Monitoring method and monitoring system for overheat fault of transformer

A technology for monitoring systems and transformers, applied in radiation pyrometry, instruments, measuring devices, etc., can solve the problems of inconvenient operation, low fault detection rate, and low degree of automation, and achieve high fault detection rate and low Good operation and maintenance cost and work stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

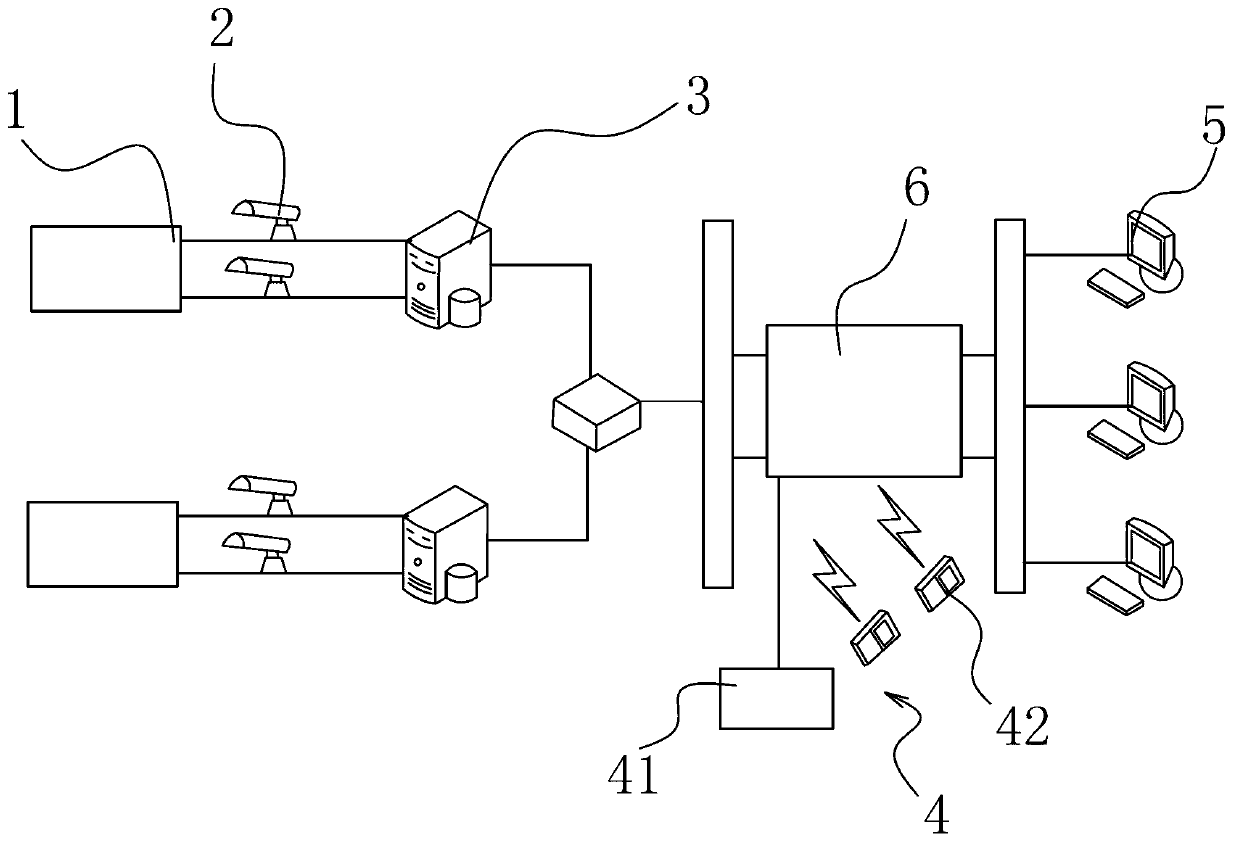

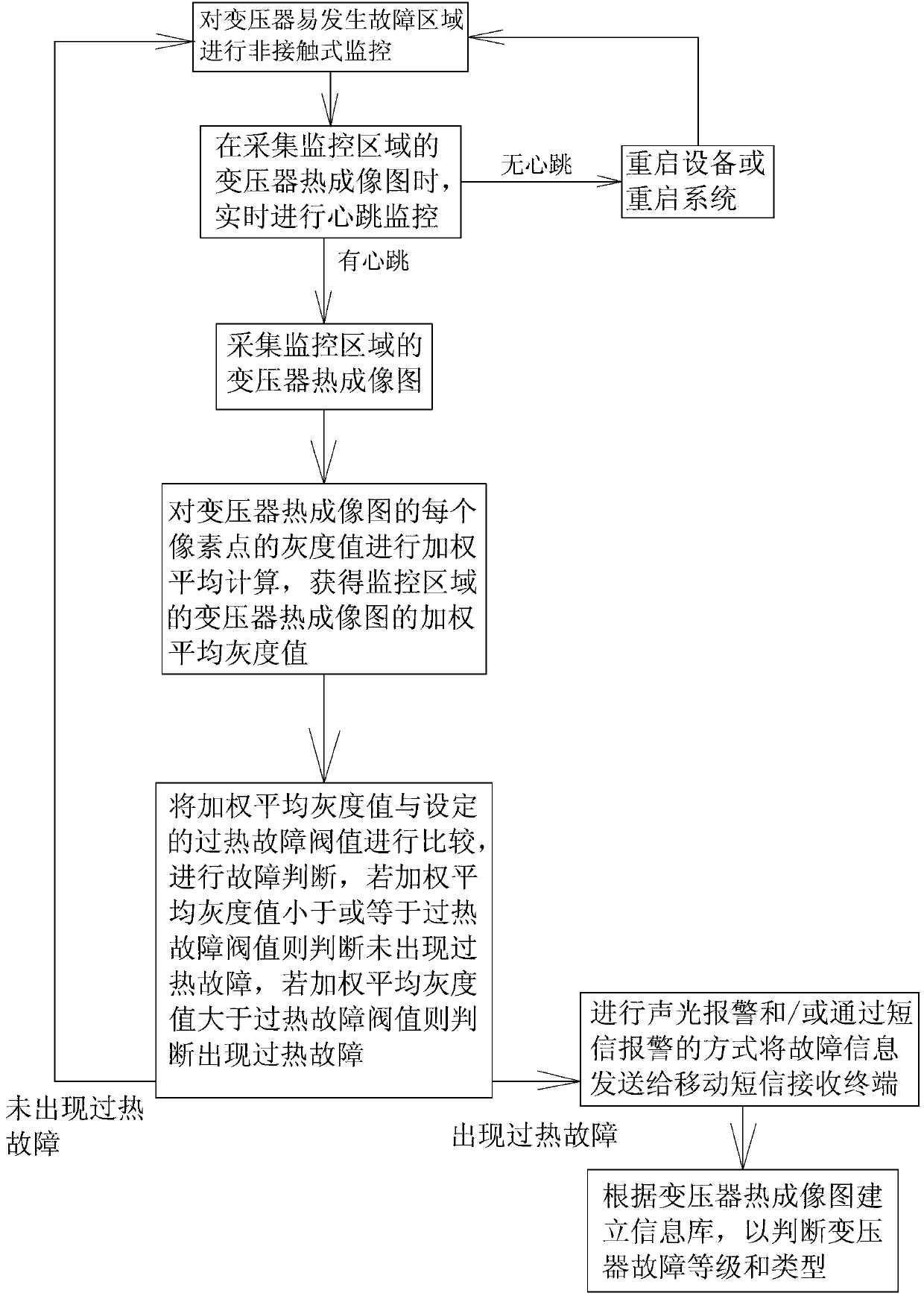

[0031] Such as Figure 1-3 As shown, the monitoring method of the transformer overheating fault, the monitoring method includes the following steps:

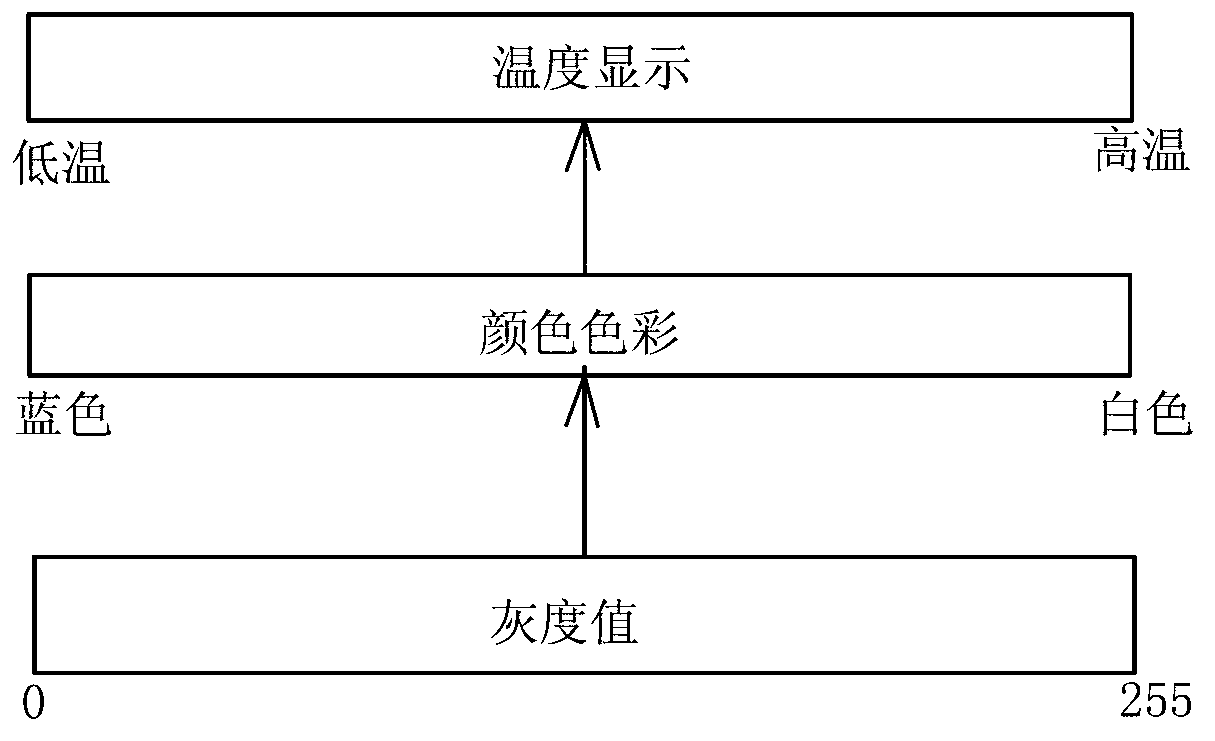

[0032] A. Thermal image collection: non-contact monitoring of transformer prone to failure areas, collecting transformer thermal imaging images in the monitoring area, and then transmitting them to the industrial computer; B, image recognition processing: the industrial computer will collect the transformer thermal imaging images Carry out identification and processing to determine whether there is an overheating fault in the transformer; C. Fault judgment and treatment: If the monitored transformer does not have an overheating fault, continue monitoring; if the monitored transformer has an overheating fault, an alarm signal will be sent. The transformer is a high-voltage product, and the invention adopts a non-contact monitoring method to ensure the safety of personnel. The fault-prone area of the transformer in the present ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com