Adjustable positioning structure for pre-buried bolt double-layered positioning plate and construction method

A technology for pre-embedded bolts and positioning structures, which is applied in basic structure engineering, building construction, construction, etc., can solve the problem that the location accuracy of pre-embedded bolts and the 100% quality pass rate cannot be guaranteed. Low efficiency and other problems, to achieve the effect of being conducive to process quality control, ensuring installation accuracy, and avoiding rework

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

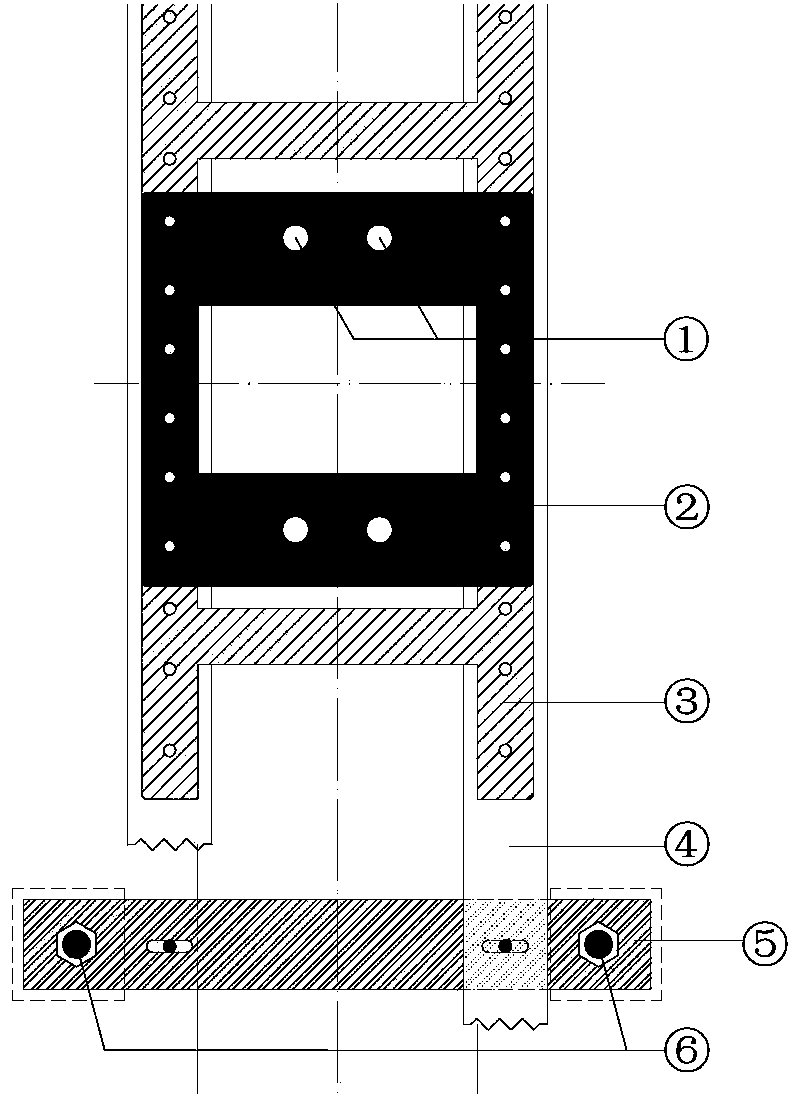

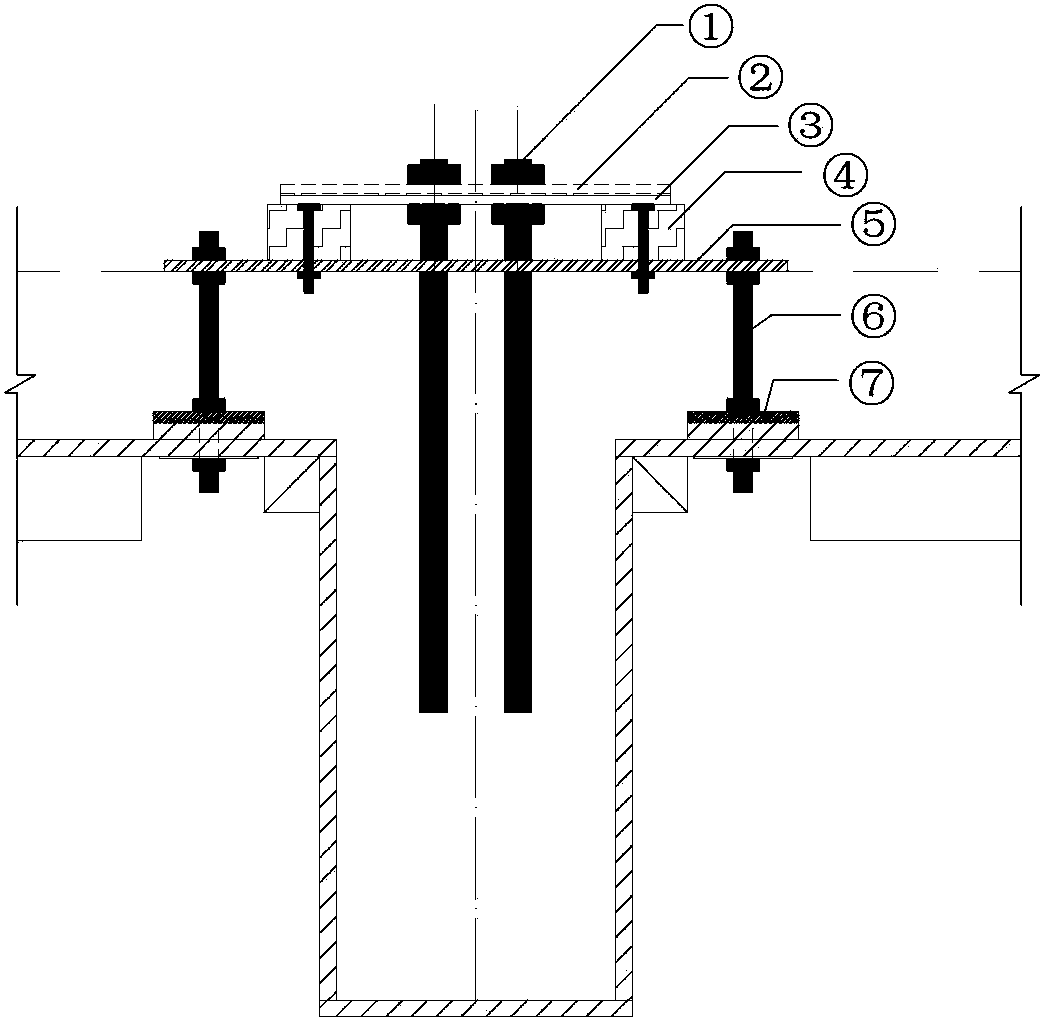

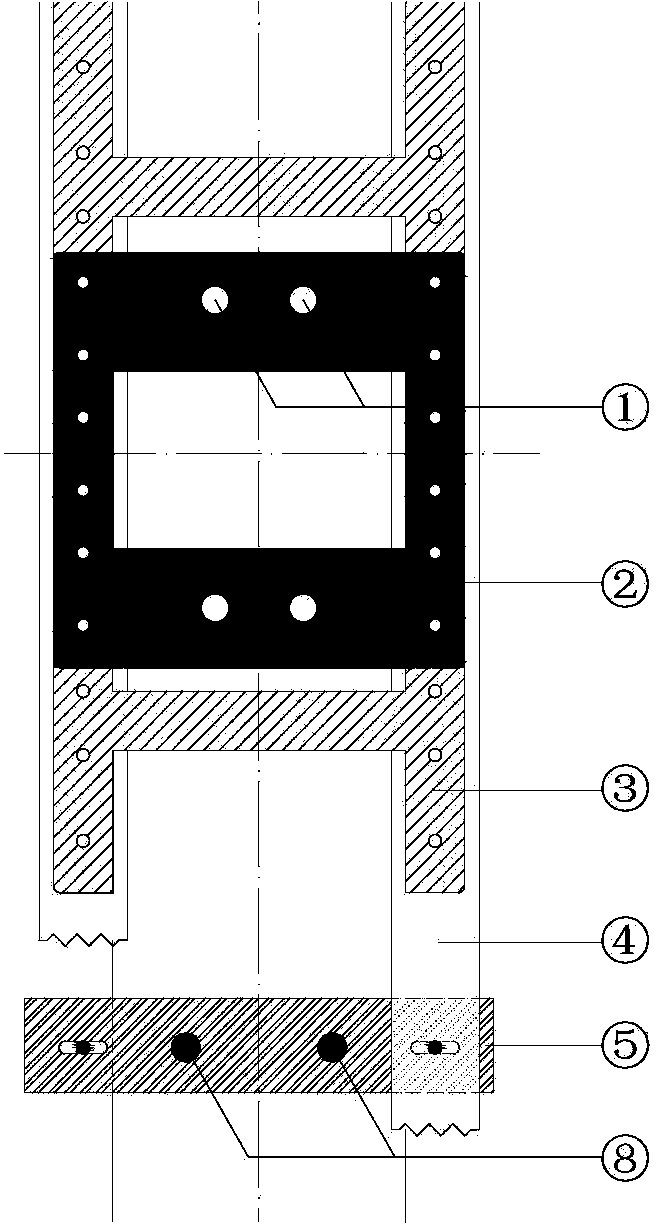

[0031] combine first Figure 1 to Figure 5 The specific structure of the adjustable positioning structure of the embedded bolt double-layer positioning plate is explained: it includes four additional embedded bolts arranged vertically on the four corners of a rectangle (M16 additional embedded bolts 6 on the beam, and 6 on the wall) M24 additional embedded bolts 8), additional iron plates 5 are arranged on the front and rear sides of the rectangle, the two ends of the additional iron plates 5 and the upper ends of the additional embedded bolts are fixed by nuts, and the additional iron plates adjust the elevation and Horizontal, two wooden squares 4 are arranged in parallel between the two additional iron plates, the additional iron plates are provided with position adjustment holes, and the wooden squares 4 are fixed with the additional iron plates through bolts and position adjustment holes To adjust the lateral position, a full-length positioning plate 3 with a frame struct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com