Production line for cold test of diesel engine

A diesel engine and production line technology, which is applied in the direction of internal combustion engine testing, engine testing, machine/structural component testing, etc., can solve the problems of large area occupied by the cold test bench and waste of production area, so as to save production area and reduce The effect of reducing the cost of rework and improving the efficiency of rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below the present invention will be further described in conjunction with the embodiment in the accompanying drawing:

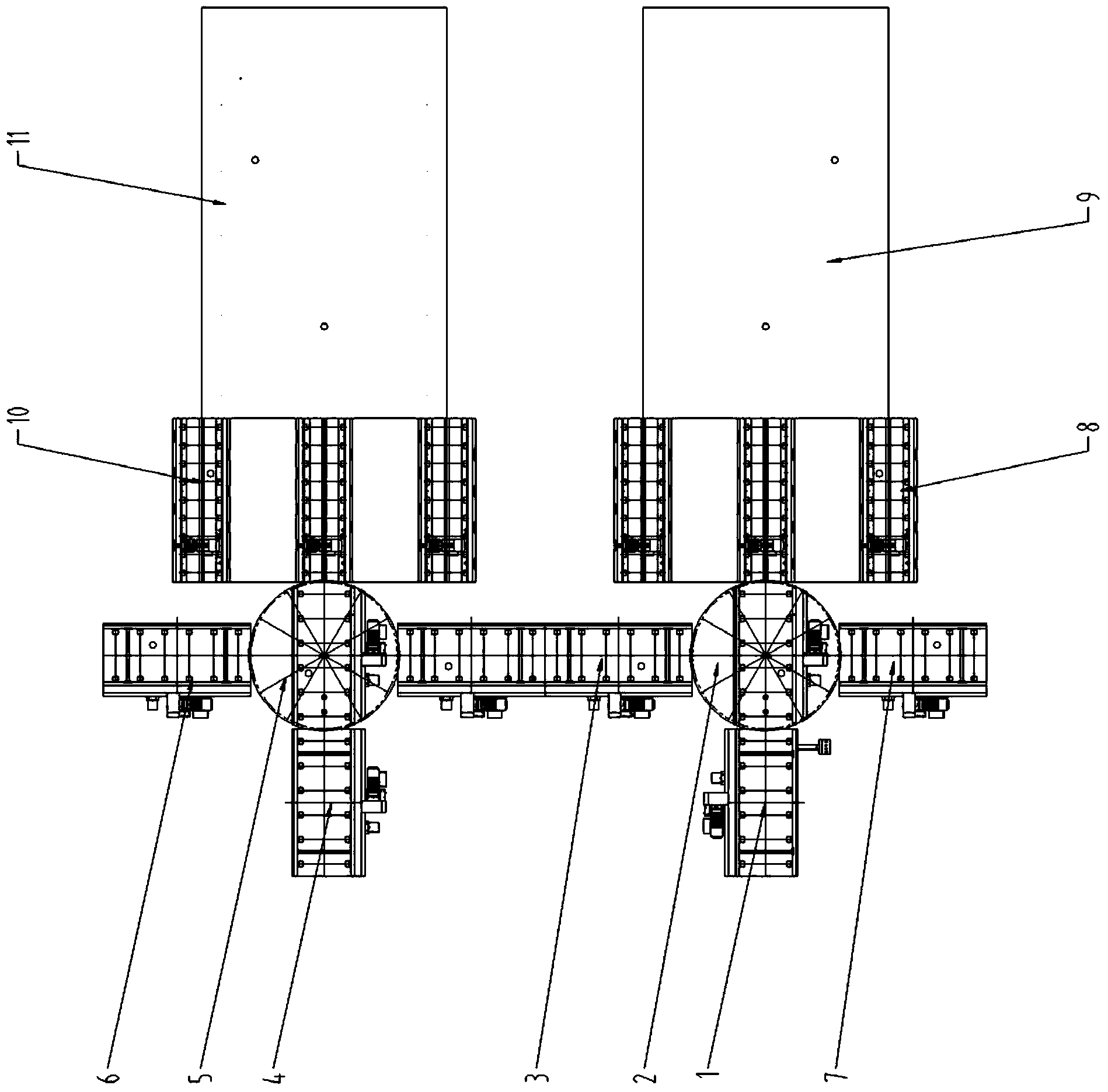

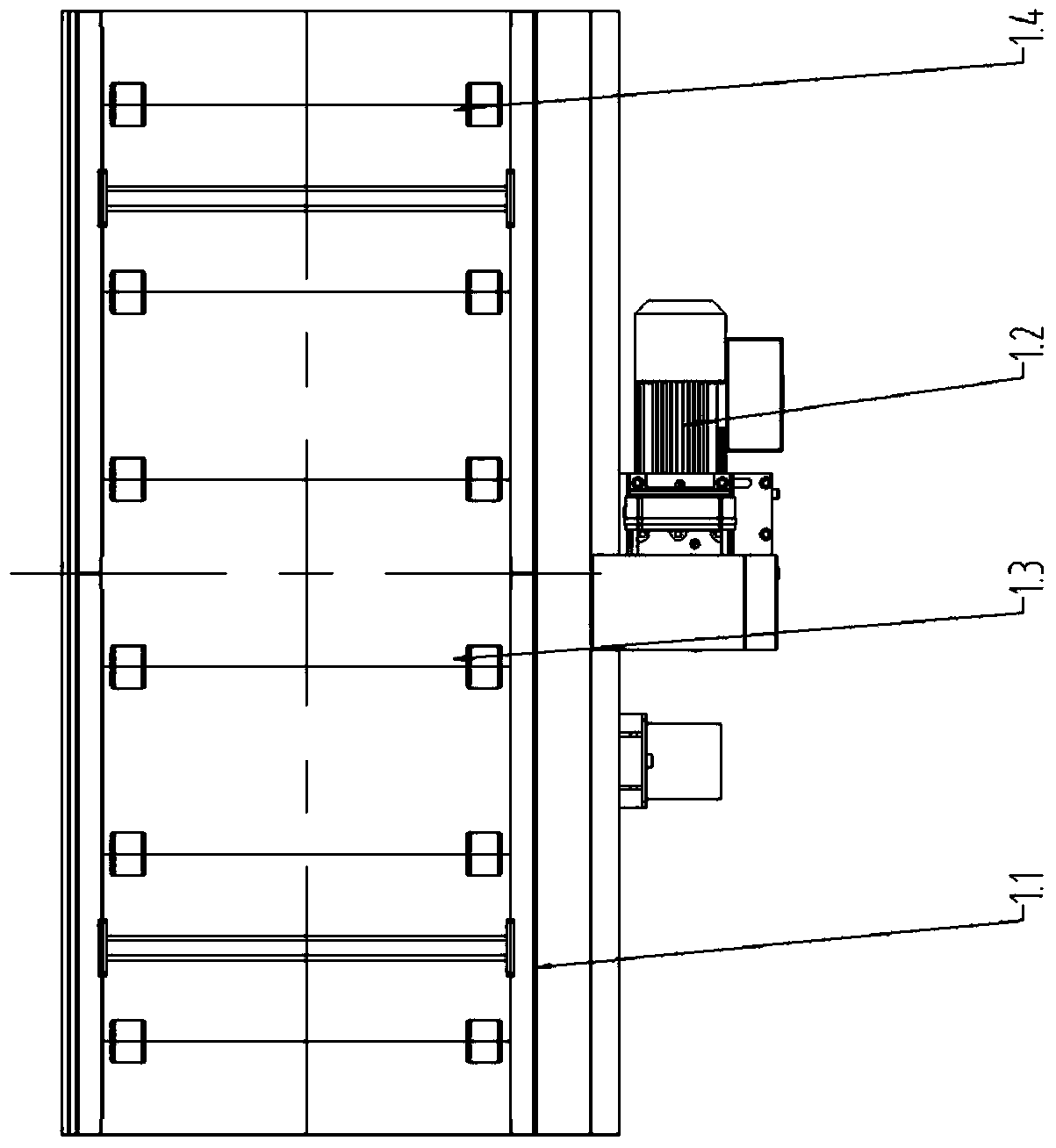

[0016] like figure 1 As shown, the present invention mainly comprises first turntable 2 and second turntable 5, and between first turntable 2 and second turntable 5, is provided with cold test transmission line body 3, and first turntable 2 is provided with cold test transmission line body 3 is provided with a first rework line body 7, and the second turntable 5 is provided with a second rework line body 6 opposite to the side where the test transmission line body 3 is provided.

[0017] One side of the first turntable 2 is provided with the previous process transmission line body 1, and the first turntable 2 is provided with the first door front moving machine 8 and the first cold test bench on the opposite side to the front process transmission line body 1 9.

[0018] One side of the second turntable 5 is provided with a subsequent process transmis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com