Extraction tank stirrer

A technology of agitator and extraction tank, which is applied in solvent extraction, agitator accessories, chemical instruments and methods, etc., can solve the problems of troublesome spare parts stocking for users, increased operating costs, and low drainage volume, and achieves the reduction of agitator load and improvement Stirring stability, effect of increasing stirring load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

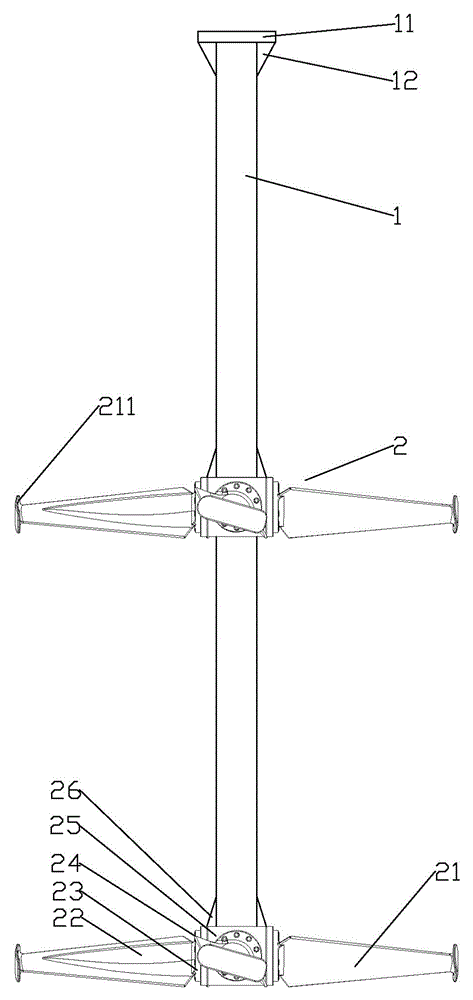

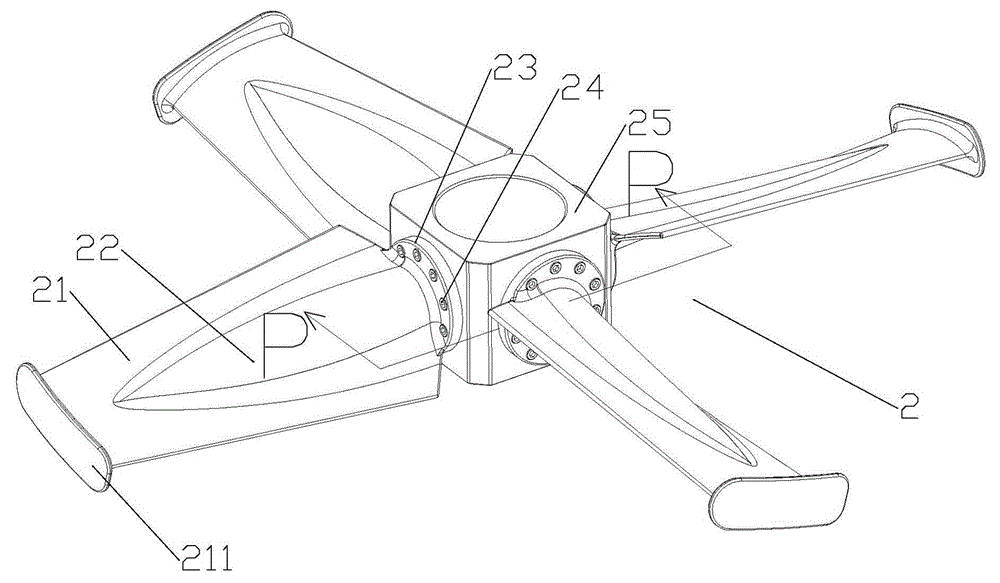

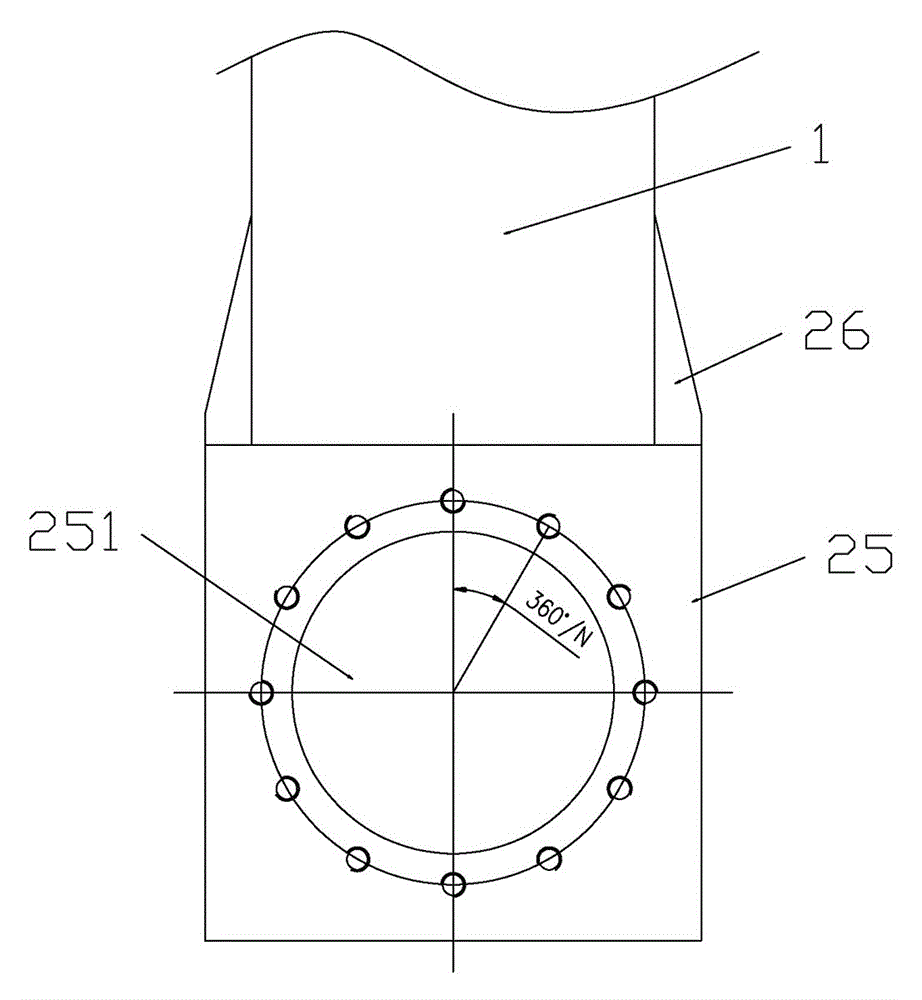

[0024] Such as Figure 1-3 Shown: an extraction tank agitator, including a stirring shaft 1, a stirring shaft flange 11 is arranged at the top of the stirring shaft 1 and the stability of the connection between the stirring shaft flange 11 and the stirring shaft 1 is strengthened through the stirring shaft rib 12; The impeller 2 is layered from top to bottom on the shaft 1, and the bottom impeller 2 is set at the bottom of the stirring shaft 1. The impeller 2 includes a square hub 25 and a paddle 21 fixed on the stirring shaft 1, and is integrally cast The profile of the square hub 25 formed by post-processing is cuboid and its inside is hollowed out into a cylindrical shape. After the stirring shaft 1 passes through the square hub 25, the two ends are welded, and the upper side of the square hub 25 is welded with a hub reinforcement rib 26 to further ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com