Method for cloth defect detection by utilizing S transformation signal extraction

A technology for transforming signals and detection methods, applied in image data processing, instruments, calculations, etc., can solve problems such as difficulty in describing textures, inaccurate identification of defect signals, etc., to achieve accurate identification, reduce labor costs, and improve cloth quality control effect of ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

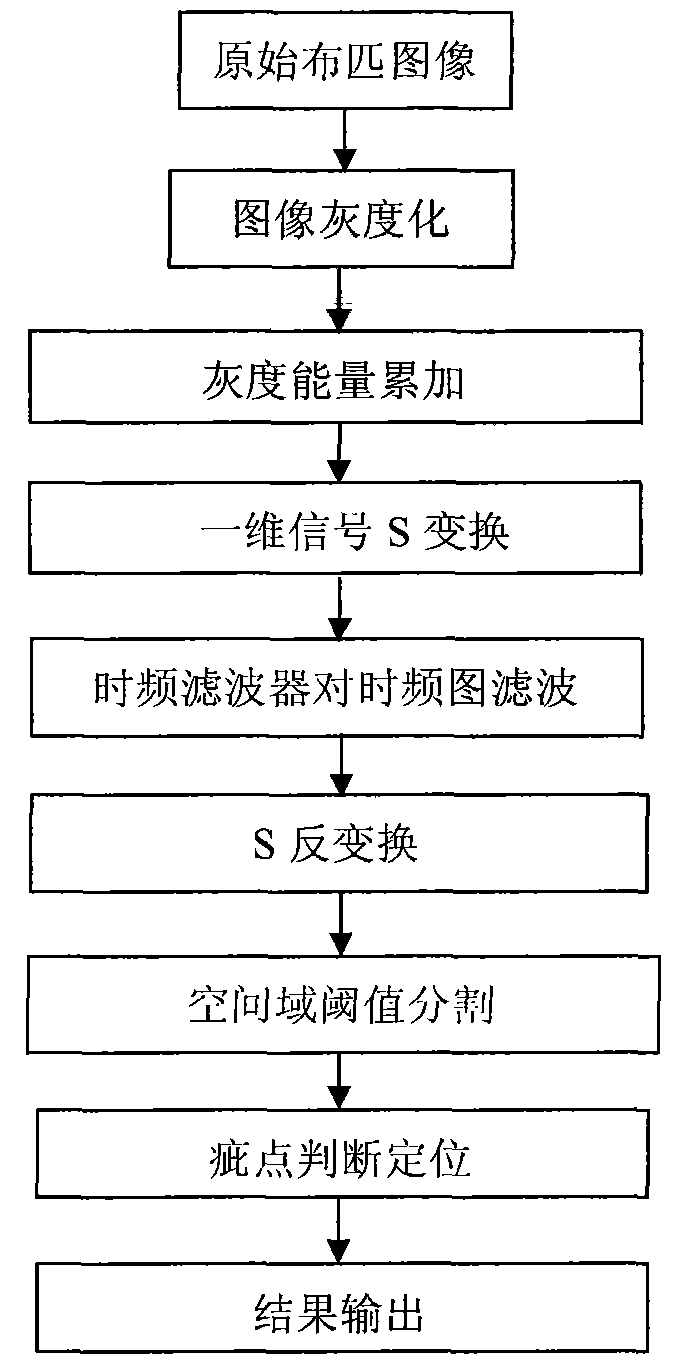

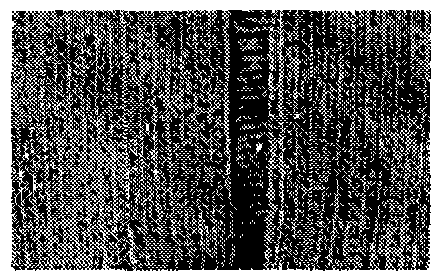

[0049] Taking the warp-knitted cloth whose texture feature is A obtained in actual production as an example, the cloth defect detection method utilizing the S-transform signal extraction method of the present invention specifically includes the following steps:

[0050] Step 1), grayscale processing is carried out to the original cloth image, such as figure 2 shown;

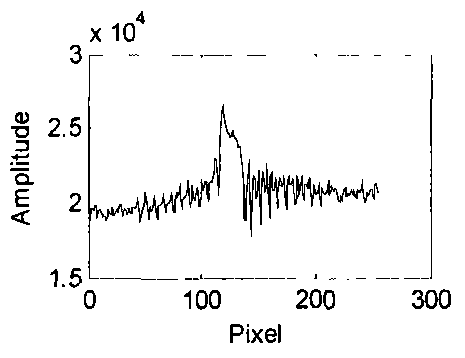

[0051] Step 2), accumulating the grayscale values of each column of the grayscaled image, thereby converting the two-dimensional image into a one-dimensional signal f whose abscissa corresponds to the original image abscissa (ie pixel position), and the ordinate is the grayscale accumulation value (p), such as image 3 shown;

[0052]Step 3), do one-dimensional Stockwell transform (one-dimensional S transform) to the obtained one-dimensional signal f (p), obtain the time-frequency diagram S (p, f) of the S transform coefficient modulus value of the one-dimensional signal, the time-frequency The abscissa of ...

Embodiment 2

[0060] Taking the warp-knitted cloth whose texture feature is B obtained in actual production as an example, the cloth defect detection method utilizing the S-transform signal extraction method of the present invention specifically includes the following steps:

[0061] Step 1), grayscale processing is carried out to the original cloth image, such as Figure 9 shown;

[0062] Step 2), accumulating the grayscale values of each column of the grayscaled image, thereby converting the two-dimensional image into a one-dimensional signal f whose abscissa corresponds to the original image abscissa (ie pixel position), and the ordinate is the grayscale accumulation value (p), such as Figure 10 shown;

[0063] Step 3), do one-dimensional Stockwell transform (one-dimensional S transform) to the obtained one-dimensional signal f (p), obtain the time-frequency diagram S (p, f) of the S transform coefficient modulus value of the one-dimensional signal, the time-frequency The abscissa ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com