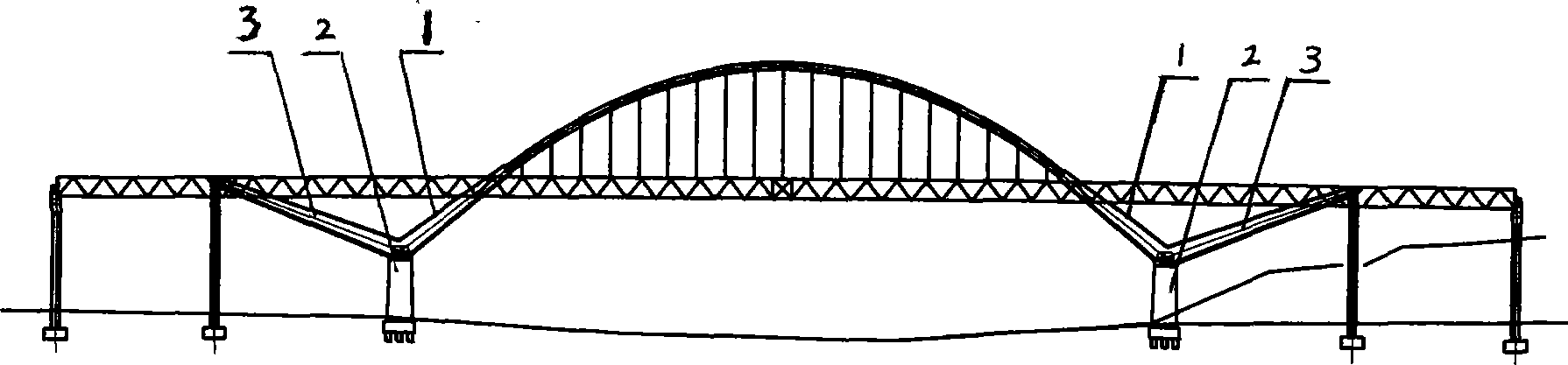

Construction method for Y-shaped frame of large-span steel box basket arch bridge

A construction method and large-span technology, applied in bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as failure to meet construction requirements, complex structural stress, and high construction difficulty, so as to improve quality control capabilities and reduce construction costs , significant economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

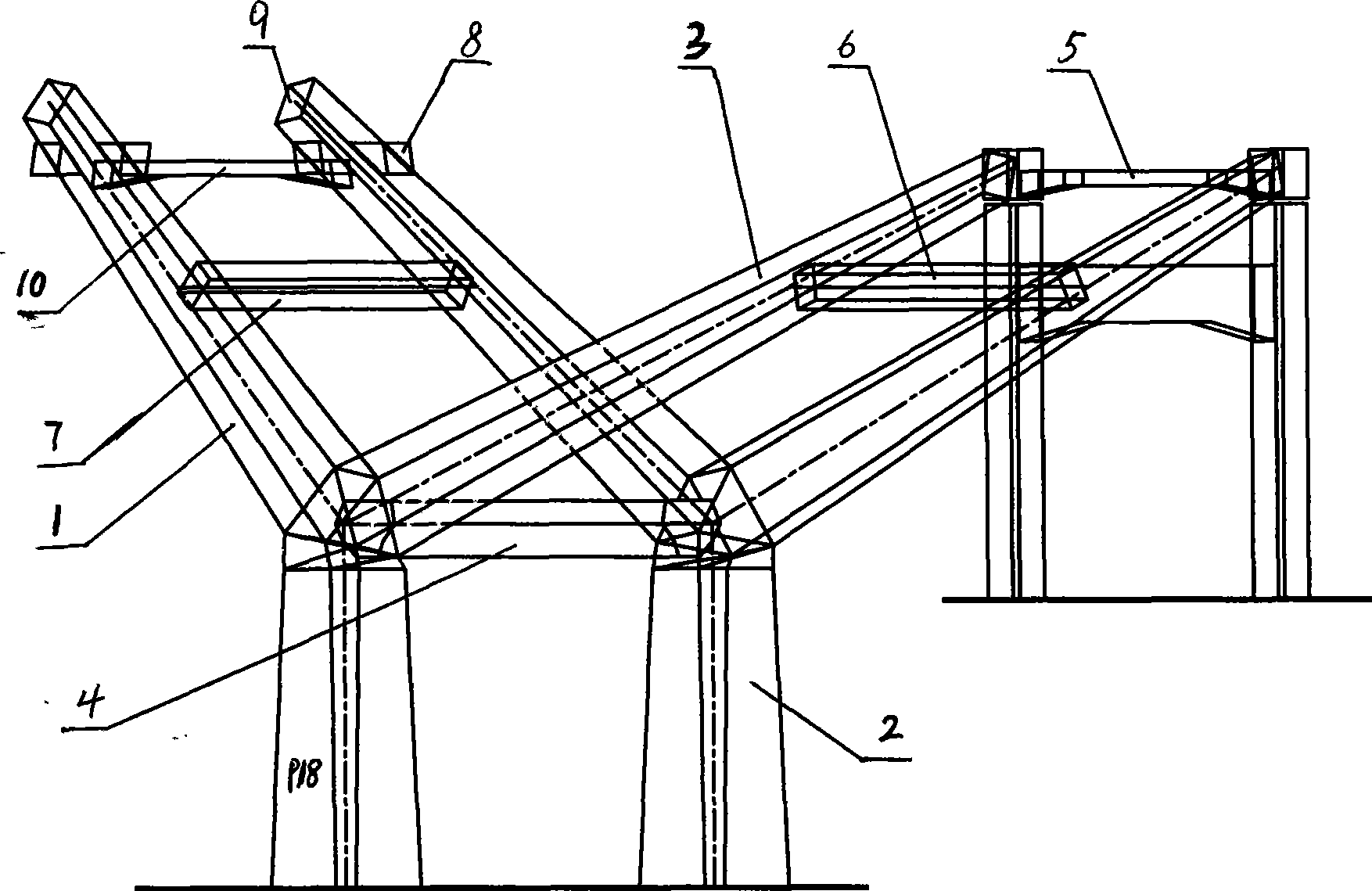

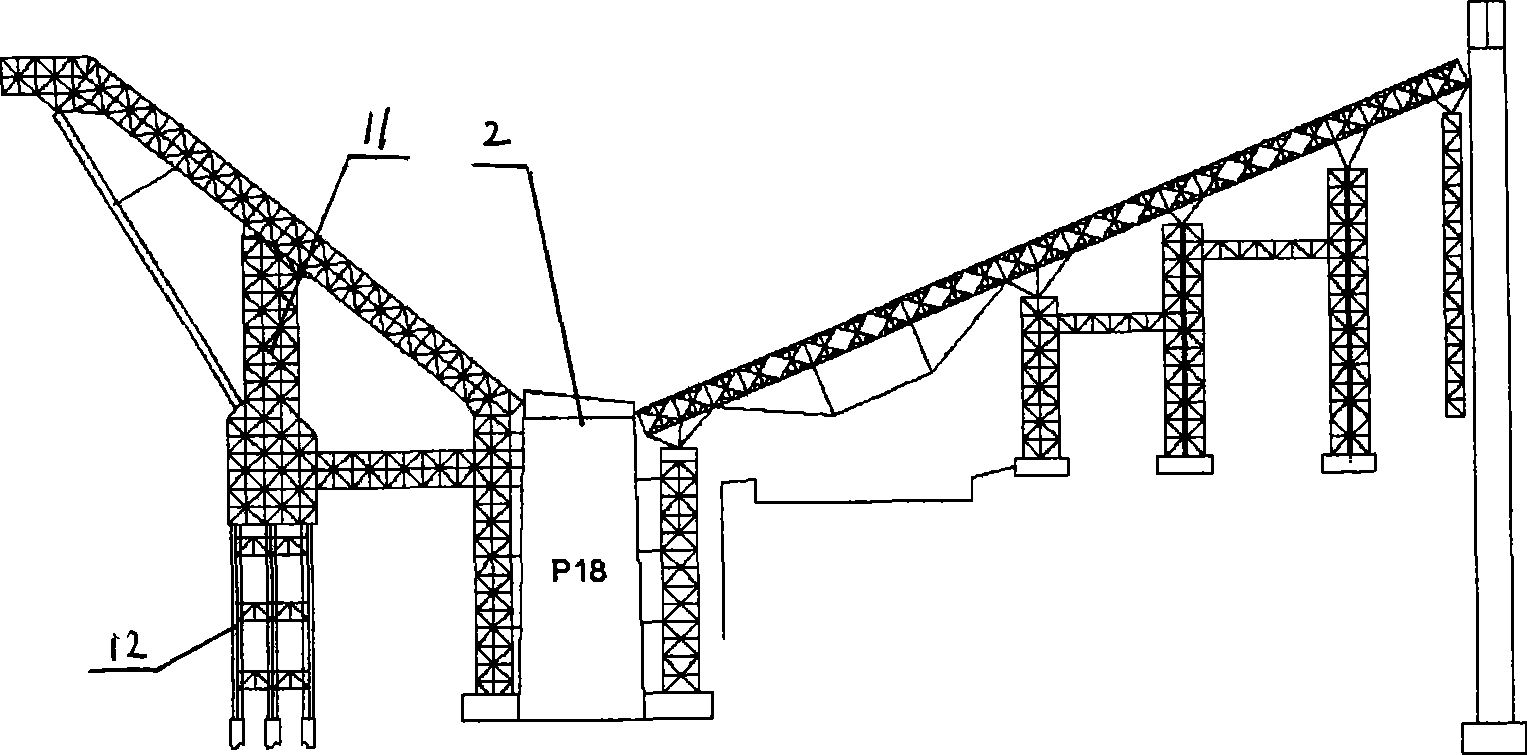

[0018] Below in conjunction with the embodiment of Chongqing Caiyuanba Yangtze River Bridge, the present invention will be further described in detail.

[0019] 1. First determine the structural form of the Y-shaped rigid structure:

[0020] The prestressed reinforced concrete Y-shaped rigid structure consists of a front cantilever beam 1, a rear cantilever beam 3, a middle beam 4, a front sub beam 10, a rear sub beam 5, a front main beam 7, a rear main beam 6, tie rod anchors 8 and rigid The structure-arch combination section is composed of 9 sections. The length of the front cantilever beam 1 is 73.7 meters, which is divided into 10 sections with different lengths, the longest section is 10 meters long, and the shortest section is 1.48 meters; There are 8 segments of different lengths. Among them, the longest section is 20.3 meters long, and the shortest section is 8 meters. The longitudinal inclination angle of the front cantilever beam 1 is 37.71°, and the transverse inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com