Process method of improving wall thickness uniformity of closed thin-walled rotary part

A thin-walled rotary and closed technology, which is used in the field of improving the wall thickness uniformity of closed thin-walled rotary parts, can solve the problems of uneven wall thickness, excessive unbalance, large coaxiality, etc., to improve product quality. 、Reduce the unbalance of parts and avoid the effect of multiple repairs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

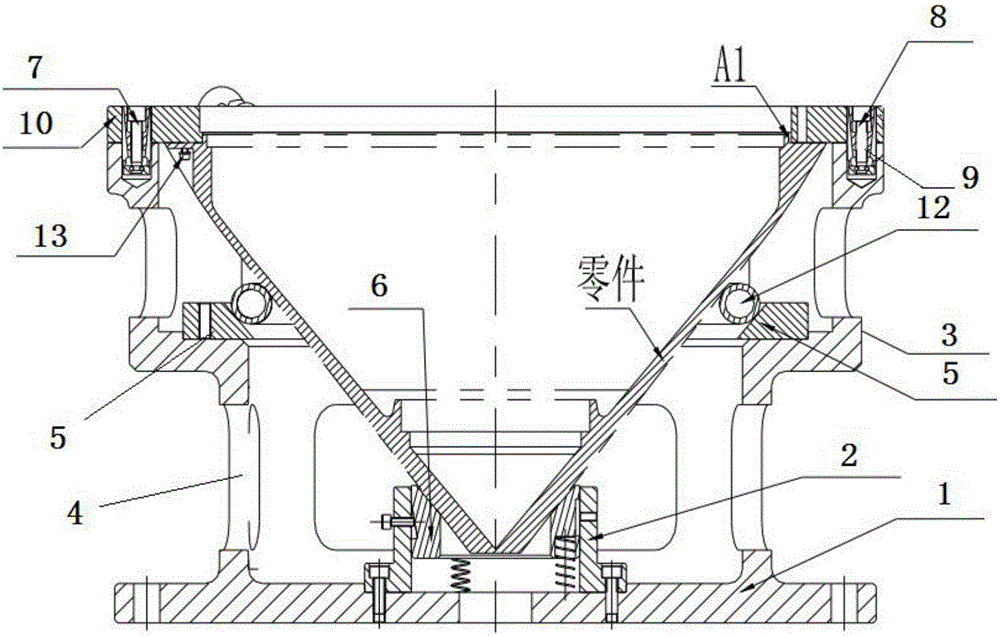

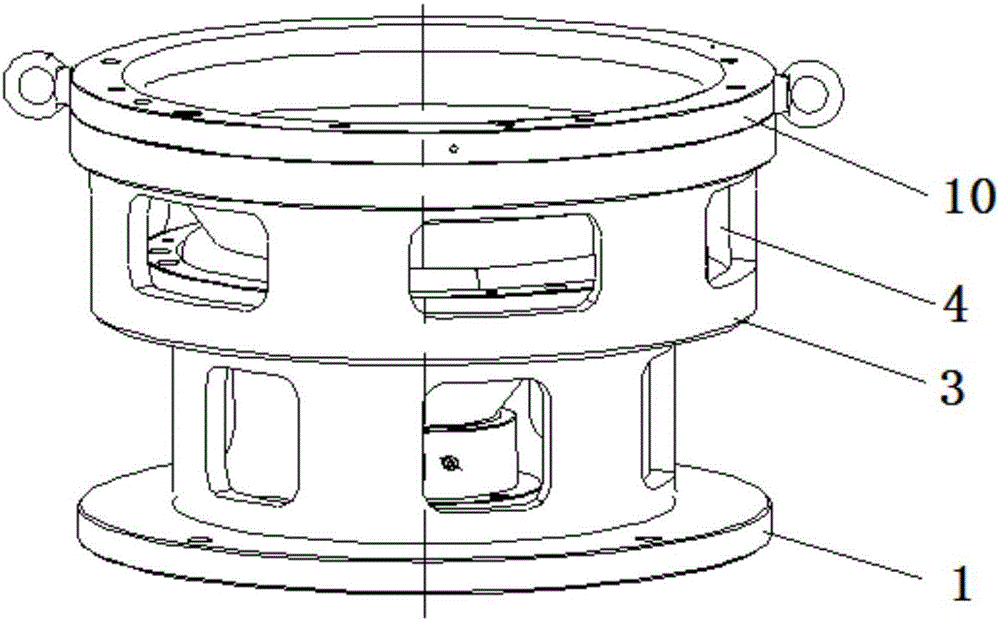

[0023] The present invention is further described in detail in conjunction with the accompanying drawings and embodiments of the description.

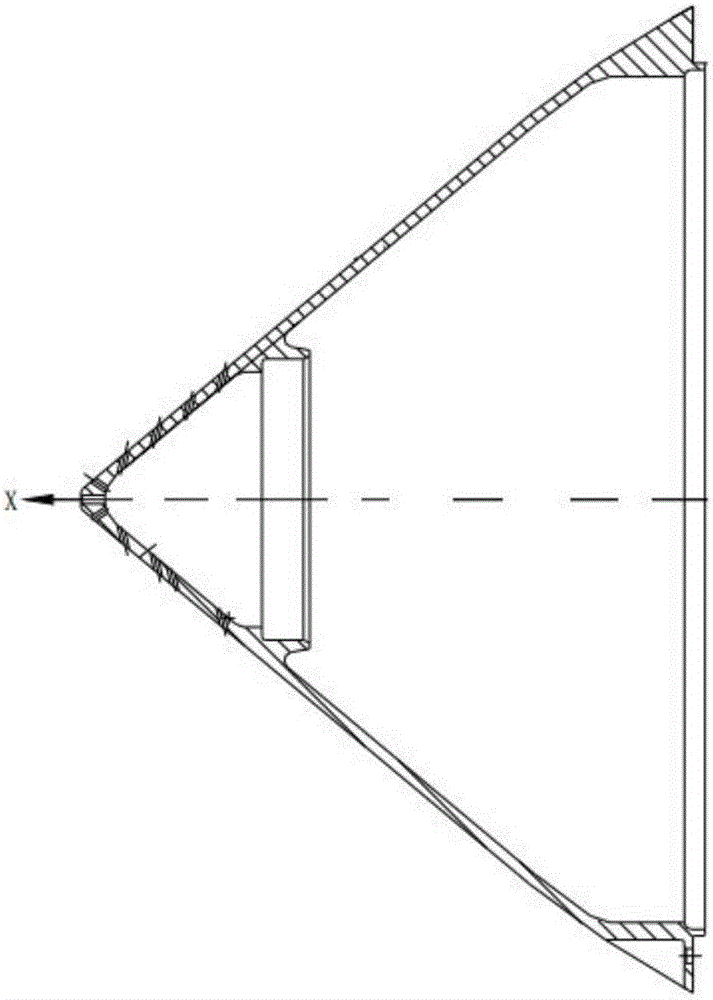

[0024] Such as Figure 1-5 As shown, this technology realizes the precise machining of inner and outer profiles in one process by improving the process route and clamping method, adjusting the machining allowance, and adopting an appropriate fixture structure, and solves the problem of wall thickness of closed thin-walled rotary parts. uneven problem.

[0025] A process method for improving the wall thickness uniformity of closed thin-walled rotary parts,

[0026] 1) Design a new structure of precision turning fixture; usually the positioning part and the base part of the turning part turning fixture are assembled into one body. In order to realize the precise positioning of the cap and cover parts during the turning process, the formulated solution is:

[0027] Divide the fixture into two parts:

[0028] The first part is the posit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com