Weld defect real-time detection method and system based on 3D point cloud

A real-time detection and defect technology, which is applied in optical testing defects/defects, image data processing, instruments, etc., to avoid weld scrap, enhance real-time performance and high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings, and the technical solution of the present invention will be explained more clearly and completely.

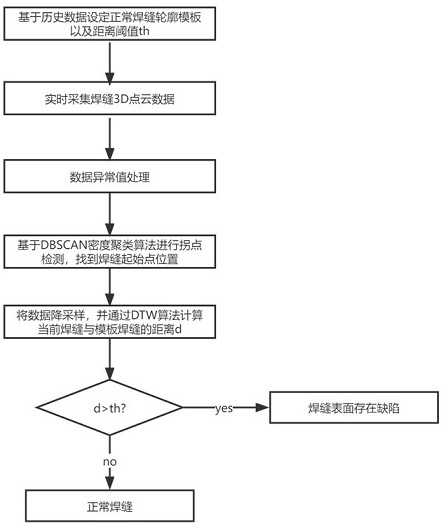

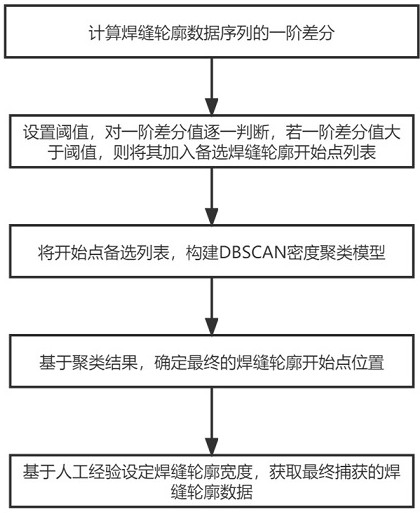

[0036] Such as figure 1 Shown is a real-time detection method for weld defects based on 3D point cloud, including the following steps:

[0037] Step 1. Set the normal weld profile template and distance threshold th based on historical data, preferably th=3;

[0038] Step 1.1, carry out down-sampling process according to the magnification of η, preferably η=0.25 in the embodiment;

[0039] In step 1.2, normalize the down-sampled data to obtain the final template data.

[0040] Step 2. Real-time collection of weld 3D point cloud data;

[0041] 3D point cloud data is formed by scanning the appearance shape of the weld seam in three-dimensional space with the line laser, that is, the longitudinal direction of the weld seam is the Y axis, the cross-sectiona...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com