Guide wire wheel for polycrystalline silicon cutting wires and preparation process thereof

A preparation process and technology of cutting wire, which is applied in the field of guide wheel for polysilicon cutting wire and its preparation process, can solve the problems of unfavorable cutting, bouncing, large centrifugal force, etc., and achieve cost reduction, prolong service life, and small friction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

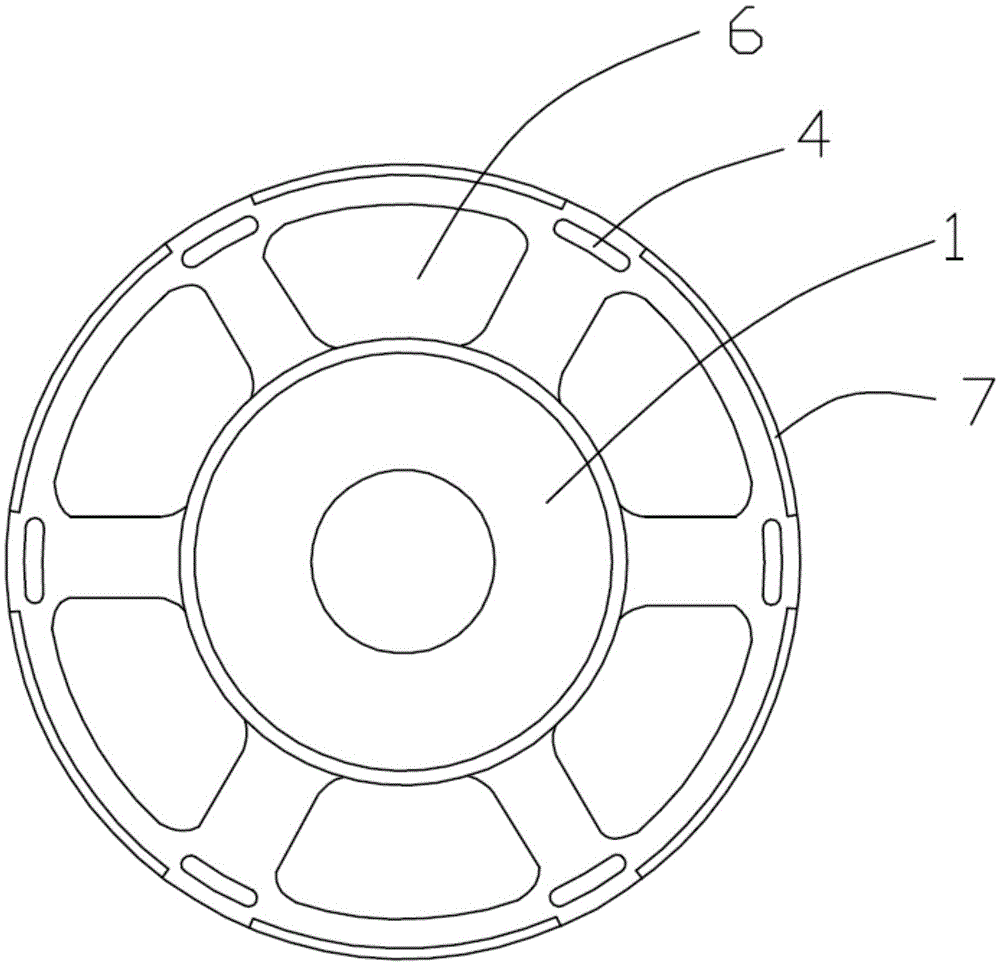

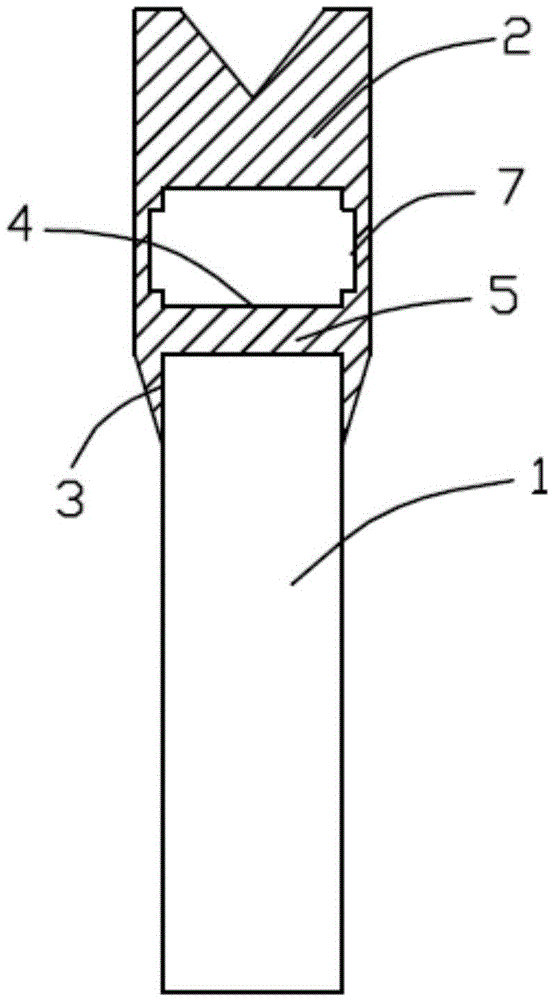

[0029] refer to figure 1 and figure 2 As shown, a wire wheel for polysilicon cutting wire includes a wire wheel body 1 made of carbon fiber, and a wire groove ring 2 is fixedly arranged on the outer circumference of the wire wheel body, and the wire groove ring is made of polyurethane.

[0030] The inner wall of the wire groove ring is provided with a fixed groove 3, and the fixed groove is clamped on the periphery of the wire wheel body for connecting with the wire wheel body, the connection is high, and it is also convenient for integral injection molding.

[0031] The surface of the wire wheel body is provided with several through holes 4 located on the circumference, and the inner walls of the fixed grooves are also connected by connecting columns 5. The connecting columns are arranged in the through holes. The material of the connecting columns is the same as that of the wire groove ring and is integrally formed. As a result, the wire groove ring is tightly attached to ...

Embodiment 2

[0043] The difference between Embodiment 2 and Embodiment 1 is that the fixed groove is bonded to the wire wheel body. This setting can save the drilling process during preparation, and use adhesive after direct co-extrusion to reduce the purchase of equipment. cost.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com