Assembling method of large box type high-voltage asynchronous motor

An asynchronous motor and assembly method technology, which is applied to electromechanical devices, manufacturing motor generators, electrical components, etc., can solve the problems of increasing processing costs, prolonging processing cycles, and large rework, ensuring normal delivery and reducing rework costs. , the effect of saving money

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

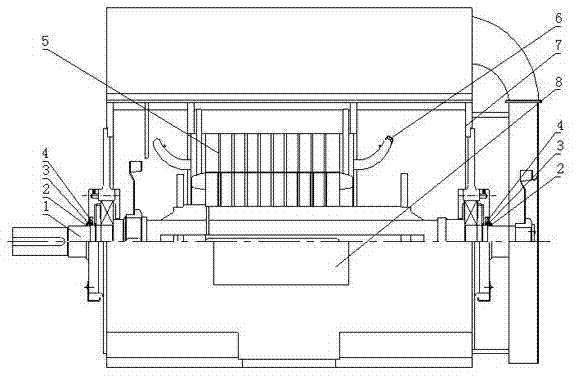

Image

Examples

Embodiment Construction

[0017] ① Firstly, the motor rotor is processed according to the following procedures, cutting the shaft - flat end surface - drilling the center hole - turning the outer circle - grinding the outer circle - pressing the rotating shaft into the cast aluminum rotor core - turning the iron core Circle—set balance plate—set fan—dynamic balance test—assemble bearing device (bearing inner cover, bearing, oil throwing ring, etc.)—assemble shaft extension end cover—assemble shaft extension end bearing outer cover.

[0018] ② Then the motor stator is processed according to the following procedures, stator coil production - embedded wire - dipping paint - winding stator core into the frame - assembly junction box - wiring - press terminal terminal - assembly Non-shaft end caps.

[0019] ③Finally, assemble the rotor of the motor according to the following procedures, hoist the rotor into the stator——assemble the outer cover of the bearing at the non-shaft extension end of the motor rotor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com