Linear-nonlinear industrial process fault detecting method based on linear evaluation factors

A technology for evaluating factors and fault detection, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as the inability to accurately describe the linear-nonlinear process information of complex systems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

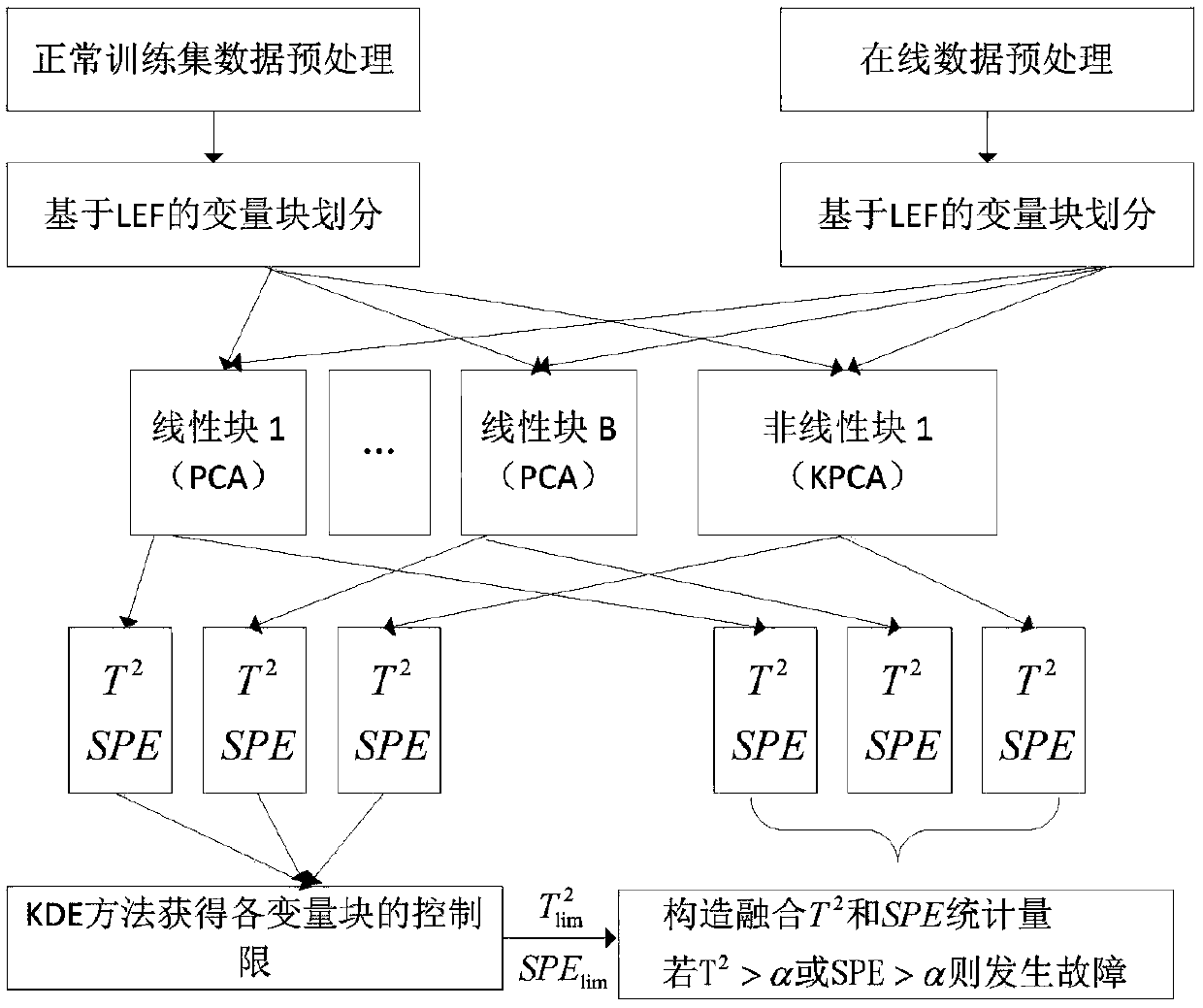

Image

Examples

Embodiment 1

[0171] Embodiment one: at first, design the numerical system that contains 8 variables, its structure is as follows:

[0172] x 1 =u+e 1

[0173] x 2 =-2x 1 +1+e 2

[0174] x 3 = u 2 -3u+e 3

[0175]

[0176] x 6 =2x 5 +1+e 6

[0177] x 7 =sin(8πu)+e 7

[0178]

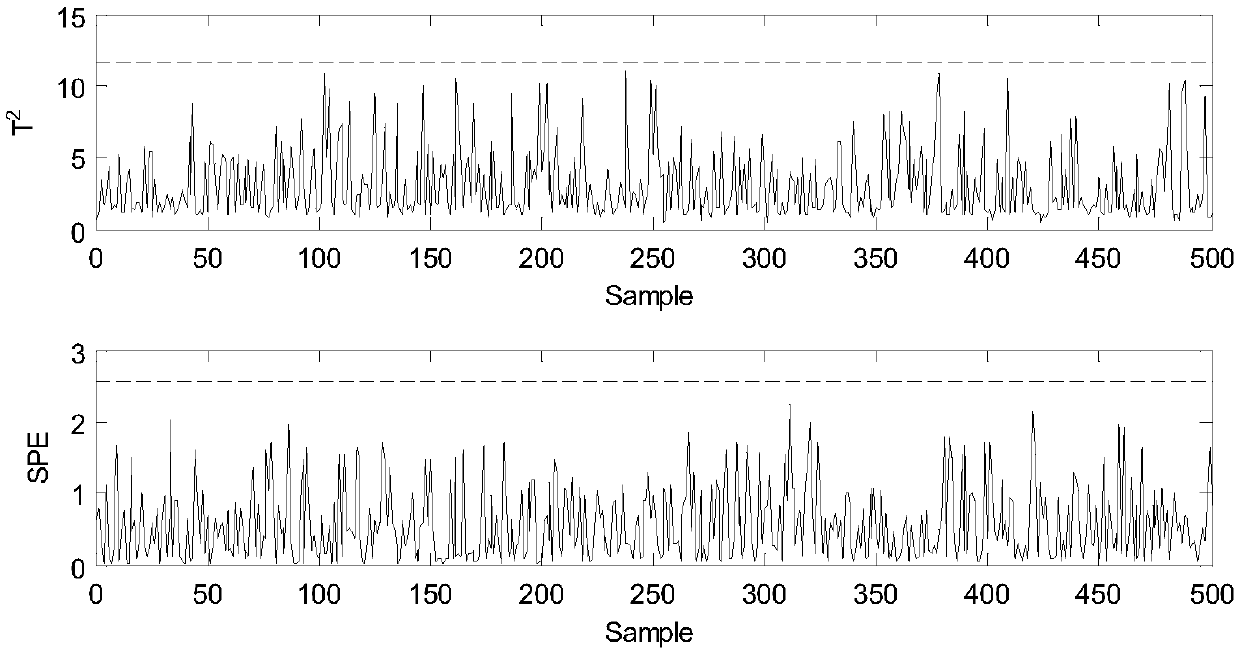

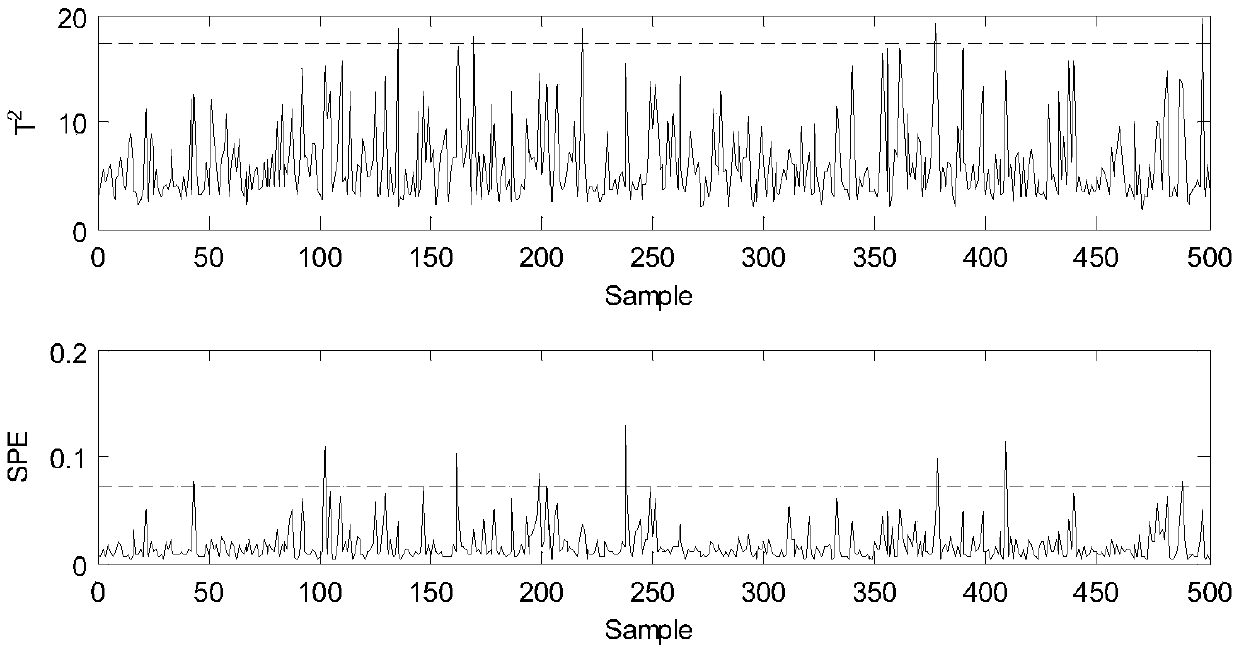

[0179] Among them, the data source signal u obeys the uniform distribution U(0, 2), e 1 ~e 8 8 independent noises with zero mean and 0.01 variance. Firstly, 500 sets of normal data are simulated as a training set for historical modeling. In addition, two sets of data containing faults are simulated as the test set, and each set of data contains 500 samples. Fault 1: variable x is given at the 201st moment 5 Add a step fault with an amplitude of 0.3.

[0180] The above-mentioned fault detection method of the present invention (hereinafter referred to as the LEF method) is used to detect the fault of the linear-nonlinear numerical system described in this embodiment. After the fault is detec...

Embodiment 2

[0188] Embodiment 2: Tennessee-Eastman (hereinafter referred to as: TE) process is an experimental platform established by Downs and Vogel of Eastman Chemical Company of the United States according to an actual chemical process, and is now widely used to verify control algorithms and process monitoring pros and cons of the method. see image 3 , the TE process is mainly composed of five units, including reactor, product condenser, gas-liquid separator, cycle compressor and stripper. There are 53 variables in the TE process, including 22 continuous measurement variables, 19 component variables and 12 operational variables. In this embodiment, referring to Table 3, 33 variables in the TE process are selected; referring to Table 4, there are 21 faults in total.

[0189] table 3

[0190] variable label

variable description

variable label

variable description

1

A feed (stream 1)

18

Stripper temperature

2

D feed (stream 2)

19

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com