Preparation method of silane crosslinked halogen-free flame-retardant polyolefin cable material

A polyolefin cable material, silane cross-linking technology, applied in the direction of insulated cables, cables, circuits, etc., can solve the lack of environmental stress crack resistance, poor dispersion effect, flame retardant dispersion performance and environmental stress crack resistance. And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

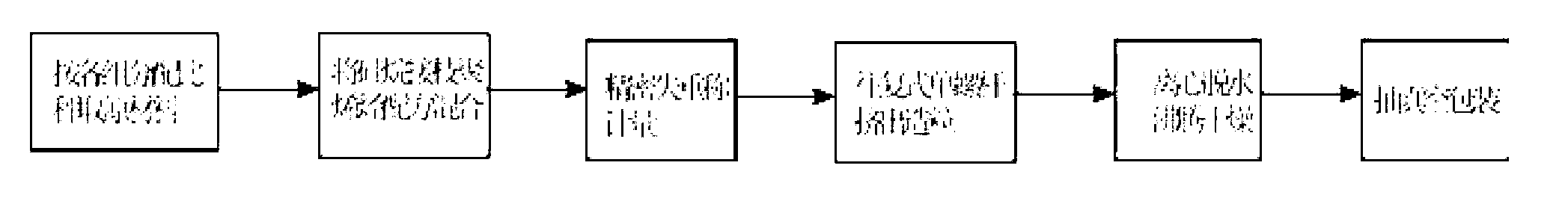

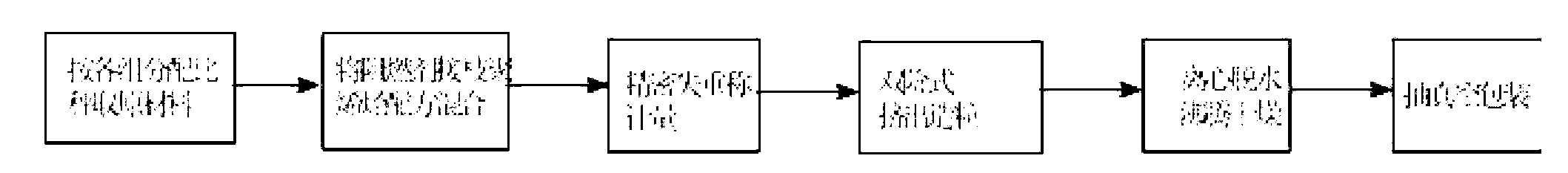

[0058] It relates to a preparation method of a silane-crosslinked halogen-free flame-retardant polyolefin cable material. The preparation method of the halogen-free flame-retardant polyolefin cable material is prepared by two-step silane crosslinking technology. The silane-crosslinked halogen-free flame-retardant The preparation method of polyolefin cable material consists of flame retardant graft A material and catalytic masterbatch B material. Most preferably, the preparation of the flame-retardant graft A material includes the following steps: firstly prepare the silane-grafted polyolefin resin; use the silane-grafted polyolefin resin as raw material, mix it with modified flame retardants, processing aids, etc. The high-precision feeding weight loss system enters the reciprocating single-screw extrusion granulation unit, kneads, shears, and extrudes at 100-150°C, and then granulates with spray granulation. After cooling, centrifugal dehydration, Boiling drying, automatic pa...

Embodiment approach

[0130] A method for preparing a silane-crosslinked halogen-free flame-retardant polyolefin cable material, comprising the steps of:

[0131] (1) Preparation of silane-grafted polyolefin: grafting silane onto polyolefin resin to obtain silane-grafted polyolefin;

[0132] (2) Use silane-grafted polyolefin as raw material, mix it with flame retardants, processing aids, etc. according to the ratio, and enter the reciprocating single-screw extrusion granulation unit through the high-precision K-TRON feeding weight loss system. Mixing, shearing and extrusion at -150°C, and then granulation by spray granulation, cooling, centrifugal dehydration, boiling drying, and automatic packaging by an automatic weighing and packaging system.

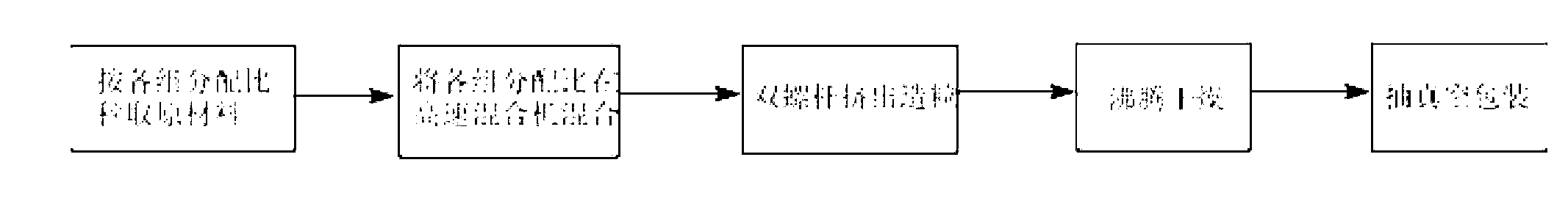

[0133] (3) Using polyolefin as the main raw material, adding catalysts, antioxidants and other processing aids, mixing for 3-5 minutes, transporting to the twin-screw, mixing and granulating at 140-190°C to obtain material B pellets;

[0134] (4) Dispers...

Embodiment 1

[0163] This example provides a method for preparing a silane-crosslinked low-smoke, halogen-free, flame-retardant polyolefin cable material. The raw materials and dosages used are shown in the table, wherein:

[0164] Ethylene-vinyl acetate resin is an ethylene-vinyl acetate copolymer resin with a vinyl acetate content of 24-28% in the molecule.

[0165] The melt index of the low-density polyethylene resin is 2±0.5g / 10min, produced by Sinopec.

[0166] The silane was Degussa's VTMO.

[0167] The initiator is DCP from Aksu.

[0168] The modified flame retardant is prepared through the following process: aluminum hydroxide is added to a high-speed mixer, and a 2% aluminate coupling agent solution whose mass is aluminum hydroxide is uniformly added under high-speed stirring.

[0169] Antioxidant is Irganox1010 type antioxidant produced by Swiss Ciba Company.

[0170] The melt index of ethylene-octene copolymer is 5g / 10min, and the hardness is 75A.

[0171] The catalyst is dib...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com