Torque rotating angle multi-dimensional sensing control device and control method for electric wrench

An electric wrench and control device technology, applied in the direction of wrenches, power tools, manufacturing tools, etc., can solve the problems of unfavorable wrenches and other tools life, motor spark interference, improvement and other problems, to improve the torque adaptability range, improve torque control accuracy, The effect of expanding the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

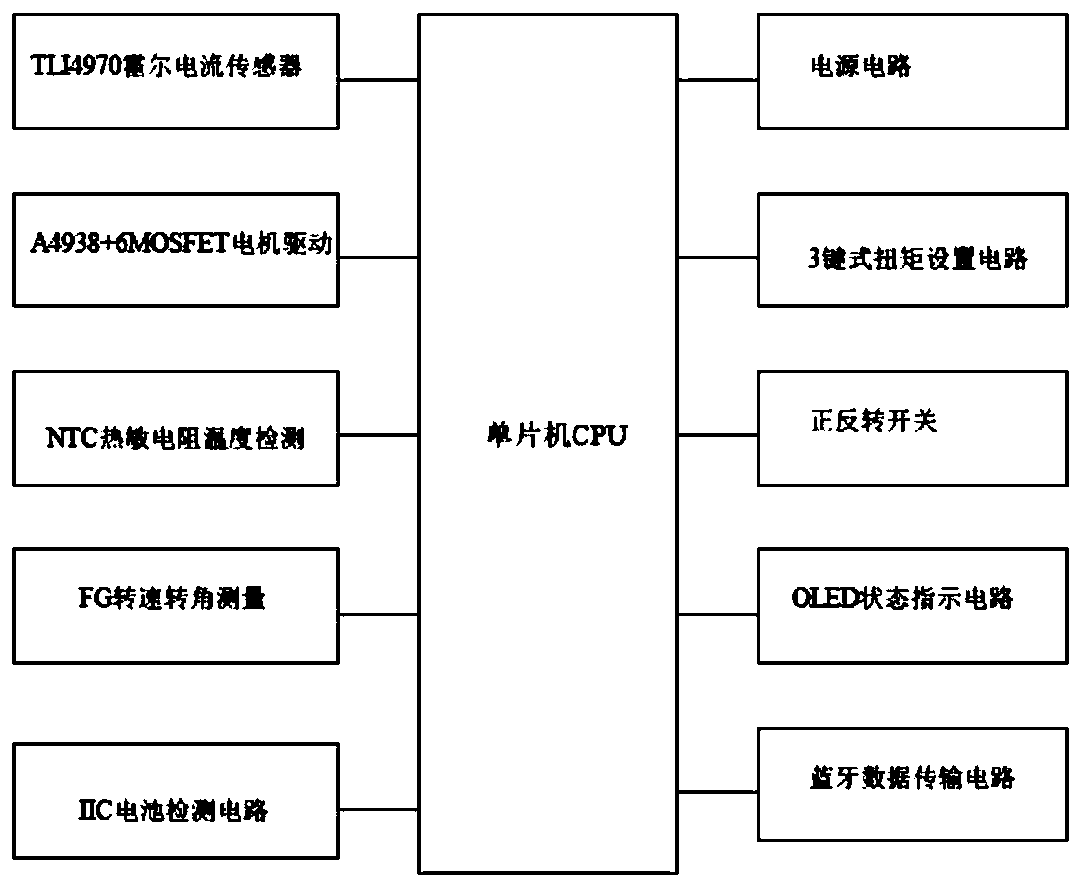

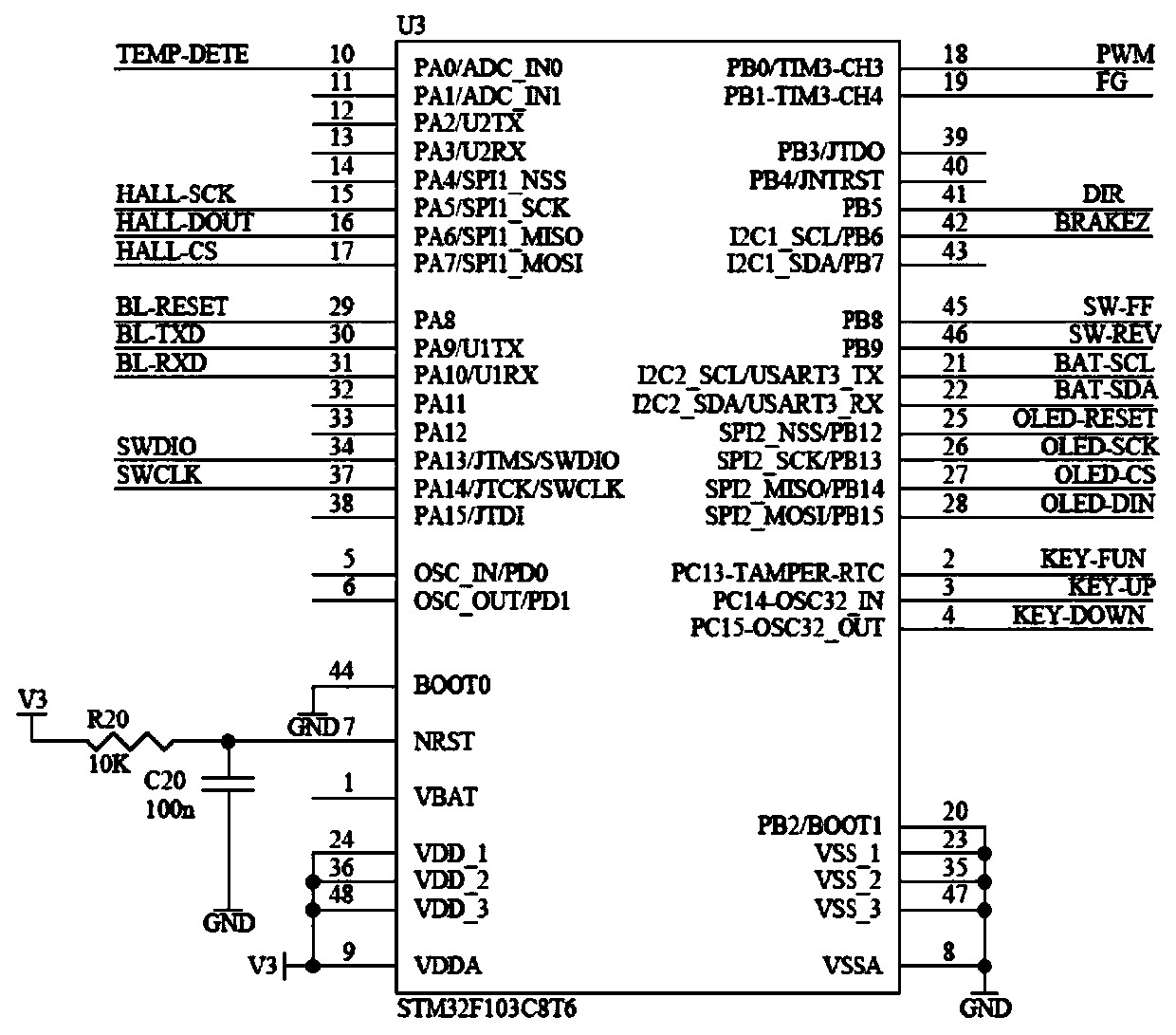

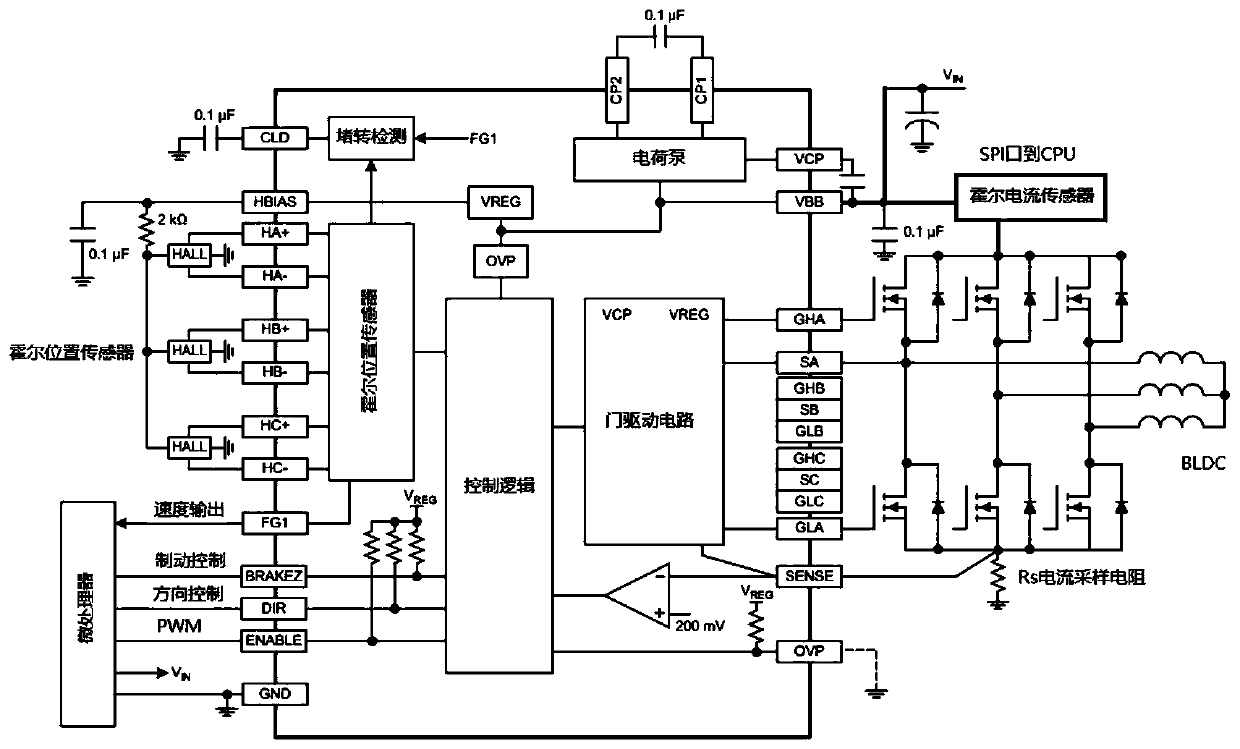

[0064] Such as figure 1 As shown, Embodiment 1 of the present disclosure provides a torque angle multi-dimensional sensing control device for an electric wrench, including a processor module, a brushless DC motor, a servo control module, and a current sensing module, and the current sensing module is connected to the wireless The brushed DC motor is connected to the processor module, which is used to collect the current of the brushless DC motor in real time and transmit it to the processor module; The torque, rotation angle and received motor current realize the adaptive control of the speed, direction, rotation angle and torque of the brushless DC motor, and realize the torque and rotation angle perception during constant torque control and / or constant rotation angle control.

[0065] The device described in this embodiment completes the torque control based on two characteristics of the DC motor:

[0066] (1) Torque control: DC motor torque is proportional to the input cur...

Embodiment 2

[0101] Embodiment 2 of the present disclosure provides an electric constant torque wrench, including a wrench body and the torque rotation angle multi-dimensional sensing control device for an electric wrench described in Embodiment 1 of the present disclosure.

Embodiment 3

[0103] Such as Figure 12 As shown, Embodiment 3 of the present disclosure provides a torque angle multi-dimensional perception control method for an electric wrench, using the wrench control device described in Embodiment 1 of the present disclosure, the steps are as follows:

[0104] Establish relationship curves between speed and torque, between speed and rotation angle, and between torque value and current value, preset speed value, torque value and / or rotation angle value, adaptive peak avoidance speed;

[0105] Press the start switch, and the motor will self-adaption peak avoidance within the preset speed after starting;

[0106] The speed is gradually increased to the speed corresponding to the set torque value, and the current value, rotation angle and voltage value of the motor are monitored in real time. When the current value reaches the current value corresponding to the preset torque or the rotation angle reaches the preset corner, the motor is turned off and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com