Micro-arc edge diamond cutter micro-notch control method based on mechanical grinding method

A diamond tool and mechanical grinding technology, which is used in the control of workpiece feed movement, grinding machine parts, manufacturing tools, etc. The sharp edge affects the processing quality and other problems, so as to achieve the effect of high tool quality and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

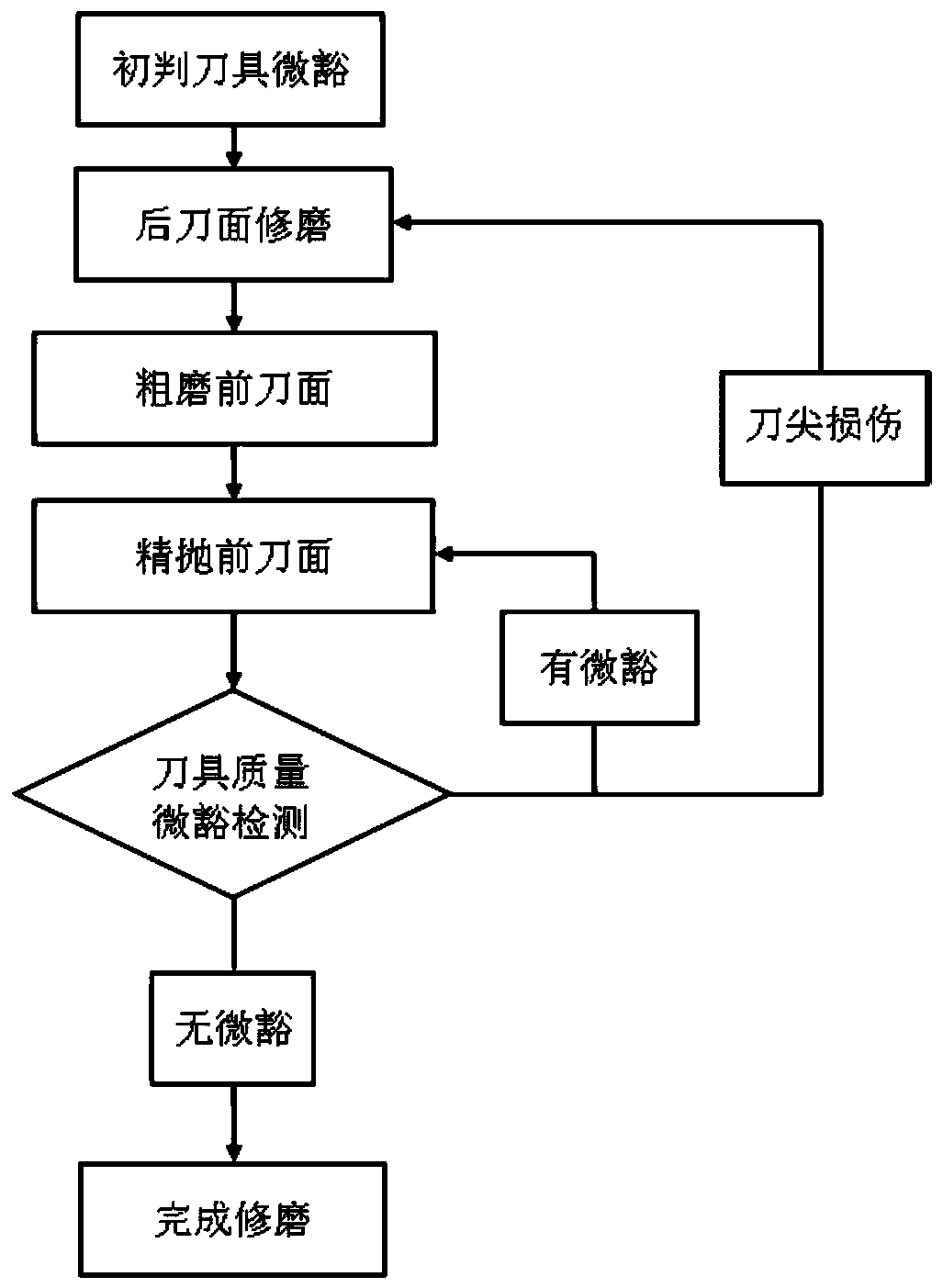

[0039] This embodiment provides a method for controlling the micro-opening of the micro-arc edge diamond tool based on the mechanical grinding method. For the micro-arc edge diamond tool, the operation steps are as follows:

[0040] Step 1. Preliminarily judge the quality of the tool after use, determine the position and size of the edge of the tool, and estimate the removal amount of the tool for repair.

[0041] Step 2. Grinding the flank of the tool, removing the slight gaps on the flank of the tool, and controlling the size of the arc of the tool at the same time. The specific operations are:

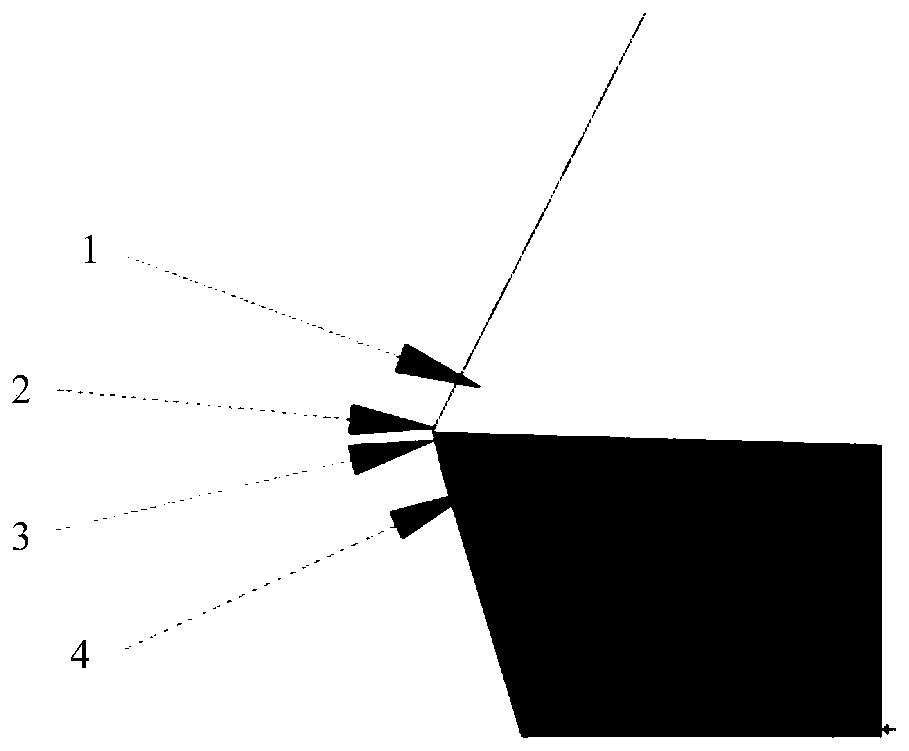

[0042] Step 2-1, set the grinding pressure to keep constant, and determine the difficult and easy grinding direction and angle according to the removal amount at different angles of the tool arc;

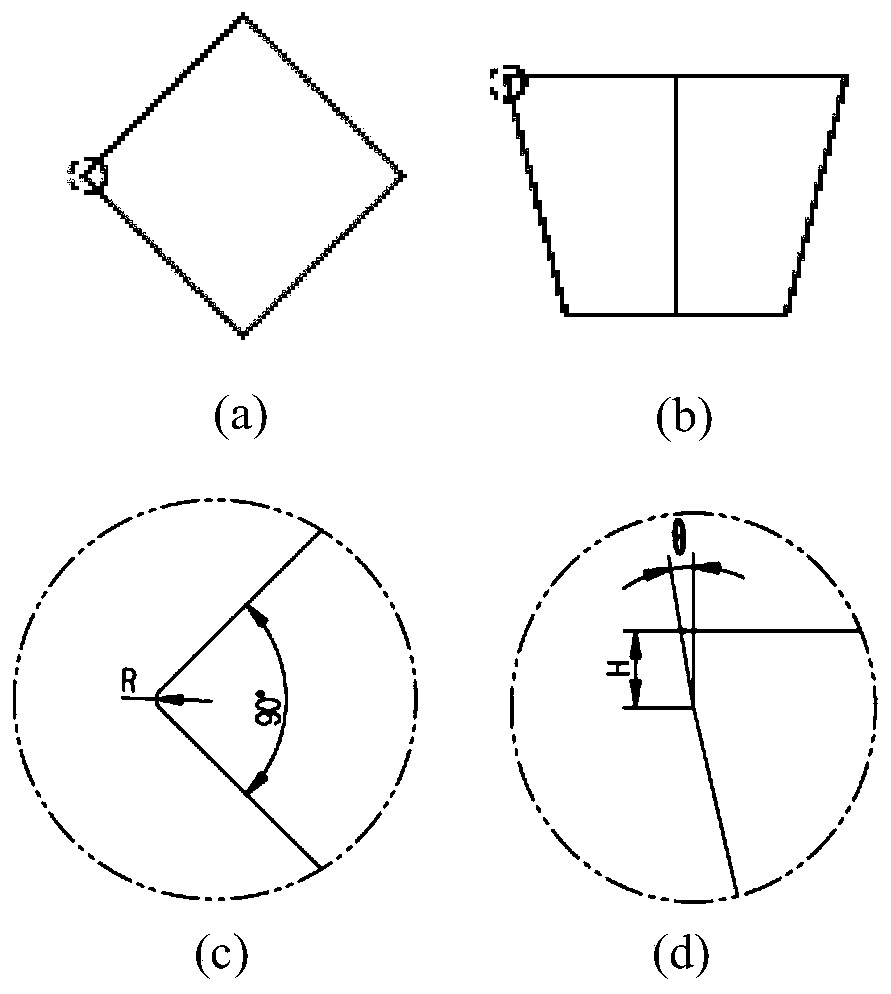

[0043] Step 2-2, according to the size of the slight opening of the flank grinding edge, reserve the height H of the grinding edge, H=R / sinθ, where R is the radius of the tool arc, and θ ...

Embodiment 2

[0050] This embodiment provides a method for controlling the micro-opening of a micro-arc edge diamond tool based on a mechanical grinding method, and the specific steps are as follows:

[0051] Step 1. By observing the micro-arc tool under a high-power optical microscope and an atomic force microscope, the quality of the tool is initially judged, the area and size of the micro-hole are confirmed, and the removal amount of the tool is estimated.

[0052] Step 2, first roughly determine the difficult and easy grinding direction of the tool flank arc. Choose the 800-grain diamond grinding wheel of the knife grinder, install the tool within 1um, 1.0KG constant pressure, speed 3000r / min, reciprocating motion cycle 5 times / min, arc rotation speed 2min / cycle (to ensure that the relationship between volume and angle is recorded Choose slow speed), the grinding direction is parallel to the flank cone surface, inject high-pressure air to keep the tool cooling, and observe the floating ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com