Patents

Literature

138results about How to "Improve fault detection rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-linear industrial process fault detection method based on Bayes kernel slow feature analysis

ActiveCN106647718AFully extractedImprove fault detection resultsElectric testing/monitoringIntegrated monitoringAlgorithm

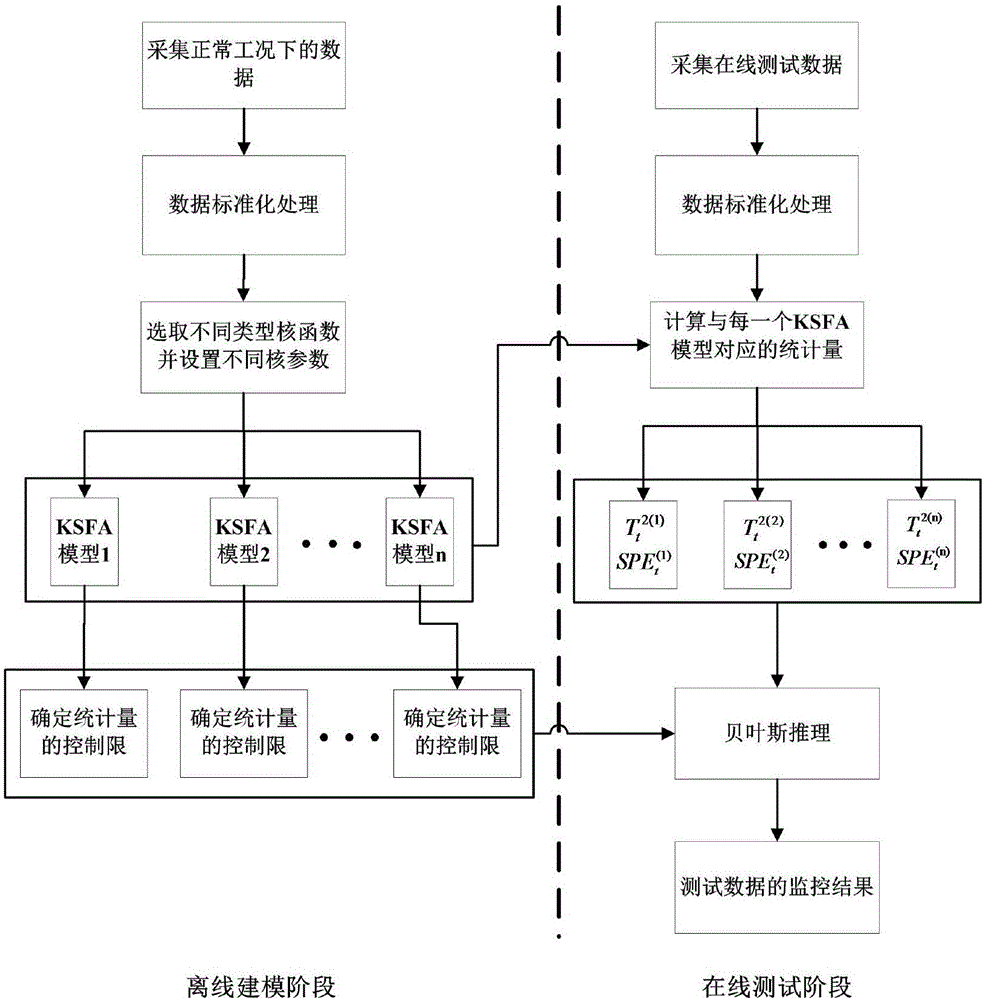

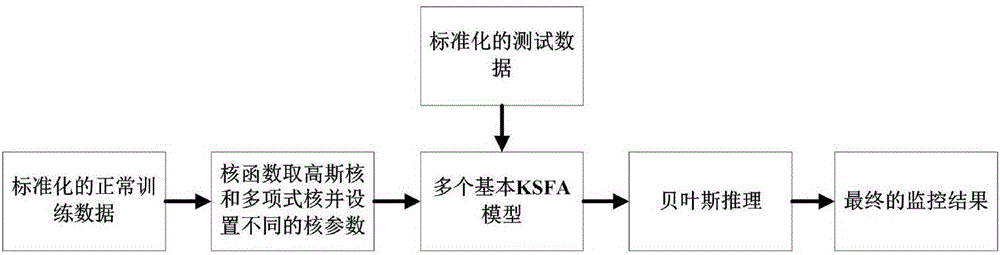

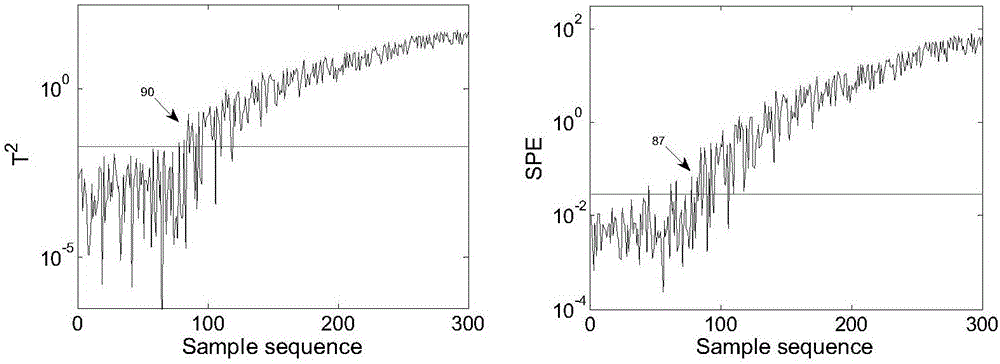

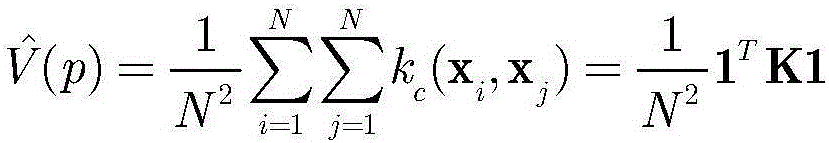

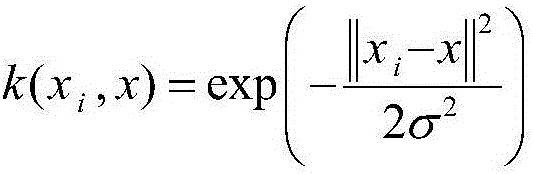

The invention relates to a non-linear industrial process fault detection method based on Bayes kernel slow feature analysis. After normalization processing of training data and test data, kernel functions of different types are adopted based on a conventional kernel feature analysis method, and the various kernel functions are configured with different kernel functions, and therefore a series of basic KSFA models are established. Non-linear slow features are more fully extracted from the normalized training data and the normalized test data by using the basic KSFA models, and the basic KSFA models are respectively used to monitor the process. The non-linear industrial process fault detection method is provided with Bayesian inference, and the test data monitoring results of the series of basic KSFA models are weighted in a combined manner by adopting a probability way, and finally the integrated monitoring result of a plurality of models is acquired, and therefore a fault detection result is improved, and a fault detection rate is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

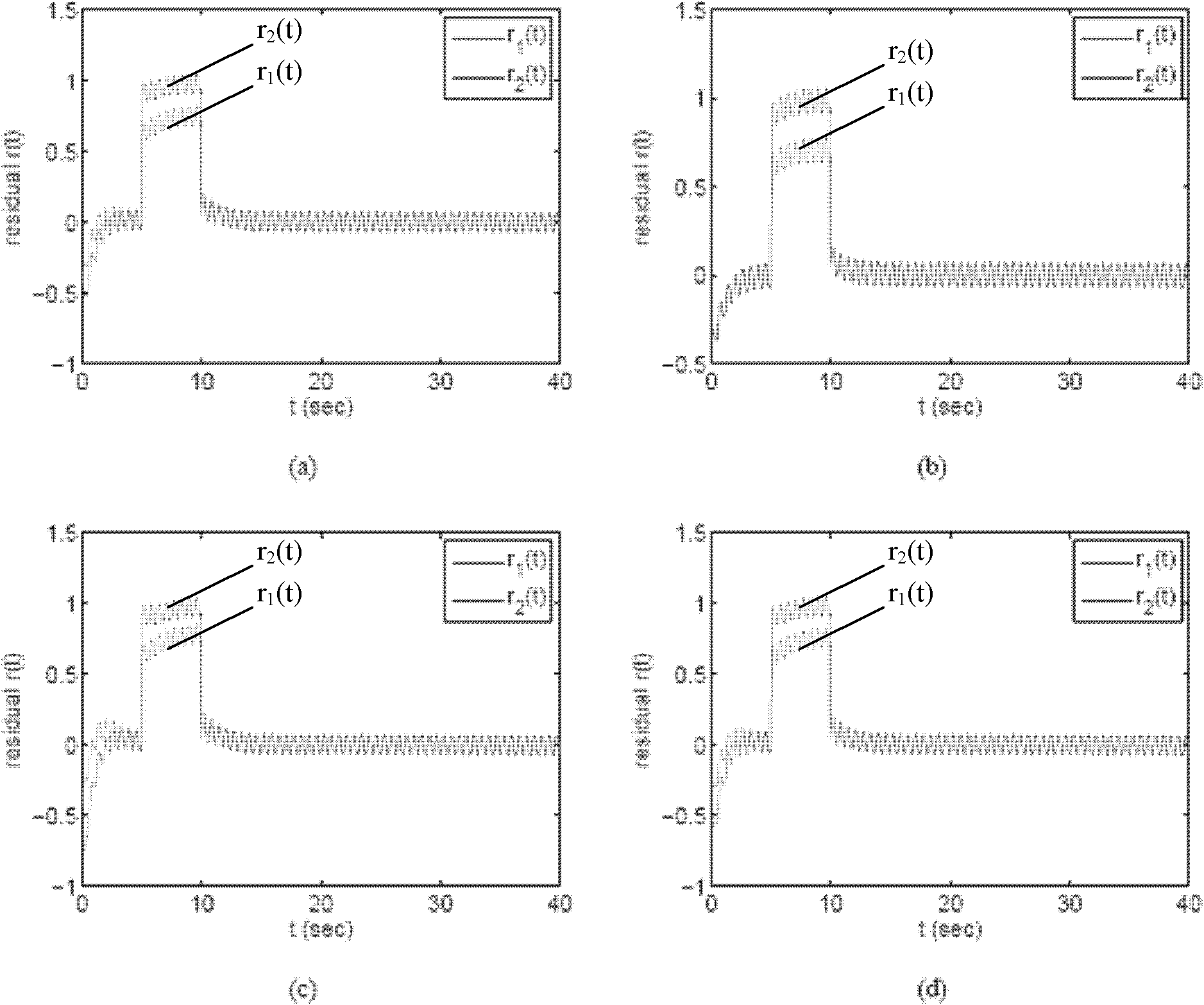

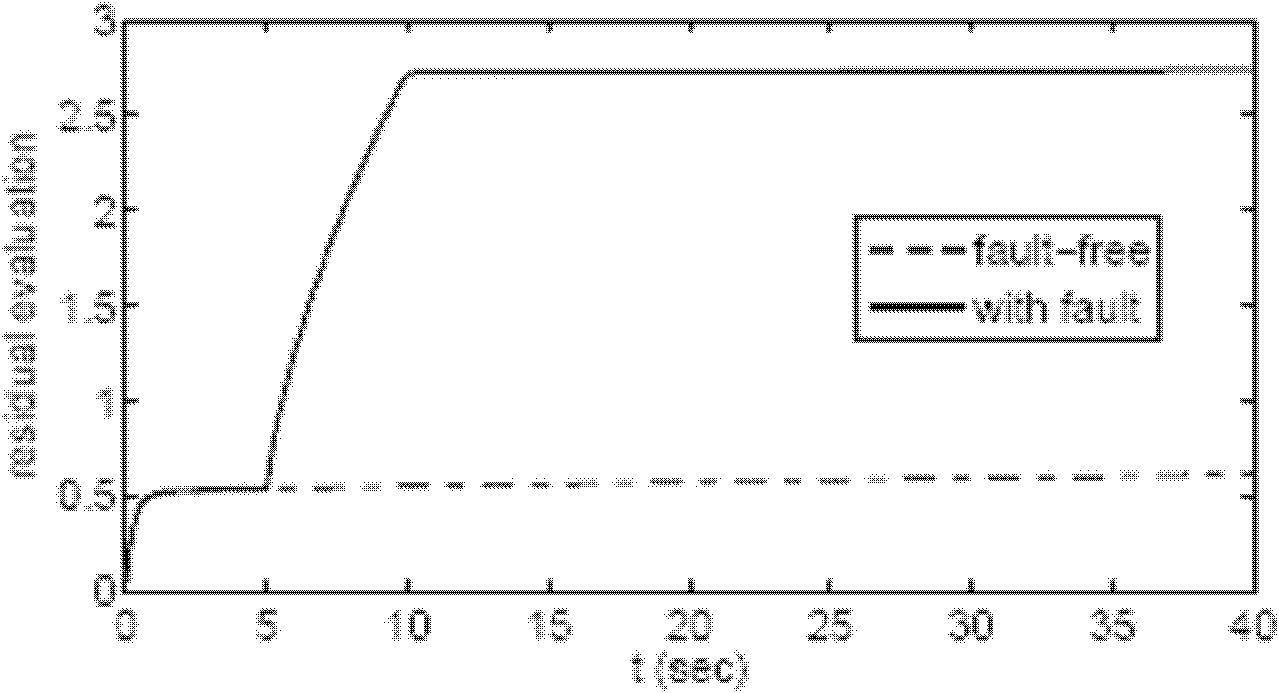

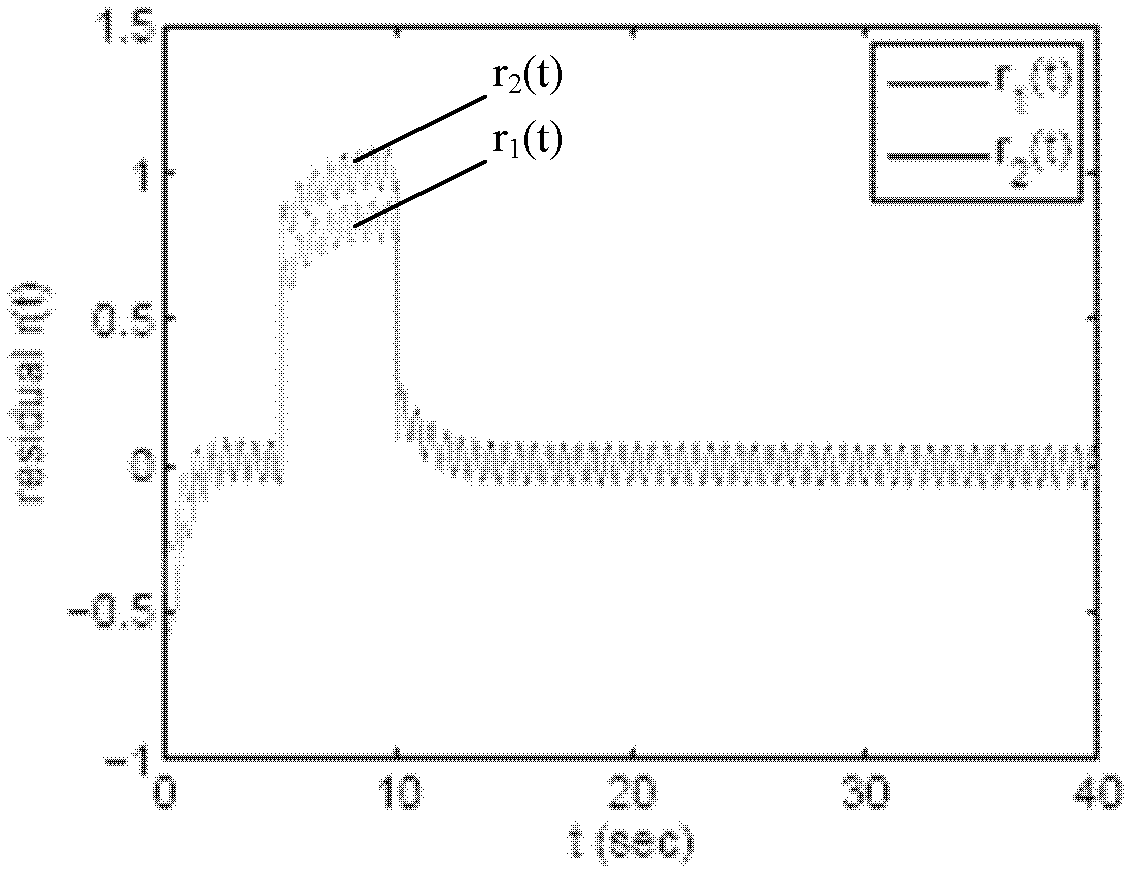

Design method of robustness fault detection filter of linear uncertain system

InactiveCN102436179ATest not conservativeExcellent RFDFTesting/monitoring control systemsAdaptive controlRobustificationUltrasound attenuation

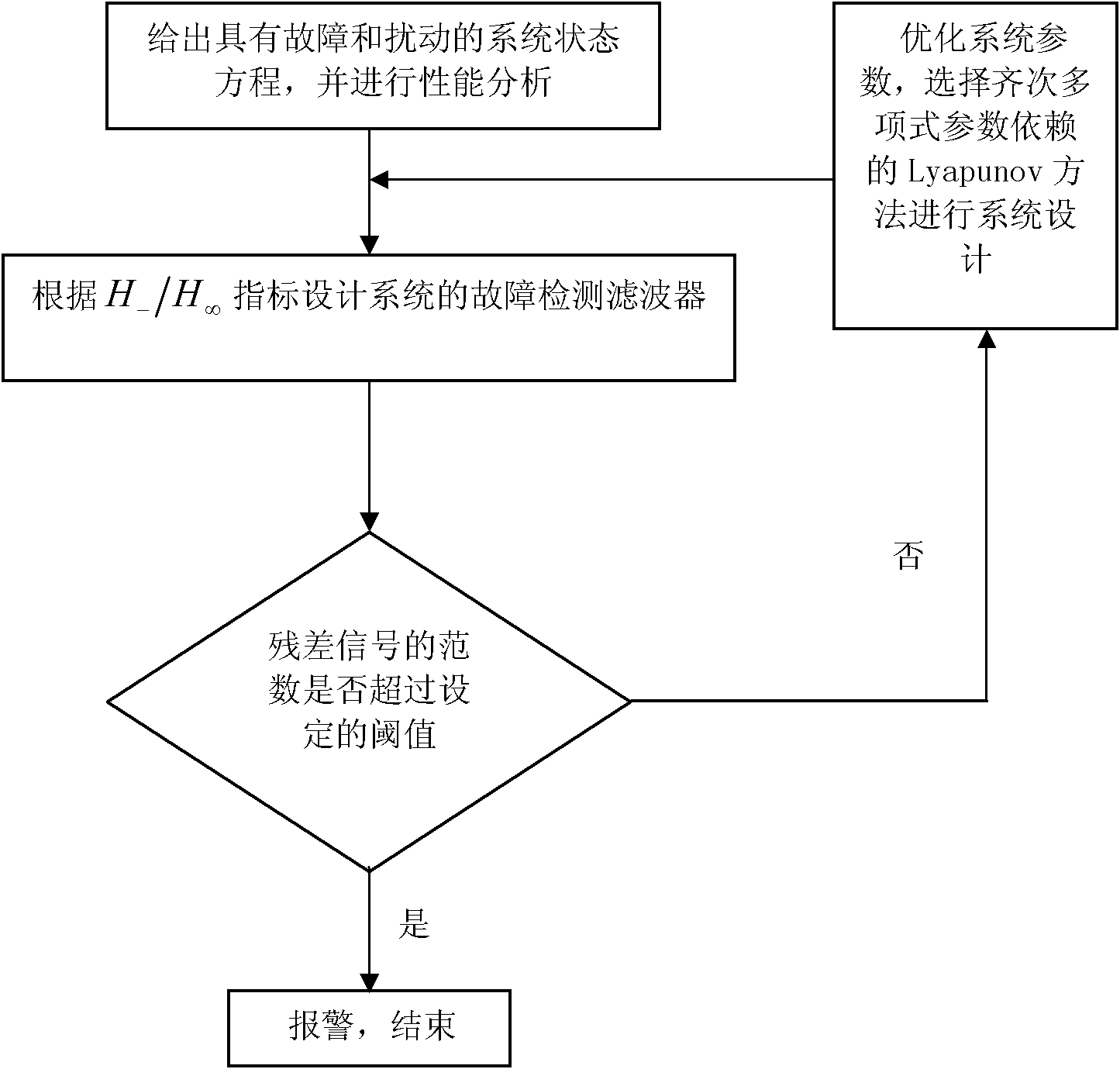

The invention belongs to the control field and provides a design method of a robustness fault detection filter of a linear uncertain system. A Lyapunov function method on which a homogeneous polynomial parameter depend is introduced into robustness fault detection of a linear time invariant system with convex polyhedron nondeterminacy. Firstly, existence of an HPPDL function used for designing an RFDF can be verified through feasibility of a linear matrix inequality; secondly, maximal fault sensitivity is obtained through solving a generalized eigenvalue problem, and an optimal RFDF is obtained. With increase of polynomial time, quantity of the linear matrix inequality and a free variable are increased, and conservation of verification is reduced substantially. The design method comprises two phases: (1) designing an optimal RFDF for a residual error generator with certain interference attenuation and largest fault sensitivity; (2) carrying out threshold design for a residual error generated by estimation. Compared with a previous analogy method, the design method in the invention has generality.

Owner:CHINA ELECTRIC POWER RES INST +1

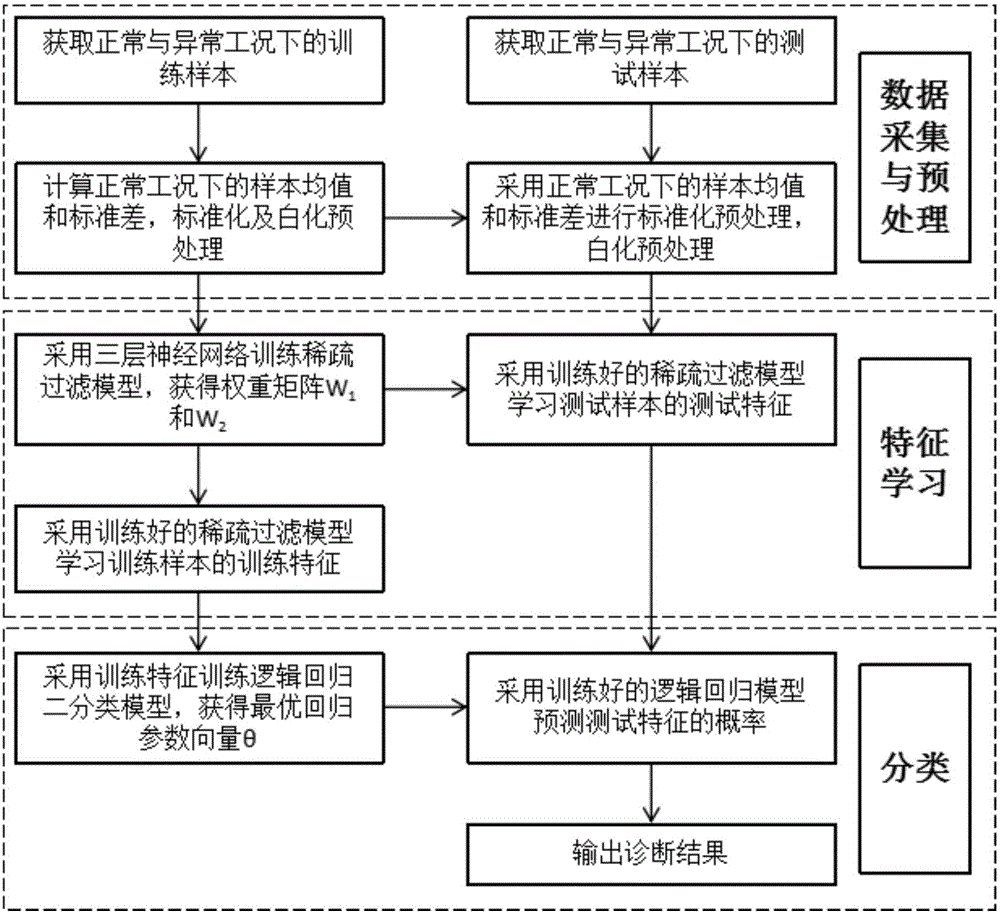

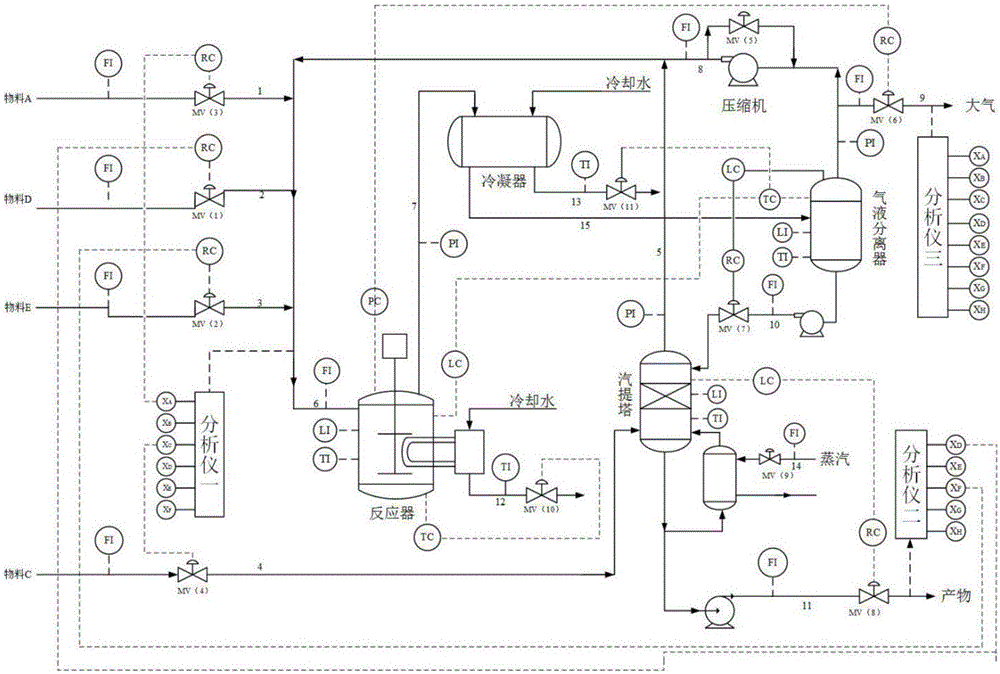

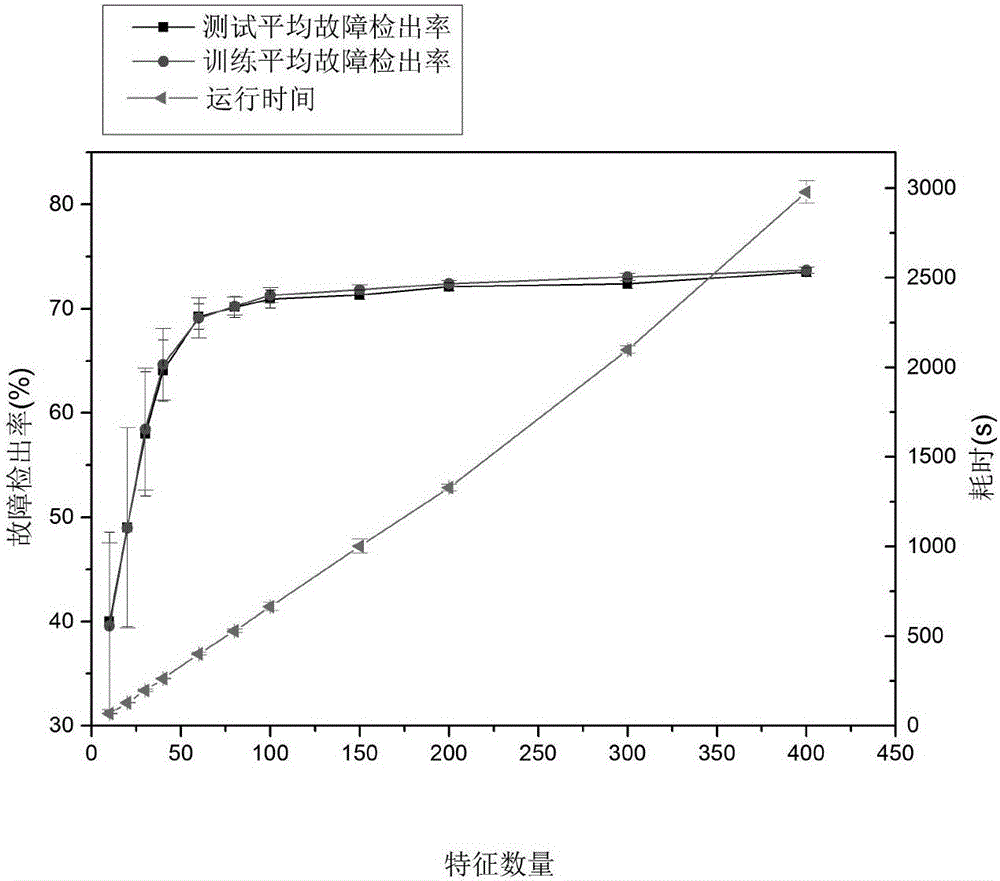

Chemical process fault detection method based on sparse filtering and logic regression

ActiveCN107436597ALabor savingShorten the timeElectric testing/monitoringAdaptive learningOriginal data

The invention discloses a chemical process fault detection method based on sparse filtering and logic regression. The method comprises steps of data acquisition and pre-processing, characteristic learning and characteristic classification, and chemical process fault detection is realized through the three steps. According to the method, firstly, the sparse filtering algorithm of depth learning is applied to chemical process characteristic learning, secondly, the learned characteristics are classified through utilizing logic regression, the characteristic learning stage utilizes monitoring-less learning, artificial data marking is not needed, characteristics of adaptive learning original data can be realized, normal data can be distinguished from each type of fault data, and application to the industry is more simple and intelligent.

Owner:SOUTH CHINA UNIV OF TECH

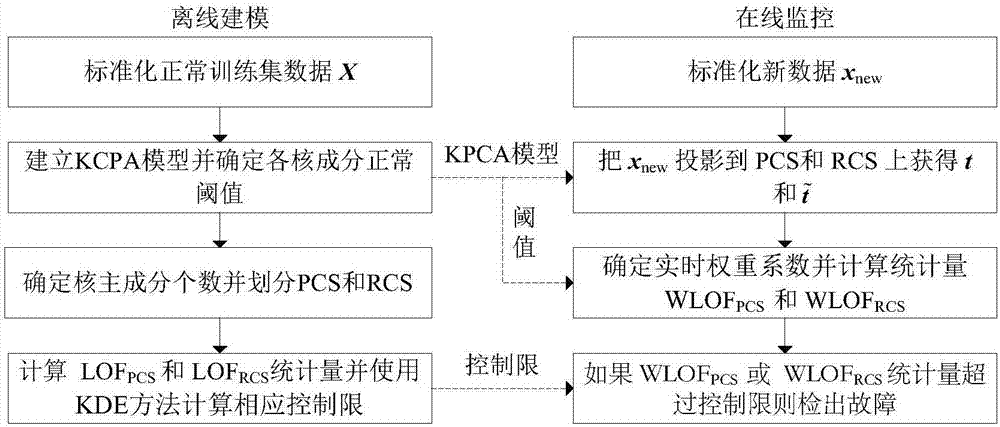

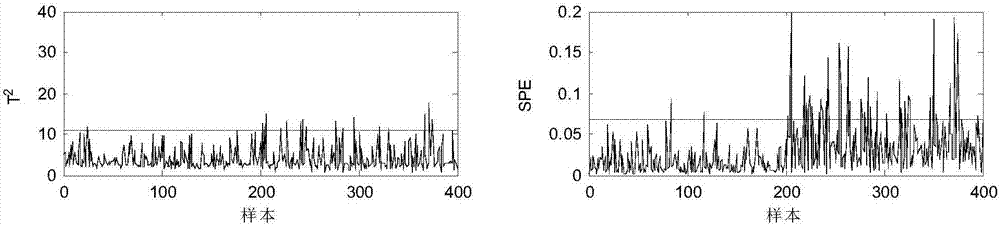

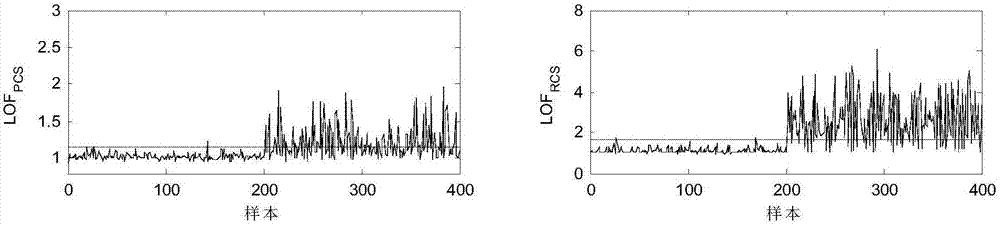

Nonlinear industrial process fault detection method based on kernel principal component analysis

ActiveCN107544477AImprove fault detection resultsImprove fault detection rateElectric testing/monitoringFault detection rateLocal outlier factor

The invention discloses a nonlinear industrial process fault detection method based on kernel principal component analysis. After conducting normalization processing on training data, a KPCA model isestablished, nonlinear features are extracted from the training data to serve as kernel components, and a normal threshold value is determined for each kernel component; a kernel principal component space (PCS) and a kernel residual error space (RCS) are divided out according to the number of the kernel principal components; a local outlier analysis algorithm is used for calculating correspondinglocal outlier value statistics LOF<PCS> and LOF<RCS>, and control limits are determined; test data is acquired, and a corresponding kernel principal component vector and a kernel residual error vectorare extracted by utilizing the KPCA model; weighting is carried out on the vectors by utilizing the normal threshold values of the kernel components, weighted local outlier value statistics WLOF<PCS>(h) and WLOF<RCS>(h) are calculated, and the control limits are used for monitoring. According to the method, a kernel component weighting technology and a local outlier factor technology are introduced into a KPCA method, nonlinear characteristic information in industrial process data can be measured accurately, and the fault detection rate is increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

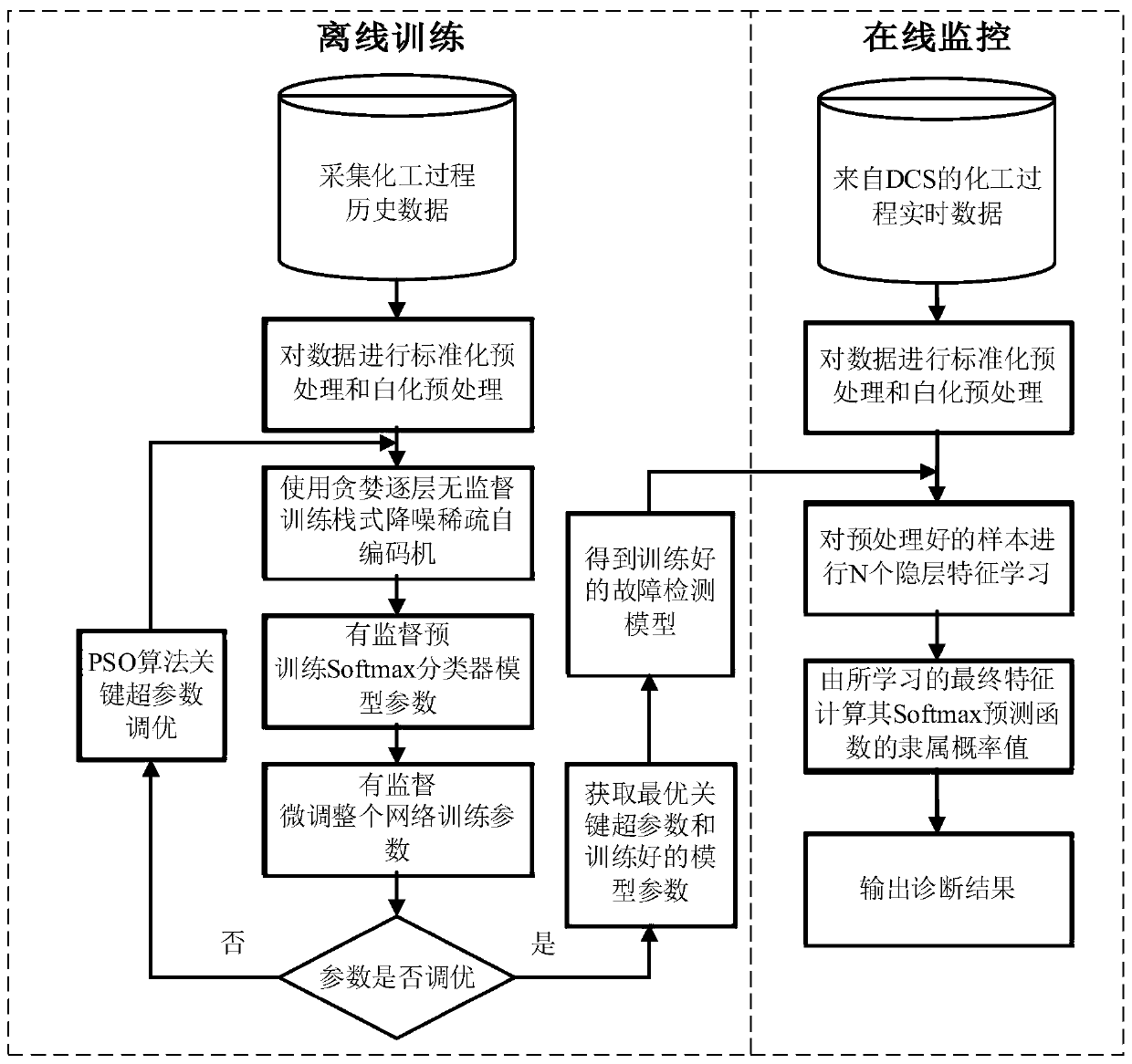

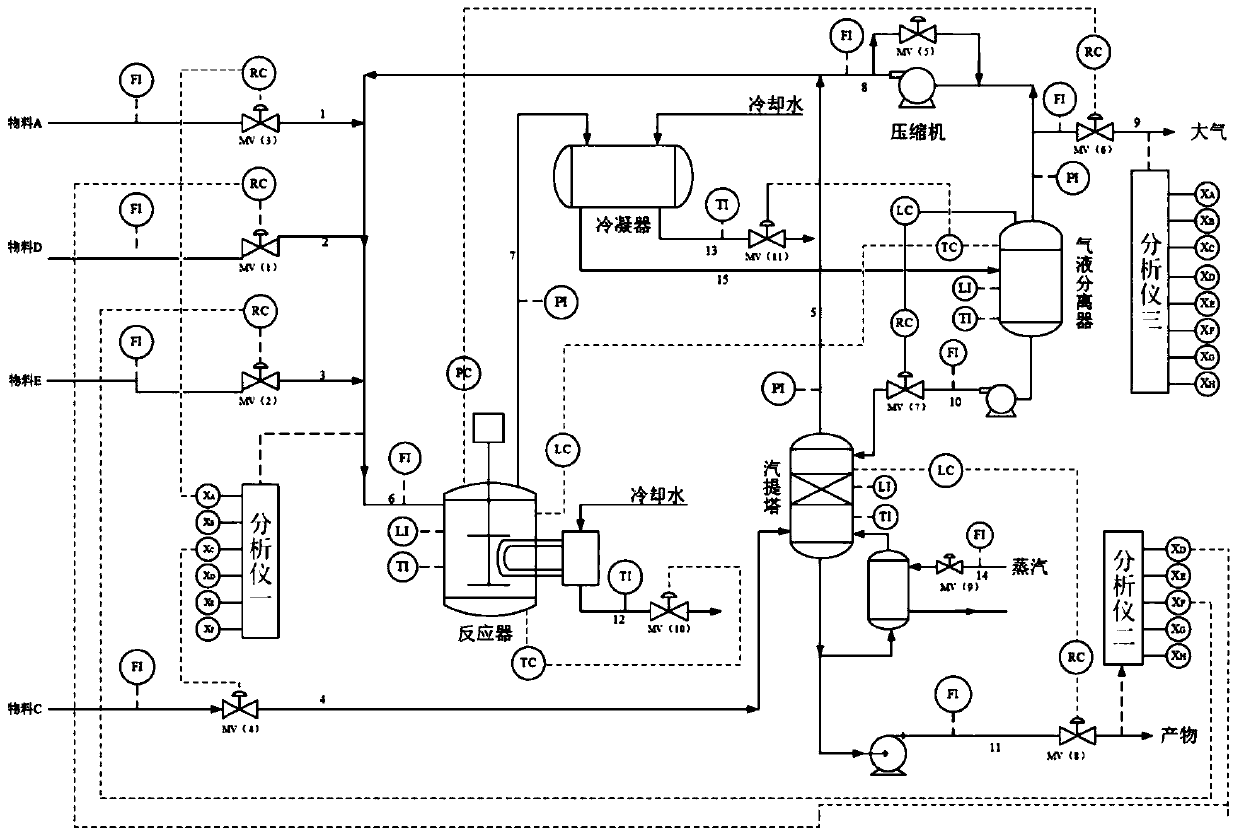

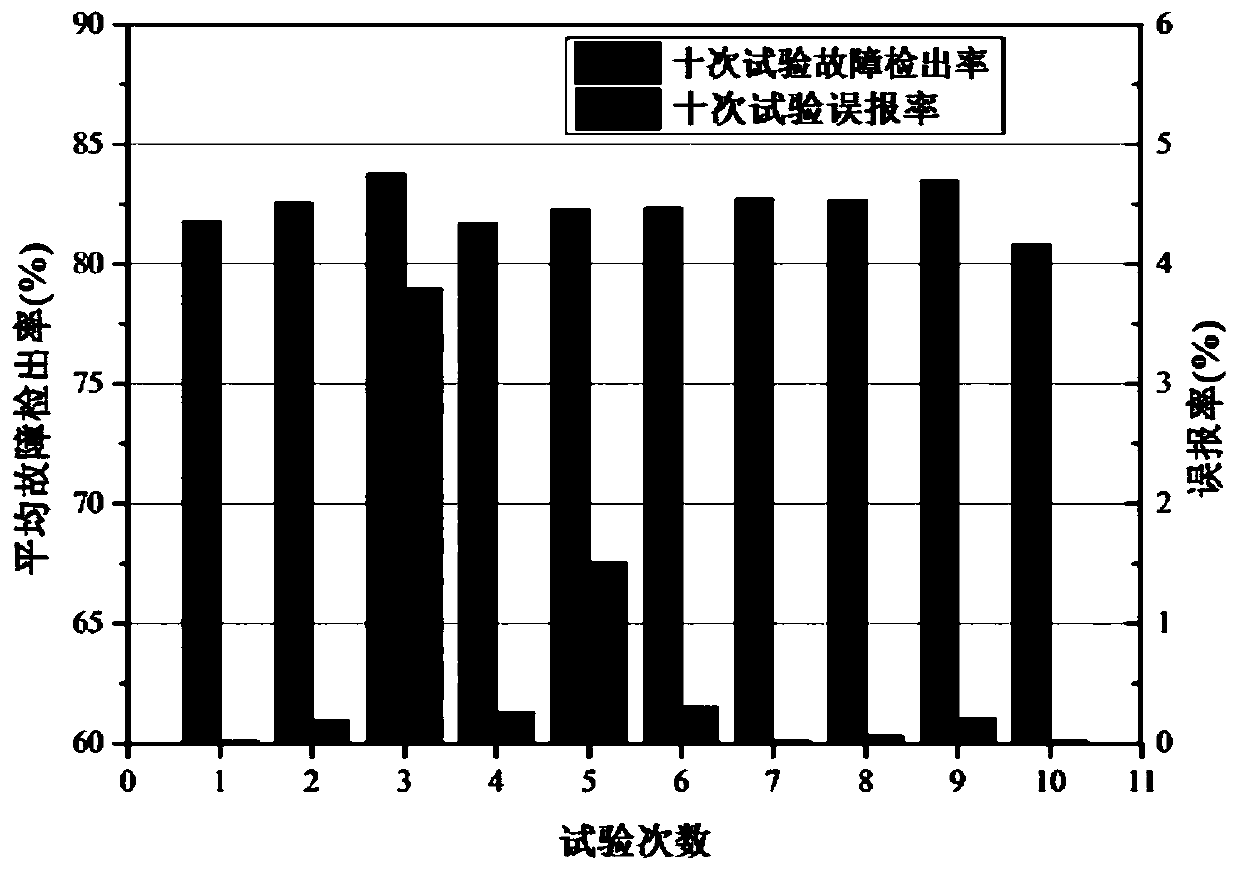

Chemical fault detection method based on particle swarm optimization and a noise reduction sparse coding machine

PendingCN109800875AGood clustering performanceSave energyCharacter and pattern recognitionNeural learning methodsChemical processSelf adaptive

The invention discloses a chemical fault detection method based on particle swarm optimization and a noise reduction sparse coding machine. The method comprises the following steps of carrying out unsupervised feature learning on standardized and whitened training data by using a plurality of stacked noise reduction sparse autocoders; carrying out Softmax classifier model training in a supervisedmanner; and finally, finely adjusting the weight parameters of the whole network through supervision, and introducing a particle swarm optimization algorithm into the key adjustable hyper-parameters for automatic optimization to obtain a trained chemical process fault detection intelligent model for fault detection of process real-time data. According to the invention, the greedy layer-by-layer training method of the deep neural network is adopted to adaptively and intelligently learn knowledge implied by original data in the chemical process; Compared with a traditional method, the method hasthe advantages that the method is more intelligent, the fault detection performance can be improved, and due to the fact that an automatic optimization algorithm is added, much time is saved comparedwith manual parameter tuning.

Owner:SOUTH CHINA UNIV OF TECH

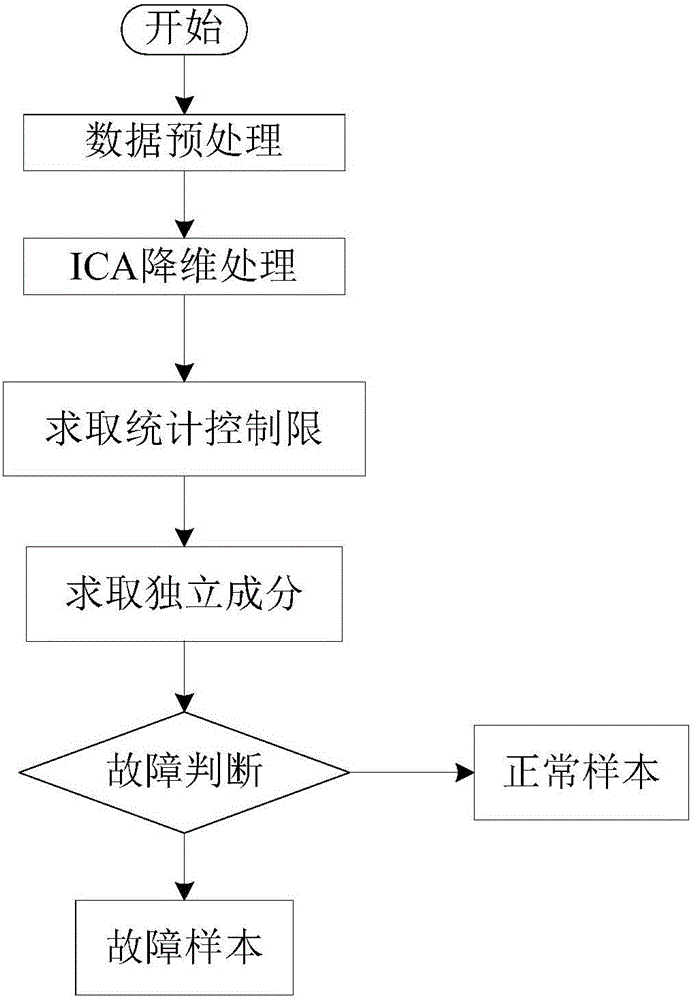

Batch process fault detecting method based on ICA-KNN

InactiveCN105739489AImprove fault detection rateReduce computational complexityElectric testing/monitoringComputation complexityData set

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

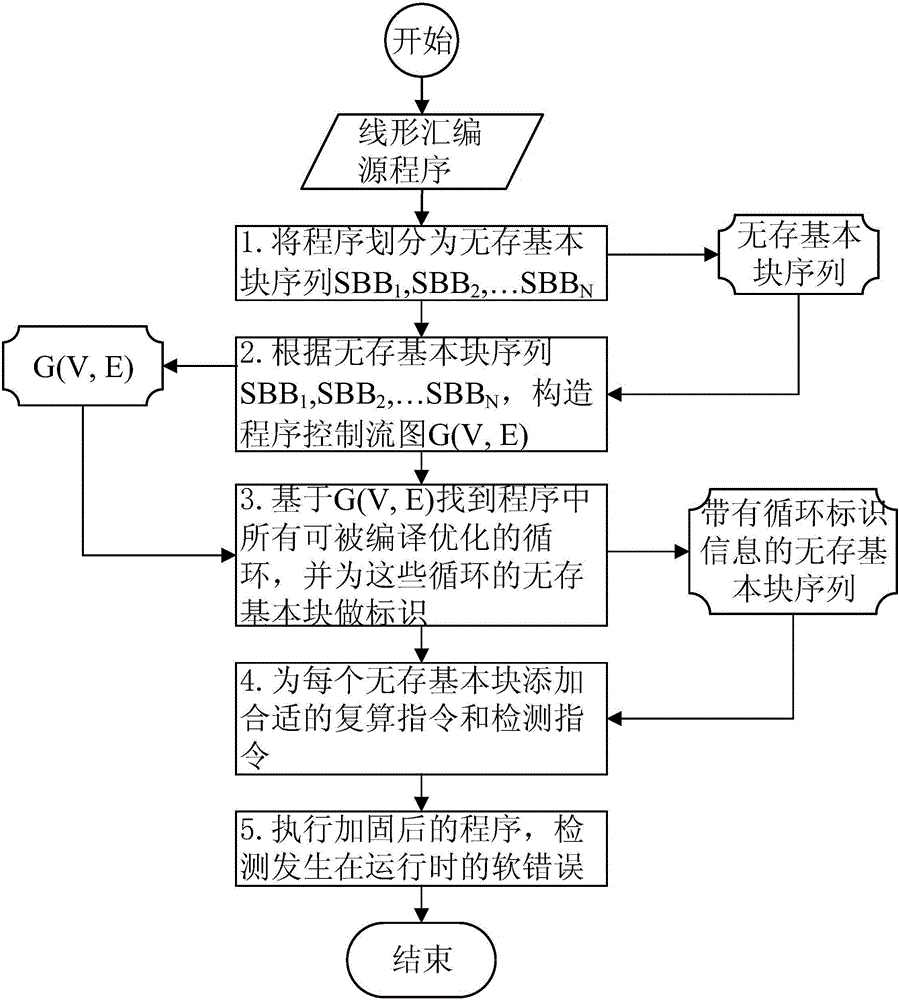

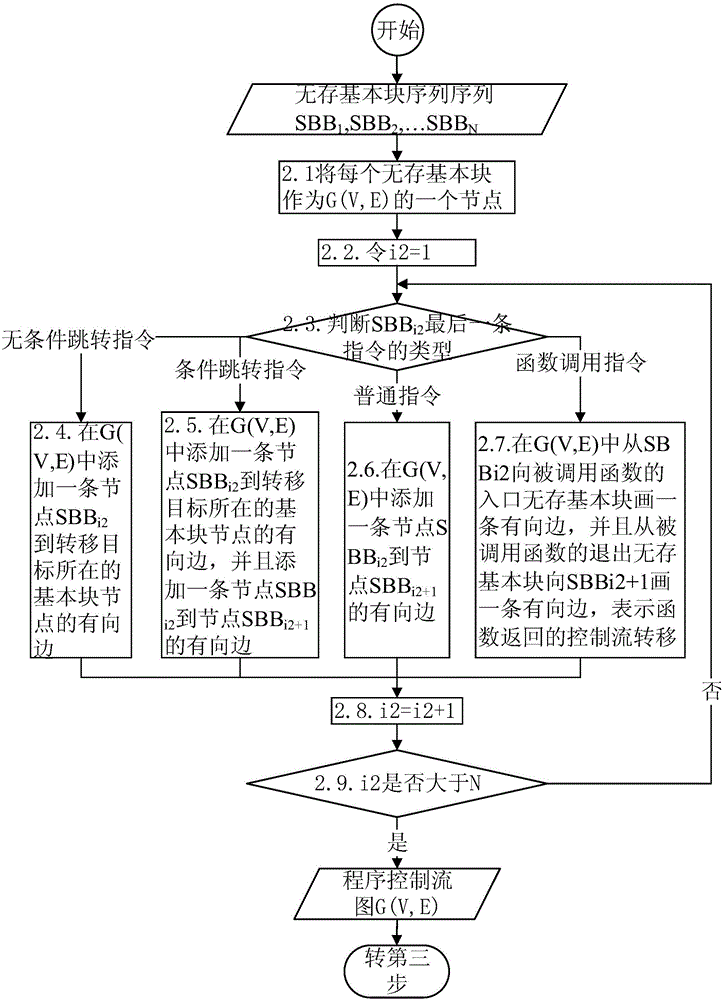

Linear assembly instruction diversity conversion based DSP soft error detection method

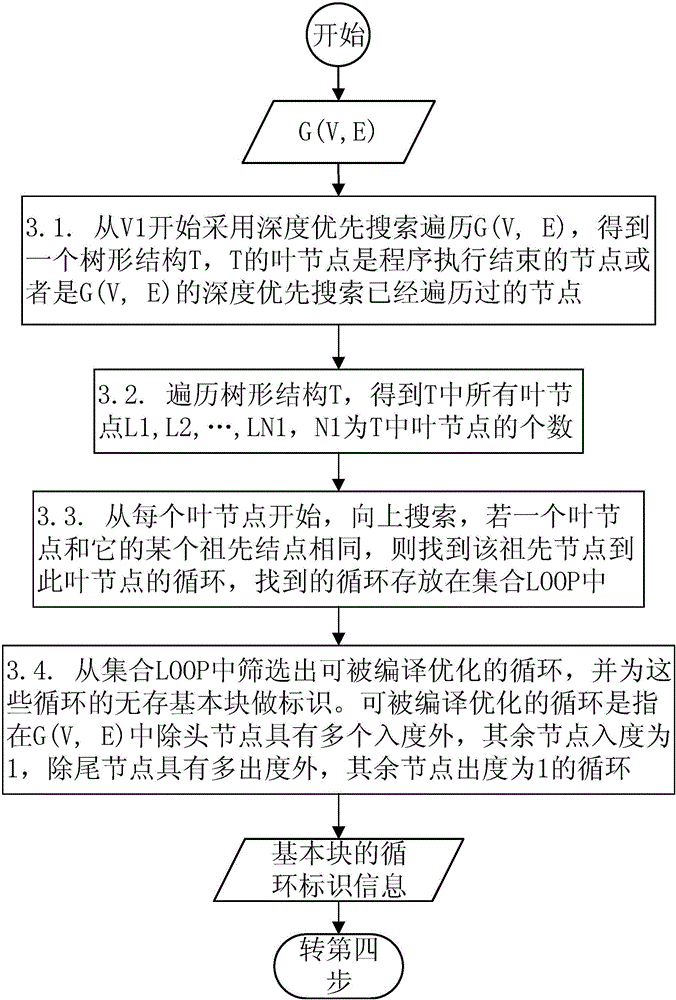

ActiveCN106021040ACapable of soft error detectionDoes not require multithreading supportFaulty hardware testing methodsSoft error detectionBasic block

The invention discloses a linear assembly instruction diversity conversion based DSP soft error detection method which can solve the problem that the conventional DSP soft error detection methods are large in performance cost. The DSP soft error detection method includes: dividing a program into storeless basic blocks, establishing a program control flow diagram, recognizing circulations, screening out circulations capable of arranging a software pipeline; reinforcing the program, adding error detection instructions to the program, performing equivalent conversion on a part of instructions through an instruction diversity conversion method, and performing double calculation on the rest instructions, inserting the detection instructions before instruction storage and instruction jumping, optimizing the detection instructions through DSP instruction condition execution characters and the equivalent conversion method, and reducing the performance cost due to reinforcement through the delay error processing method for the circulations capable of arranging the software pipeline; and executing the reinforcement program, and detecting soft errors during operation. The DSP soft error detection method is a DSP reinforcement method of pure software, is high in detection rate of date errors, and is low in performance cost of reinforcement.

Owner:NAT UNIV OF DEFENSE TECH

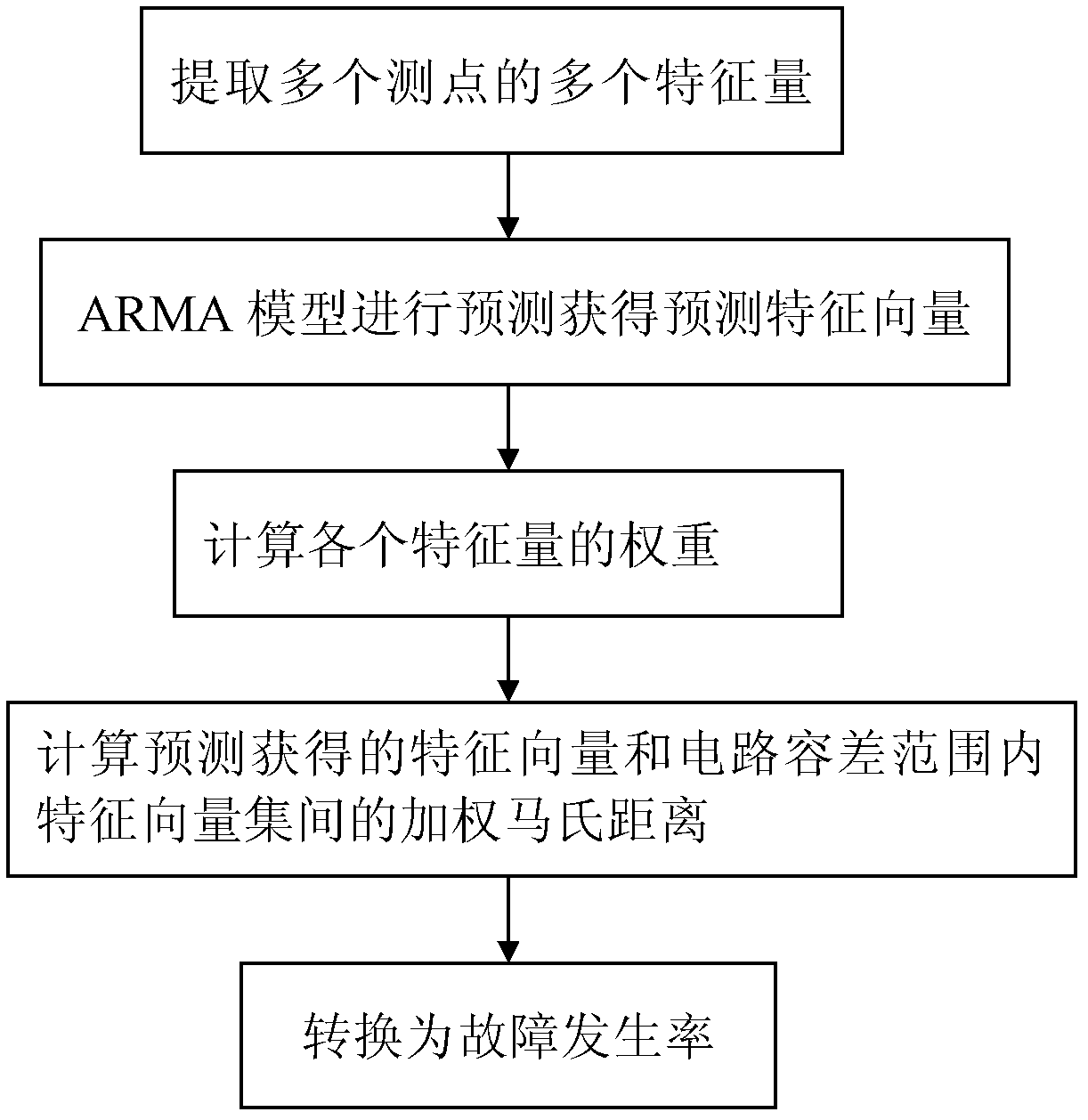

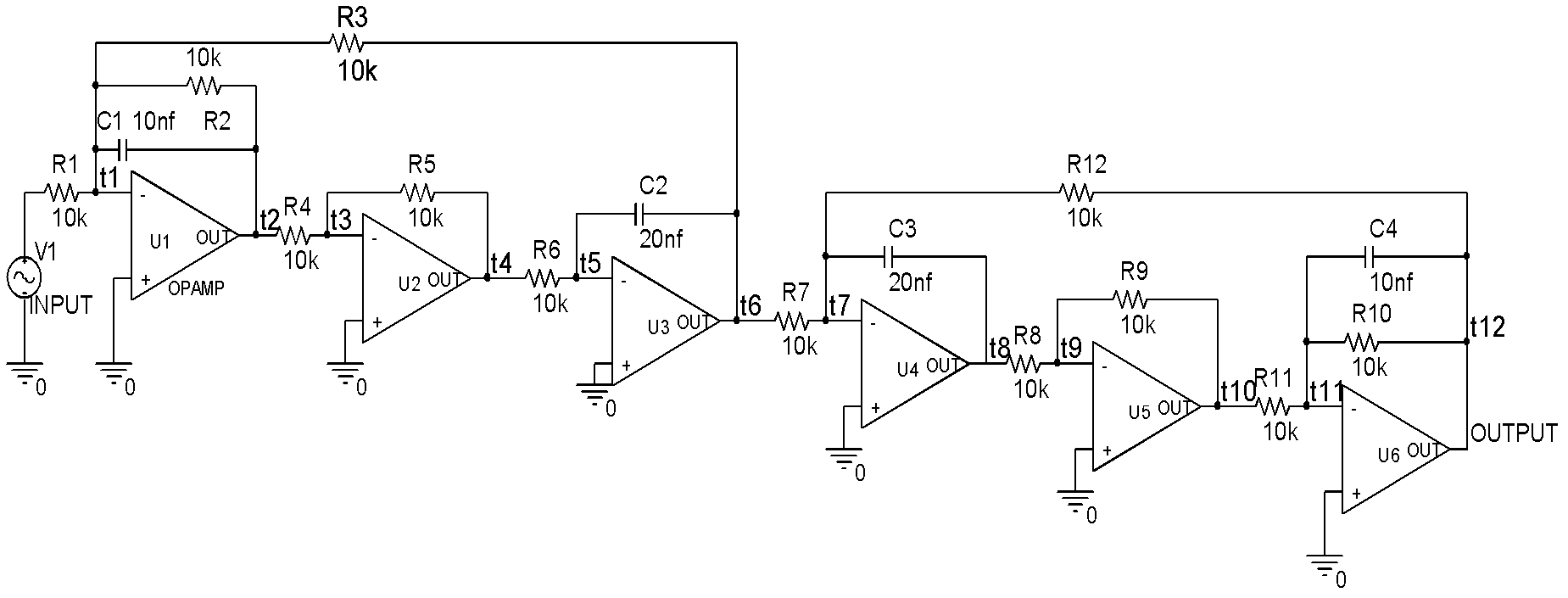

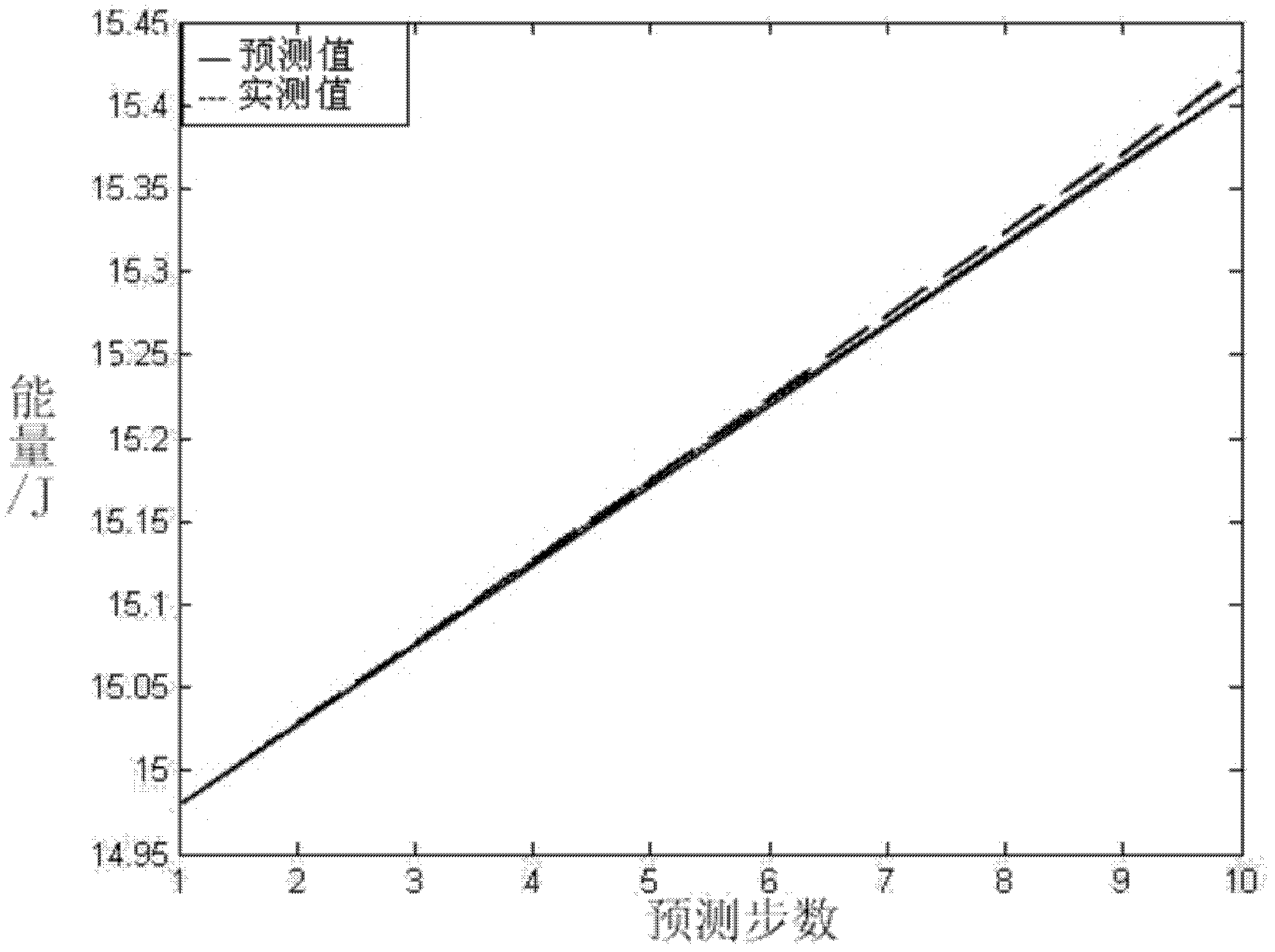

Analog circuit fault prediction method based on ARMA (Autoregressive Moving Average)

InactiveCN102222151AGood predictionImprove fault detection rateSpecial data processing applicationsFault detection rateMoving average

The invention discloses an analog circuit fault prediction method based on ARMA (Autoregressive Moving Average), which comprises the following steps: extracting a plurality of characteristic quantities of a plurality of measuring points of an analog circuit to form a characteristic vector which can characterize fault information; utilizing an ARMA model to predict the characteristic vector to obtain a predicted characteristic vector; using the weighting Mahalanobis distance to calculate the distance between the obtained characteristic vector and a characteristic vector set in a circuit fault-free tolerance range; comparing the calculated distance and the maximum value of the Mahalanobis distance in the fault-free tolerance range, and converting the deviation degree of the calculated distance and the maximum value of the Mahalanobis distance to a fault occurring rate; and more intuitively monitoring the healthy state of the analog circuit. By experiment verification, the method can be used for better predicting the health state of the analog circuit, has a high fault detection rate, and can be used for the early monitoring of the analog circuit fault well.

Owner:UNIV OF ELECTRONIC SCI & TECH OF CHINA

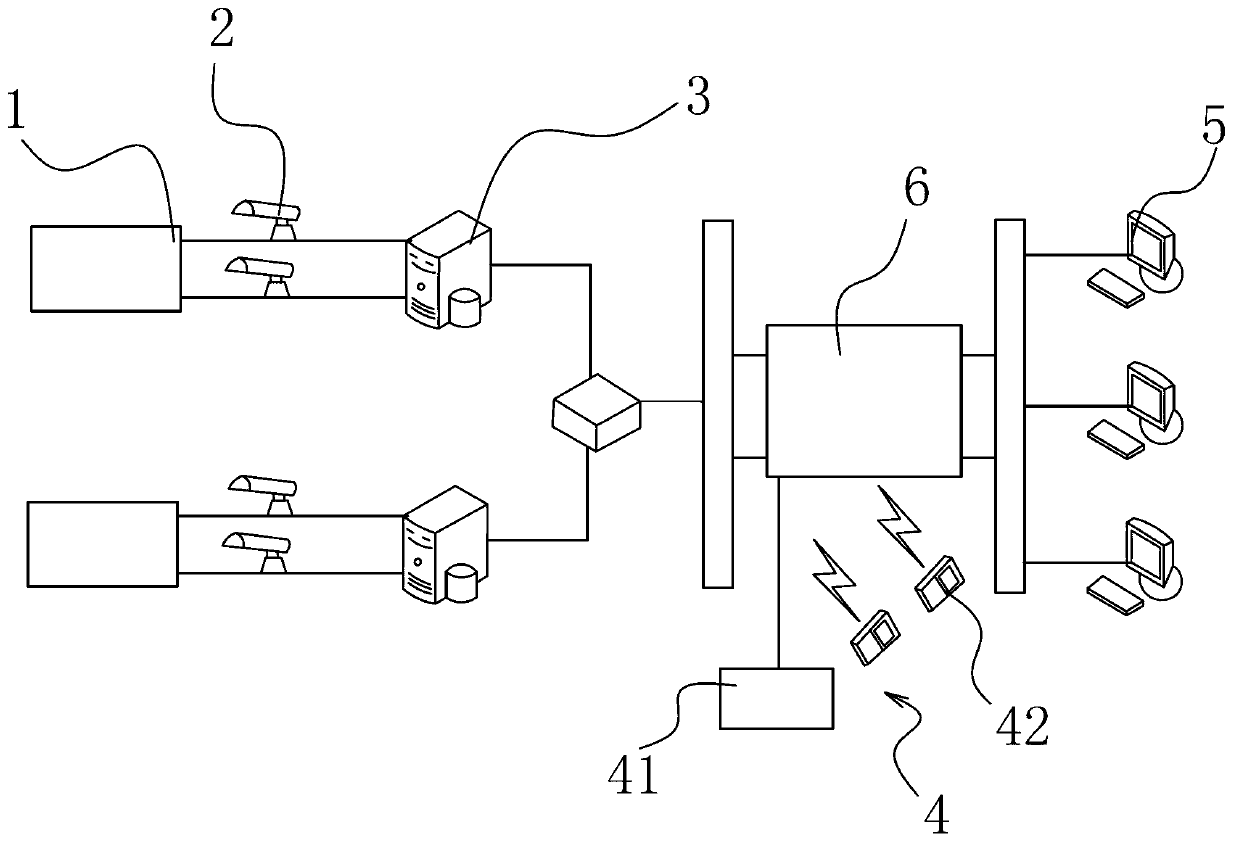

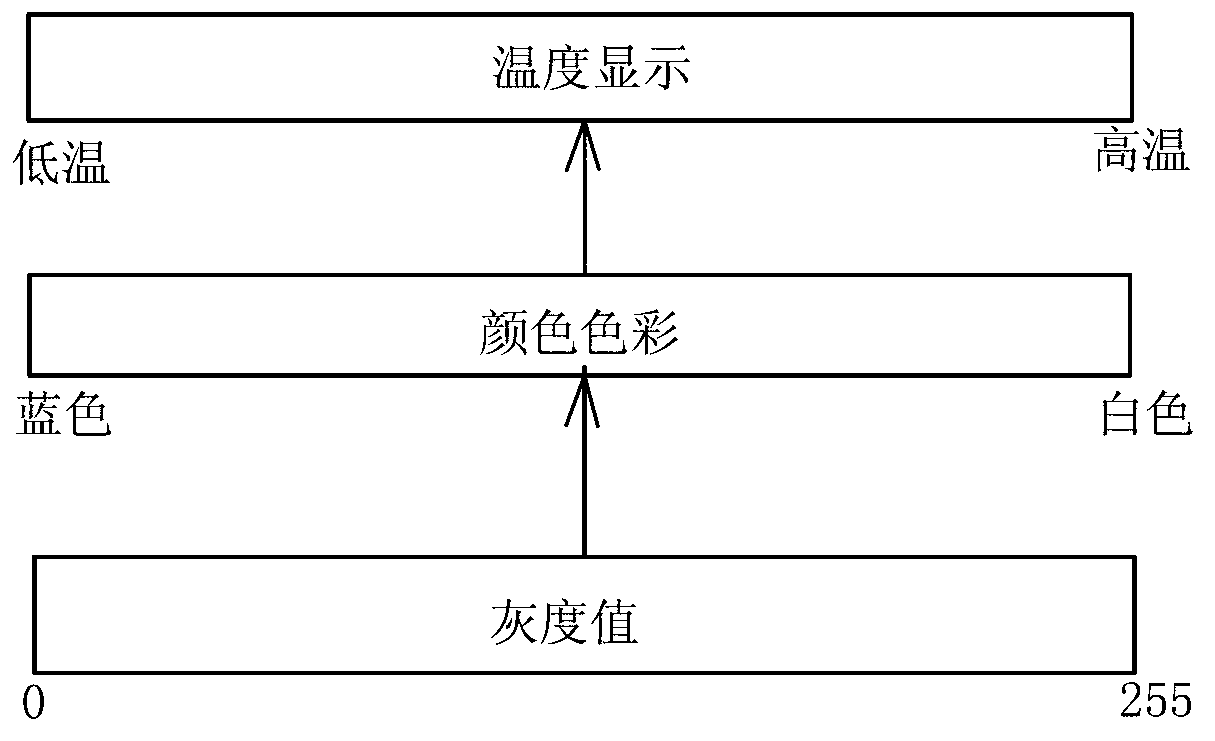

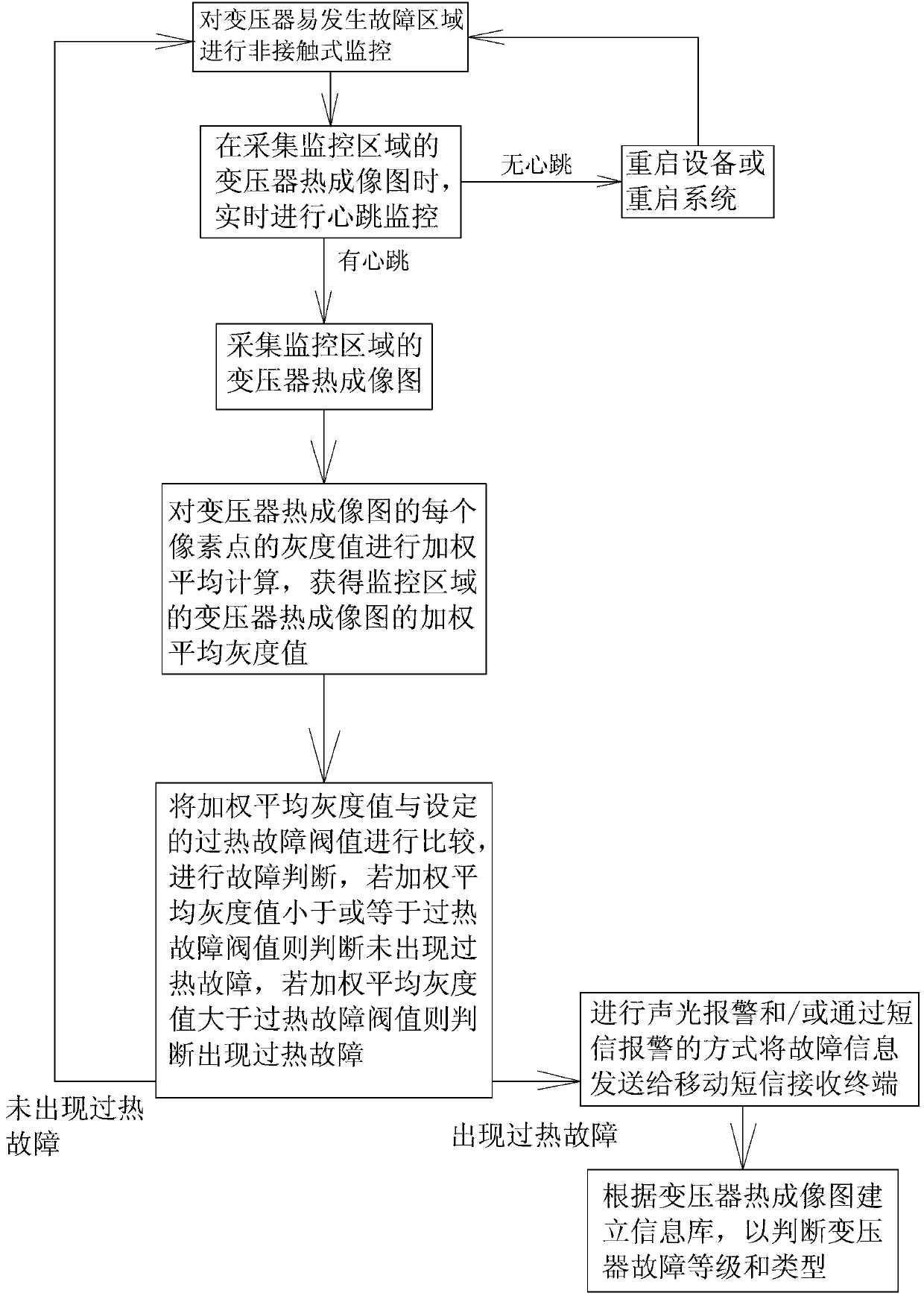

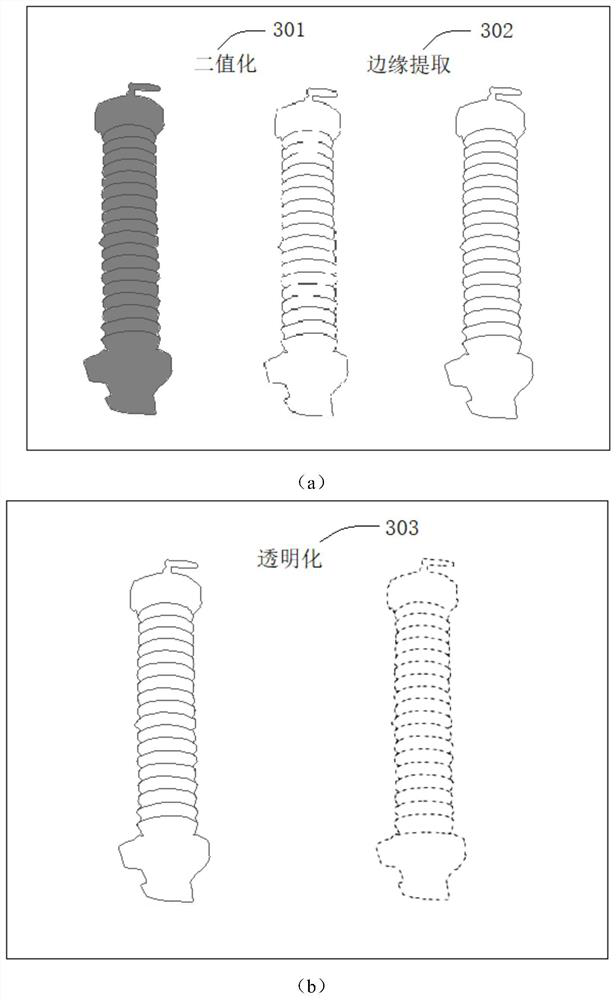

Monitoring method and monitoring system for overheat fault of transformer

InactiveCN103278244AAvoid slow recognitionRapid diagnosisRadiation pyrometryCircuit arrangementsSystems designTransformer

The invention belongs to the technical field of electrical equipment monitoring and relates to a monitoring method and a monitoring system for an overheat fault of a transformer. The technical problems that traditional monitoring methods and monitoring systems in the prior art are not reasonable enough and the like are solved by the invention. The monitoring system comprises the following steps: A, thermal image acquisition; B, image recognition processing; and C, fault diagnosis and processing. The monitoring method and the monitoring system for the overheat fault of the transformer have the advantages that acquired image information is recognized by adopting a non-contact monitoring mode to realize fast recognition and diagnose of the part, the degree the type of the early potential fault of the transformer. The monitoring method and the monitoring system for the overheat fault of the transformer have the characteristics that the safety, the reliability and the efficiency are high. Meanwhile, by utilizing the non-contact monitoring mode, a condition is provided for realizing all-weather state monitoring on the transformer on the premise that the operation of the transformer is not influenced, and therefore, the safe, stable and reliable operation of equipment is ensured, the maintenance level of the transformer is comprehensively promoted, and the maintenance cost is reduced. The system is reasonable in design, simple in structure, good in working stability and high in fault detection rate.

Owner:苏州求臻智能科技有限公司

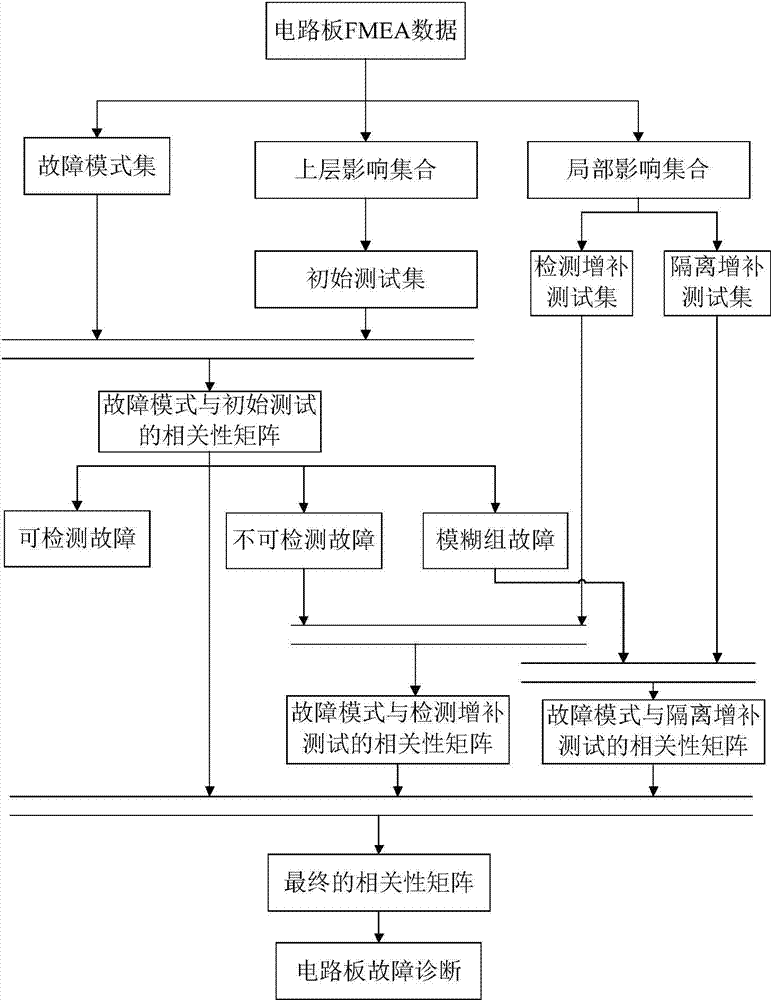

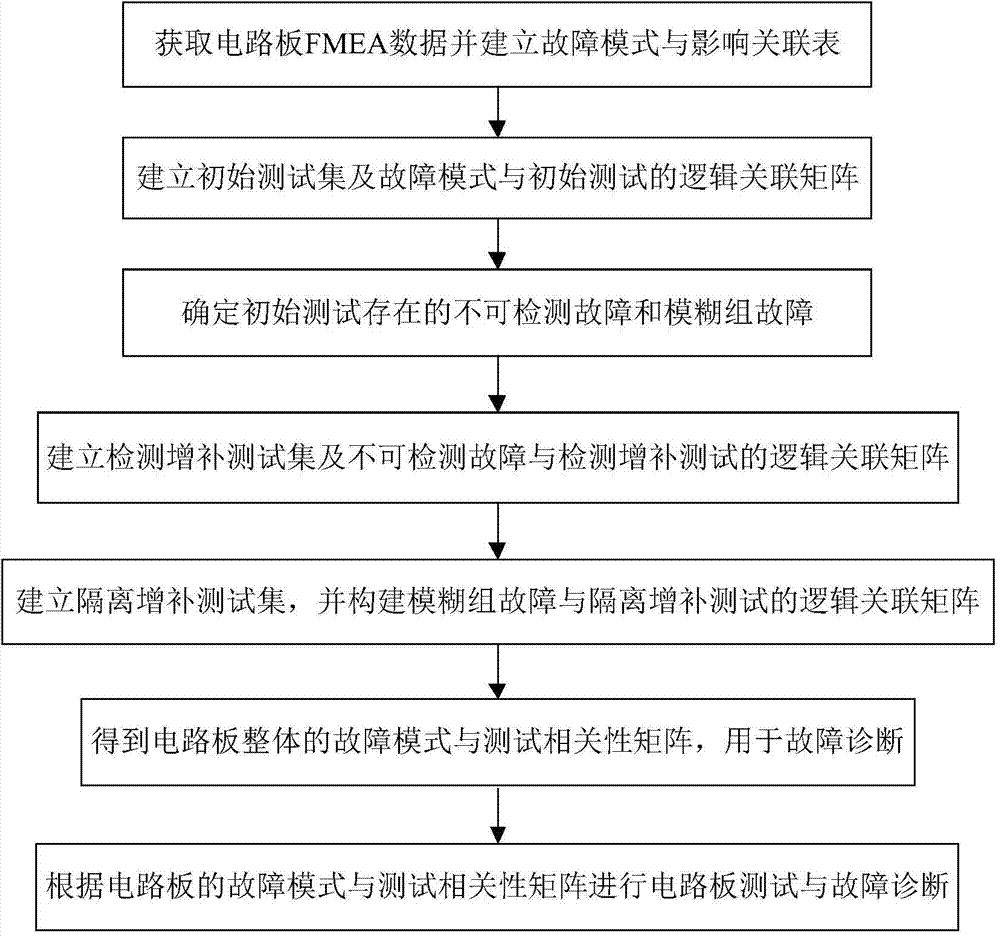

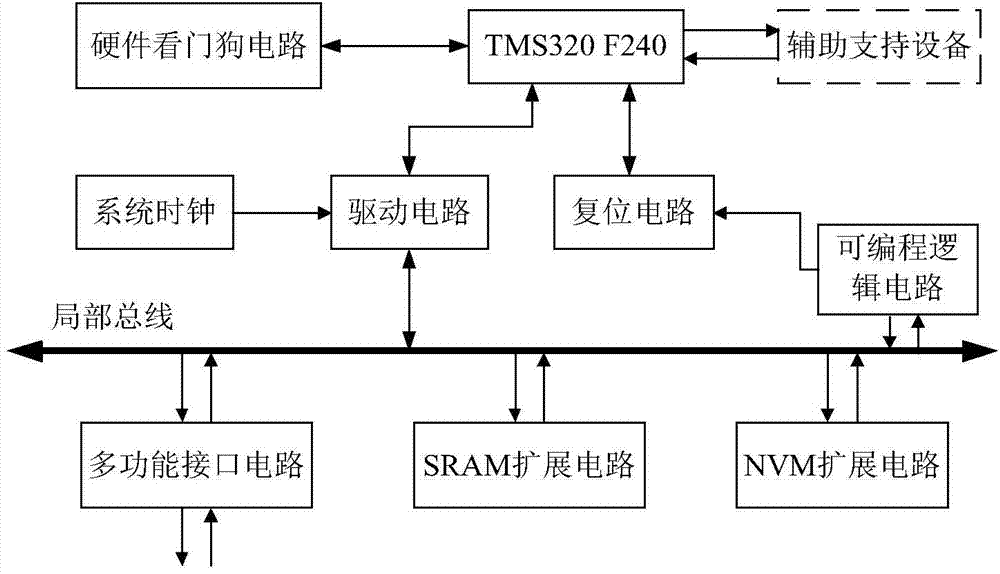

Circuit board test design and relevant matrix establishing method based on fault effect data in FMEA

ActiveCN103792486AImprove fault detection rateAvoid analysis procedures and the use of specialized toolsElectronic circuit testingSpecial data processing applicationsFailure diagnosisTest design

The invention discloses a circuit board test design and relevant matrix establishing method based on fault effect data in FMEA for the fault diagnosis field. The method includes the steps of establishing a fault mode and effect association table through FMEA data of a circuit board, establishing a logical association matrix of an initial test set and an initial test and a logical association matrix of fault modes and the initial test according to the upper layer effect, determining faults which can not be detected and ambiguity group faults in the initial test, establishing a detection supplement test set and an isolation supplement test set according to local effect of the faults which can not be detected and the ambiguity group faults, setting up a logical association matrix of the faults which can not be detected and the ambiguity group faults and a logical association matrix of the ambiguity group faults and an isolation supplement test, conducting combination and arrangement to obtain a circuit board integrity test set and a circuit board fault mode and test relevant matrix so as to conduct circuit board tests and fault diagnosis. By means of the circuit board test design and relevant matrix establishing method, the highest fault detect rate is ensured, test points which can be easily measured are selected preferentially, and fault diagnosis on the circuit board can be conveniently and rapidly conducted.

Owner:BEIHANG UNIV

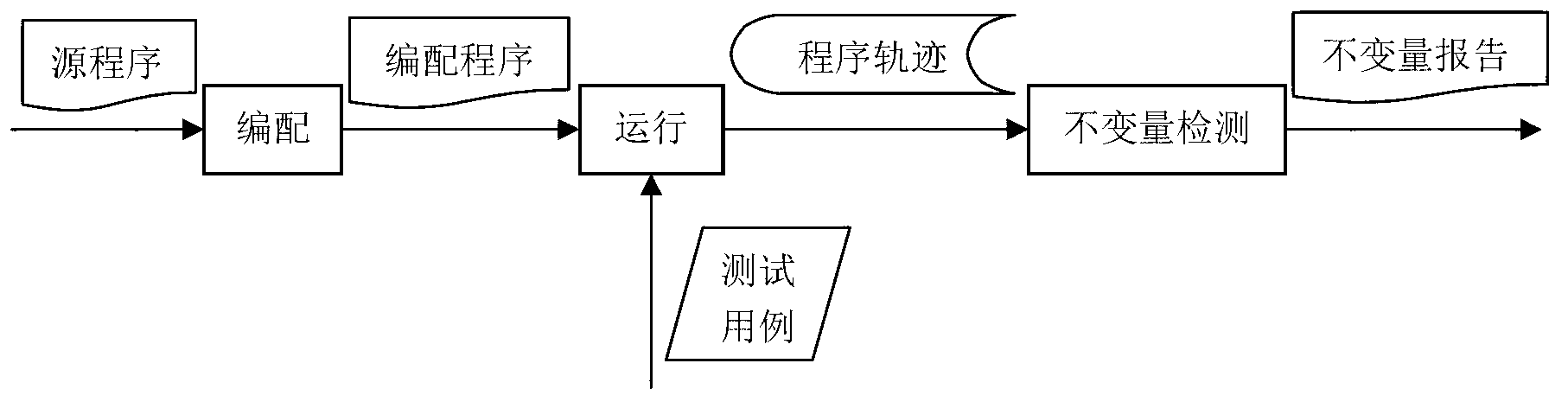

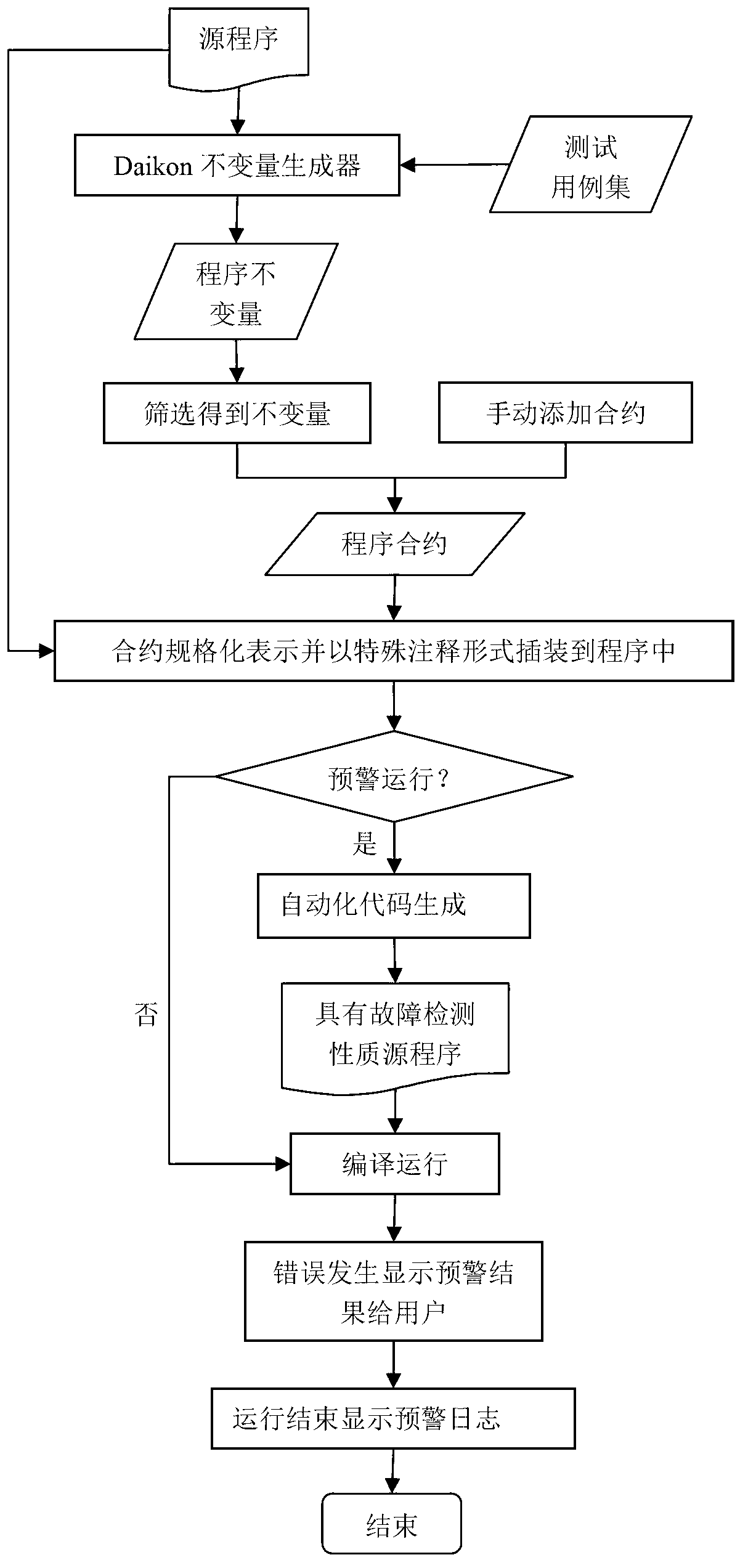

Early warning method for contract-type software fault based on program invariants

ActiveCN103294596ASolve contract formulation difficultiesEffective early warningHardware monitoringSoftware testing/debuggingTheoretical computer scienceSoftware fault

An early warning method for contract-type software fault based on program invariants includes 1), generating the program invariants for programs in need of early warnings by a Daikon tool, operating source programs to generate invariants on the Daikon tool according to a test case suite, and outputting the program invariants; 2), screening the invariants; 3), manually generating a data contract composed of Boolean assertions; 4), signifying the contracts acquired from the step 2) and the step 3) in a normalized manner, and inserting the contracts signified in the normalized manner into relevant positions of the source programs by annotations; 5), converting the annotations inserted into the relevant positions in the step 4) to codes with a fault detection function, and inserting the codes into corresponding target positions of the source programs; 6), operating the source programs processed from the step 1) to the step 5), if a program contract is violated during program operation, the codes with the fault detection function can automatically display monitored faults to users.

Owner:XIDIAN UNIV

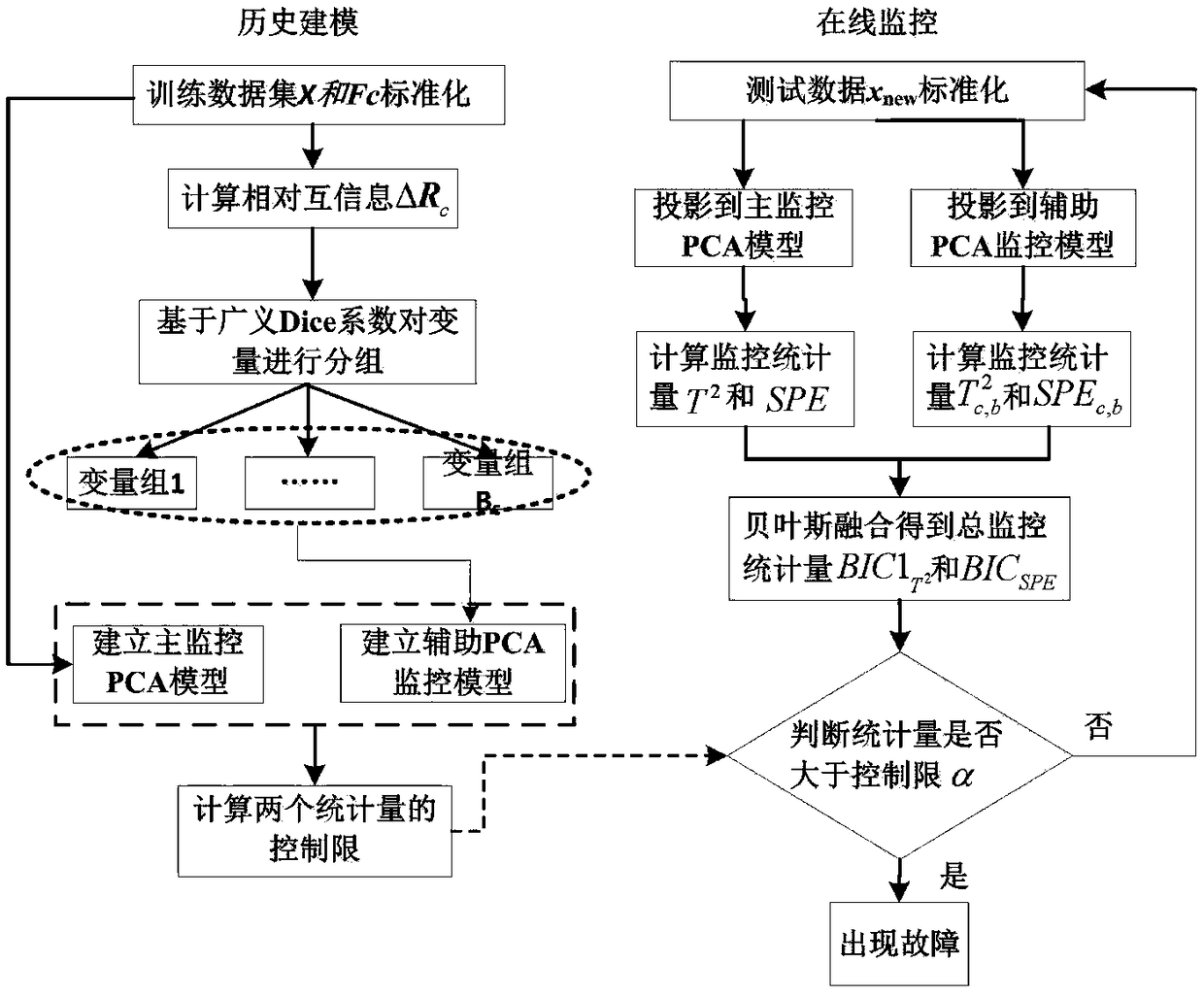

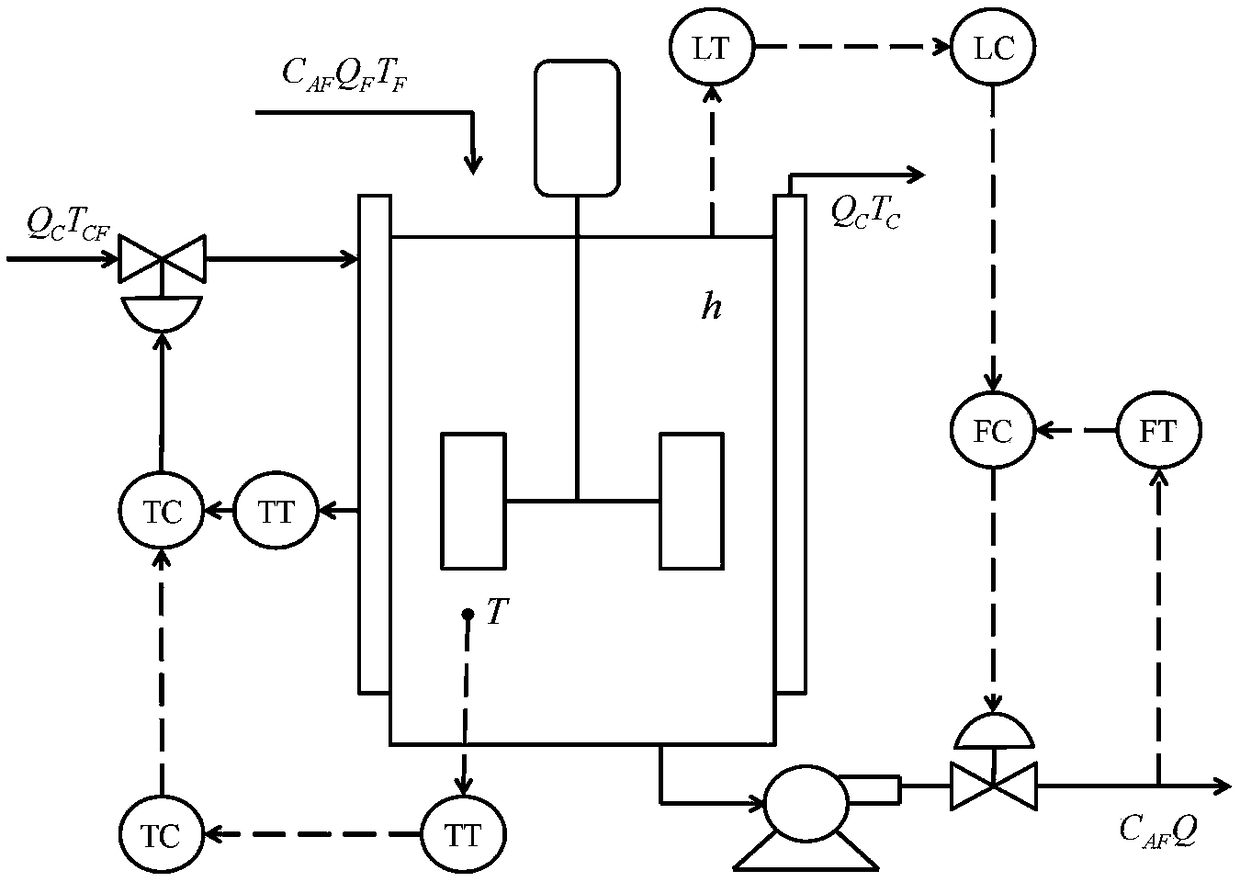

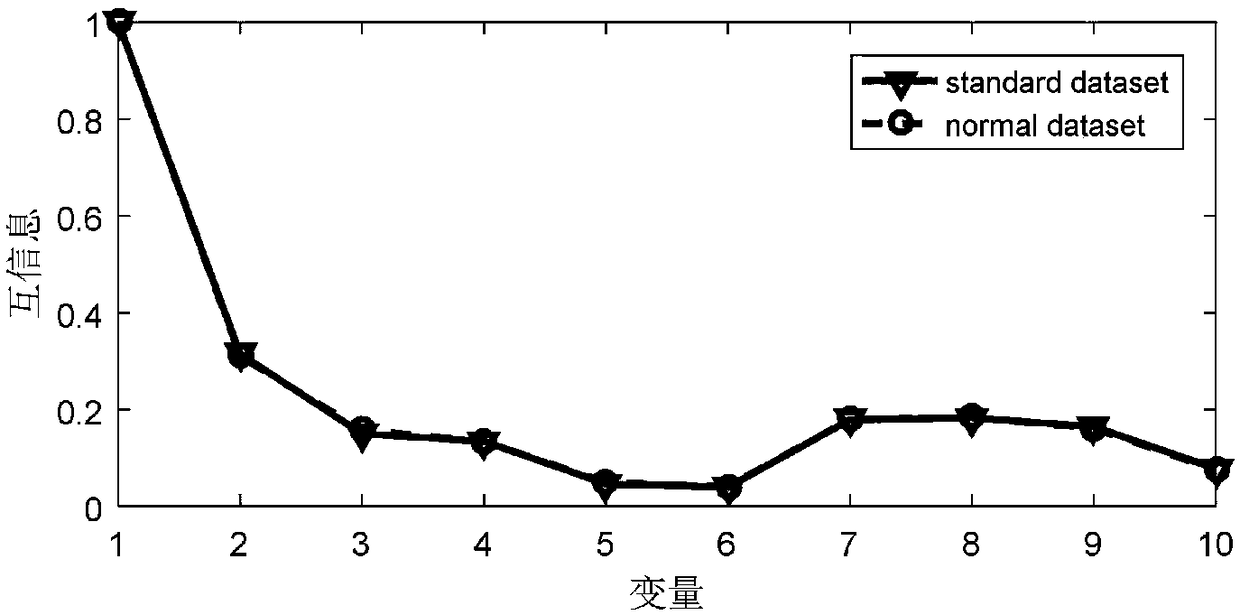

Multi-variable industrial process fault detection method based on primary assisted PCA model

ActiveCN109407652AAvoid wastingAvoid missingProgramme controlElectric testing/monitoringData setFault detection rate

The invention relates to a multi-variable industrial process fault detection method based on a primary assisted PCA model. The method comprises standardizing a normal data set and a prior fault data set; establishing a PCA model as a master monitoring model for the normal data set; calculating the relative mutual information of the prior fault and the normal data; grouping variables by virtue of generalized Dice; establishing a PCA model as an auxiliary monitoring model for a grouped data set; standardizing the test data set; projecting the test data set onto the master monitoring model and the auxiliary monitoring model separately; calculating the statistics of the test data set projected onto the master monitoring model and the auxiliary monitoring model; integrating the variable group information by using a Bayesian theory to obtain the total monitoring statistics; and determining whether the test data set has a fault according to whether the monitoring statistics exceed a control limit. The method not only reduces the omission and waste of some important prior fault information, but also mines the variable local information by variable grouping so as to improve a fault detection rate and improves fault detection performance.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

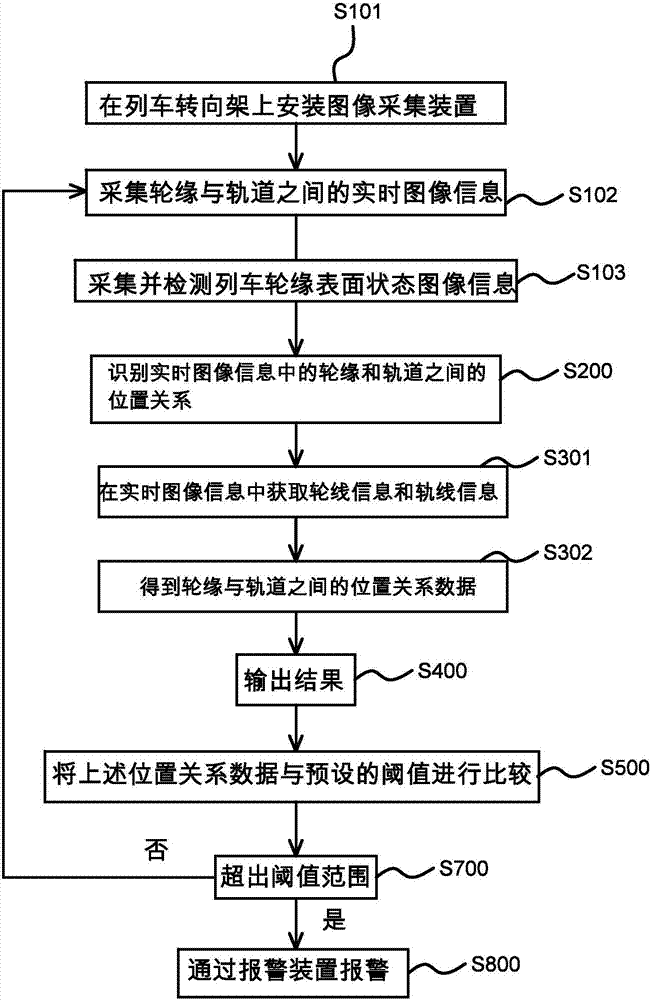

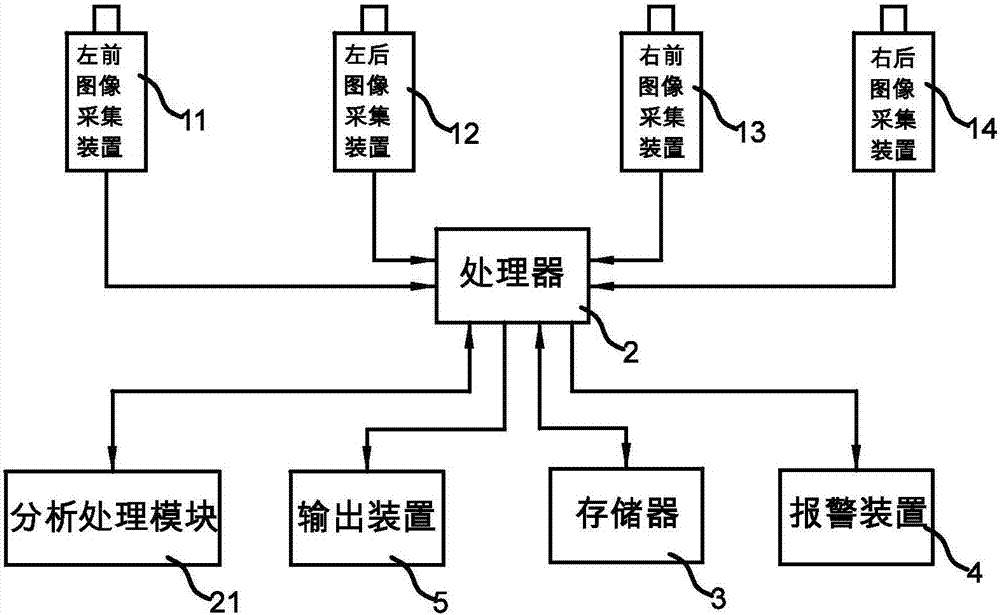

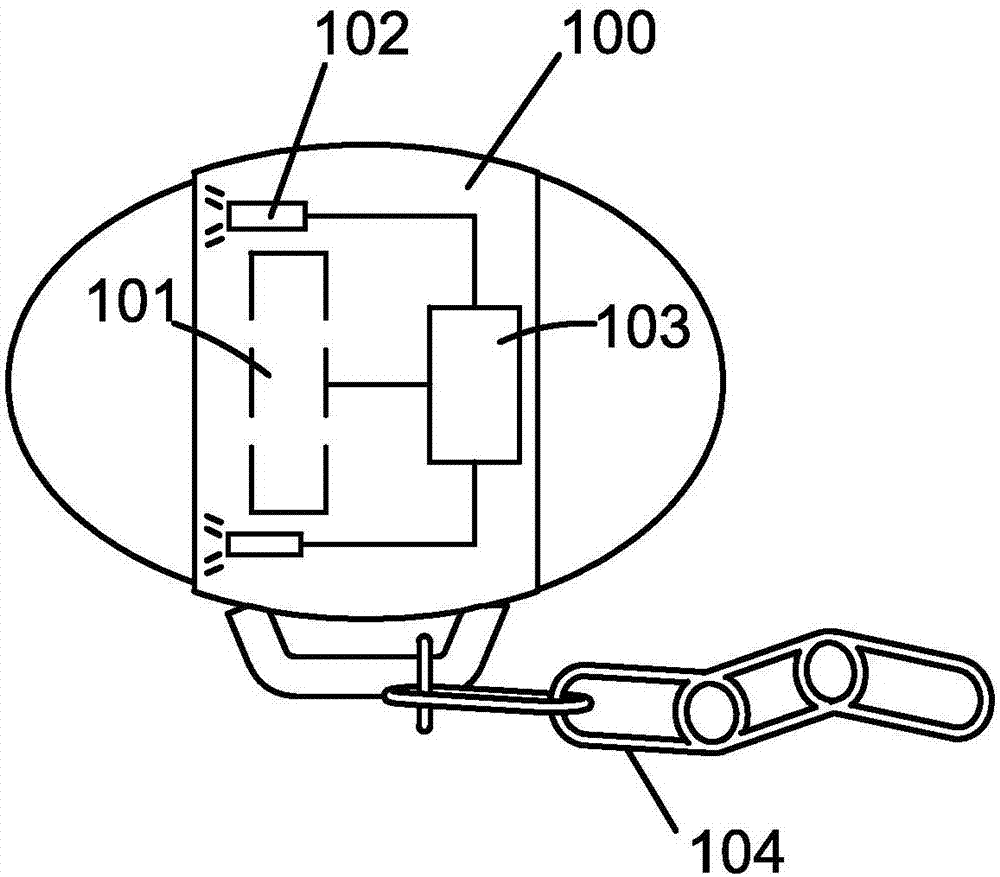

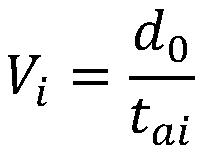

Train wheel-rail state detection system and method

PendingCN107399340AGuaranteed safe operationReal-time monitoring of cooperation statusVehicle route interaction devicesRailway vehicle testingBogieFault detection rate

The invention relates to a train wheel-rail state detection system and method. Image acquisition devices are arranged on the left side and the right side of a train bogie respectively, and image information between a left wheel flange and a left rail and between a right wheel flange and a right rail of a train is acquired in real time; the left wheel flange, the right wheel flange, the left rail and the right rail in the real-time image information are recognized through a processor, and the position relation between the wheel flanges and the rails is calculated according to the real-time image information; the position relation between the wheel flanges and the rails is output through an output device. By means of the system and method, the matching state between the wheel flanges and the rails of the train can be monitored in real time, the operation abnormity can be found in time, the fault detection rate is increased, and the safe operation of the train is guaranteed.

Owner:SUZHOU NEW VISION SCI & TECH

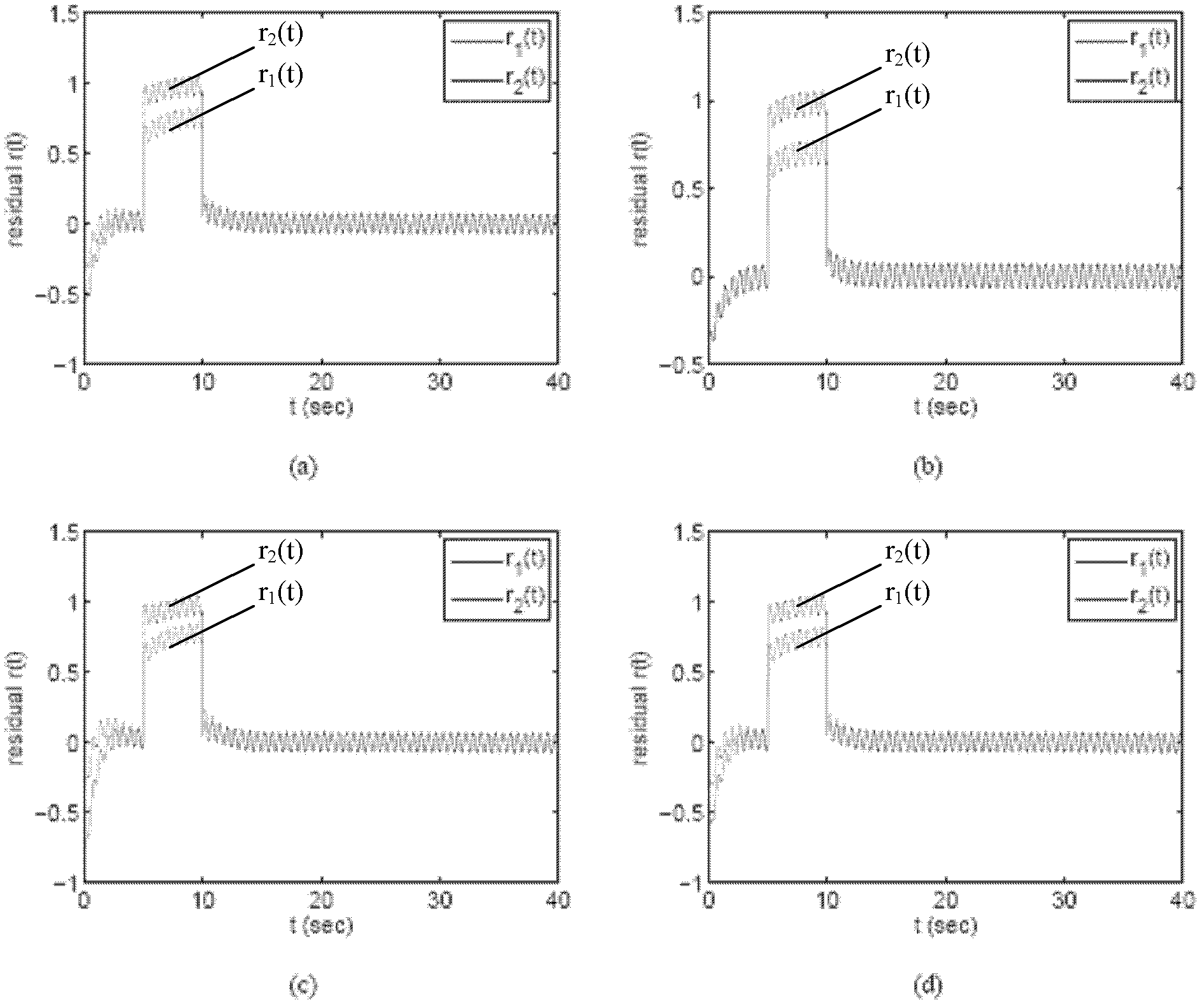

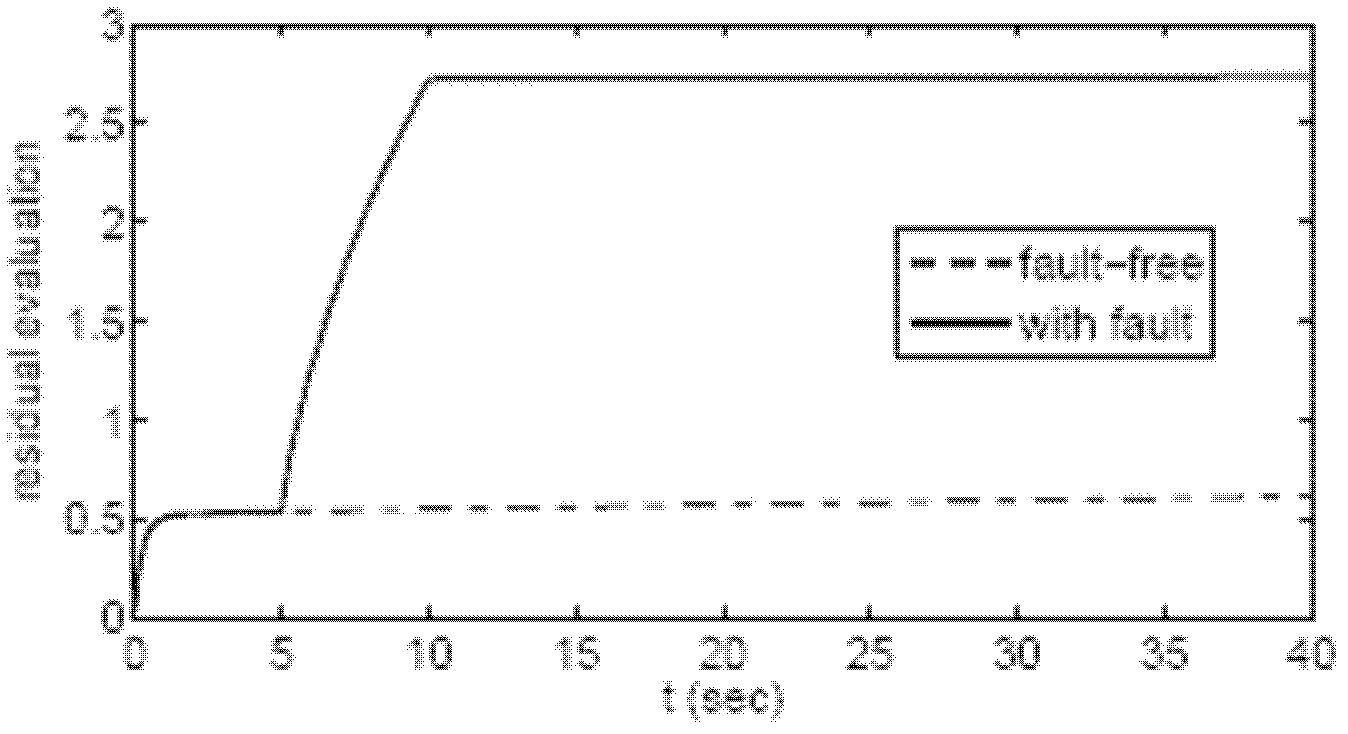

Design method for robust fault detection filter (RFDF)

InactiveCN102436180AReduce conservatismImprove fault detection rateTesting/monitoring control systemsAdaptive controlUltrasound attenuationRobust analysis

The invention belongs to the field of control, and provides a design method for a robust fault detection filter (RFDF) on the basis of a parameter-dependent Liapunov function method. A PDLF method is introduced into robust fault detection of a linear time-constant system with convex polyhedron non-determinacy. During processing of the RFDF design, the problem is distinguishing faults and other interference, which is remarkably different from robust analysis and control. An H_ / H infinite normal form is adopted, which comprises two phases: (1) an optimal RFDF design method of a residual error generator with certain interference attenuation and maximum fault sensitivity, and (2) a method for designing a threshold value for a residual error generated by estimation.

Owner:CHINA ELECTRIC POWER RES INST +1

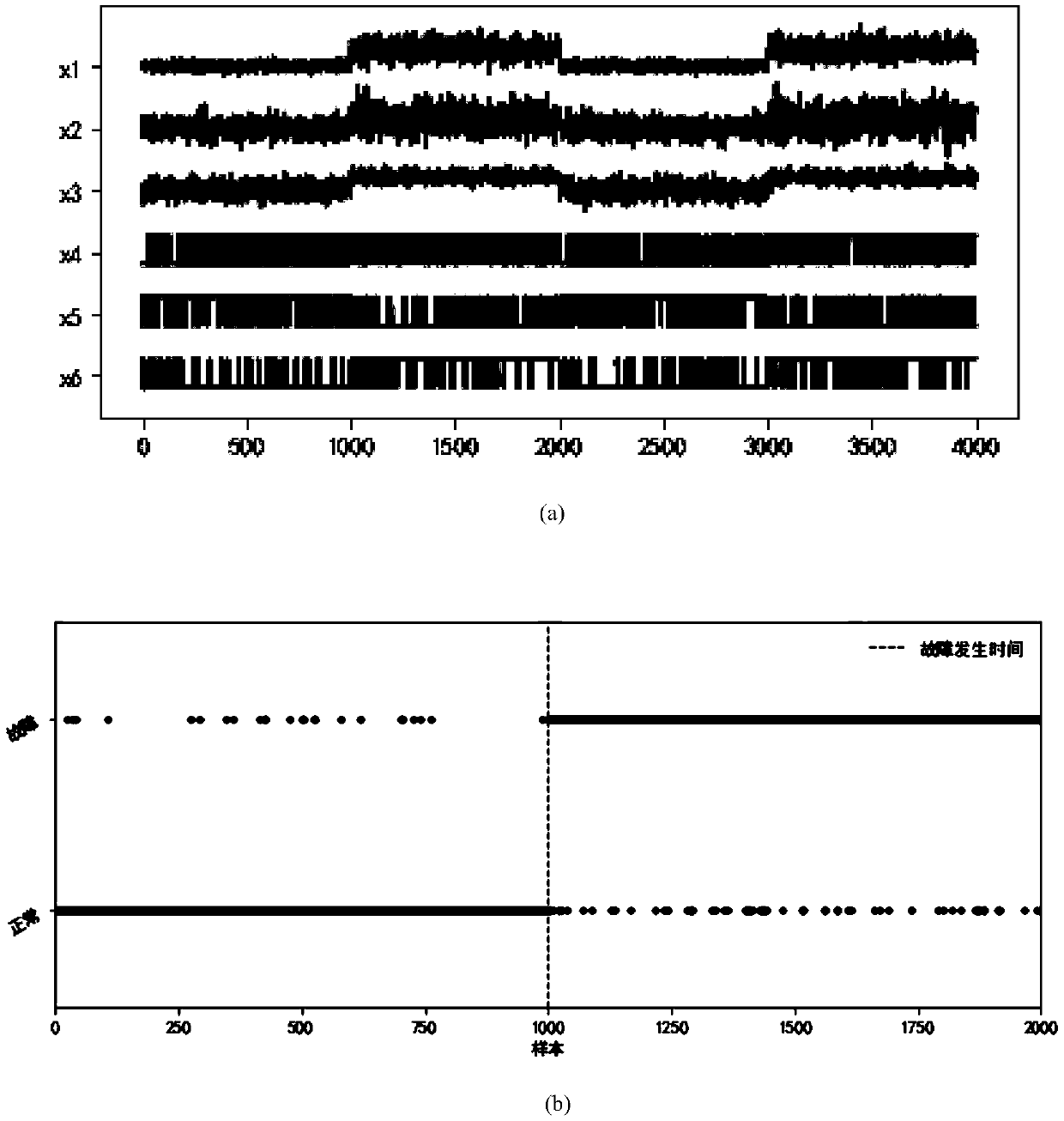

Method for detecting intermittent faults in industrial process

ActiveCN109739214ARealize detectionImprove fault detection rateElectric testing/monitoringSliding time windowPrincipal component analysis

The invention relates to a method for detecting intermittent faults in an industrial process. The method comprises the steps of: establishing a canonical variate analysis model according to data in anormal working condition in the industrial process to obtain canonical variates and divide to form two parts consisting of a state space and a residual space, introducing a sliding time window to establish a principal component analysis model for average data matrixes of the state space and the residual space, giving a significance level, calculating the control limit of fault detection indexes, collecting real-time data of the industrial process as test data, employing the established principal component analysis model to calculate the fault detection indexes of the test data, and comparing the fault detection indexes of the test data with the control limit to determine whether faults are generated or not. Based on the traditional canonical variate analysis (CVA), the sliding time windowis introduced to provide a new fault detection index to perform averaging of the data of the state space and the residual space to make the fault detection index more sensitive for faults so as to timely and effectively achieve detection of intermittent faults, effectively improve the fault detection rate and reduce the false alarm rate.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA) +1

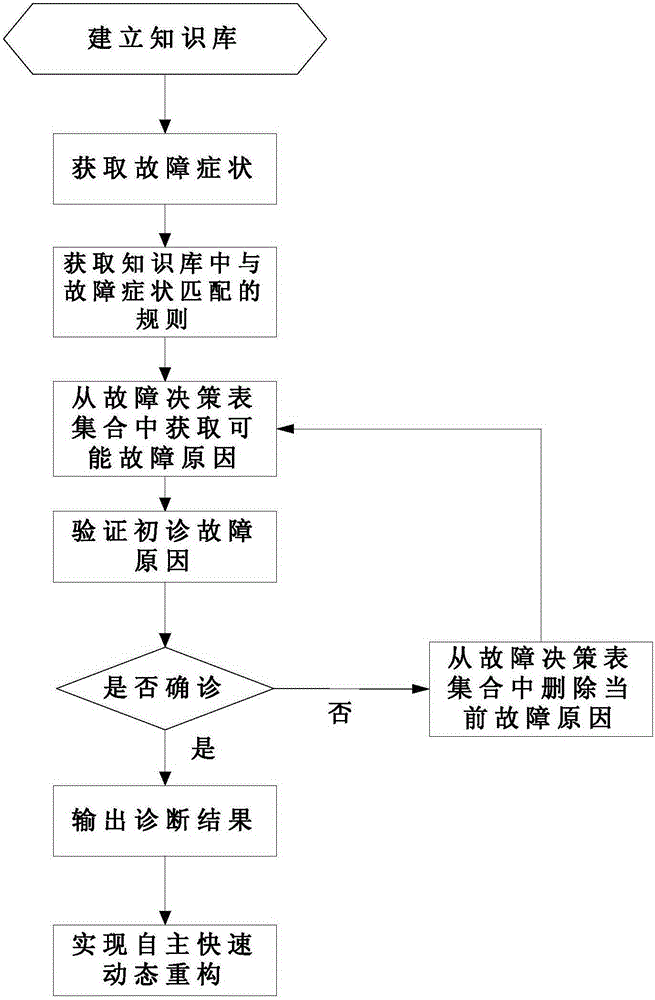

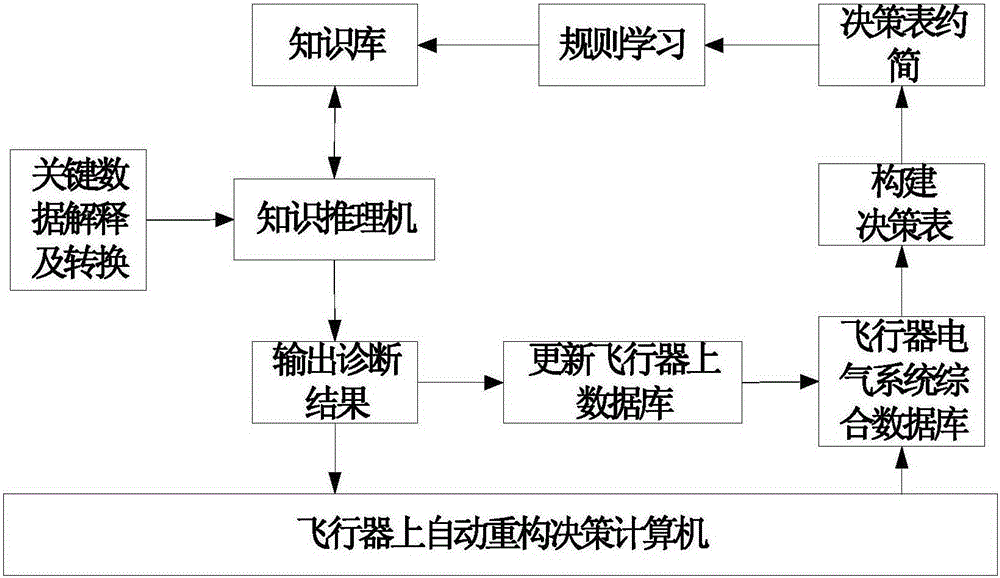

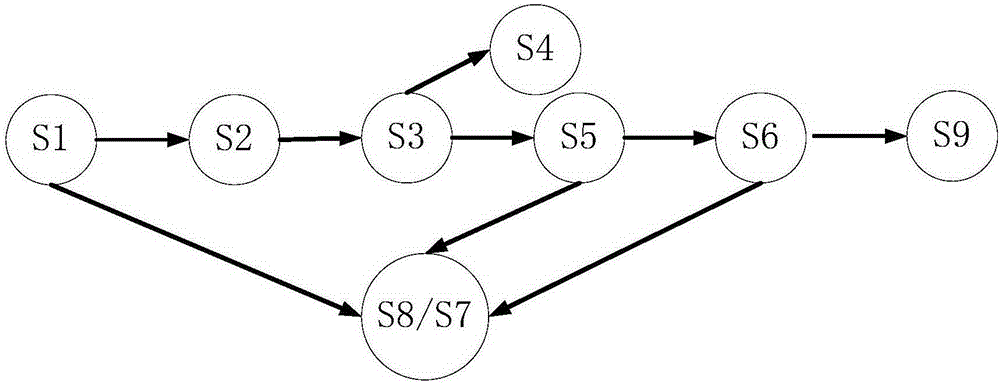

Fault diagnosis method suitable for electrical system of unmanned aerial vehicle

ActiveCN105183937AImprove fault detection rateImprove reliability and fault toleranceElectric testing/monitoringSpecial data processing applicationsUnmanned spacecraftFailure diagnosis

A fault diagnosis method suitable for an electrical system of an unmanned aerial vehicle comprises the following steps of: establishing a fault diagnosis knowledge library and a fault symptom set of the electrical system of the unmanned aerial vehicle at first and then taking out a fault diagnosis rule completely containing all symptoms and all fault diagnosis decision tables; and outputting a fault reason with the highest diagnosis success frequency as a fault diagnosis prediction result, verifying the fault reason, and if the verification is passed, taking the fault reason as a final diagnosis result for positioning a fault mode to finish autonomous and quick dynamic reconfiguration, otherwise, reselecting the fault reason. The method greatly improves the reliability and fault-tolerant capability of the electrical system, thereby having relatively high engineering application values.

Owner:CHINA ACAD OF LAUNCH VEHICLE TECH

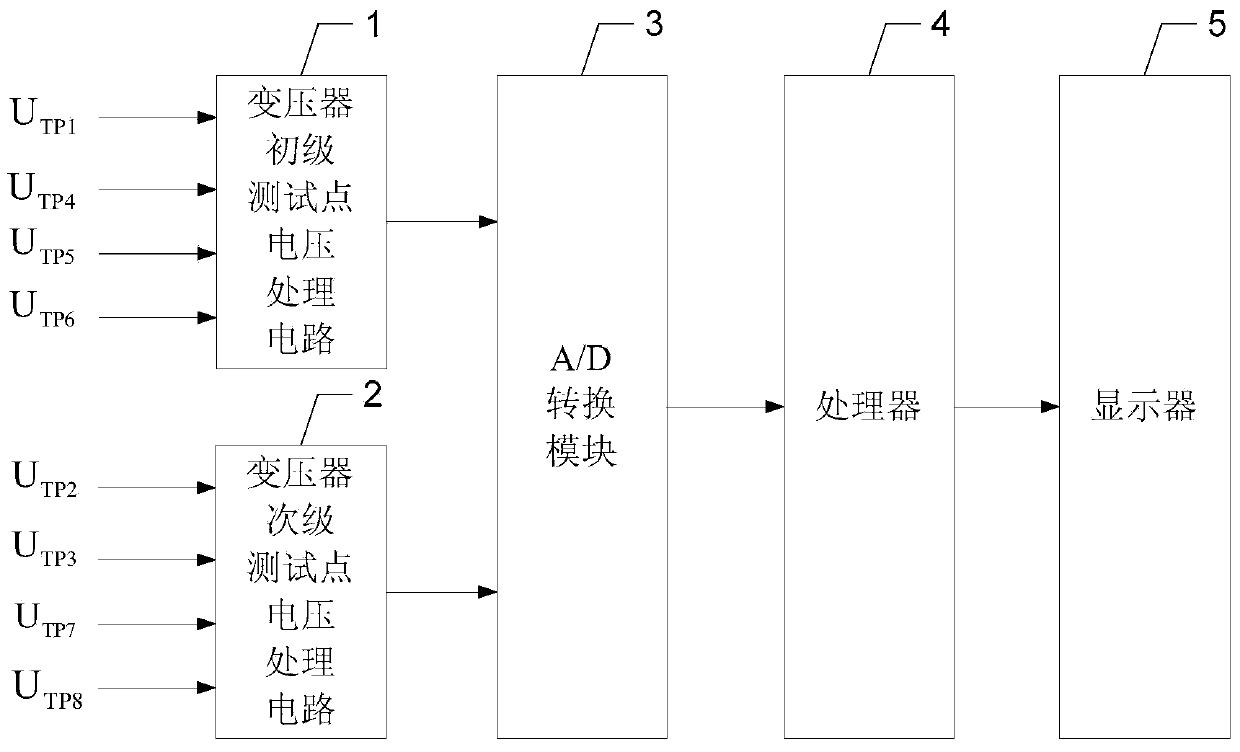

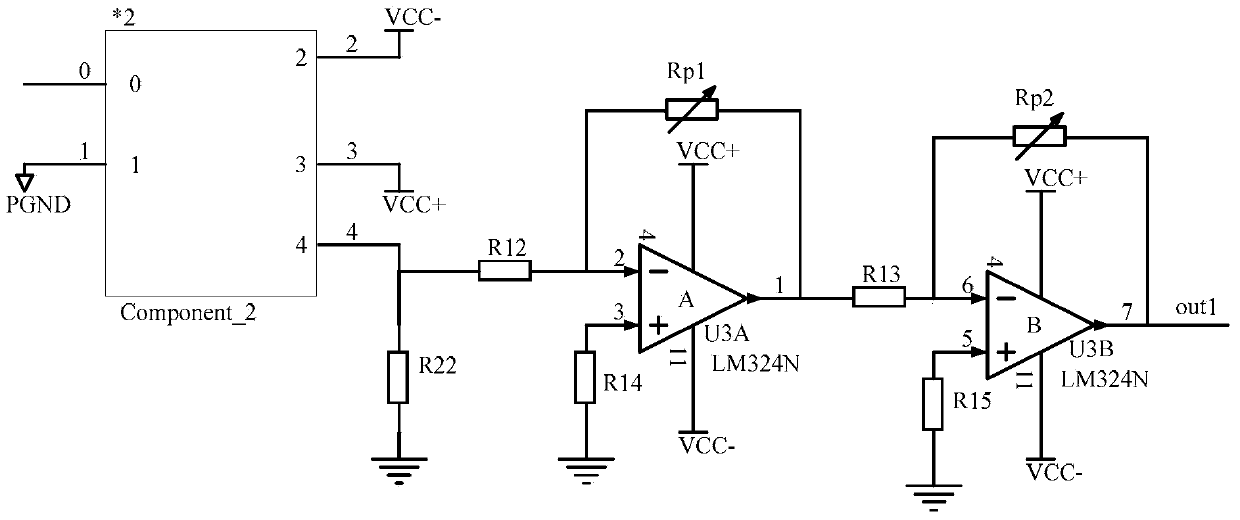

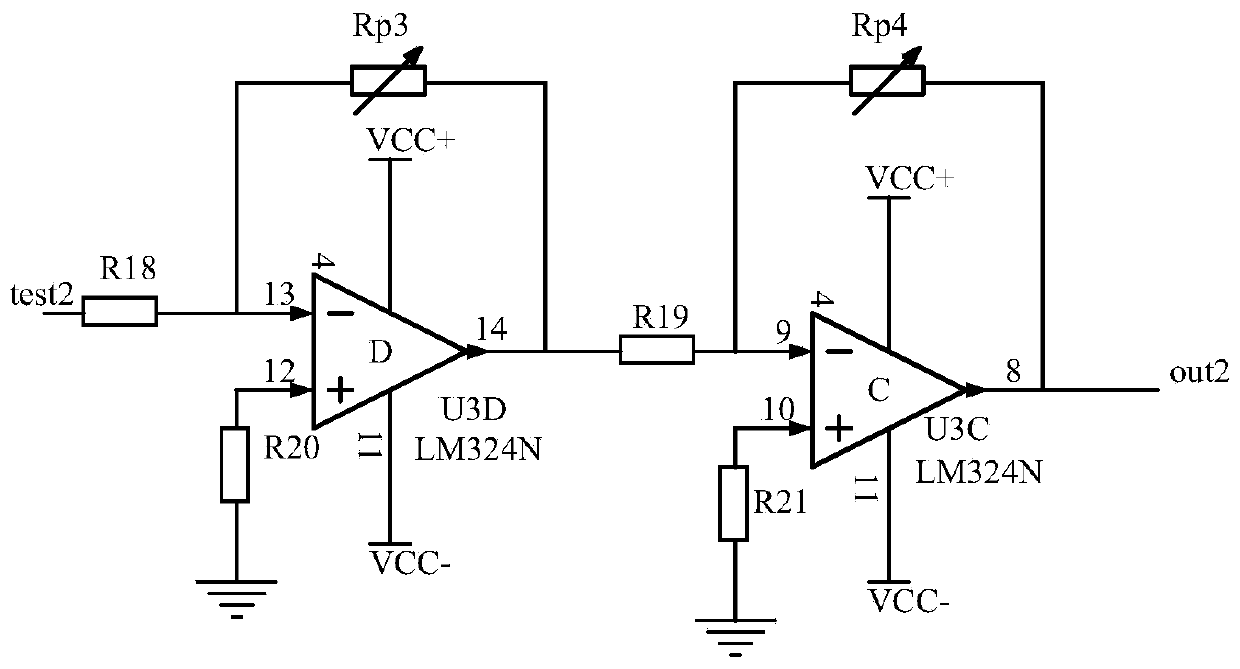

Switching power supply with testability function and testing method thereof

InactiveCN103701303AImplement automated testingImprove fault detection ratePower supply testingPower conversion systemsDisplay deviceTested time

The invention relates to a switching power supply with a testability function and a testing method thereof and belongs to the field of power supplies. The switching power supply with the testability function is used for solving the problems that during power failure, the manual testing process is complicated, the testing time is long, the maintenance support is difficult, the maintenance cost is high and the like caused due to the fact that the existing switching power supplies do not have testability. According to the switching power supply and the testing method thereof, the switching power supply is universal, eight test points are selected from the switching power supply, four test points are selected from the primary side of a transformer, four test points are selected from the secondary side of the transformer, eight voltages are processed and then are transmitted to a processor, judgment is carried out sequentially on TP4, TP5, TP1-TP2-TP3 (side by side in a group) and TP6-TP7-TP8 (side by side in a group), failure information is obtained easily and is displayed on a display, and then, maintenance personnel can quickly and accurately diagnose failure and isolate components and devices which are in failure, so that the workload of human judgment is reduced greatly.

Owner:HARBIN INST OF TECH

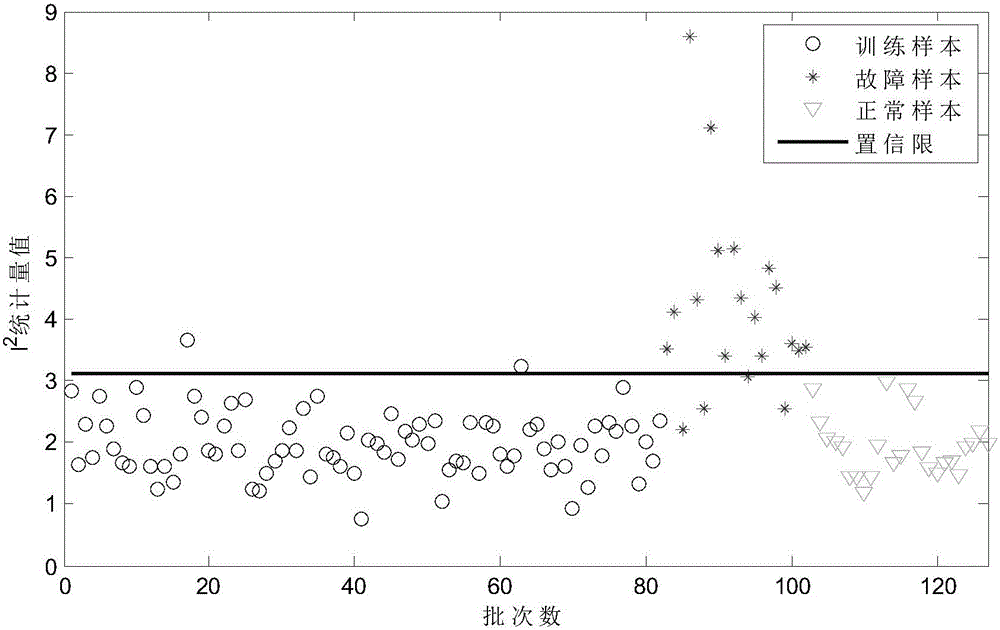

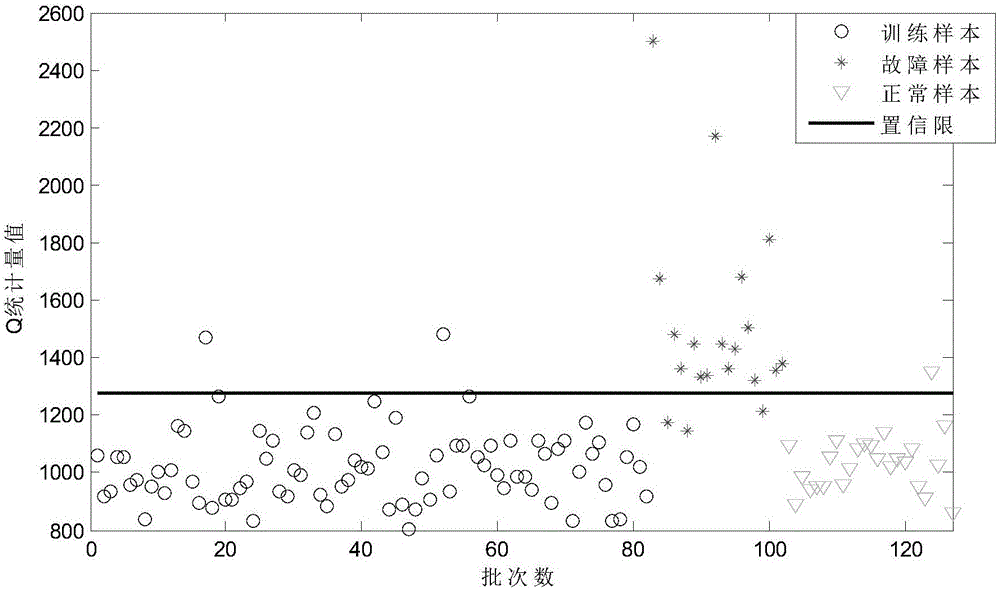

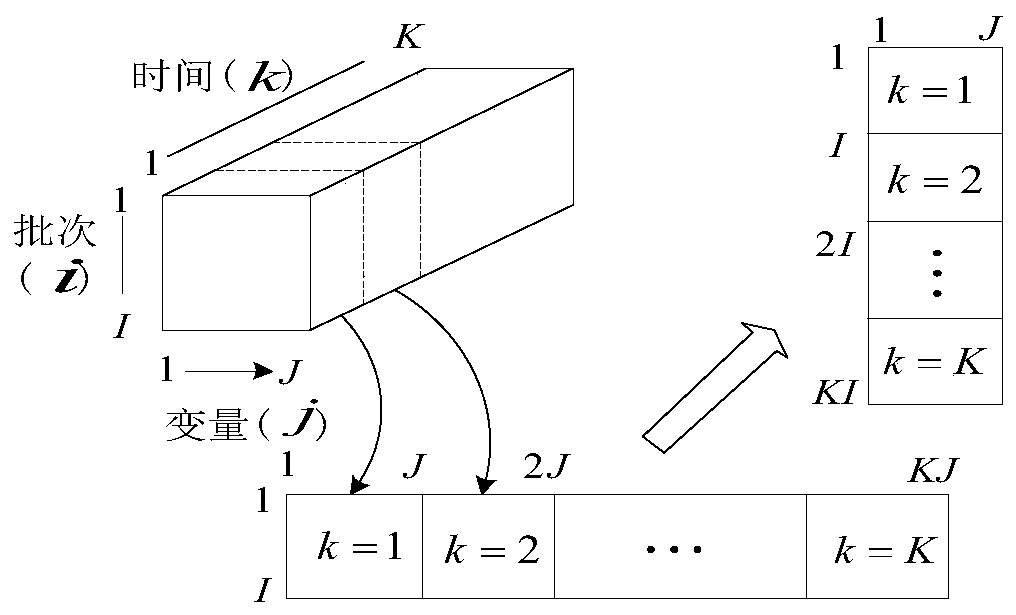

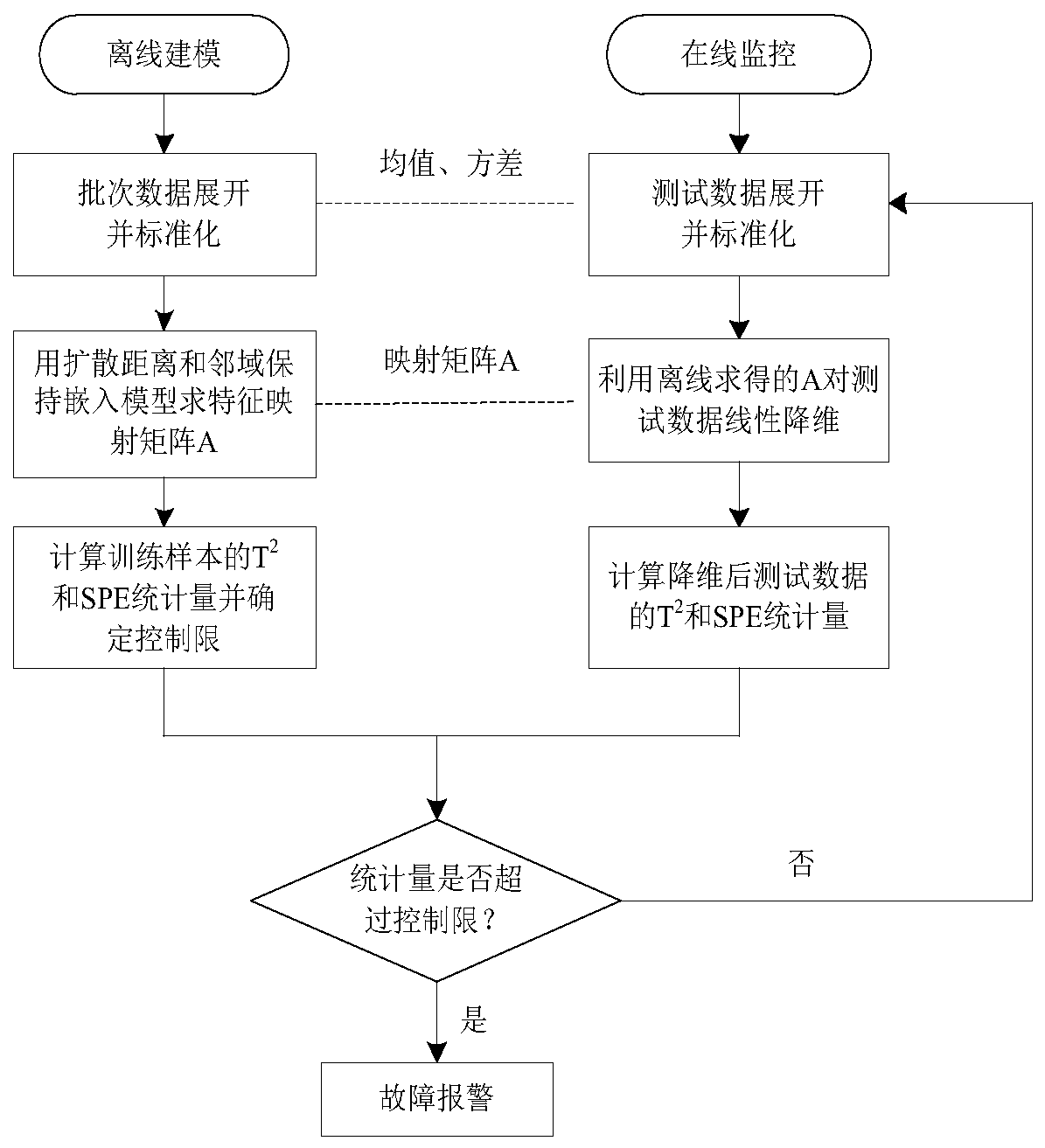

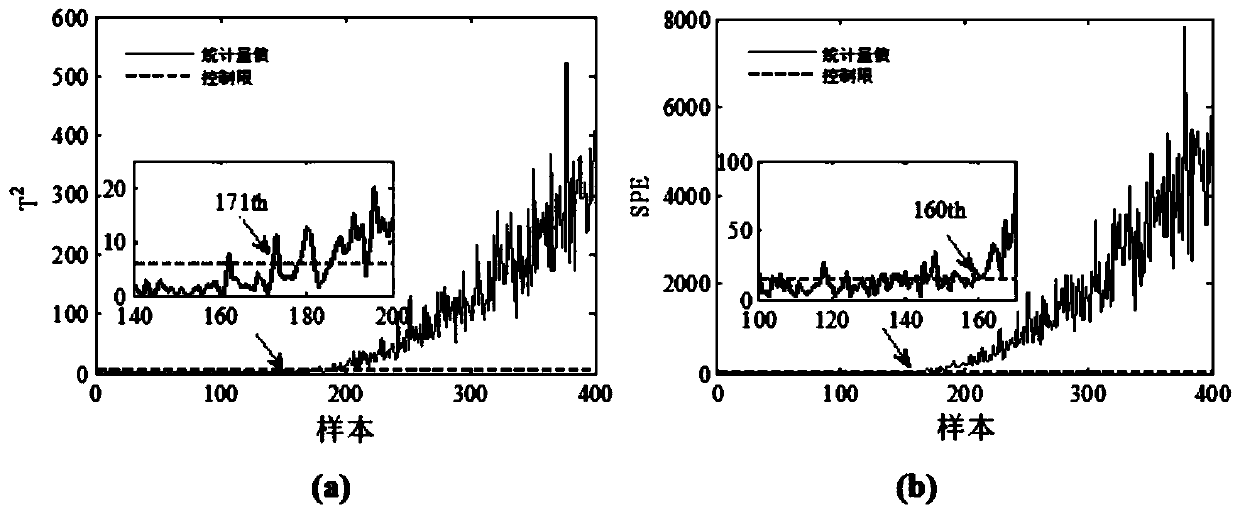

Diffusion distance improvement-based neighborhood preserving embedding intermittent process fault detection method

PendingCN111506041ALearning and feature extraction are goodImprove fault detection rateProgramme controlElectric testing/monitoringStatistical modelTransformation matrix

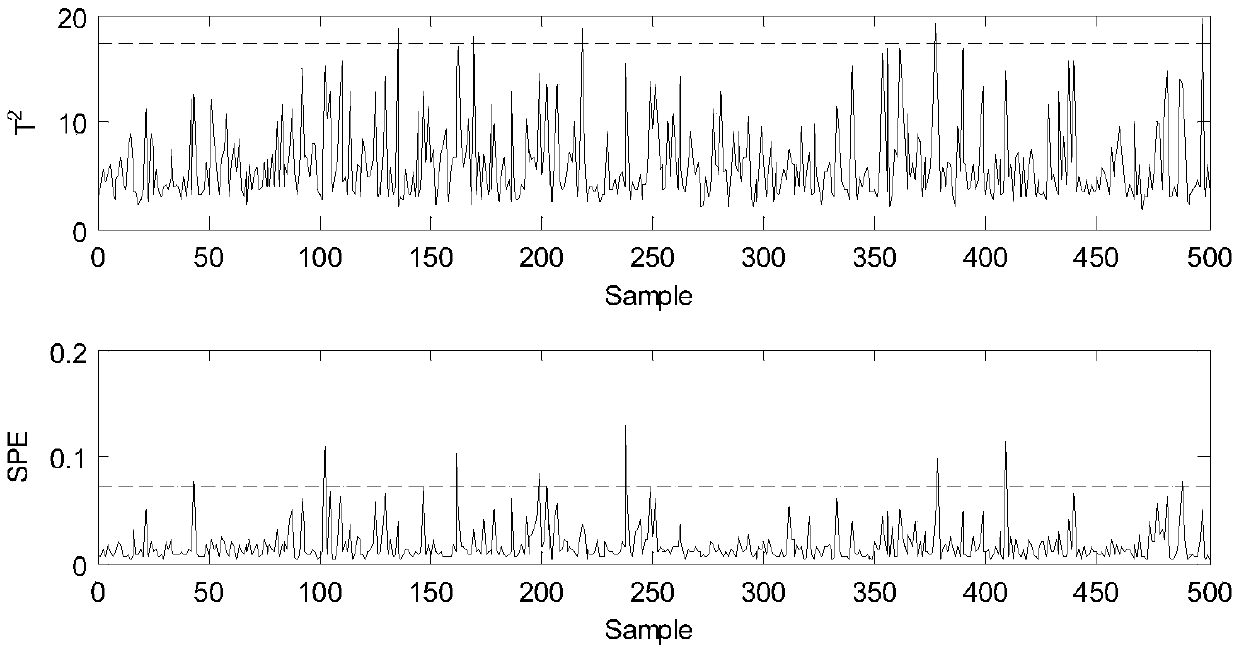

The invention provides a diffusion distance improvement-based neighborhood preserving embedding intermittent process fault detection method, which mainly comprises the following steps of (1) acquiringintermittent process data of a plurality of batches under normal working conditions to form three-dimensional training data, (2) unfolding the acquired three-dimensional training data into two-dimensional data and performing standardization processing, (3) establishing a neighborhood preserving embedding model based on diffusion distance improvement, and solving a mapping transformation matrix, (4) establishing statistics of a Hotelling statistical model T2 and a square prediction error statistical model SPE under normal data, and solving control limits of the statistics, (5) collecting online intermittent process data to form test data, and performing unfolding and standardization processing on the test data according to the method in the step (2), (6) projecting the preprocessed test data through the mapping transformation matrix obtained in the step (3), and (7) calculating the statistics of the Hotelling statistical model T2 and the square prediction error statistical model SPE of the test data, and judging whether a fault occurs or not.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

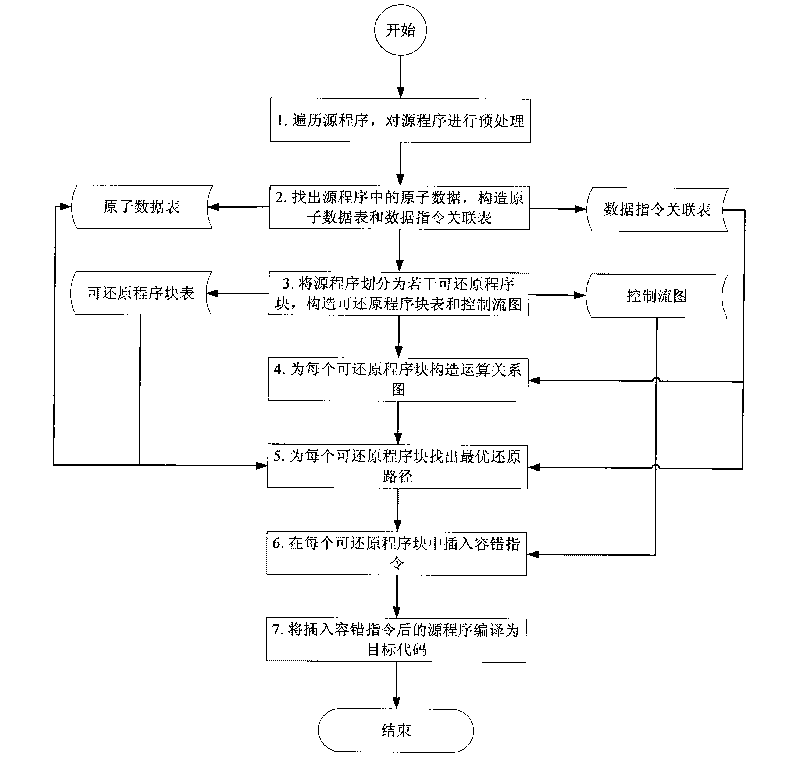

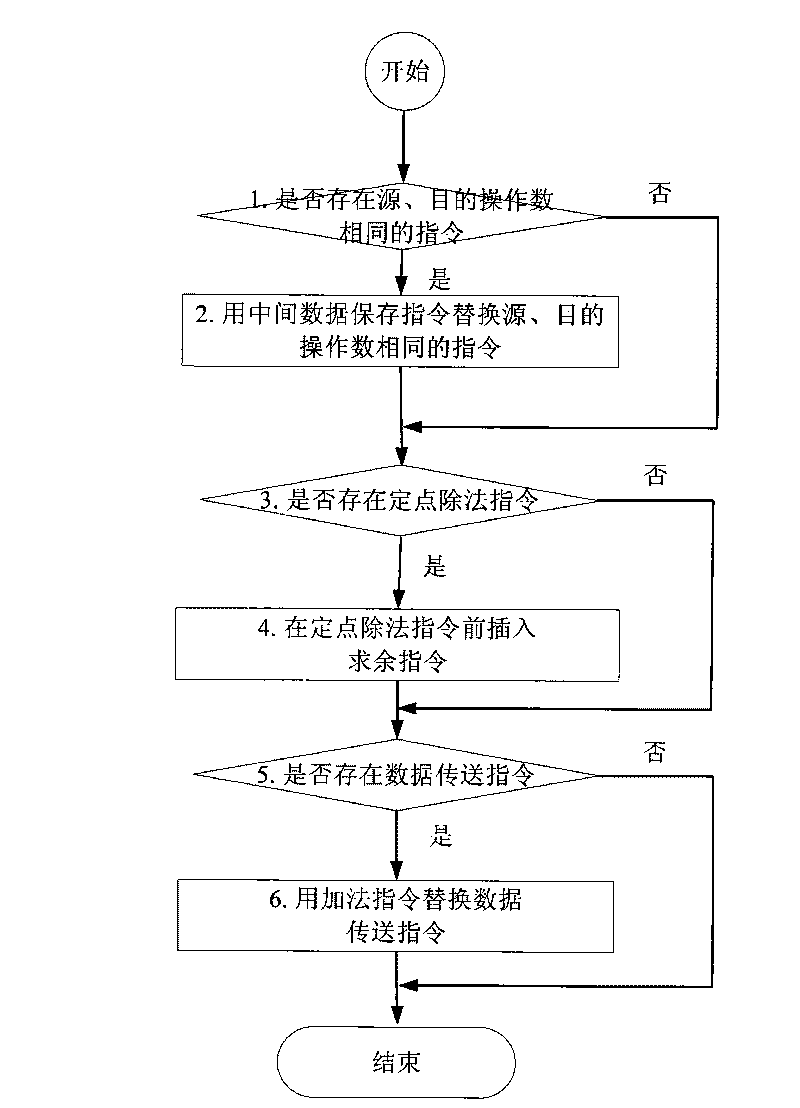

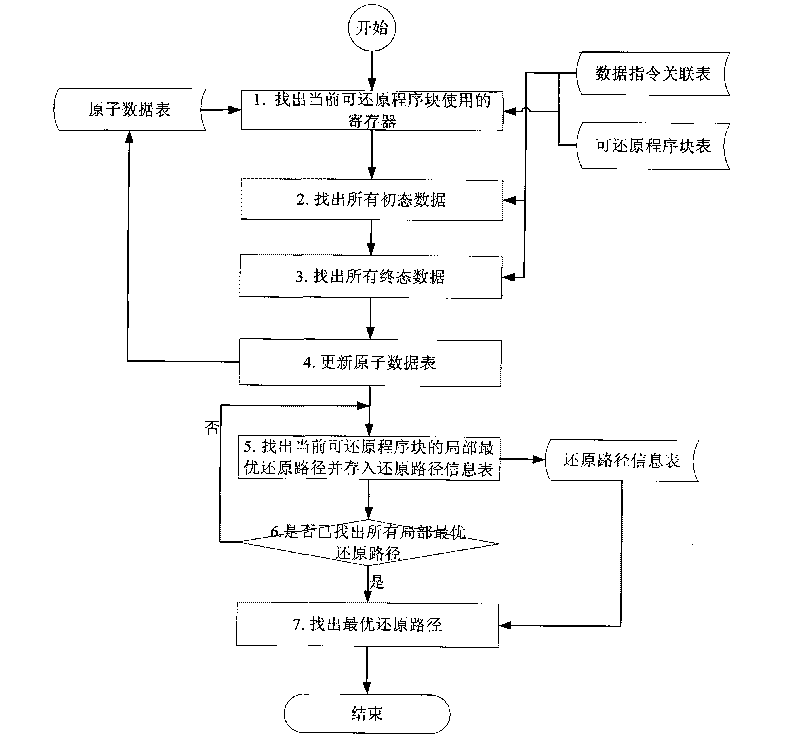

Hardware fault detection method based on reducing program

InactiveCN101751334AEffective detection of permanent faultsIncrease differentiationSoftware testing/debuggingControl flowFault tolerance

The invention discloses a hardware fault detection method based on a reducing program, and aims at increasing space-time difference when a source program and a redundant program run, overcoming the problems, such as data overflow and the like, and improving the fault detection rate of transient faults and permanent faults. The technical scheme comprises: traversing the source program, pre-processing the source program, finding out the atomic data in the source program, and constructing an atomic data list and a data command association list; then dividing the source program into a plurality of reducible program blocks, constructing a reducible program block list and a control flow chart, and constructing an operation relation chart for each reducible program block; then finding out an optimal reducing path for each reducible program block; and finally inserting a fault-tolerance command into each reducible program block, and encoding the source program into which the fault-tolerance command is inserted as a target code. The invention can be used for detecting the transient faults and the permanent faults, improve the fault detection rate, overcome the problem of data overflow, and save storage resource.

Owner:NAT UNIV OF DEFENSE TECH

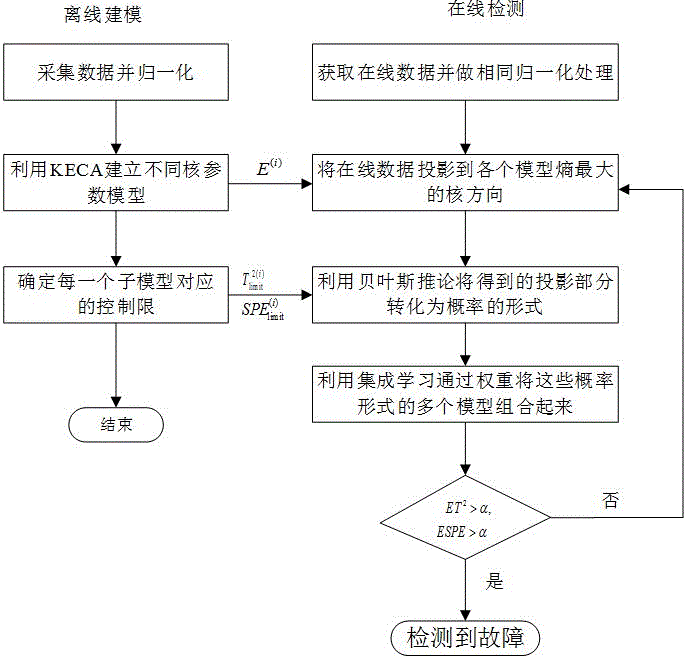

Improved kernel entropy component analysis based nonlinear fault detection method and application thereof

InactiveCN106094749AAvoid the problem of blind selectionImprove fault detection rateTotal factory controlProgramme total factory controlGeneration processEnsemble learning

The invention discloses an improved kernel entropy component analysis based nonlinear fault detection method and an application thereof. According to the method, monitoring for the industrial generation process is realized through combining a Kernel entropy component analysis method and integrated learning and Bayesian interference so as to judge whether a fault occurs in the production process or not. In allusion to a nonlinear problem of data in the practical production process, kernel entropy component analysis is adopted, consideration for actual distribution conditions such as Gaussian distribution and non-Gaussian distribution of data is effectively avoided by using characteristics of information entropy, and multiple models are introduced through integrated learning, so that a problem of kernel function parameter blind selection in kernel entropy component analysis is avoided. The detection effect of faults in the industrial generation process is effectively improved.

Owner:ZHEJIANG UNIV

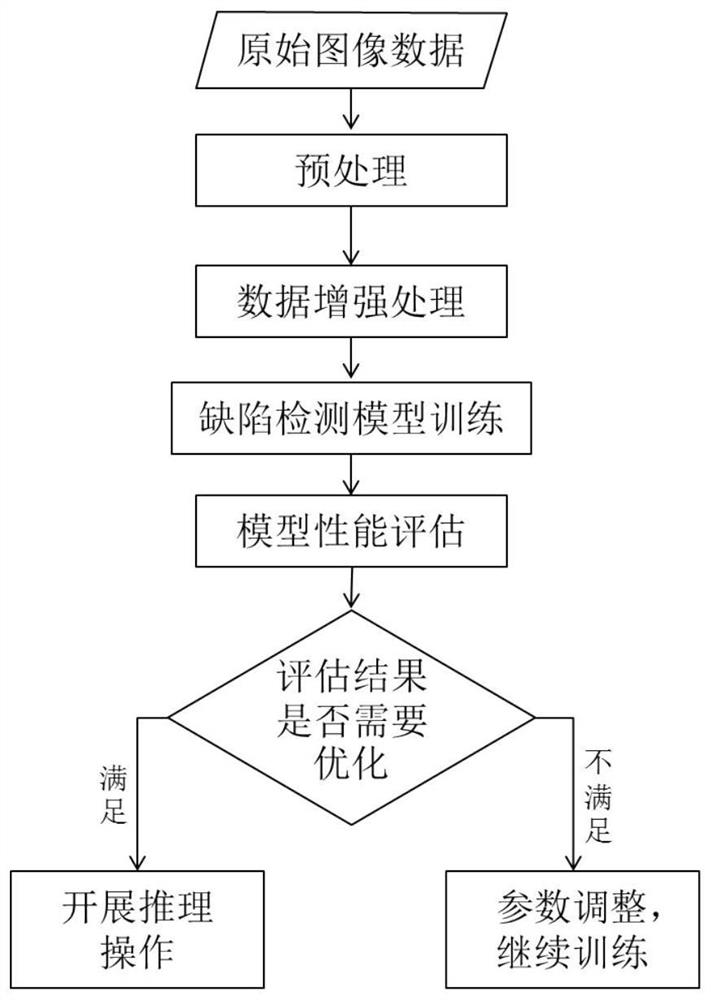

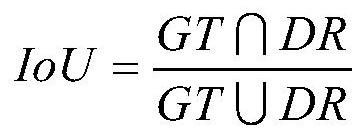

PCB defect automatic detection method based on deep learning

PendingCN111862025ASolve some problemsEasy to detectImage enhancementImage analysisPattern recognitionEvaluation result

The invention discloses a PCB defect automatic detection method based on deep learning, and the method comprises the following steps: (1) carrying out the preprocessing of original data, carrying outthe data format and size conversion, and completing the data set division; (2) performing data enhancement processing on the preprocessed image; (3) inputting the enhanced data into a new micro defectdetection network, and training a defect detection model; (4) performing performance evaluation on the model obtained after training; and (5) further optimizing the model by referring to an evaluation result in the step (4). According to the invention, automatic detection and target identification of PCB defects are realized, the problems of low efficiency and low precision during PCB defect detection are solved, and the efficiency and reliability of defect detection are greatly improved while the labor cost is saved; and the automatic defect detection method provided by the invention is easyto expand to micro defect detection in other fields, such as fabric defect detection and metal surface defect detection.

Owner:716TH RES INST OF CHINA SHIPBUILDING INDAL CORP

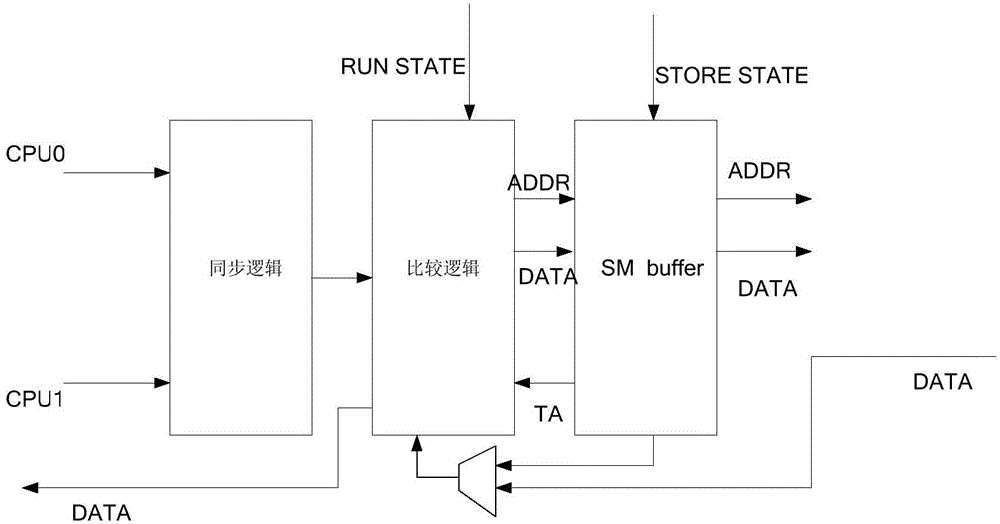

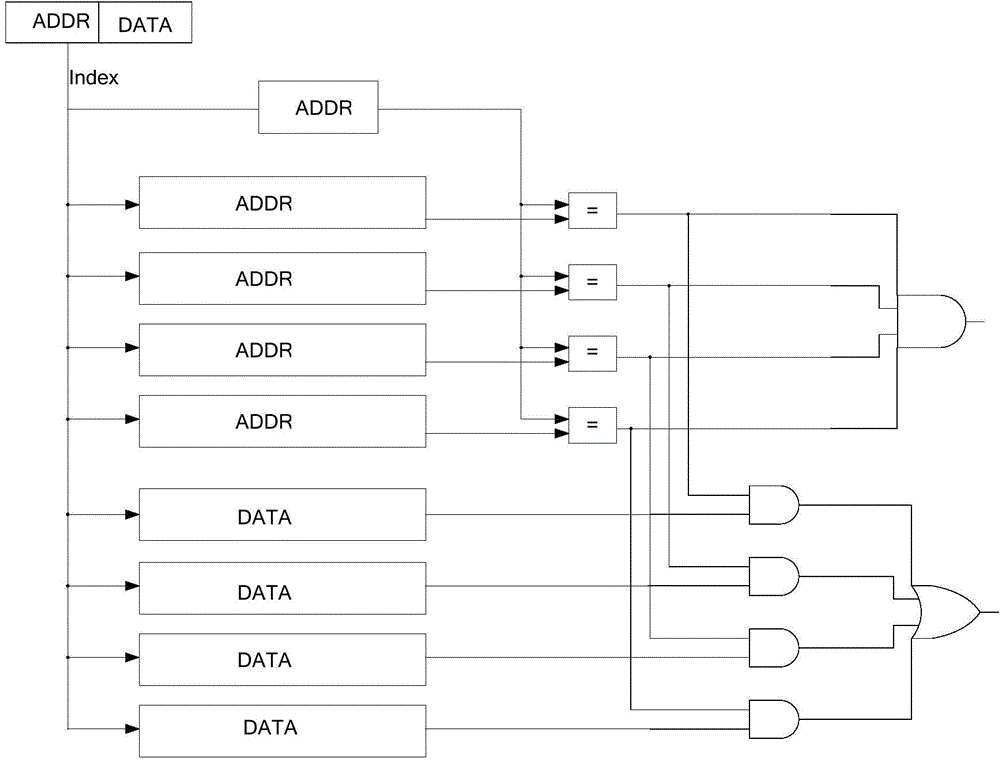

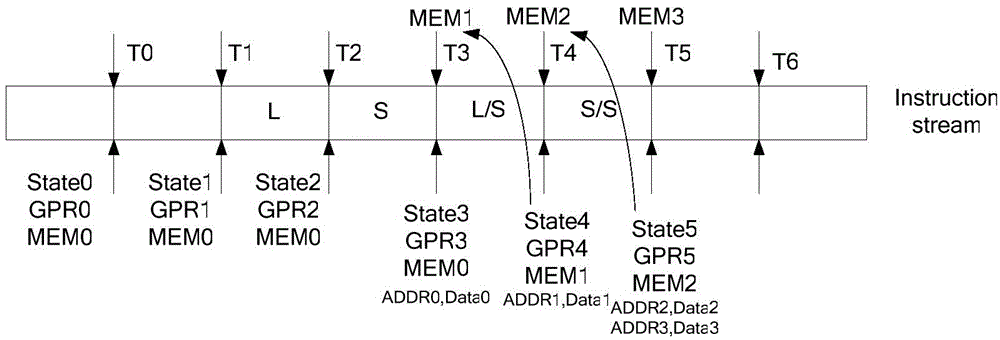

Error recovery method based on lockstep architecture

ActiveCN104699550AImprove fault toleranceImprove reliabilityFault responseHardware monitoringRecovery methodElectricity

The invention relates to an error recovery method based on a lockstep architecture. The method comprises steps as follows: 1) Lock-Step module running state and switching: after a Lock-Step module is powered on, state is saved on the basis of the time stream, a hardware signal is sent through a hardware timer after a period, and software saves the state of a processor after reading the state; 2) the state of hardware is switched, saving recovery of the hardware is divided into two states, namely, a running state and a saving state, if the processor performs the write operation in the running state, the operation of writing of address data of an SM is finished by the SM in the time slice of the running state, and data consistency is guaranteed. According to the error recovery method based on the lockstep architecture, transient errors of running of a computer running can be discovered under the computer architecture, the errors can be recovered by a recovery mechanism, the error-tolerant capability of the computer can be improved, and the reliability of the computer is high.

Owner:AVIC NO 631 RES INST

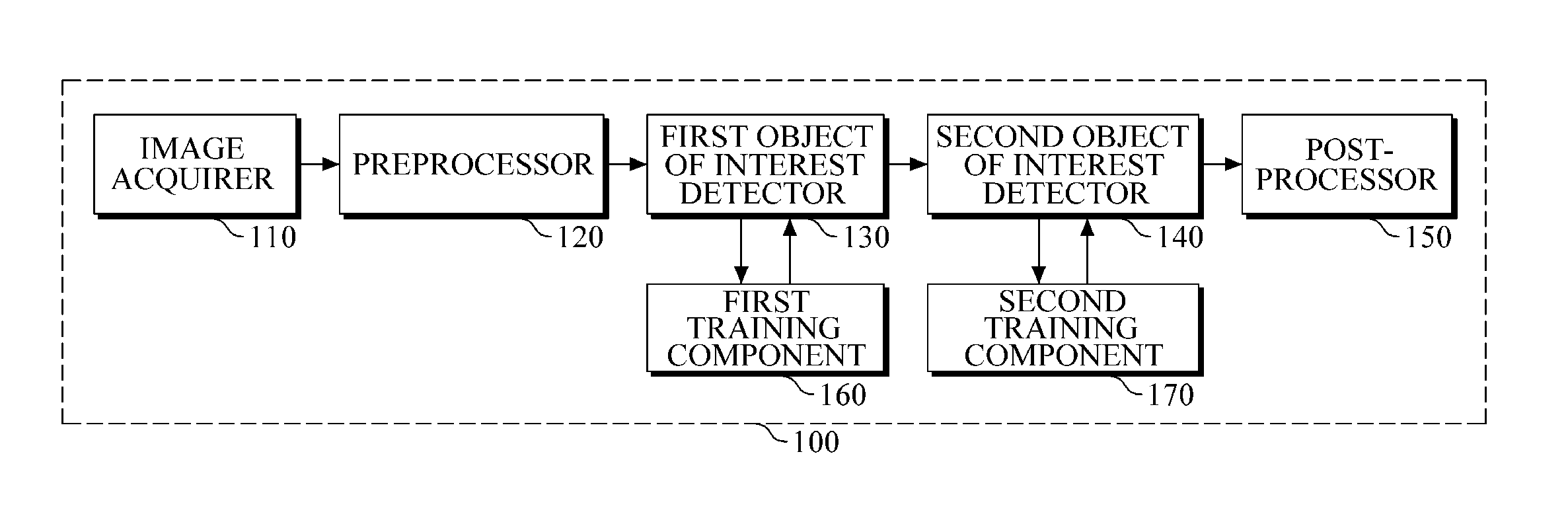

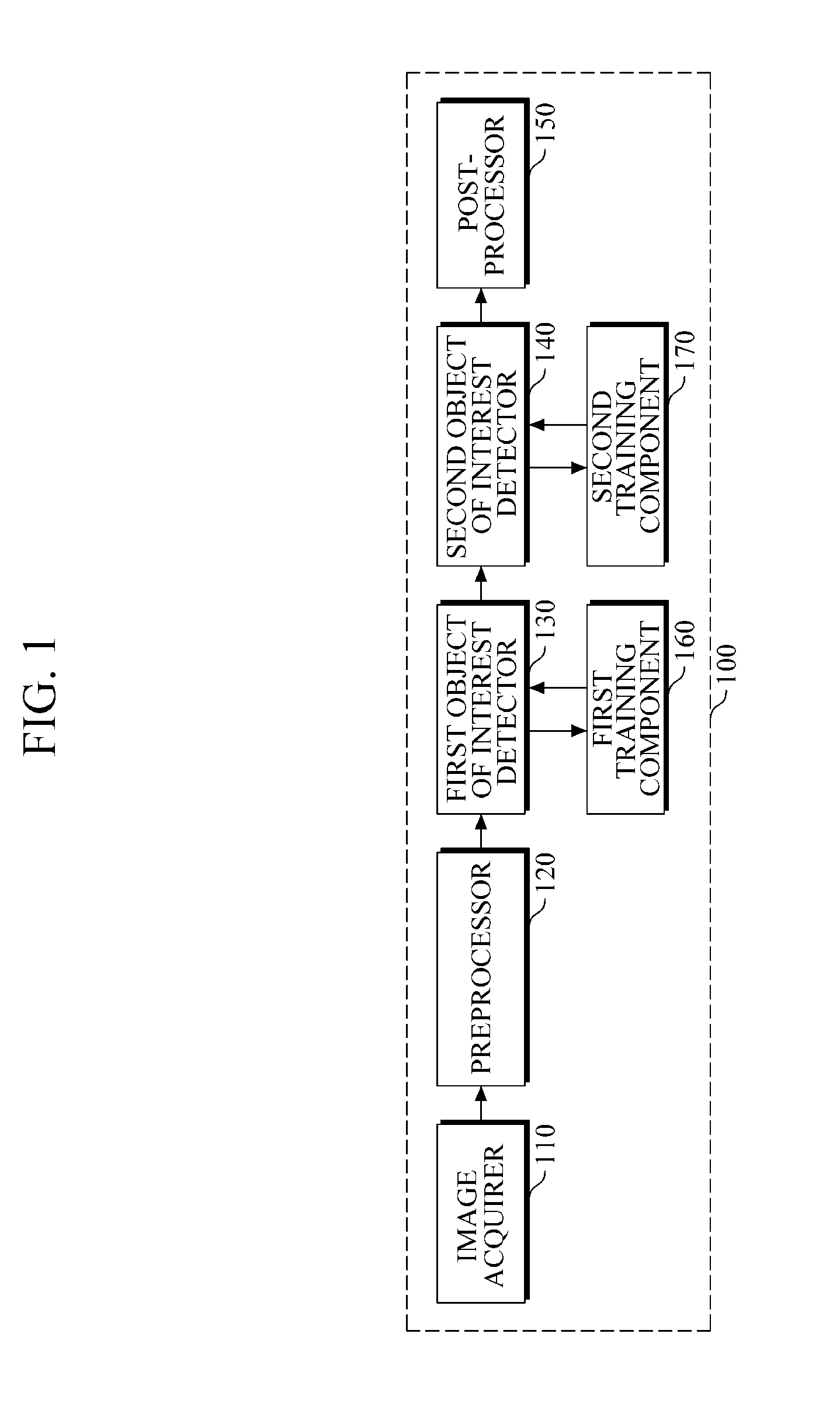

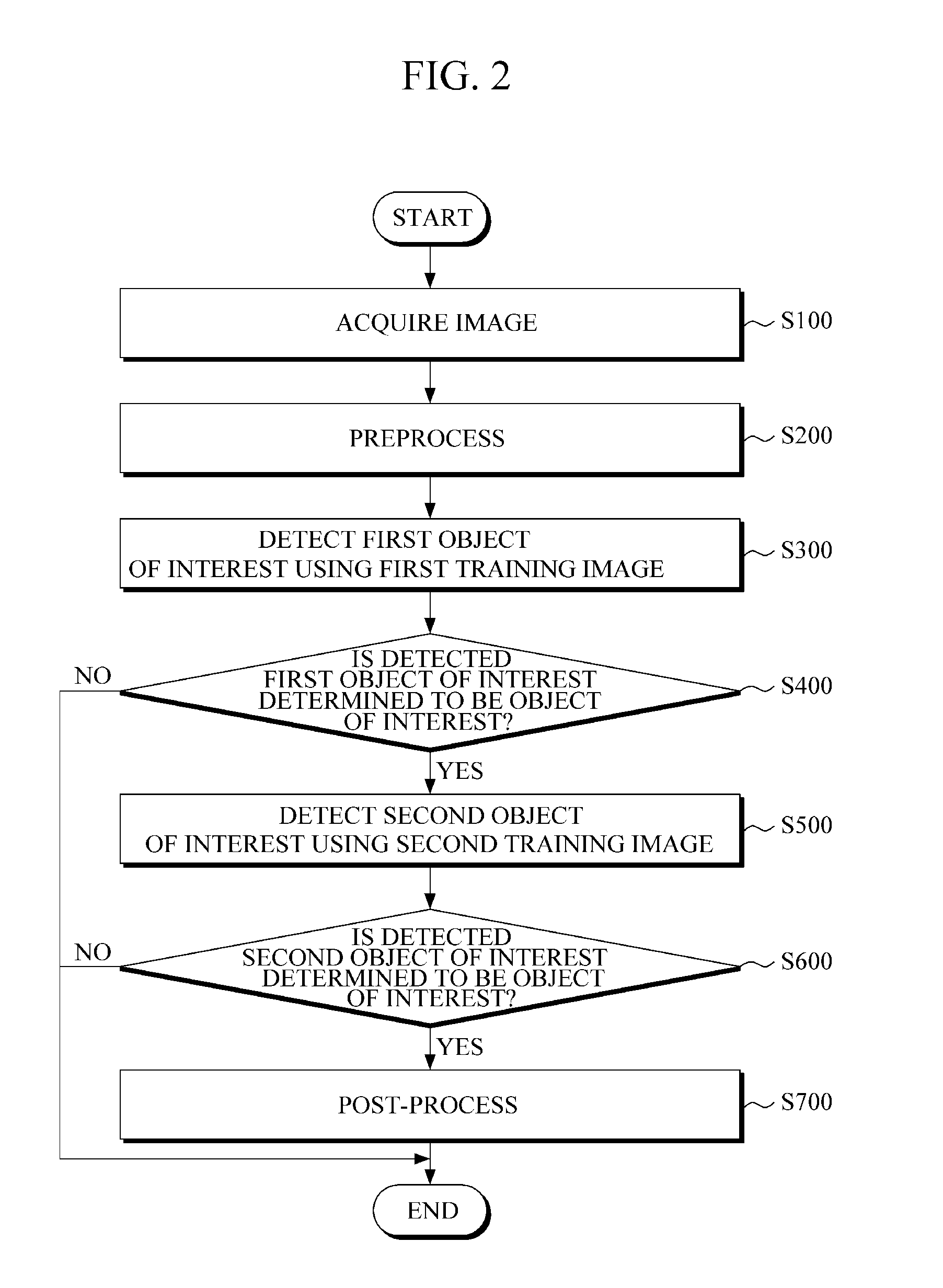

Apparatus and method for rapidly detecting object of interest

InactiveUS20150235105A1Less time to detectImprove fault detection rateImage enhancementImage analysisComputer scienceRegion detection

An apparatus for rapidly detecting an object of interest includes: a first object of interest detector configured to determine a region of an object of interest for an image, from which the object of interest is to be detected, by using a first training image; and a second object of interest detector configured to detect the object of interest from the region of the object of interest determined by the first object of interest detector by using a second training image, which is bigger in size than the first training image.

Owner:ELECTRONICS & TELECOMM RES INST

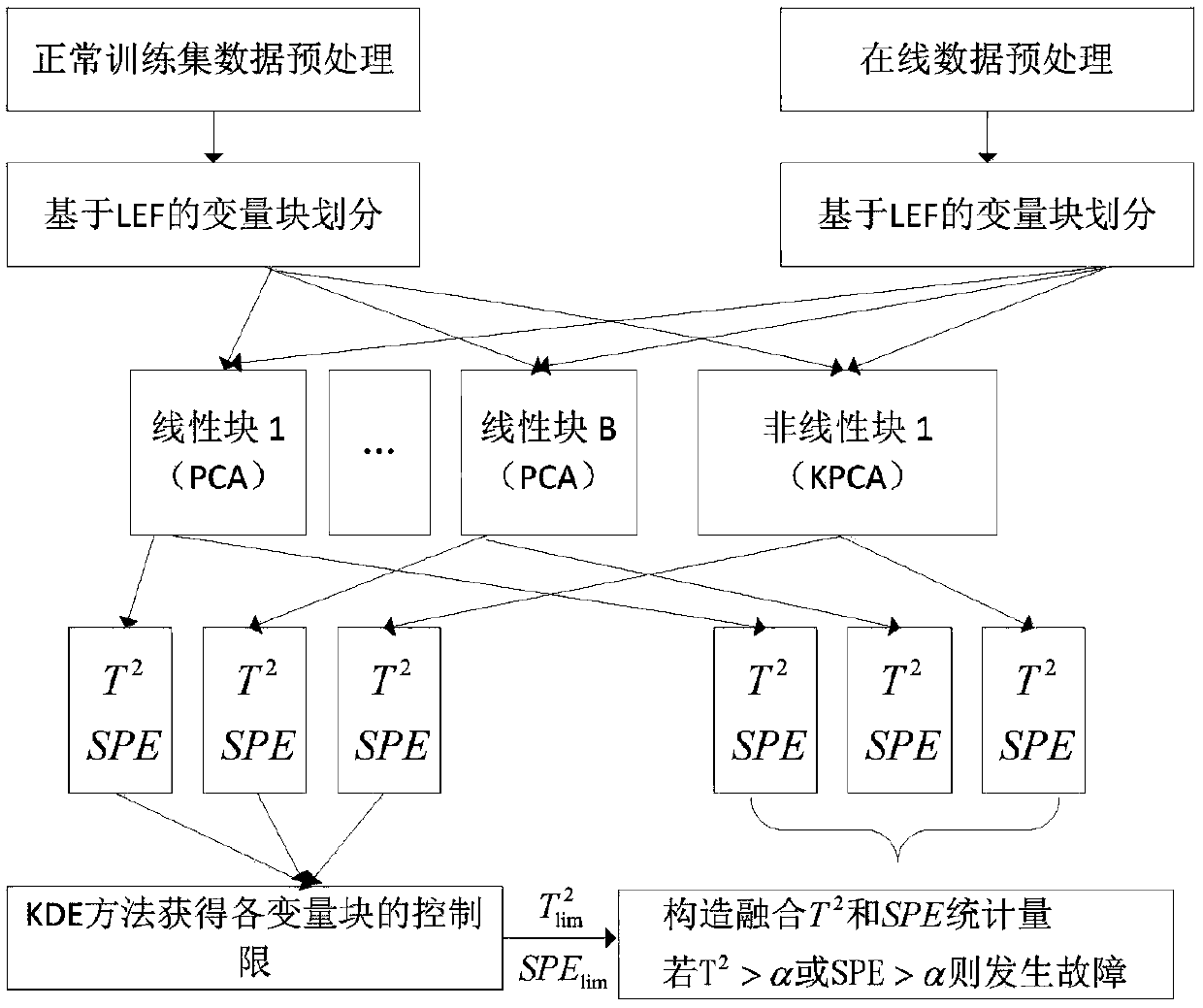

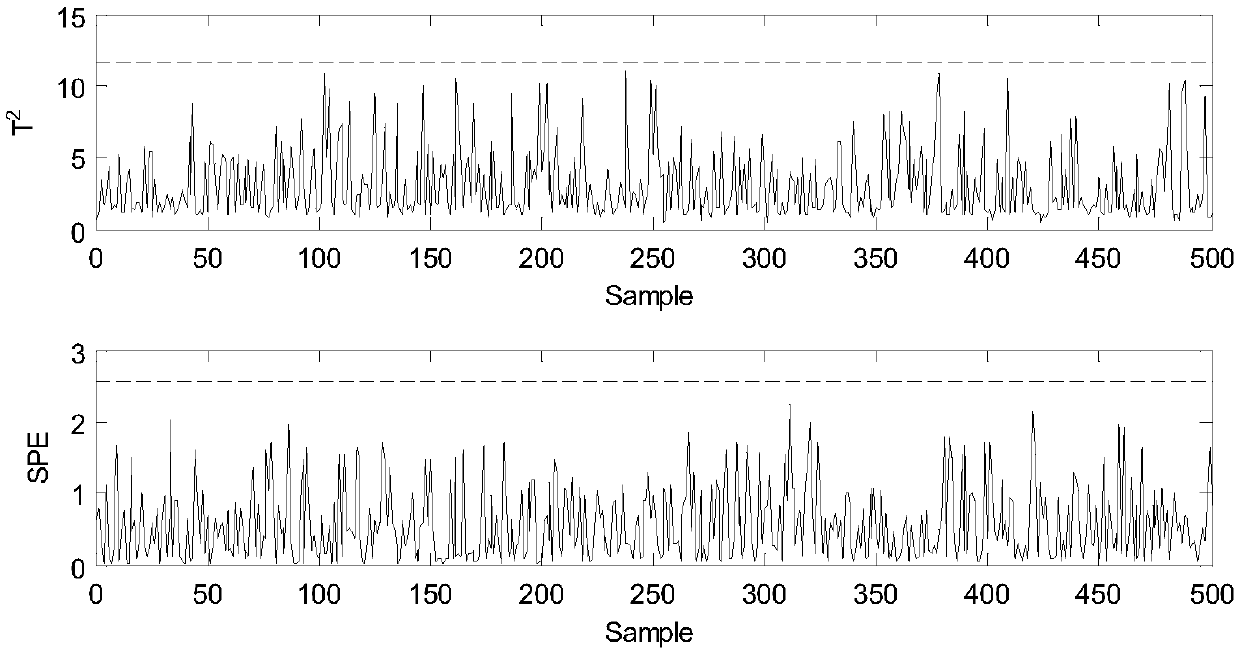

Linear-nonlinear industrial process fault detecting method based on linear evaluation factors

ActiveCN108830006AFully extractedImprove fault detection resultsCharacter and pattern recognitionDesign optimisation/simulationLocal variableFault detection rate

The invention relates to a linear-nonlinear industrial process fault detecting method based on linear evaluation factors. The linear-nonlinear industrial process fault detecting method comprises the steps that firstly, normalization processing is conducted on training data and testing data; secondly, the linear evaluation factor LEF (xi, xj) is defined, different correlations of variables are measured through the linear evaluation factor LEF (xi, xj), linear and non-linear blocks in the industrial process are divided by the linear evaluation factor, the correlations of local variables can be described in more detail; on this basis, a PCA model and a KPCA model are respectively established in different sub-blocks, and the information of all blocks is fused; whether a fault occurs or not isjudged according to the statistical amount after fusion, thus fault detection results are improved, and the fault detection rate is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

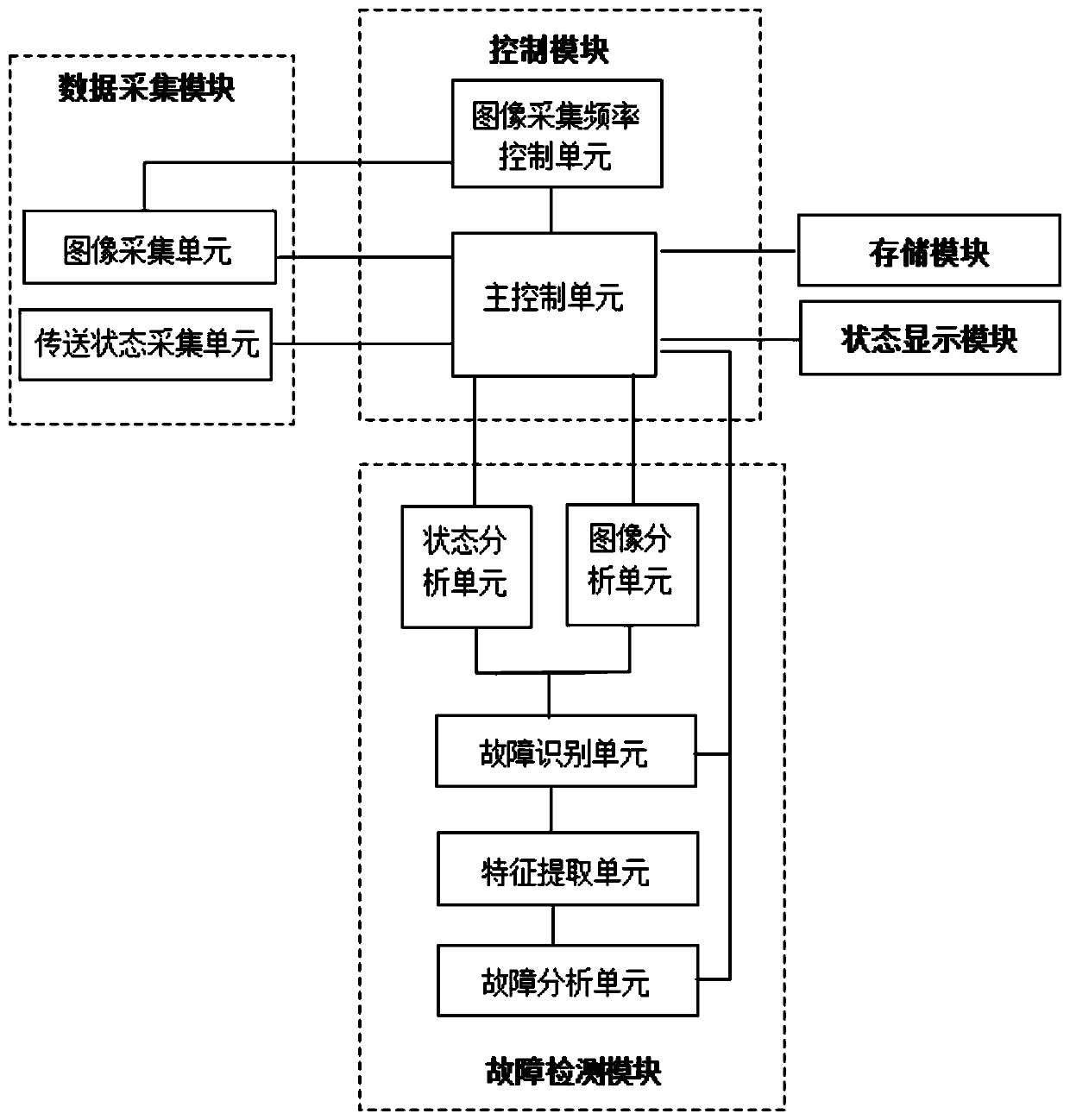

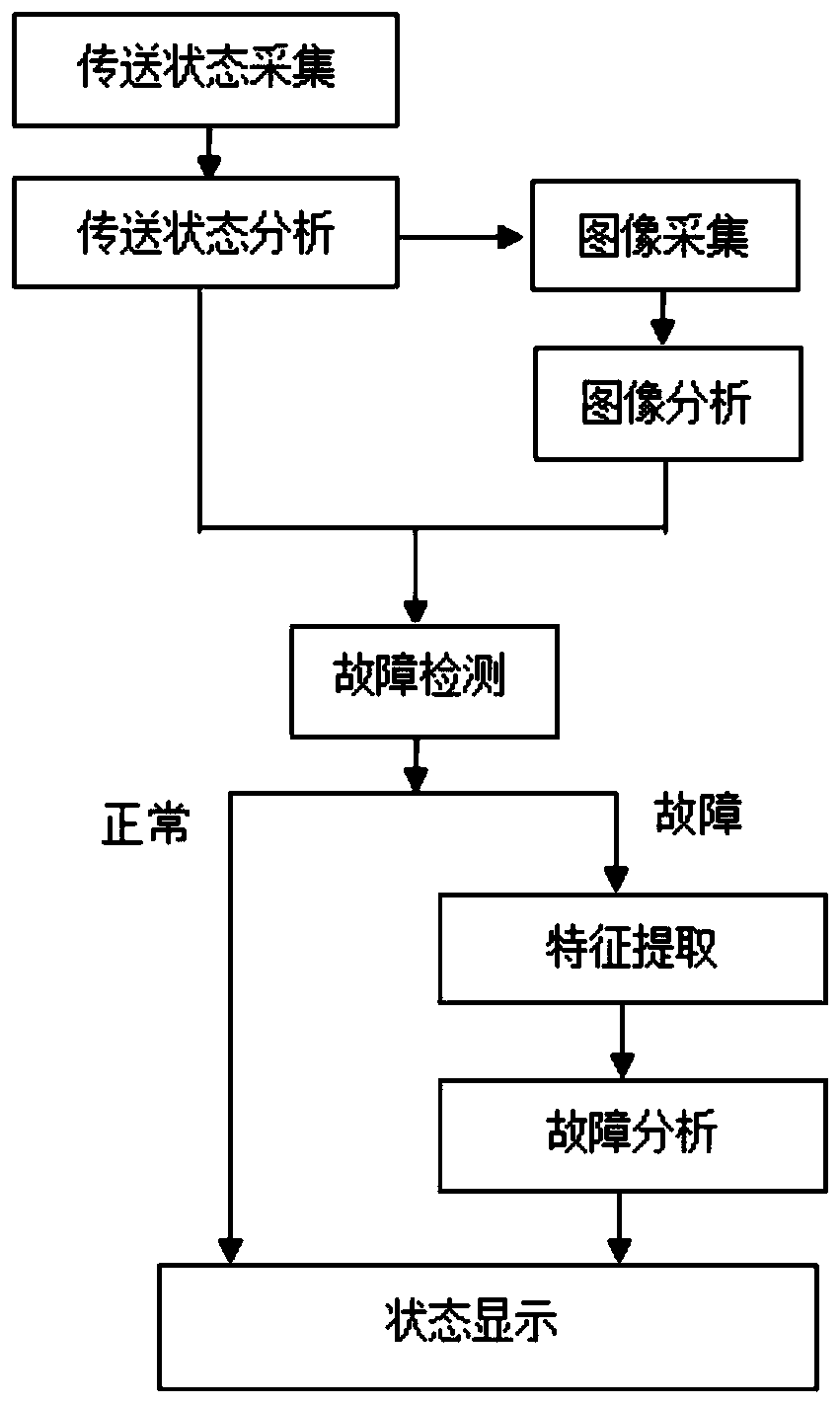

Intelligent spinning packaging production line fault detection system

ActiveCN111552243AReduce the impactReal-time monitoring of transmission statusTotal factory controlProgramme total factory controlYarnBobbin

The invention discloses a fault detection system for an intelligent spinning and packaging production line. The system comprises a data acquisition module, a control module, a fault detection module,a storage module, a state display module and an information transmission module, wherein the control module is connected with the data acquisition module, the fault detection module, the storage module and the state display module through the information transmission module; the data acquisition module is used for acquiring the conveying state of each bobbin and images of the bobbins before and after single yarn packaging in real time, and the fault detection module is used for analyzing and detecting fault reasons. By means of the mode, the conveying states of all links on the packaging production line can be monitored in real time, faults can be found in time and automatically analyzed, measures can be conveniently taken in time, and the influence of the faults is reduced; in addition, image acquisition and analysis can be carried out on bobbins before and after single yarn packaging, faults of overturning and single yarn packaging links are further detected, the fault detection rateis increased, and the product packaging quality is guaranteed.

Owner:武汉裕大华纺织有限公司

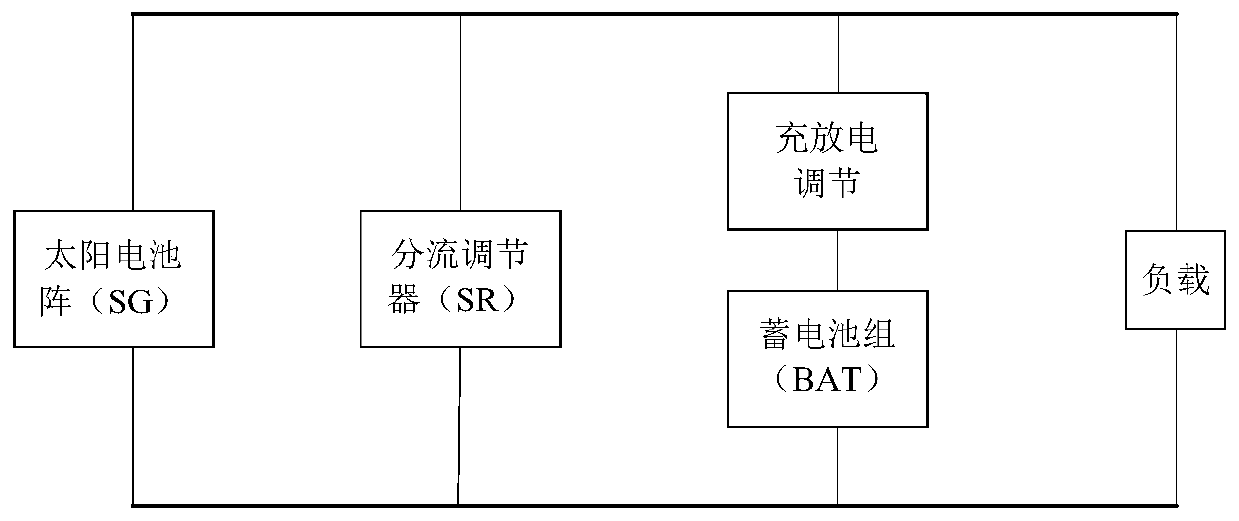

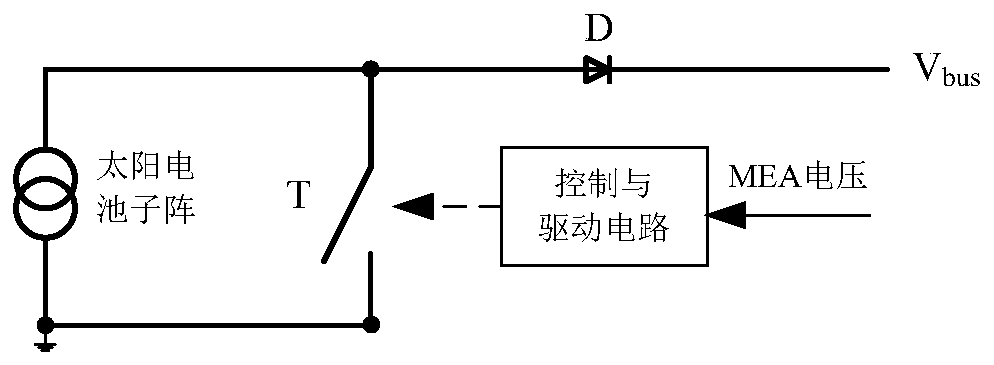

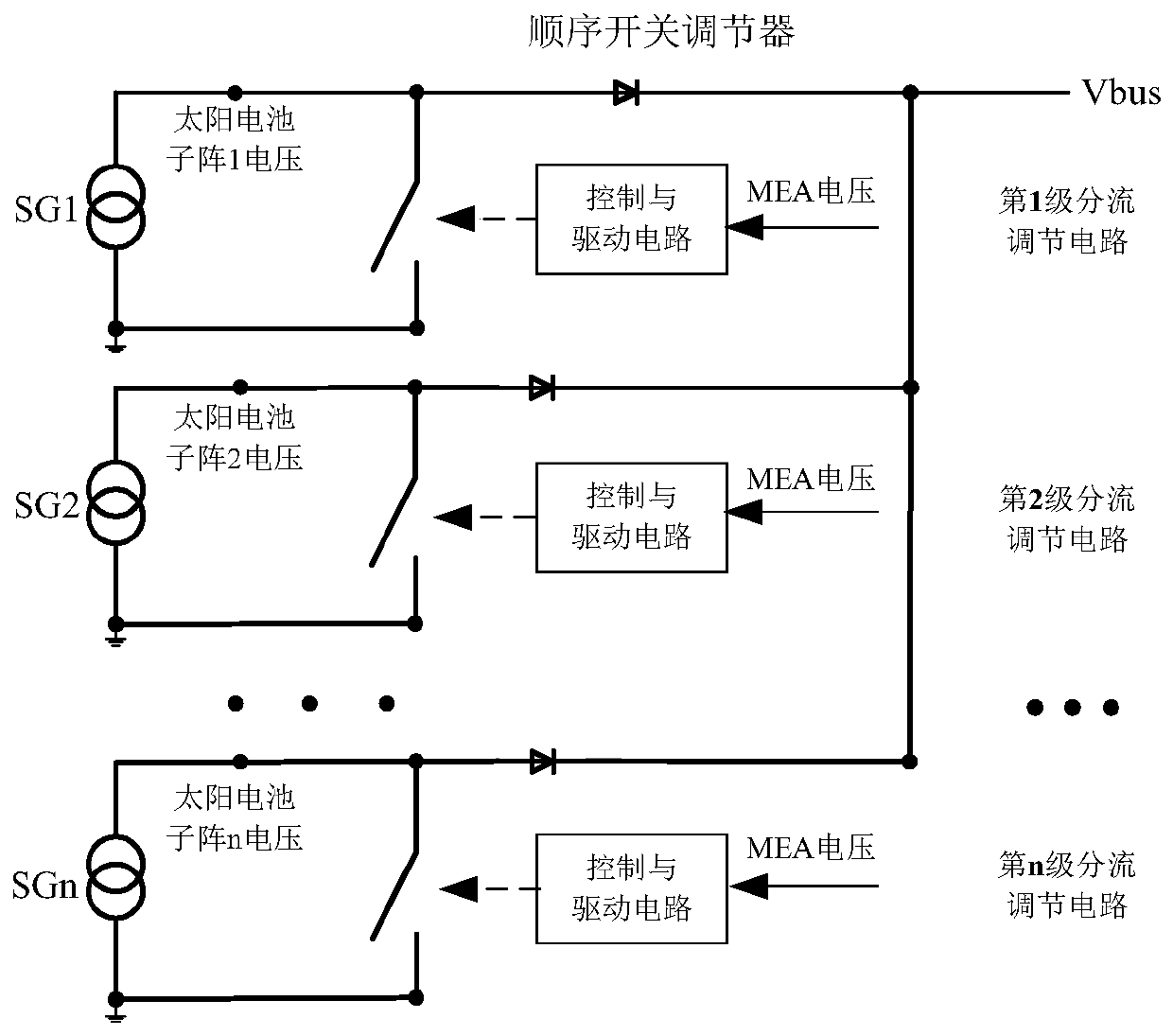

Fault diagnosis method for sequentially switched parallel regulator

ActiveCN109831159AAccurate detectionPrecise positioningBatteries circuit arrangementsPhotovoltaic monitoringDiagnosis methodsEngineering

The invention provides a fault diagnosis method for a sequentially switched parallel regulator. The method comprises the following steps that the work state of the sequentially switched parallel regulator in a faultless condition is analyzed; a fault mode of the sequentially switched parallel regulator is obtained by analysis; a detection point is selected for the solar cell sub-array voltage corresponding to each shunting adjustment circuit, and a sampling frequency is selected; the time length of sampling data is selected, and covers the complete switching period of the solar cell sub-arrayvoltage; the solar cell sub-array voltage corresponding to each shunting adjustment circuit is sampled, and an adjusted level is searched for; according to the found adjustment level, fault diagnosisis carried out; and sampling and diagnosis in the next round is turned to. According to technical schemes of the invention, it is only required to add the detection quantity of the solar cell sub-array voltage to each shunting adjustment circuit to carry out detection and positioning accurately, the method is simple, the fault detecting rate is high, the fault can be located rapidly and diagnosedrapidly, and fewer detection quantities are added.

Owner:SHENZHEN AEROSPACE NEW POWER TECH +1

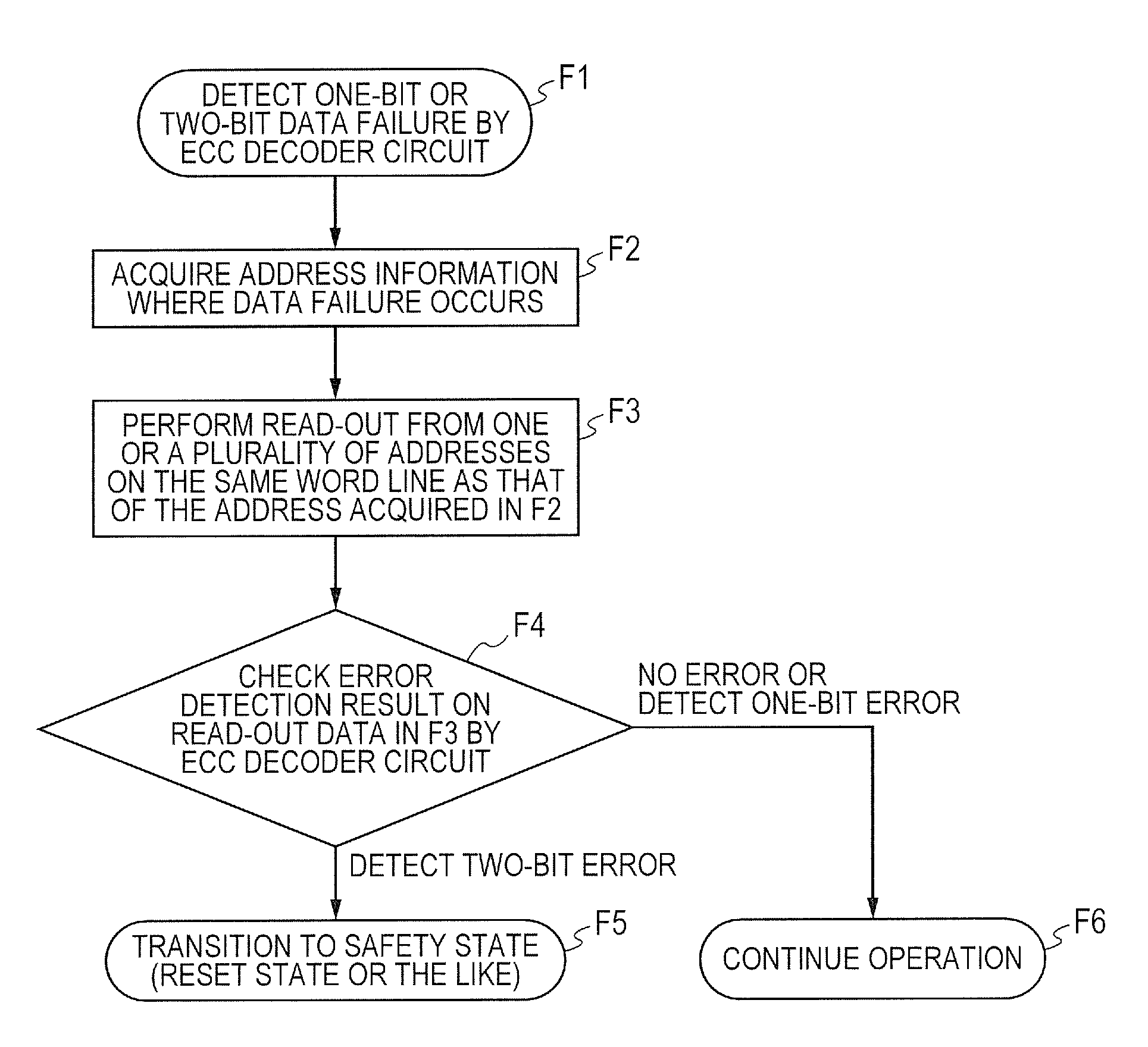

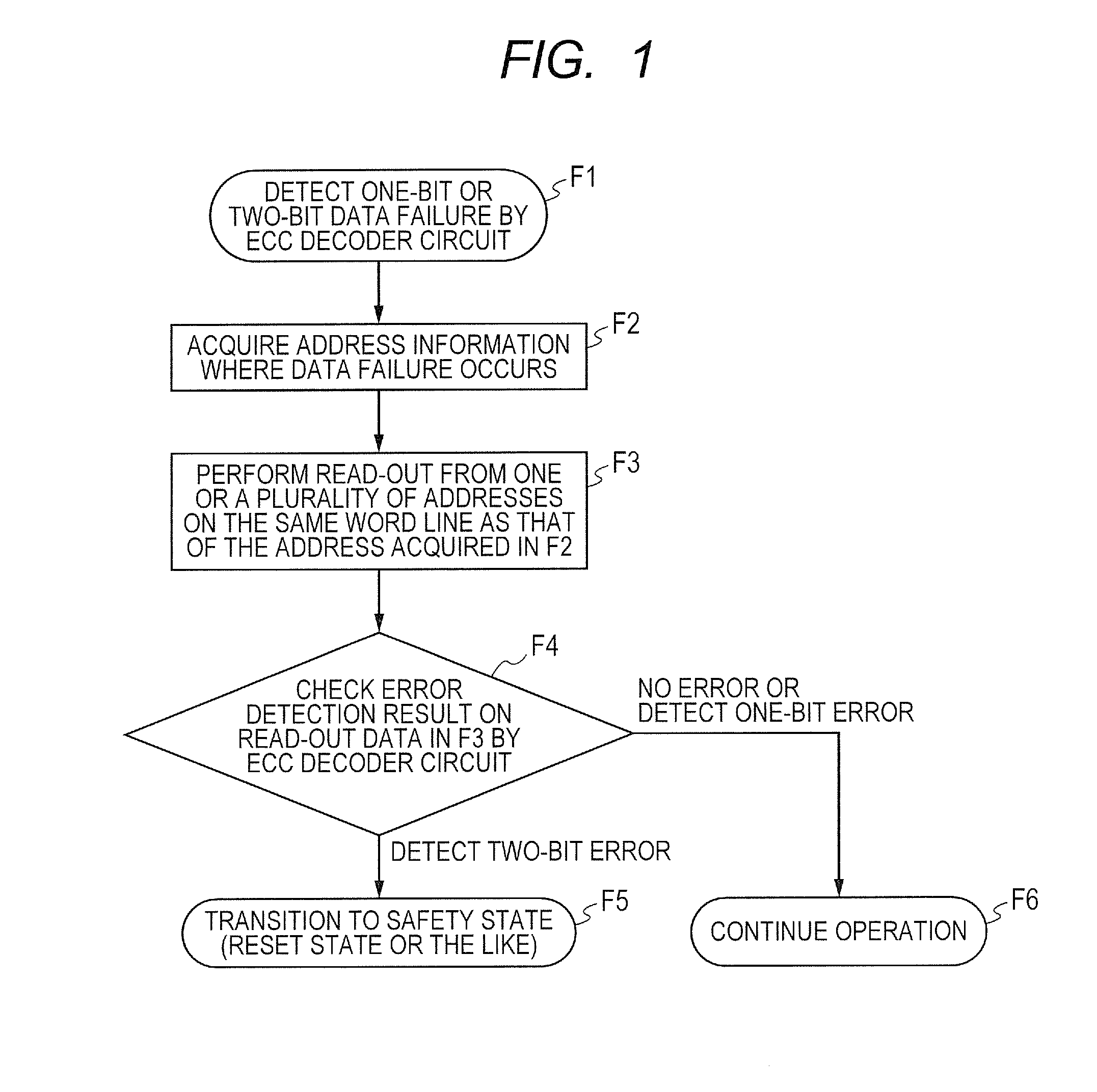

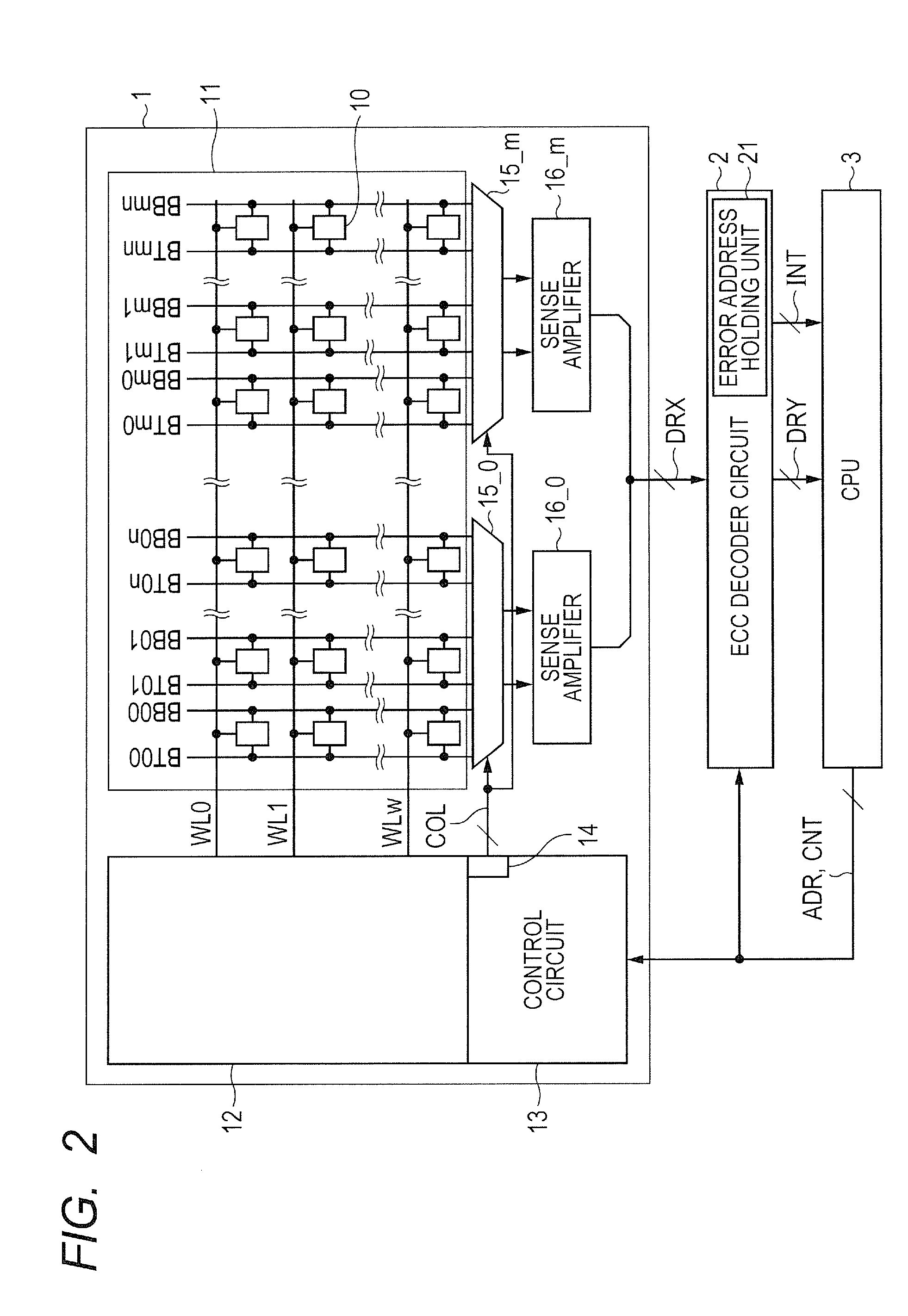

Diagnostic program, diagnostic method, and semiconductor device

InactiveUS20160283339A1Improve fault detection rateDetecting faulty computer hardwareDigital storageDiagnostic programComputer science

In a memory with ECC, a failure detection rate of an address circuit of the memory is improved without using address information to generate redundant bits and without rewriting the memory.The memory stores data of addresses different from each other and redundant bits added to the data in a plurality of memory cells sharing the same selection signal wiring (for example, a word line or a column line) and outputs read-out data corresponding to a specified address. An ECC decoder performs error detection on the read-out data. When an error is detected by the ECC decoder, a failure diagnosis of the memory is performed by accessing one or a plurality of addresses which are selected by the same selection signal wiring as selection signal wiring that selects read-out data where the error is detected and which are different from the address of the read-out data and evaluating a result of the error detection for the read-out data.

Owner:RENESAS ELECTRONICS CORP

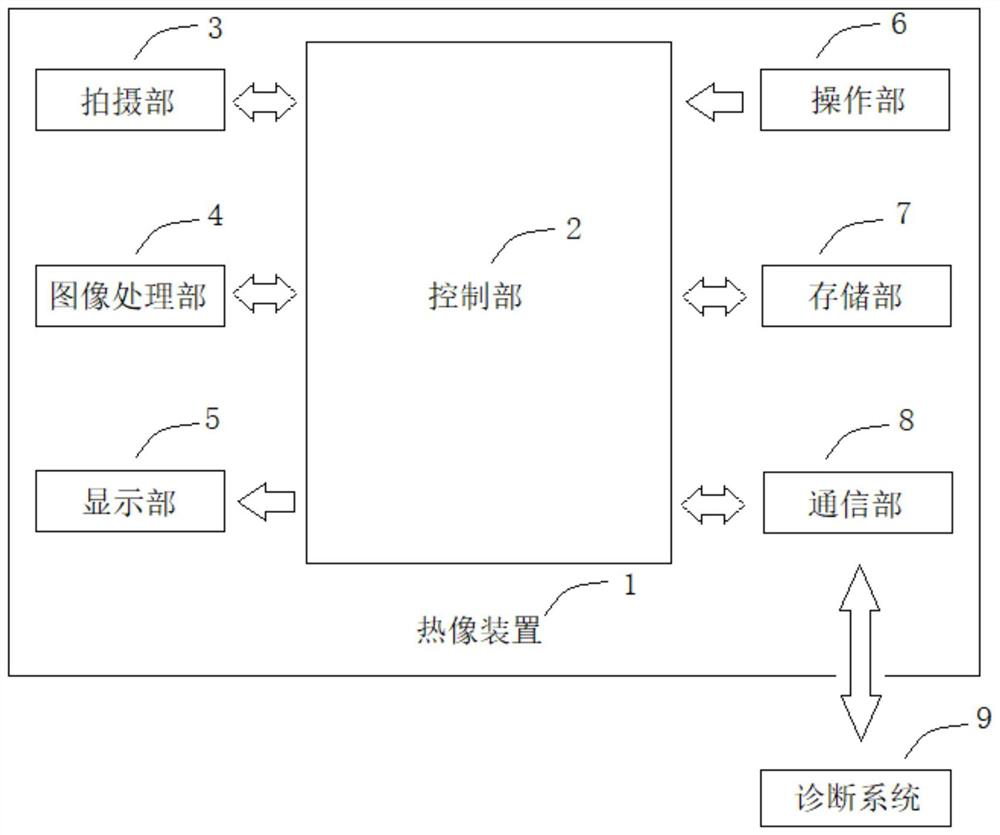

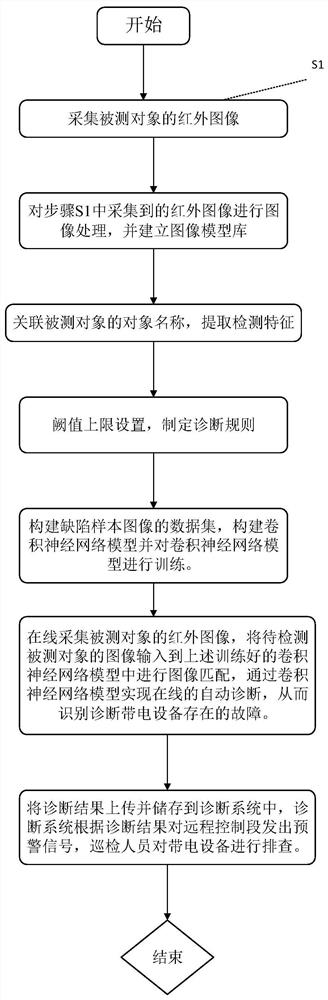

Electrified equipment fault diagnosis method based on neural network model

PendingCN111798407ARealize precise identificationImprove accuracyImage enhancementRadiation pyrometryData setAlgorithm

The invention discloses an electrified equipment fault diagnosis method based on a neural network model. The electrified equipment fault diagnosis method comprises the following main steps: S1, acquiring an infrared image of a measured object; S2, performing image processing, and establishing an image model library; S3, associating object names of the detected objects, and extracting detection features; S4, setting a threshold upper limit, and formulating a diagnosis rule; S5, constructing a data set of the defect sample image, constructing a convolutional neural network model, and training the convolutional neural network model; and S6, acquiring an infrared image of the measured object online, and realizing online automatic diagnosis through the convolutional neural network model, thereby identifying and diagnosing faults of the electrified equipment. According to the method, the trained convolutional neural network model is applied to identification of the defect image of the electrified equipment, so that accurate identification of the fault of the electrified equipment is realized, the operation is simple and convenient, the data is standard and unified, the working difficultyof electric power inspection can be reduced, the inspection efficiency is improved, and the fault detection rate is increased.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER CO LTD JIAXING POWER SUPPLY CO

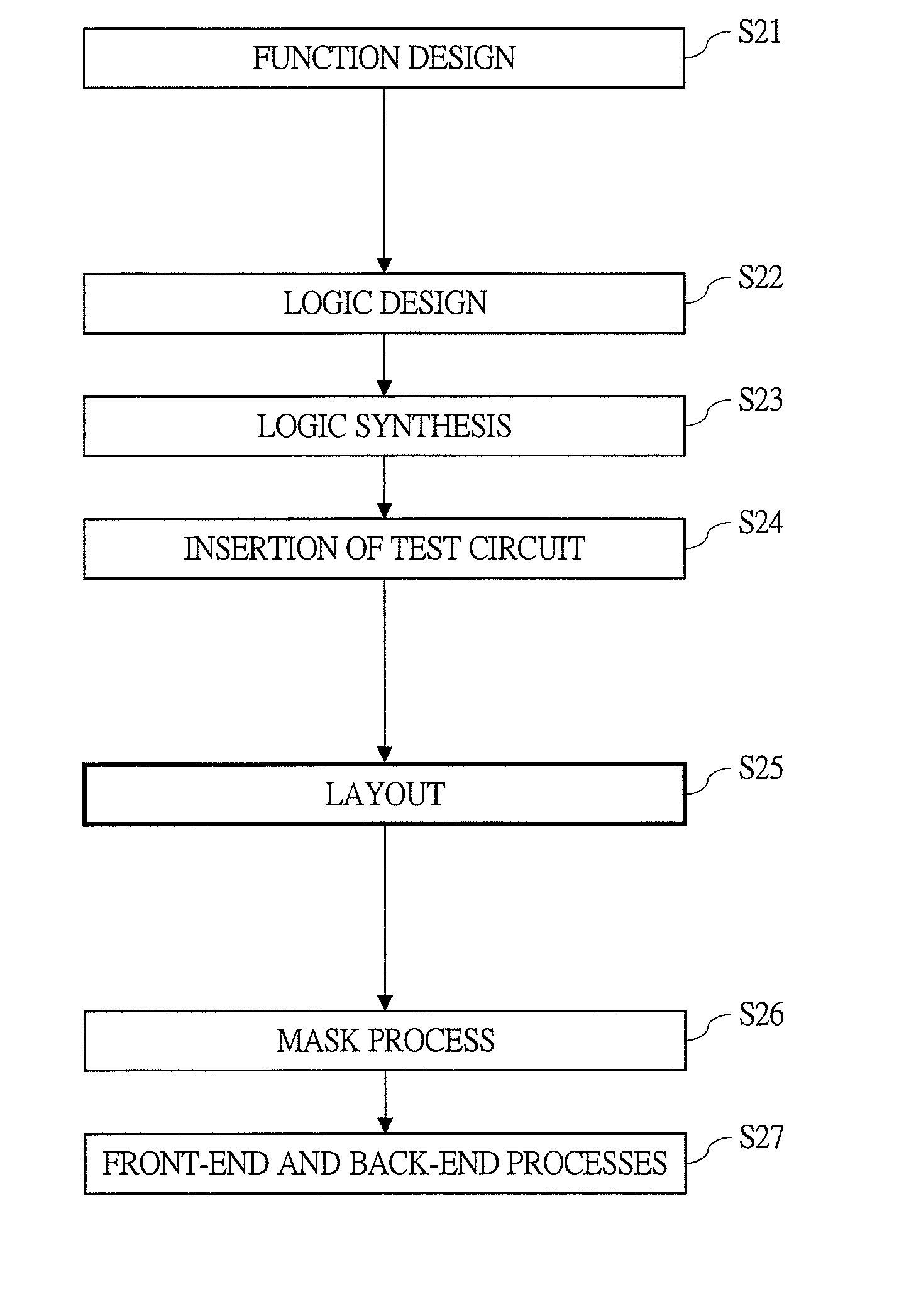

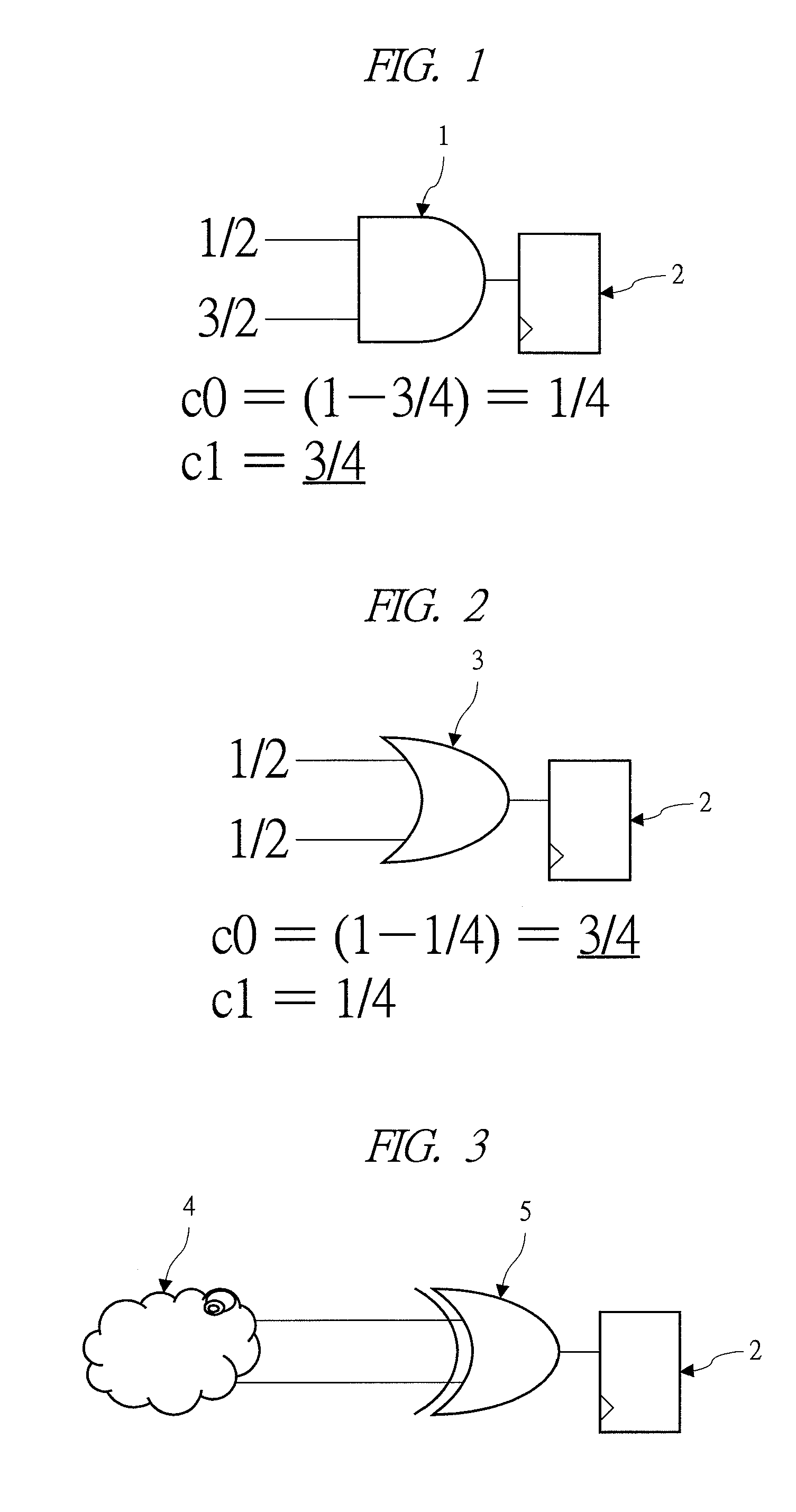

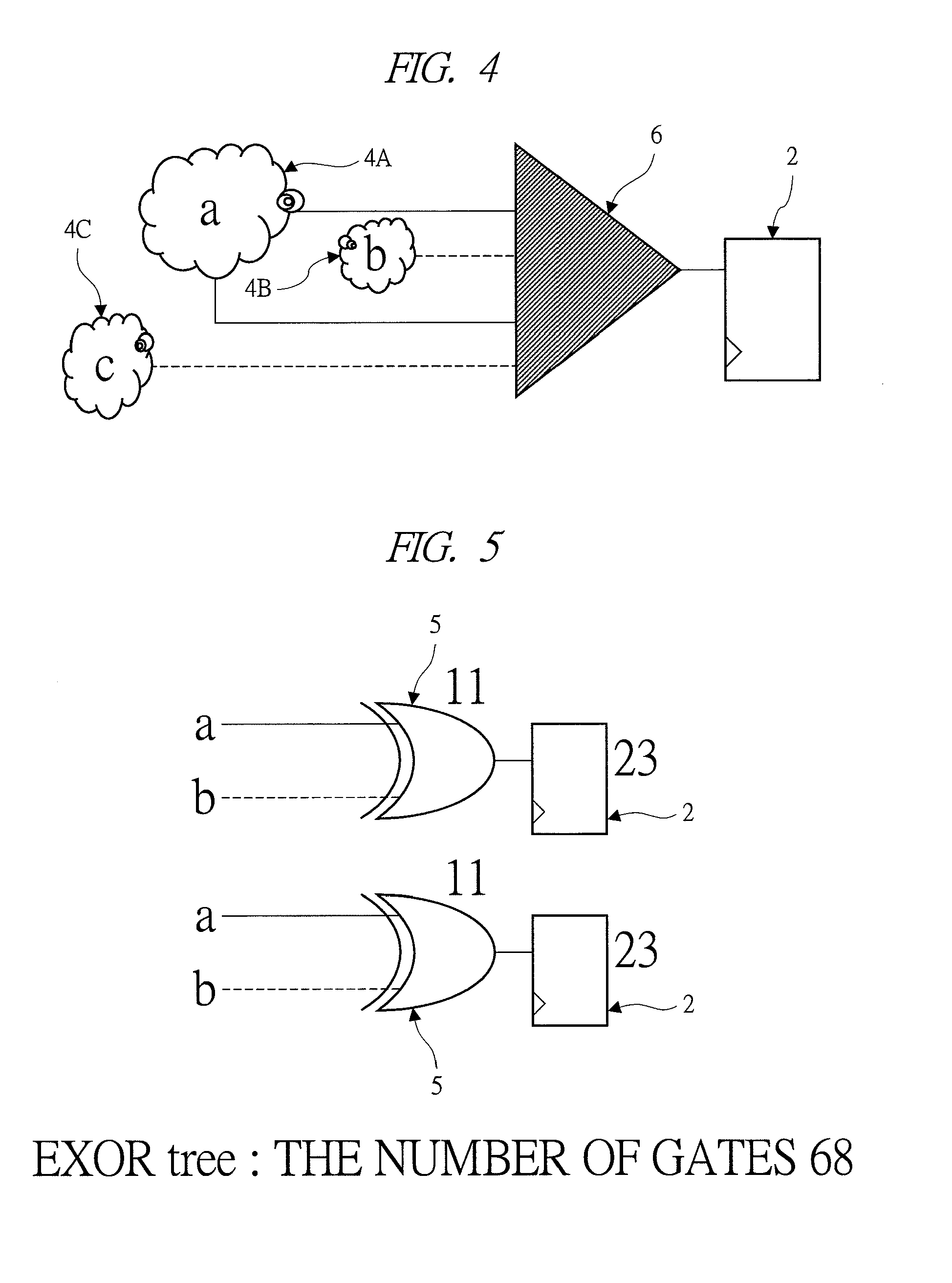

Method and software for designing semiconductor integrated circuit

InactiveUS20110265053A1Improve fault detection rateDetecting faulty computer hardwareCAD circuit designFlip-flopHemt circuits

In order to improve a failure detection rate in a layout automatic design process of a DFT circuit, signal lines of the DFT circuit are aggregated by an AND tree circuit 1 or an OR tree circuit instead of an EXOR tree circuit, and outputs thereof are received by an observation flip-flop 2. When a failure detection process of the DFT circuit is performed by using the EXOR tree circuit in the case where partial circuits outputting respective signal lines are shared or the partial circuits have the same structure, the signals cancel each other and the failures of the original partial circuits cannot be detected in some cases. However, such a trouble can be prevented by using the AND tree circuit 1 or the OR tree circuit instead of the EXOR tree circuit.

Owner:RENESAS ELECTRONICS CORP

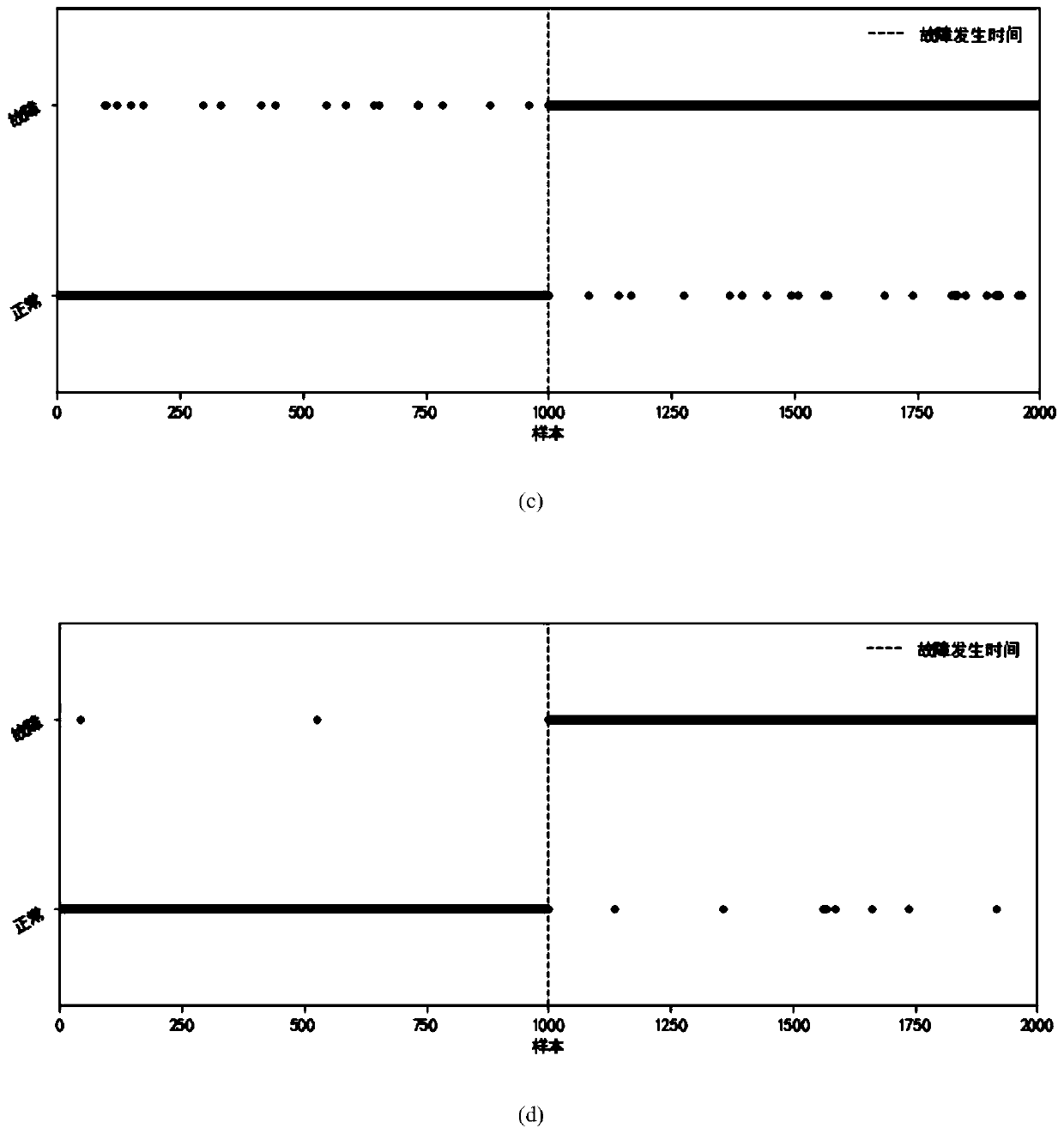

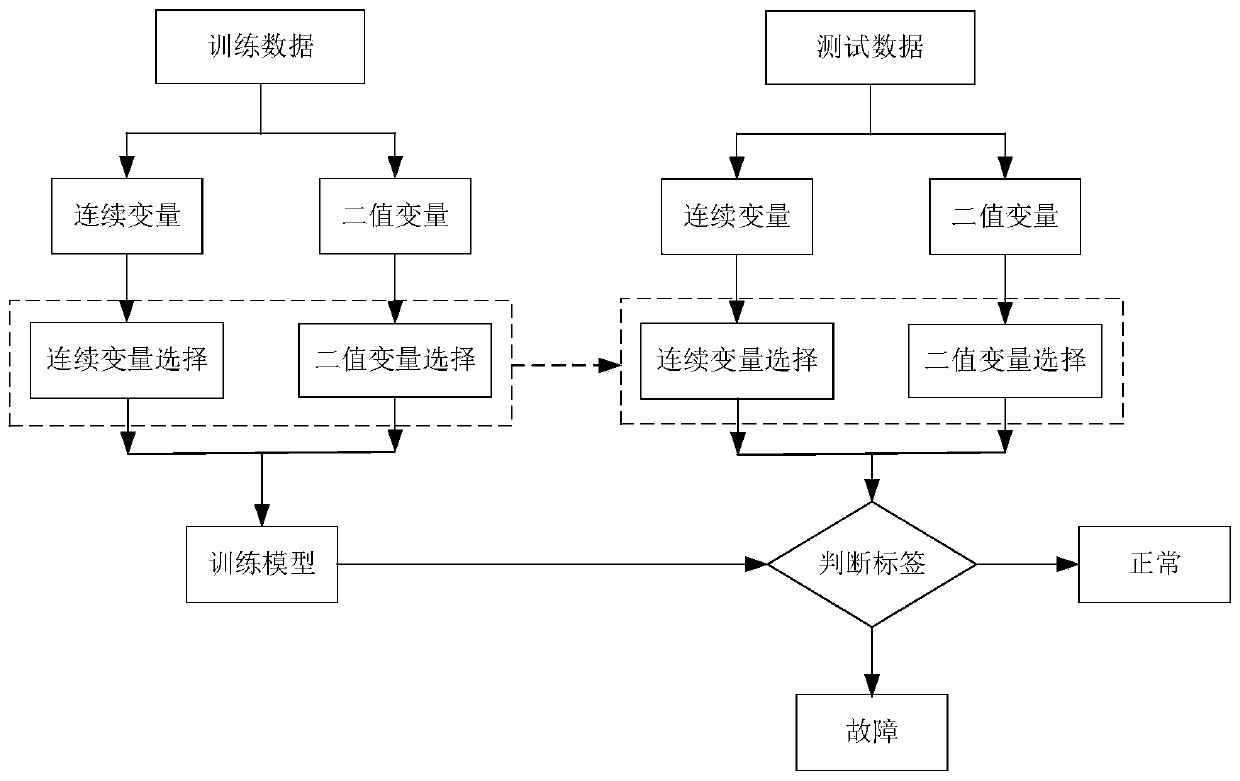

Anomaly detection method based on hybrid hidden naive Bayesian model

ActiveCN111414943AGood effectReduce false alarm rateCharacter and pattern recognitionAnomaly detectionEngineering

The invention discloses an anomaly detection method based on a hybrid hidden naive Bayesian model, and belongs to the field of fault diagnosis. According to the method, through selection of continuousvariables and binary variables, correlations between the continuous variables, between the binary variables and between the binary variables and between the binary variables are considered, and a hybrid hidden naive Bayesian model containing information of the continuous variables and the binary variables at the same time is constructed. Compared with a traditional method, due to the fact that the information of the binary variable is added, the method has higher performance on detection of anomalies in the process industry, the fault false alarm rate can be remarkably reduced, and the faultdetection rate is effectively increased.

Owner:SHANDONG UNIV OF SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com