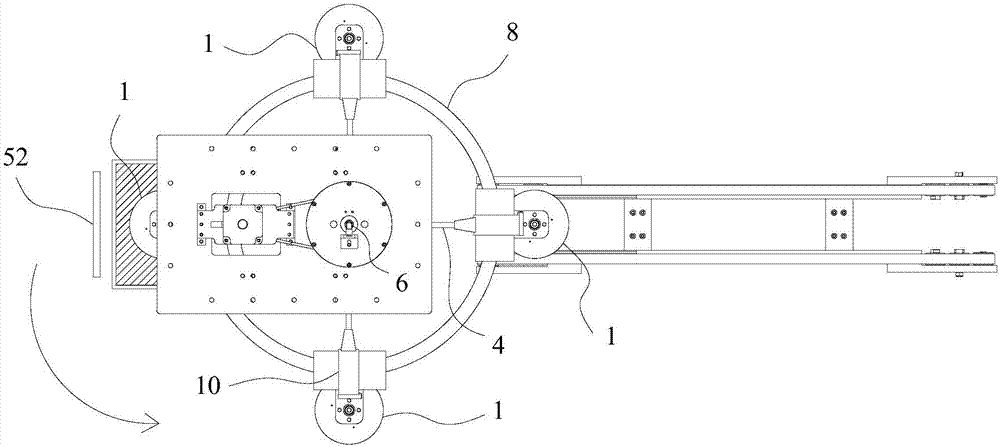

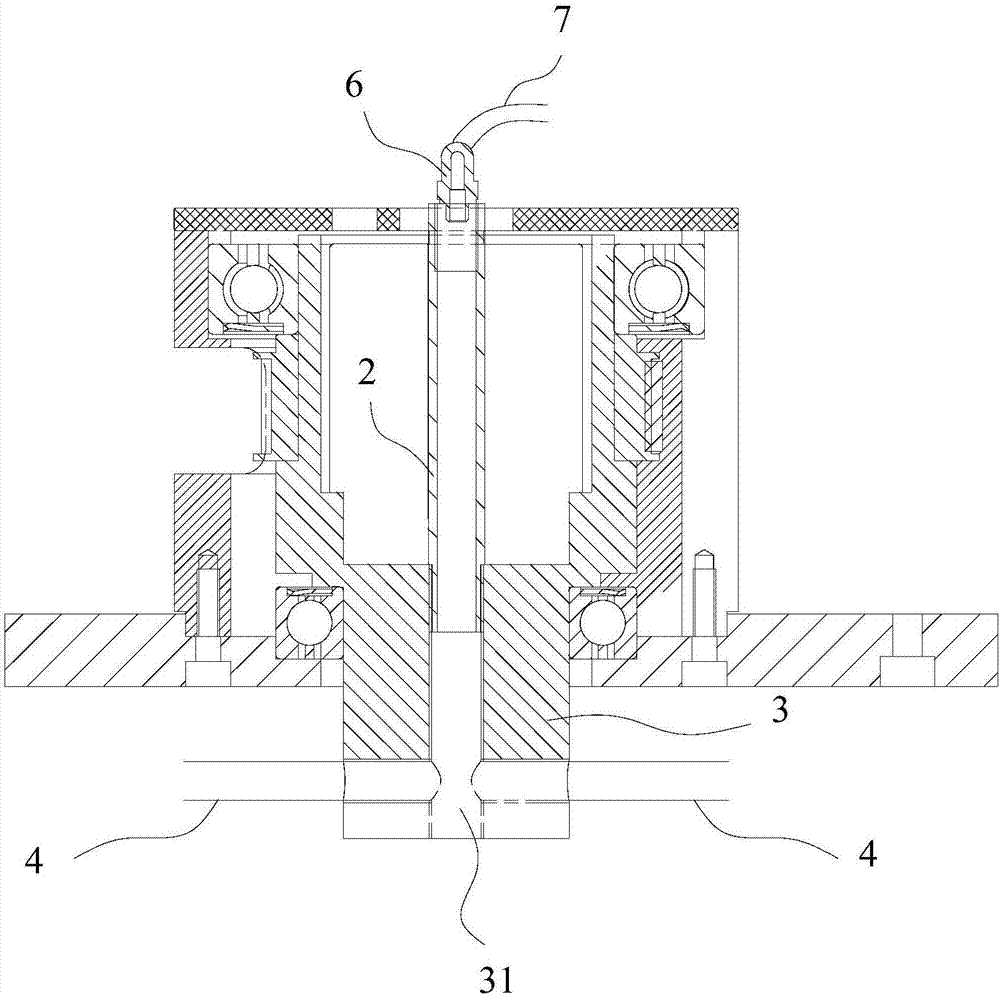

[0047] Such as Figure 1-3 , a feeding mechanism for solar silicon wafers according to the present invention includes a grabbing component, an annular track 8, a gas distribution component, a feeding device, a feeding device, a drive system and a control system, and the control system controls the drive The system drives the grabbing part, air distribution part, feeding device and unloading device, the grabbing part includes four suction cups 1, the air distribution assembly includes an air guide tube 2 and a sleeve 3, and the air guide tube 2 It is a copper tube with a hollow structure, the sleeve 3 is provided with an inner hole 31, the lower end of the air guide tube 2 communicates with the inner hole 31, and the upper end of the air guide tube 2 is provided with an opening 1, the opening One is connected to the air pipe two 7 through the rotary joint 6, the air pipe two 7 is connected to the negative pressure source, four vertical connecting plates 9 are slidably connected...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com