Method for removing residual solder tin from soldering-pan during repair and replacement of ball grid array (BGA) chip

A technology of chips and pads, which is applied in the field of removing residual solder on pads when BGA chips are repaired and replaced, can solve the problems of low yield rate, low efficiency, and long time-consuming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

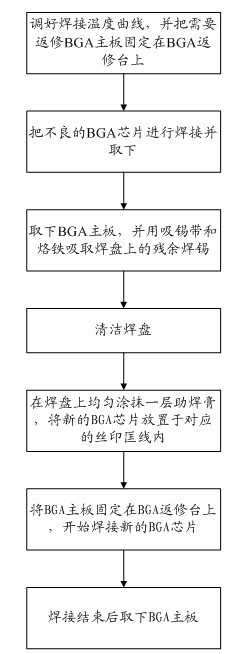

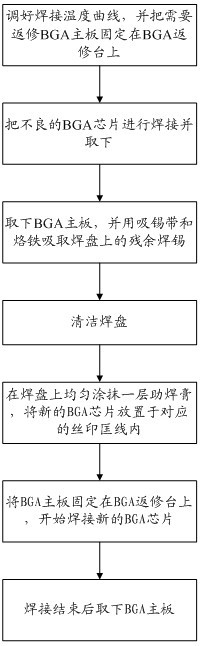

[0016] see figure 1 , the invention provides a method for removing residual solder on pads when a BGA chip is repaired and replaced, comprising the following steps:

[0017] a. Adjust the soldering temperature curve, and fix the BGA motherboard that needs to be repaired on the BGA repair table;

[0018] b. Solder and remove the bad BGA chip;

[0019] c. Remove the BGA main board, and absorb the residual solder on the pad with a tin absorber and a soldering iron;

[0020] d. Clean the pad;

[0021] e. Apply a layer of solder paste evenly on the pad, and place the new BGA chip in the corresponding silk screen line;

[0022] f. Fix the BGA mothe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com