Control method and system for tobacco shred water content of airflow tobacco shred drying

A control method and moisture content technology, applied in tobacco, tobacco preparation, tobacco treatment, etc., can solve the problem of inaccurate and uneven control of moisture content at the outlet of air-dried shredded silk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0050] In order to enable those skilled in the art to better understand the solutions of the embodiments of the present invention, the embodiments of the present invention will be further described in detail below in conjunction with the drawings and implementations.

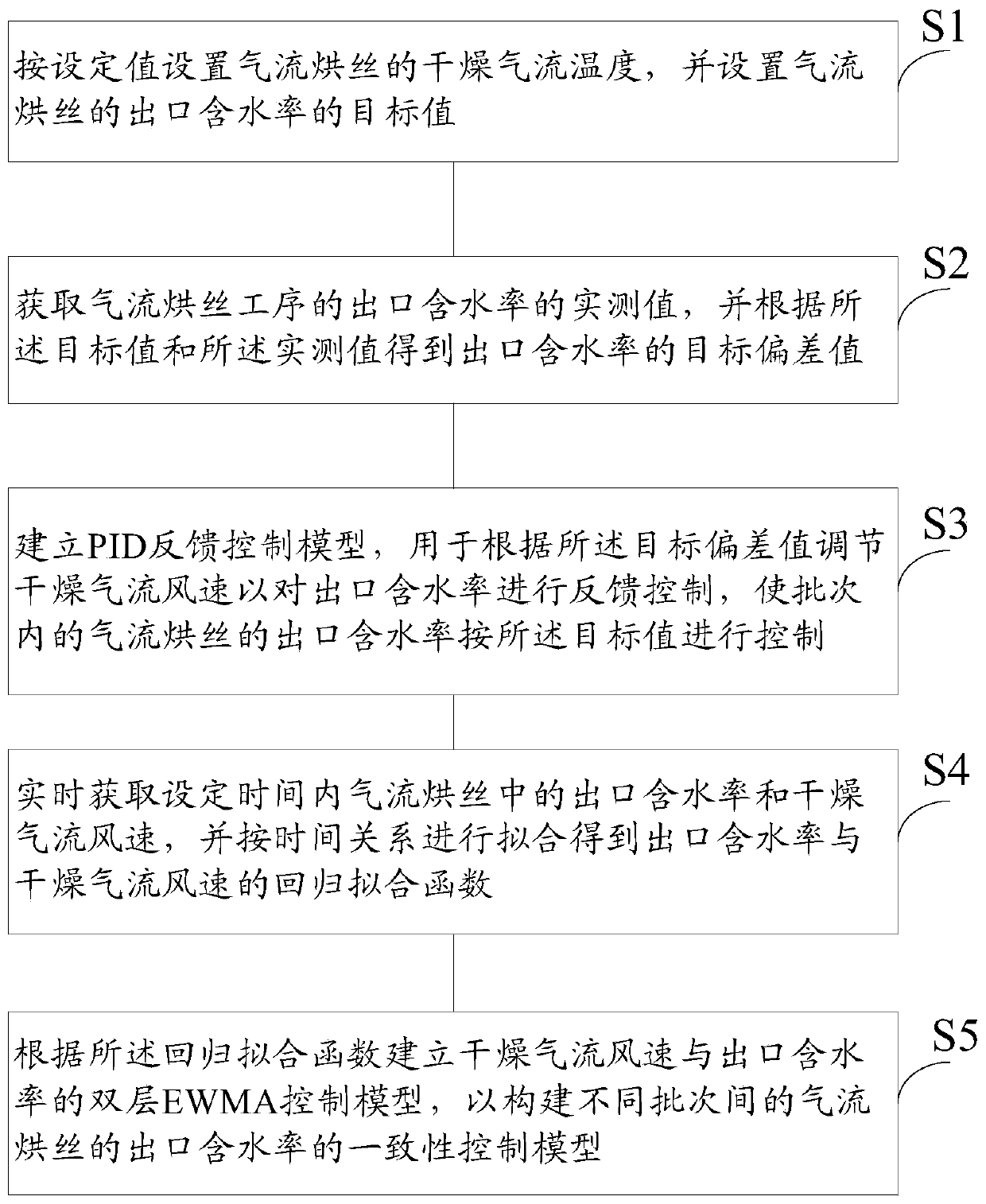

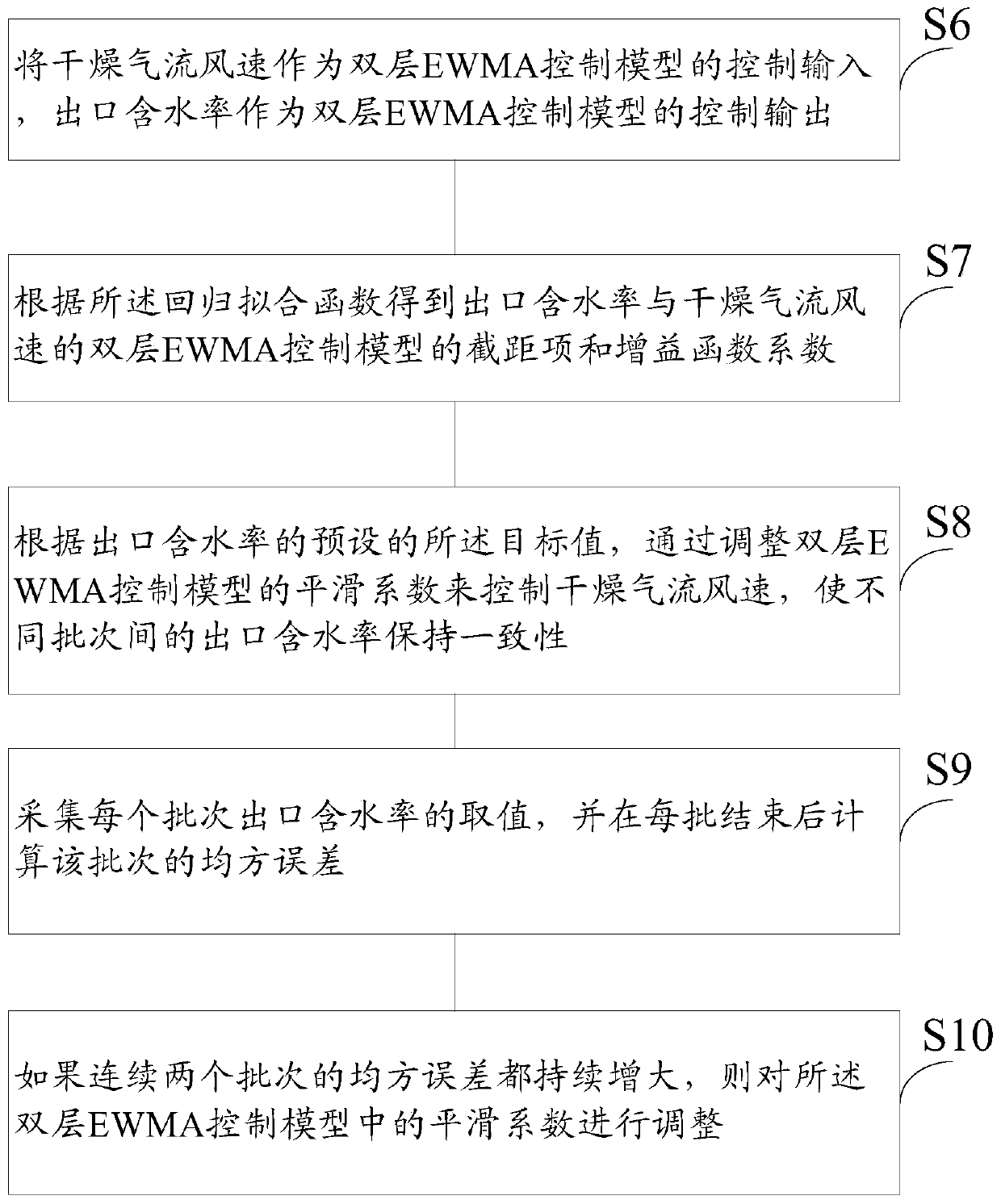

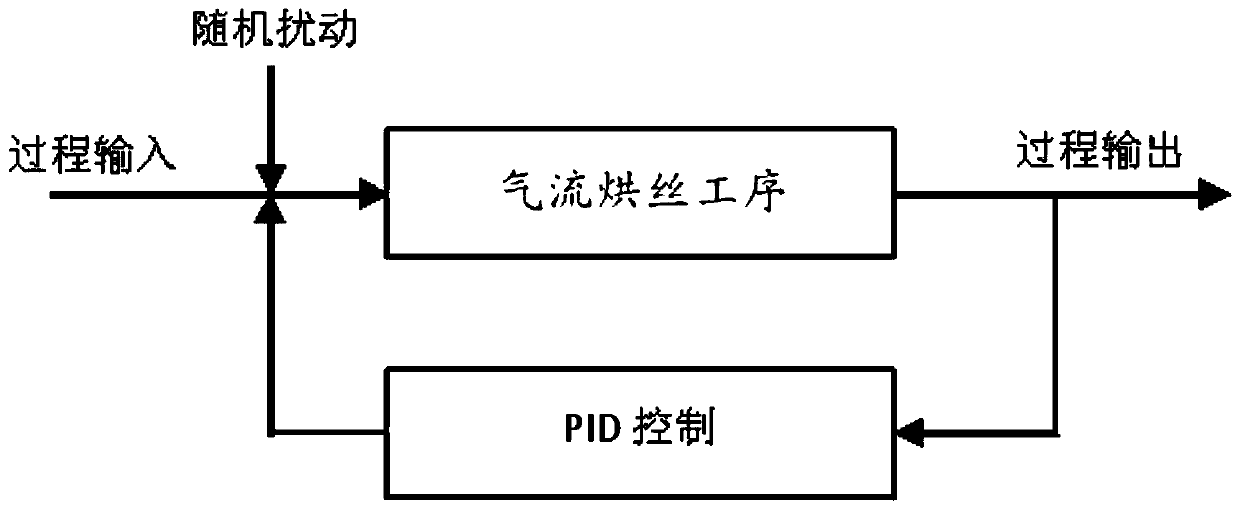

[0051]Aiming at the inaccurate and uneven control of outlet moisture content in current air-dried shredded tobacco, which may easily cause inconsistent quality of tobacco leaves within or between batches and affect the quality of tobacco, the present invention provides a method for controlling the moisture content of shredded tobacco in air-dried shredded tobacco And the system, in the same batch by setting the PID feedback control model to adjust the drying air speed to control the outlet moisture content, solve the problem of inaccurate and uneven control of the outlet moisture content of the existing air-dried shredded silk, and can improve the drying efficiency of each batch of air-flow drying. The consistenc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com