Online detection and control method and device of periphery of filtering rod

An automatic detection and control method technology, applied in the field of tobacco machinery, can solve the problems of low precision, poor stability, long cycle, etc., and achieve the effect of high precision, stable performance and advanced indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

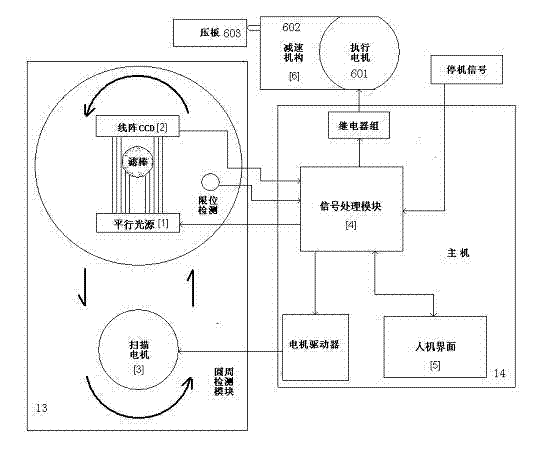

[0029] Such as Figure 1-5 shown.

[0030] An online automatic detection and control method for the circumference of a filter rod, which comprises the following steps:

[0031] First, install a parallel light source capable of emitting parallel light and a linear array CCD detector for receiving parallel light on the opposite sides of the filter rod;

[0032] Secondly, the parallel light source and the linear array CCD detector are installed on a turntable at the same time, so that the parallel light source and the linear array CCD assembly are driven by the scanning motor to rotate around the filter rod at the same time;

[0033] Third, according to the set rotation angle, the CCD detector receives the light emitted by the parallel light source to obtain the projected width value of the filter rod on the CCD detector. The projected width value is the diameter of the filter rod. According to the measured diameter value and the corresponding The length of the arc segment corr...

Embodiment 2

[0045] Such as Figure 1-6 shown.

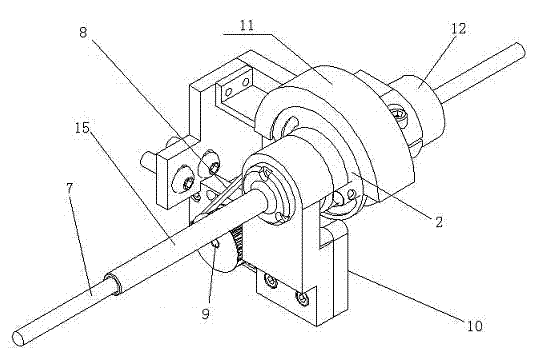

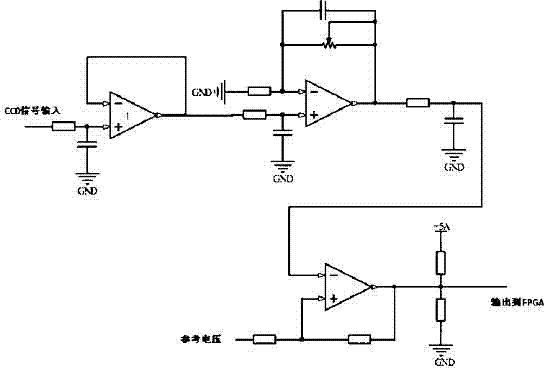

[0046] An online automatic detection and control device for the circumference of a filter rod, which mainly consists of a parallel light source 1, a linear array CCD detector 2, a scanning motor 3, a signal processing module 4, a man-machine interface 5 (computer and display) and an actuator 6 (execution Mechanism 6 is composed of executive motor 601 driving deceleration mechanism 602 to move, and deceleration mechanism 602 drives the pressing plate 603 to adjust the filter rod diameter), as figure 1 , the parallel light source 1 and the linear array CCD detector 2 are respectively located on the opposite sides of the filter rod, and the scanning motor 3 drives the parallel light source 1 and the linear array CCD detector 2 to rotate around the filter rod; the signal input of the signal processing module 4 terminal is connected to the signal output terminal of the linear array CCD detector 2, and the signal output terminal of the signal pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com