Patents

Literature

44results about How to "Improve maintenance level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

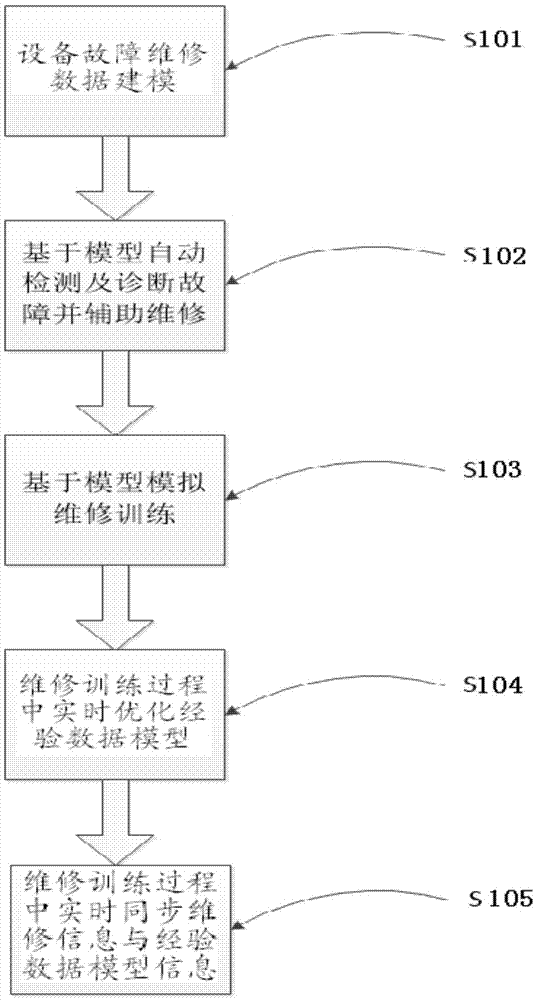

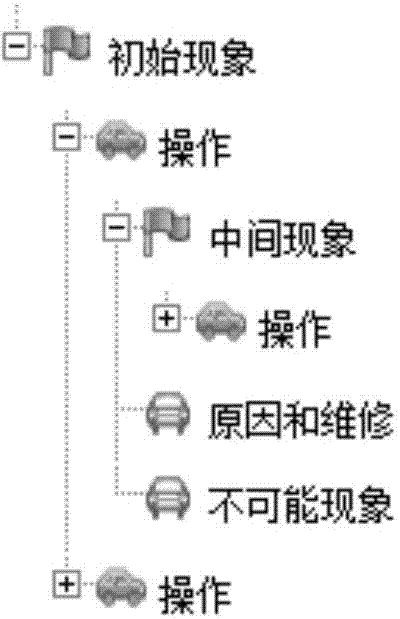

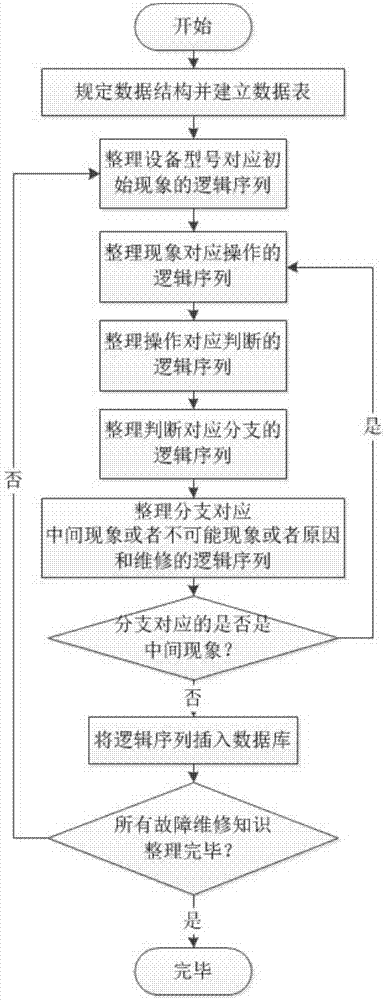

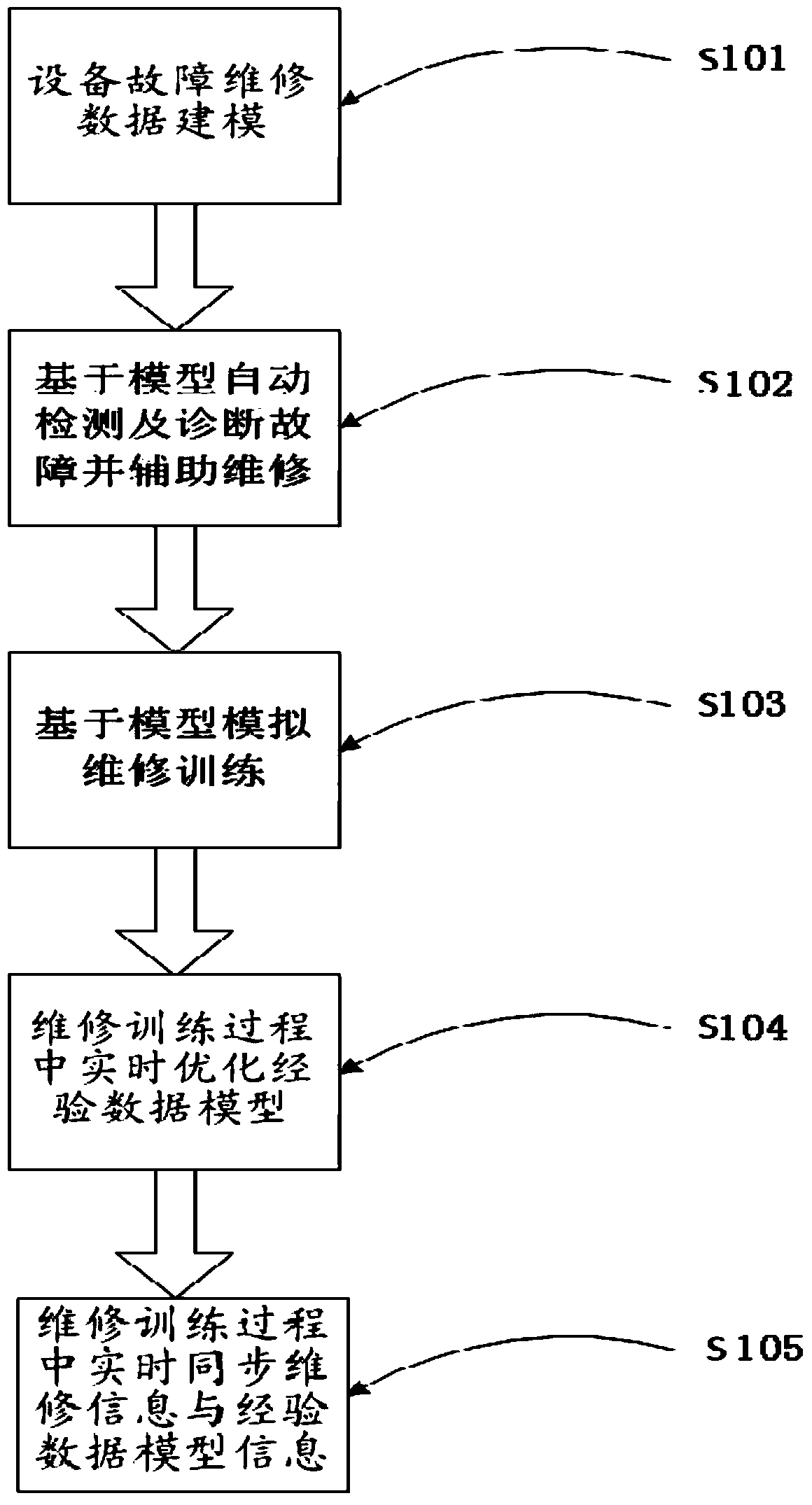

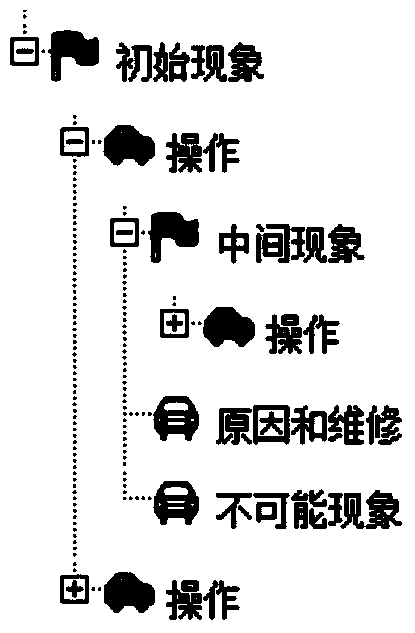

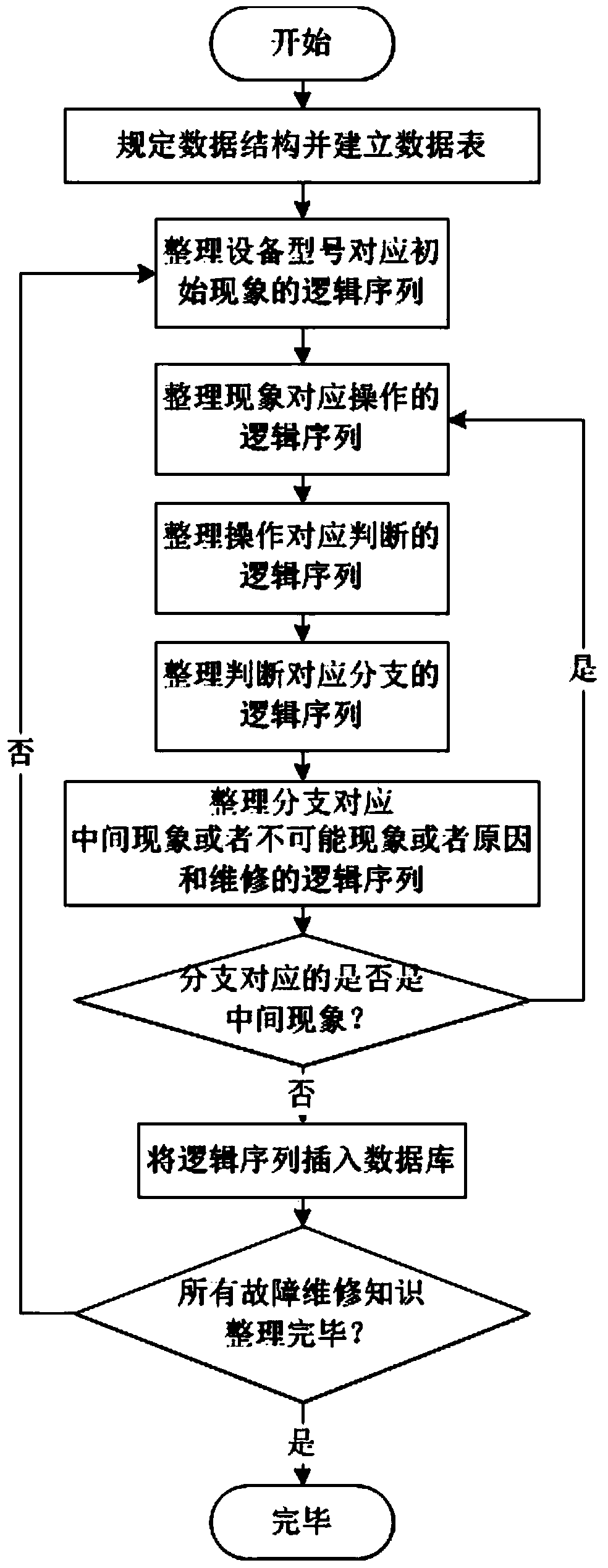

General fault detecting and maintenance method for equipment

InactiveCN103617576ARealize accumulationAchieve sharingDetecting faulty computer hardwareForecastingMaintenance strategySimulation training

The invention discloses a general fault detecting and maintenance method for equipment. The general fault detecting and maintenance method for the equipment comprises the following steps of carrying out modeling on maintenance knowledge of the equipment faults, automatically detecting and diagnosing the faults and carrying out auxiliary maintenance based on a model, simulating maintenance training based on the model, optimizing an experience knowledge model in real time in the maintenance training process, and synchronizing maintenance information and experience knowledge model information in the maintenance training process. Compared with an existing equipment maintenance method, the general fault detecting and maintenance method for the equipment enables the accumulation and the sharing of equipment maintenance experience knowledge and the automatic diagnosis of equipment faults to be achieved, and assistance can be provided for related maintenance strategies through the analysis and the exploitation of the maintenance record information. In addition, effective transmission of the experience of experts to primary maintainers is achieved through the step of simulation training. The general fault detecting and maintenance method for the equipment is especially suitable for chemical defense troops and other occasions where a large amount of complex equipment needs to be maintained frequently and where the turnover rate of maintenance personnel is high. Practice proves that the general fault detecting and maintenance method for the equipment can obvious improve equipment maintenance efficiency, promote maintenance levels and improve maintenance quality.

Owner:NANJING UNIV +1

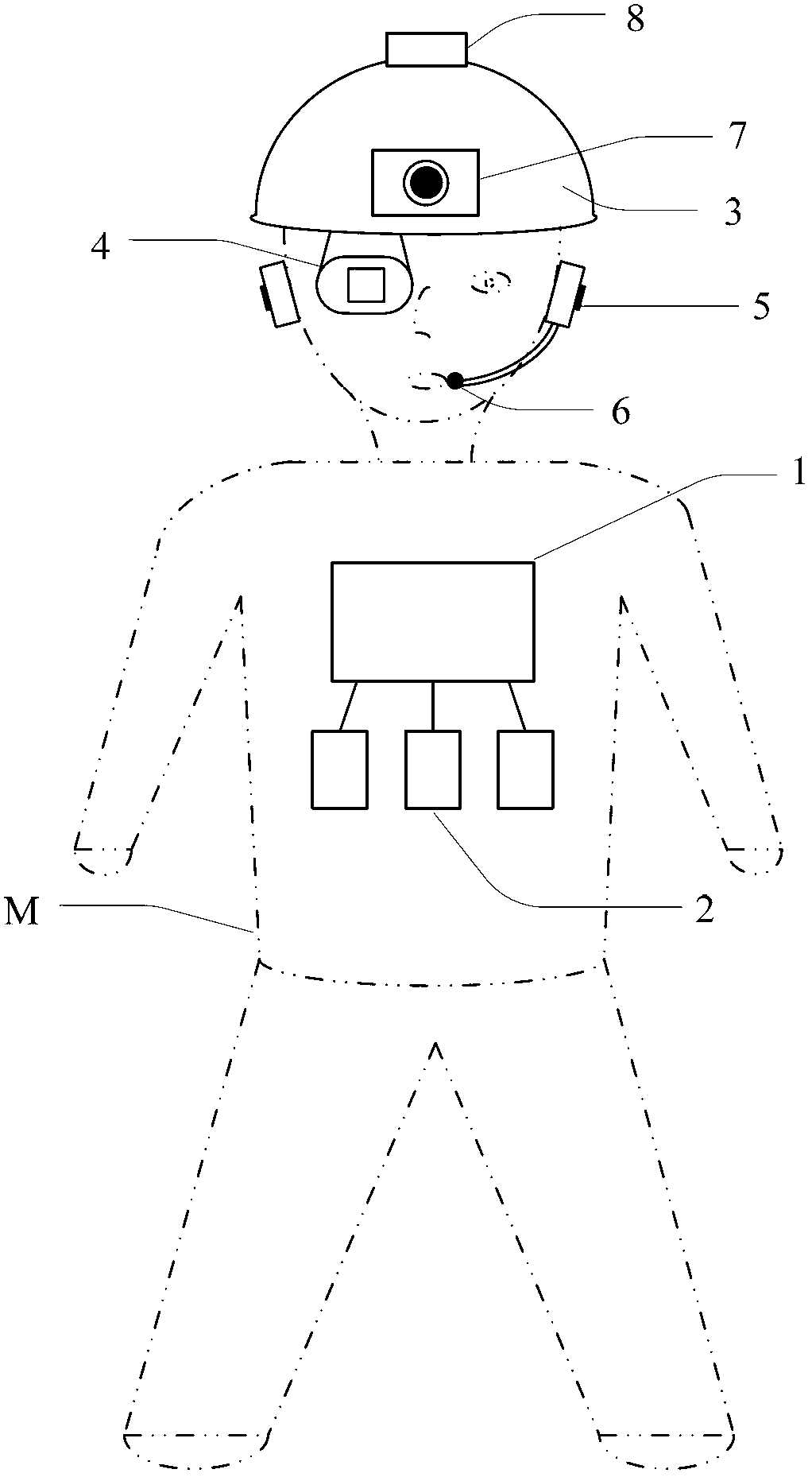

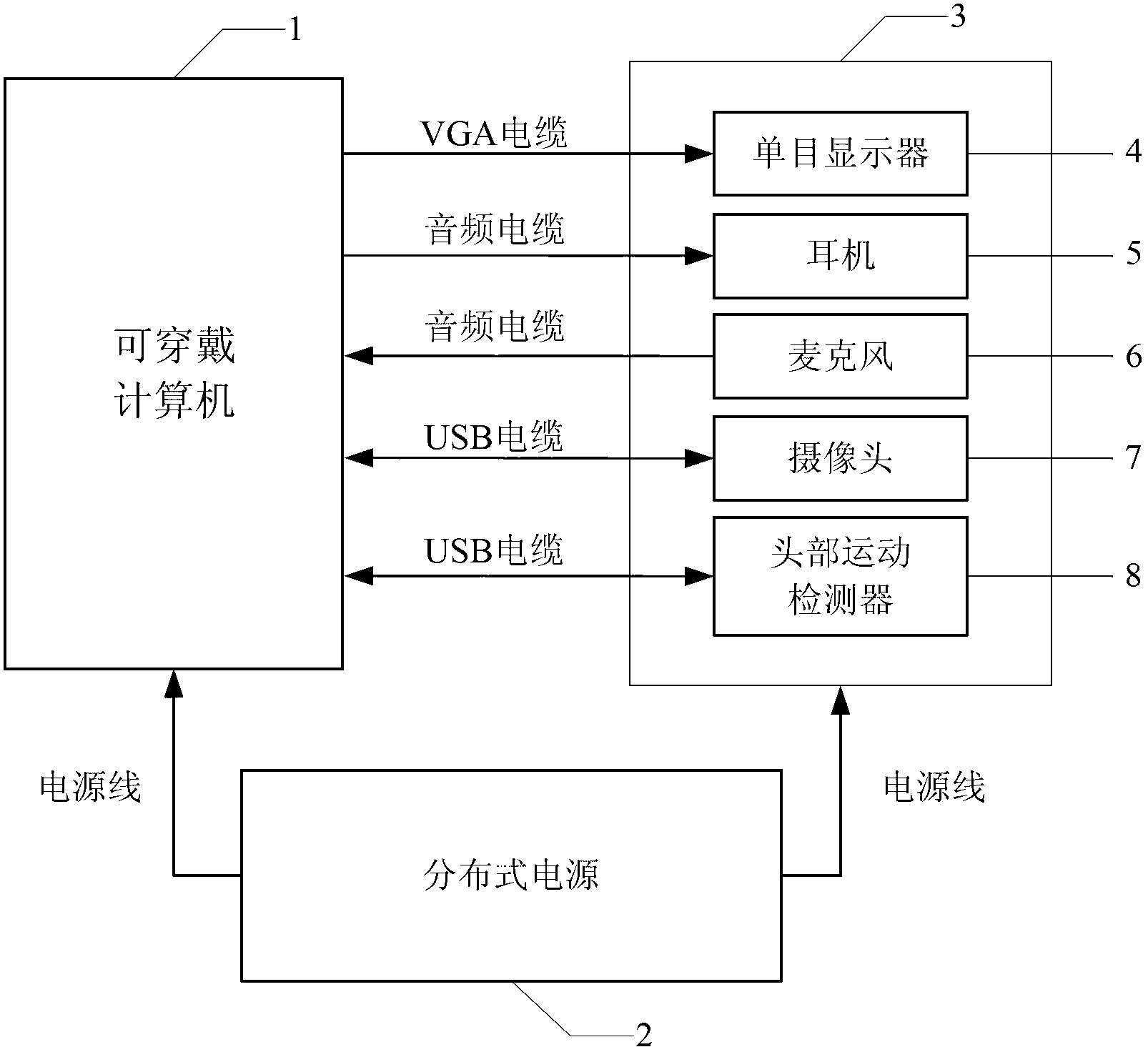

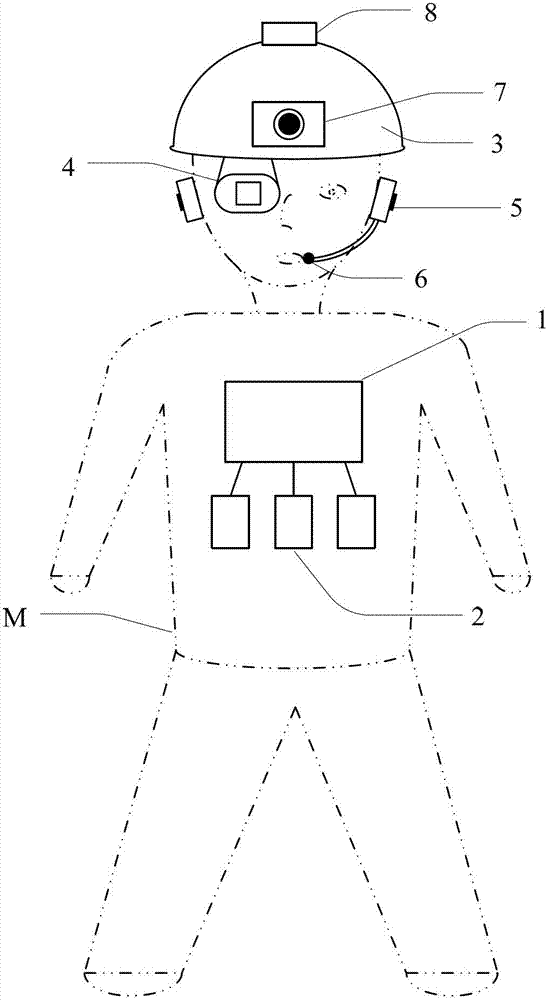

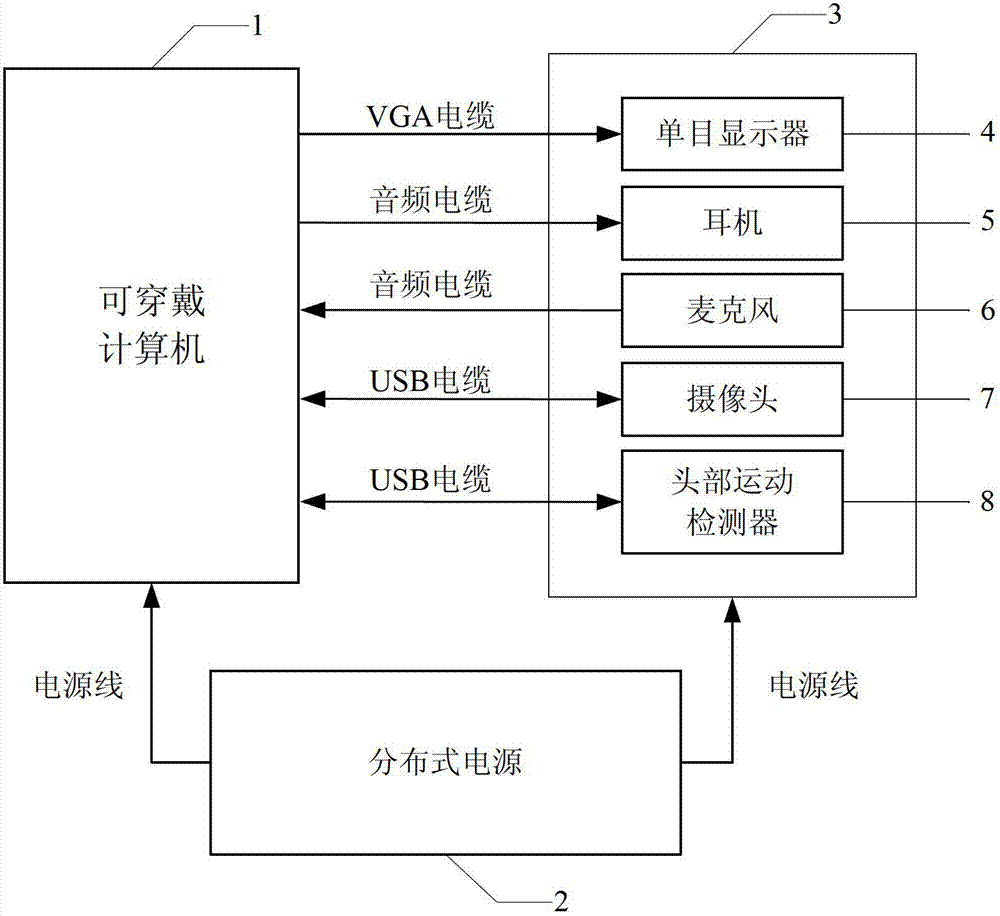

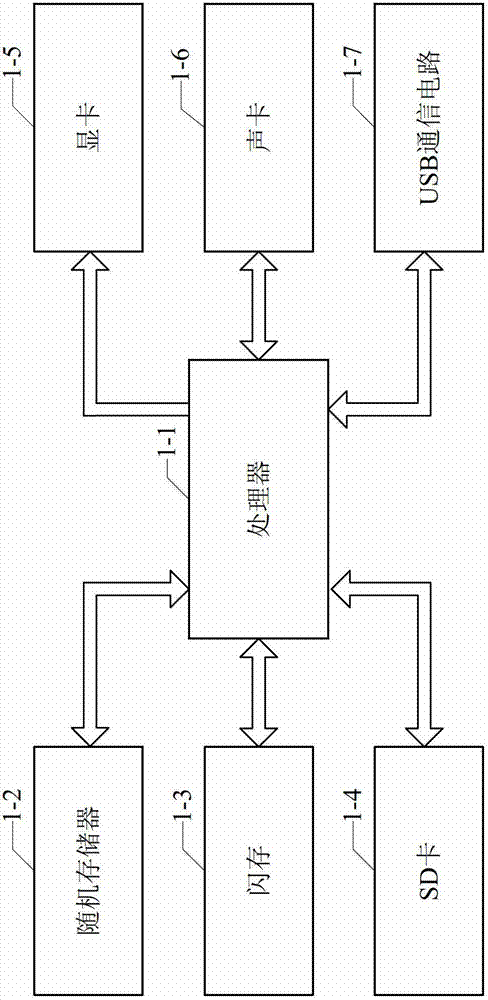

Wearable auxiliary device for aircraft maintenance

InactiveCN102795349AAvoid misuseImprove maintenance levelAircraft maintainanceMotion detectorHead movements

The invention belongs to wearable auxiliary equipment for aircraft maintenance in the field of the maintenance of aviation machines. The wearable auxiliary equipment comprises a wearable computer, a head motion detector which contains a helmet, an inertial sensor with a gyroscope or a gyroscope of the helmet, a microcontroller and a communication circuit, a camera, a monocular display, earphones, a microphone and a power supply. According to the wearable auxiliary equipment, the head wearable camera is arranged additionally to take pictures and record videos for reference on conditions of maintenance sites and the like, and an operation request is sent by using voice and is confirmed or denied in modes of nodding and shaking a head, so that the auxiliary equipment for maintenance has the characteristics that a comprehensive function is high, the auxiliary equipment can be maintained without manual operation, the conditions (such as failure phenomena and maintenance results) of the maintenance sites and the like can be photographed and recorded accurately and objectively at any time to analyze failure and track the maintenance results subsequently, the maintenance quality and the maintenance efficiency can be improved effectively, the maintenance cost can be reduced and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

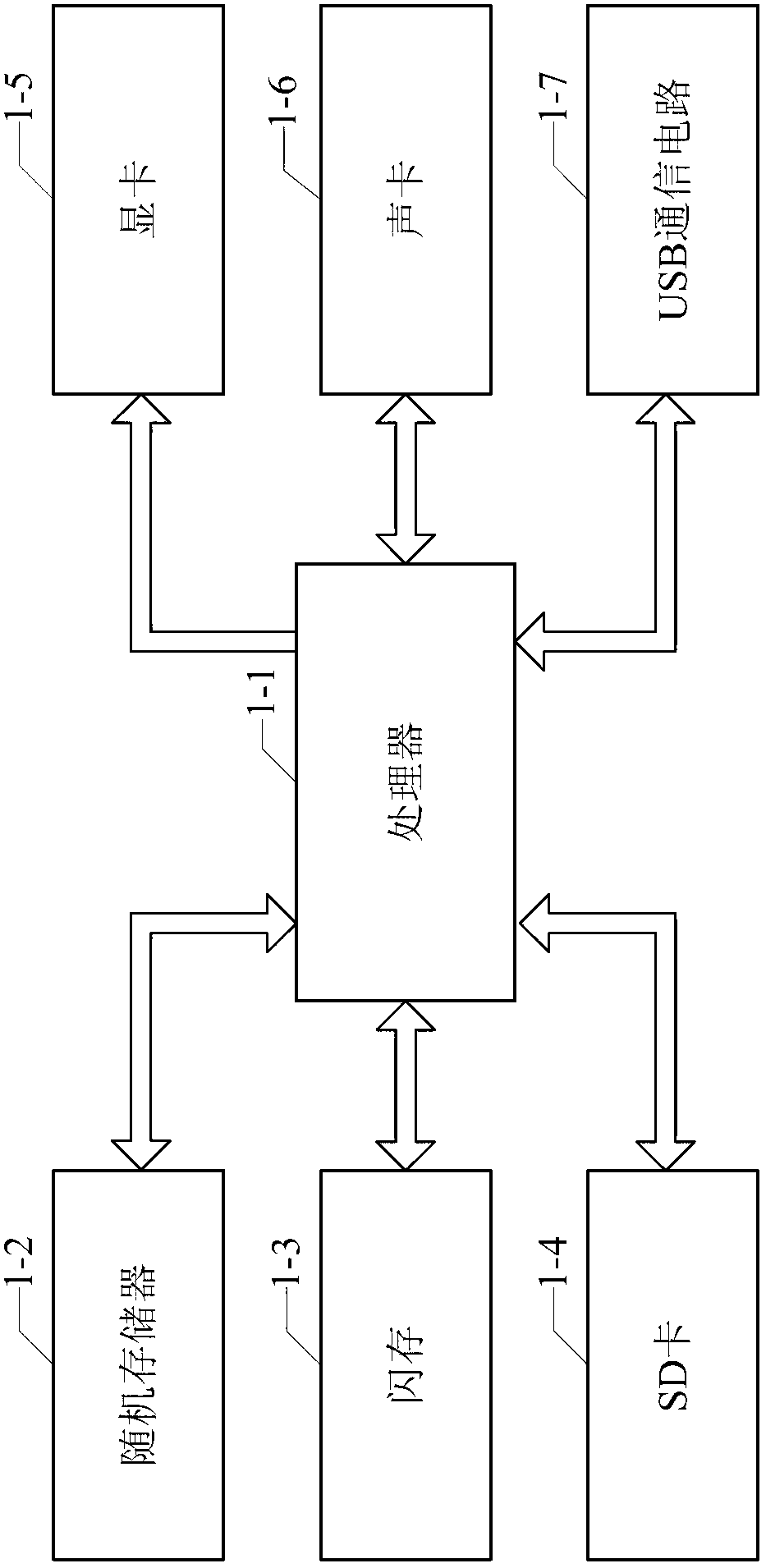

Integrated information platform system based on intelligent hydraulic power plant

ActiveCN104460635APromote intelligent constructionRealize informatizationTotal factory controlProgramme total factory controlInformatizationControl system

The invention discloses an integrated information platform system based on an intelligent hydraulic power plant. The integrated information platform system comprises a centralized control center, a transmission network, a plurality of intelligent hydraulic power plant systems, a water regimen subsystem and a weather subsystem. Each intelligent hydraulic power plant system comprises an intelligent regulation device and a front end collection sensor, the front end collection sensors are used for collecting front end equipment information and are connected with the intelligent regulation devices through hydraulic power plant networks, and collected data are stored into a database. The intelligent regulation devices are used for regulating equipment and control systems according to the internal data of the system. The intelligent hydraulic power plant systems transmit data to the centralized control center through the transmission network. The water regimen subsystem and the weather subsystem are connected with the centralized control center through a communication network and used for providing water regimen and weather information. The integrated information platform system based on the intelligent hydraulic power plant has the advantages that a plurality of independent automation subsystems are connected to form a real-time organic and unified whole, the intelligent construction of the hydraulic power plant can be better promoted, and the informatization and the intelligence of the hydraulic power plant are achieved.

Owner:SICHUAN YITIAN JIQUN TECH

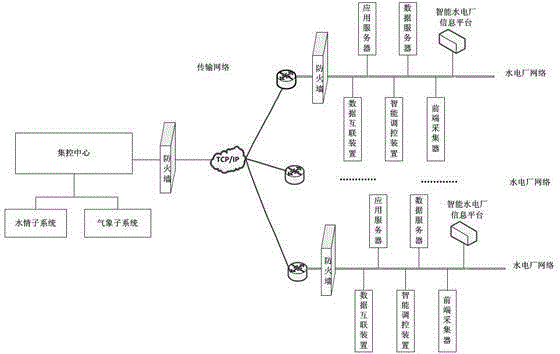

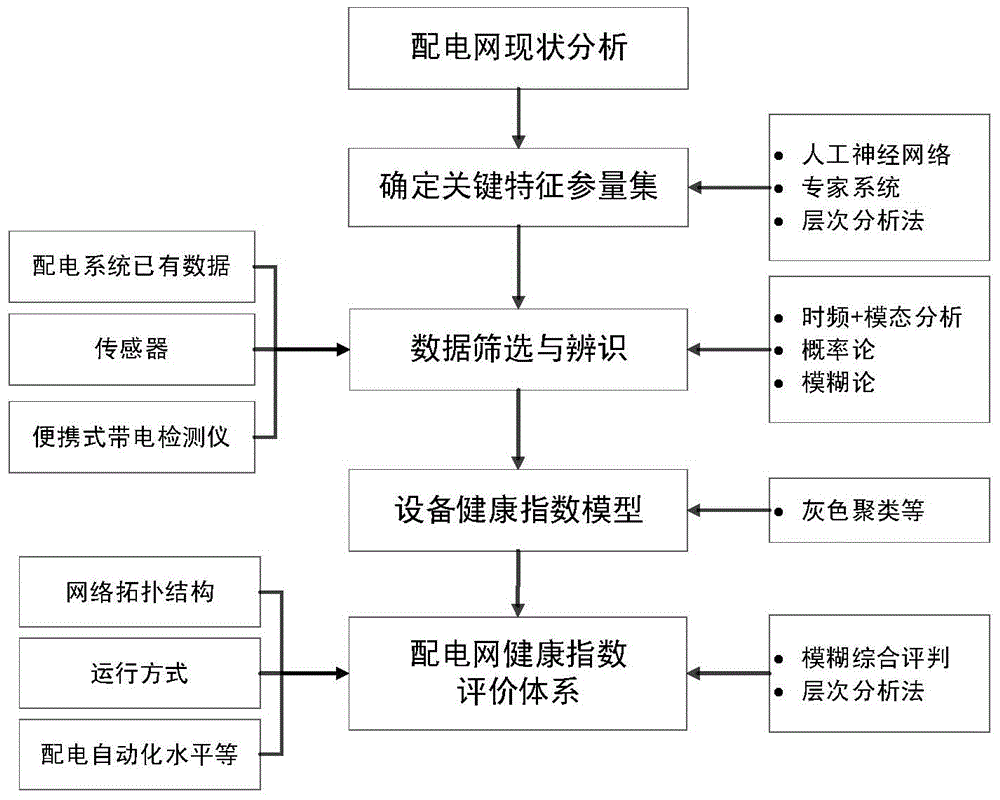

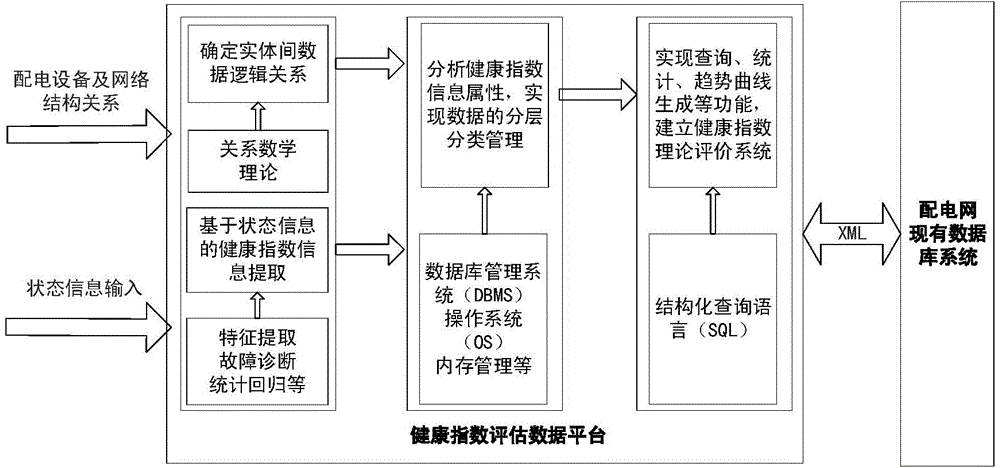

Power distribution network health index assessment engineering application system

ActiveCN105426980AEasy to planImprove maintenance levelForecastingResourcesHealth indexData platform

The invention relates to a power distribution network health index assessment engineering application system. The system comprises a power distribution network health index assessment method layer, a platform layer and an application layer. The system considers a power distribution network equipment state, an operation condition and network topology, a load, safety and environment conditions and other key characteristic parameters, a power distribution network health index assessment method is established from two levels of equipment and a network, a power distribution network health index data platform and an assessment system are established on the basis, an application of health index assessment in power distribution network optimization planning and maintenance fields is achieved, power distribution network asset management can be effectively promoted to be lean, scientific and systematic, and a solid foundation is laid for active power distribution network construction.

Owner:CHINA ELECTRIC POWER RES INST +2

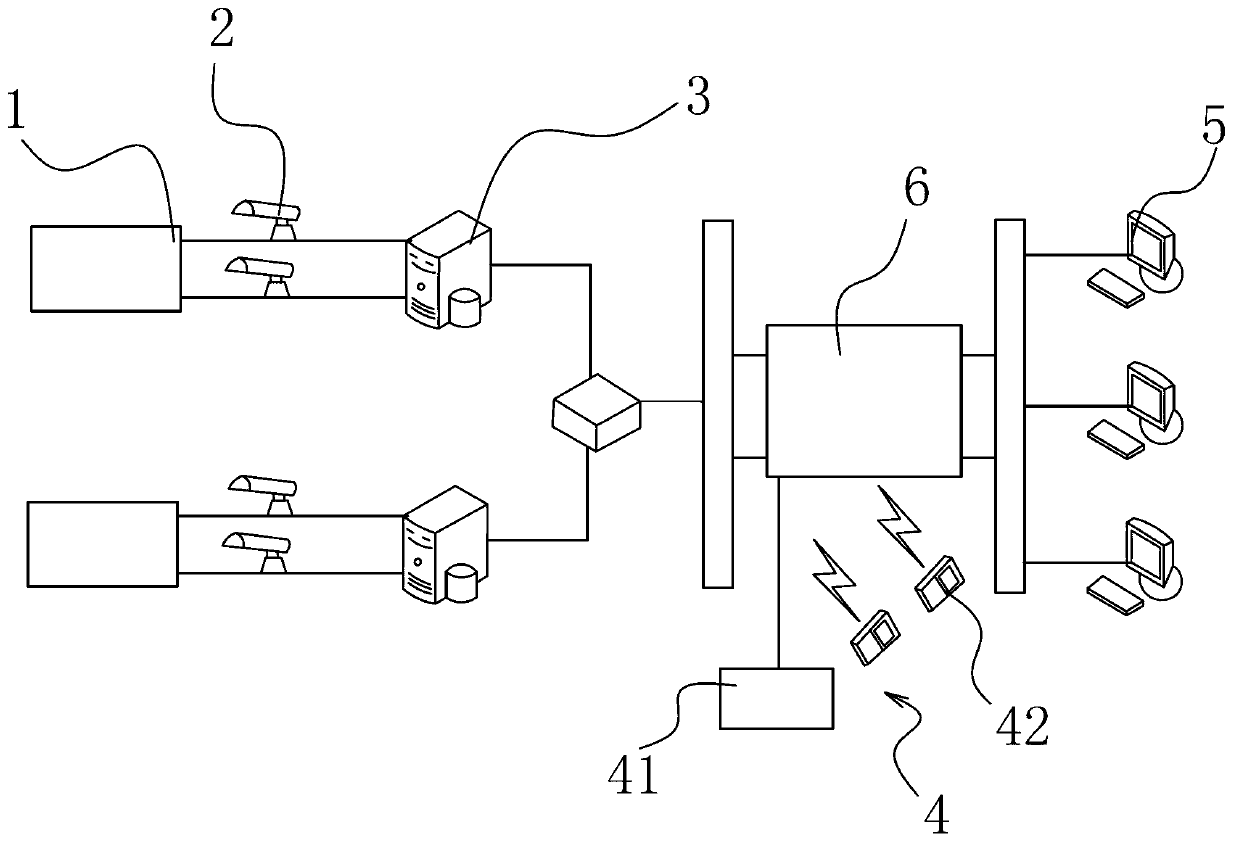

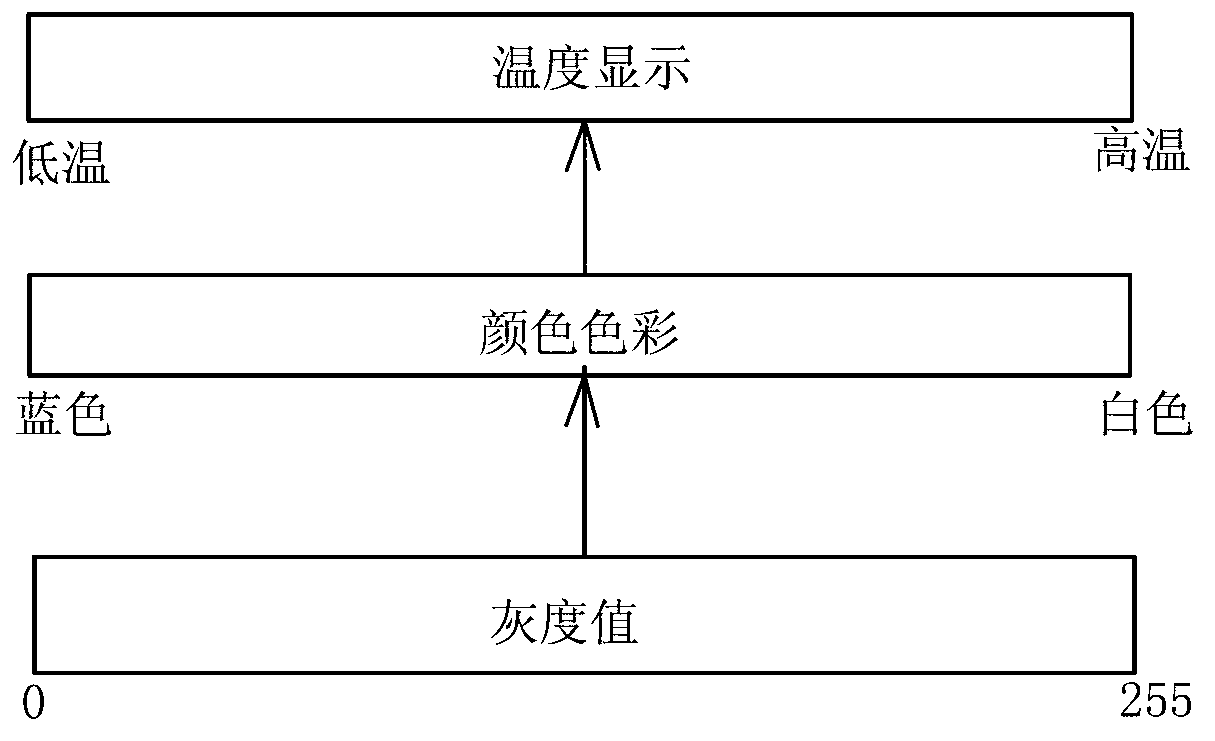

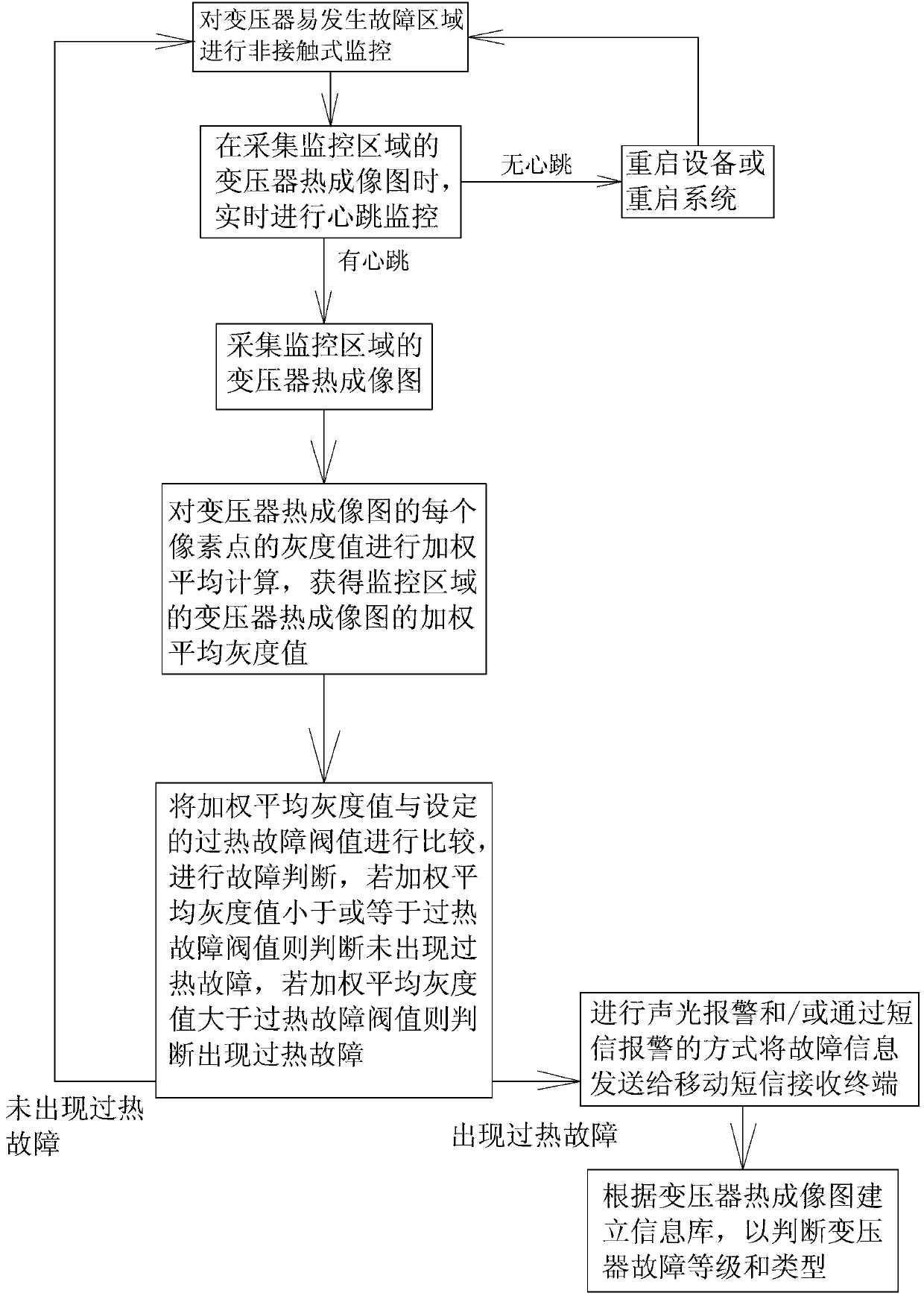

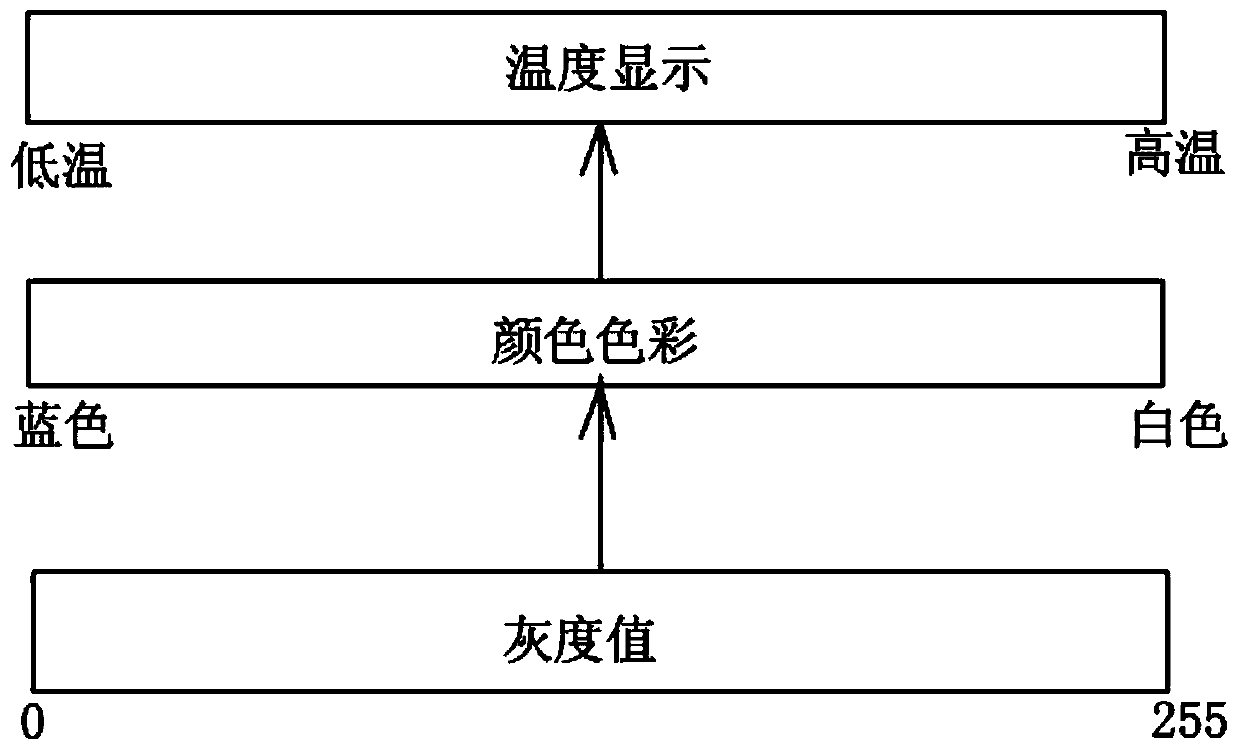

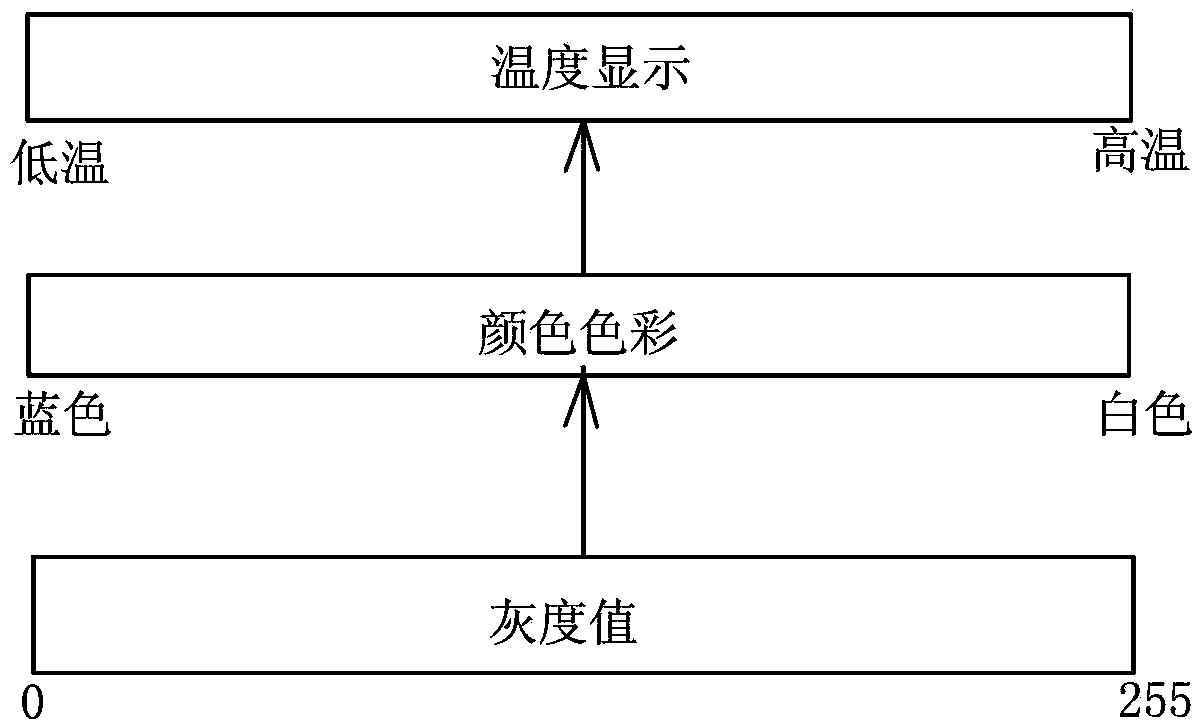

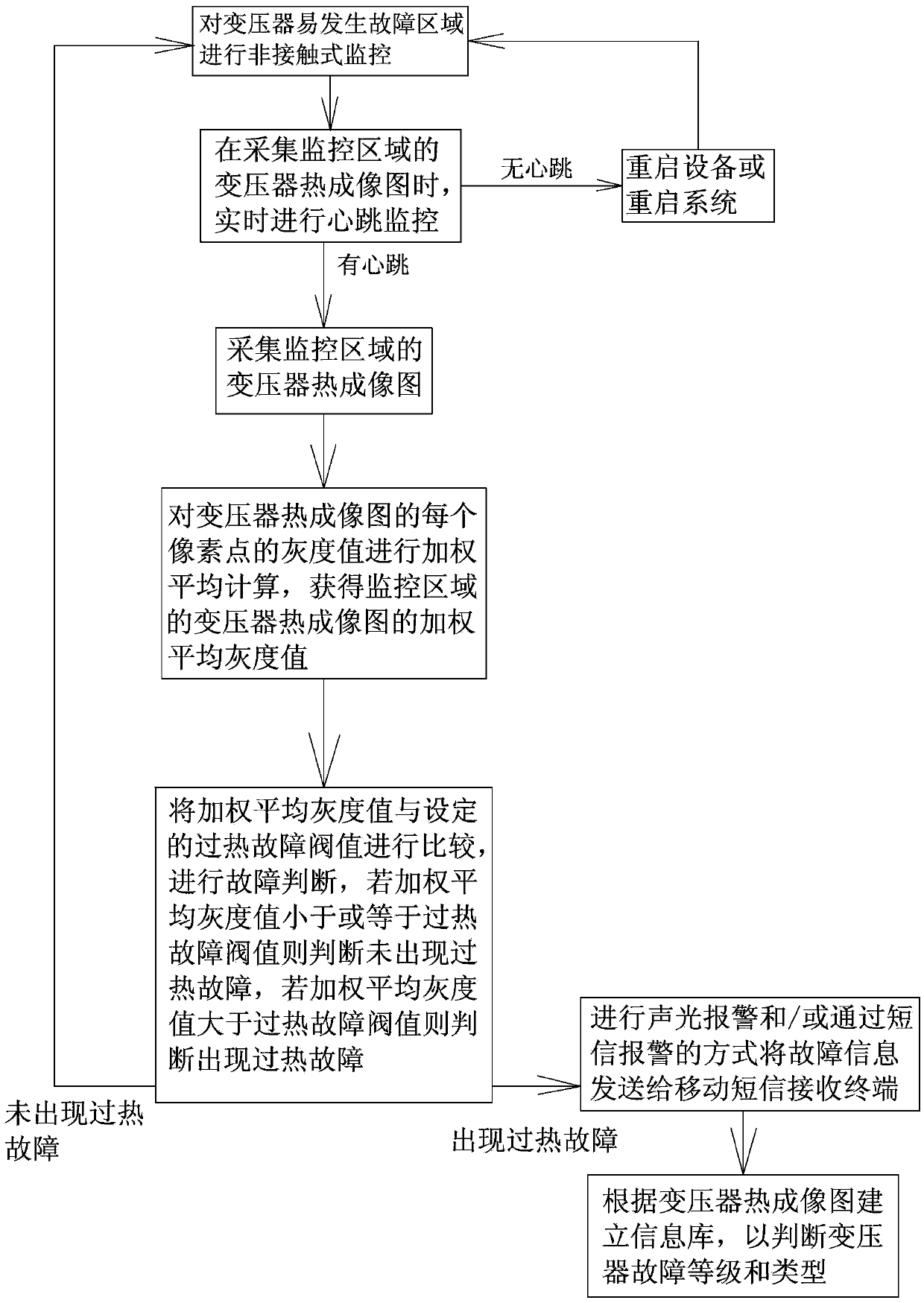

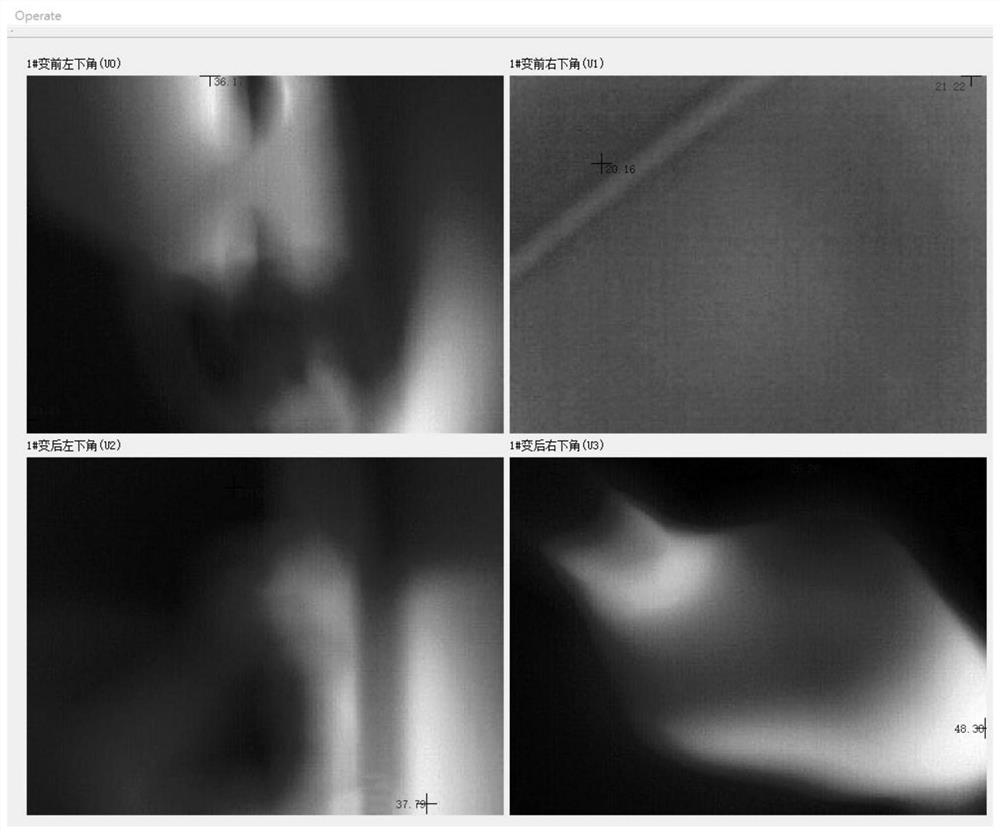

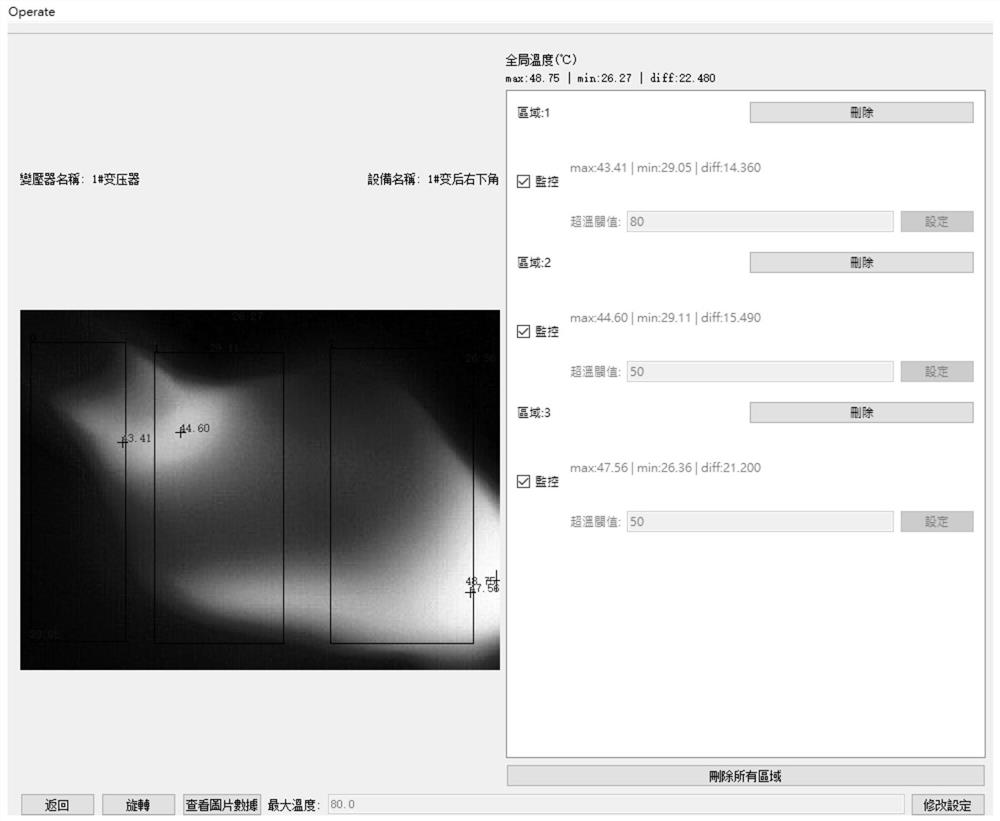

Monitoring method and monitoring system for overheat fault of transformer

InactiveCN103278244AAvoid slow recognitionRapid diagnosisRadiation pyrometryCircuit arrangementsSystems designTransformer

The invention belongs to the technical field of electrical equipment monitoring and relates to a monitoring method and a monitoring system for an overheat fault of a transformer. The technical problems that traditional monitoring methods and monitoring systems in the prior art are not reasonable enough and the like are solved by the invention. The monitoring system comprises the following steps: A, thermal image acquisition; B, image recognition processing; and C, fault diagnosis and processing. The monitoring method and the monitoring system for the overheat fault of the transformer have the advantages that acquired image information is recognized by adopting a non-contact monitoring mode to realize fast recognition and diagnose of the part, the degree the type of the early potential fault of the transformer. The monitoring method and the monitoring system for the overheat fault of the transformer have the characteristics that the safety, the reliability and the efficiency are high. Meanwhile, by utilizing the non-contact monitoring mode, a condition is provided for realizing all-weather state monitoring on the transformer on the premise that the operation of the transformer is not influenced, and therefore, the safe, stable and reliable operation of equipment is ensured, the maintenance level of the transformer is comprehensively promoted, and the maintenance cost is reduced. The system is reasonable in design, simple in structure, good in working stability and high in fault detection rate.

Owner:苏州求臻智能科技有限公司

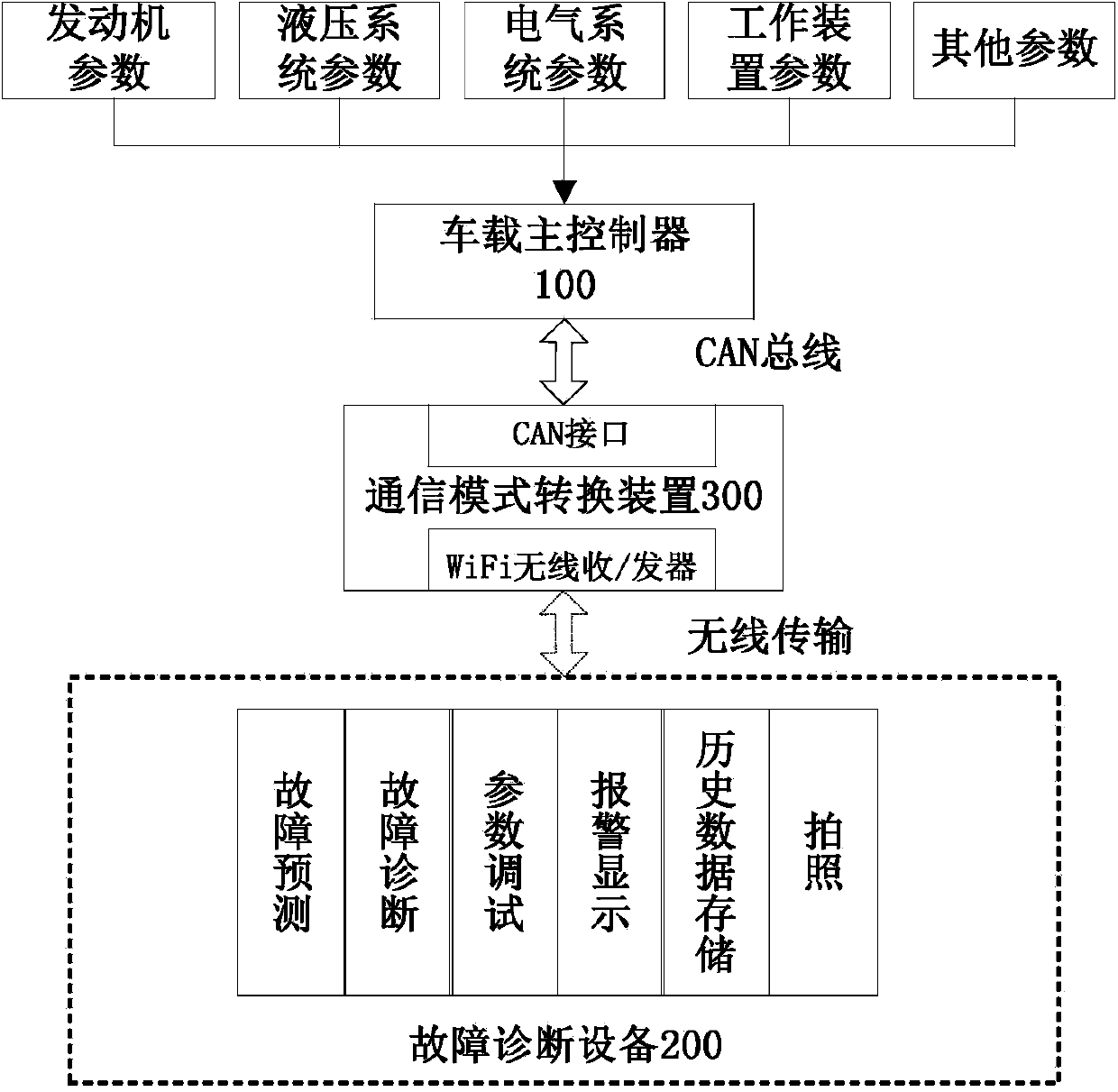

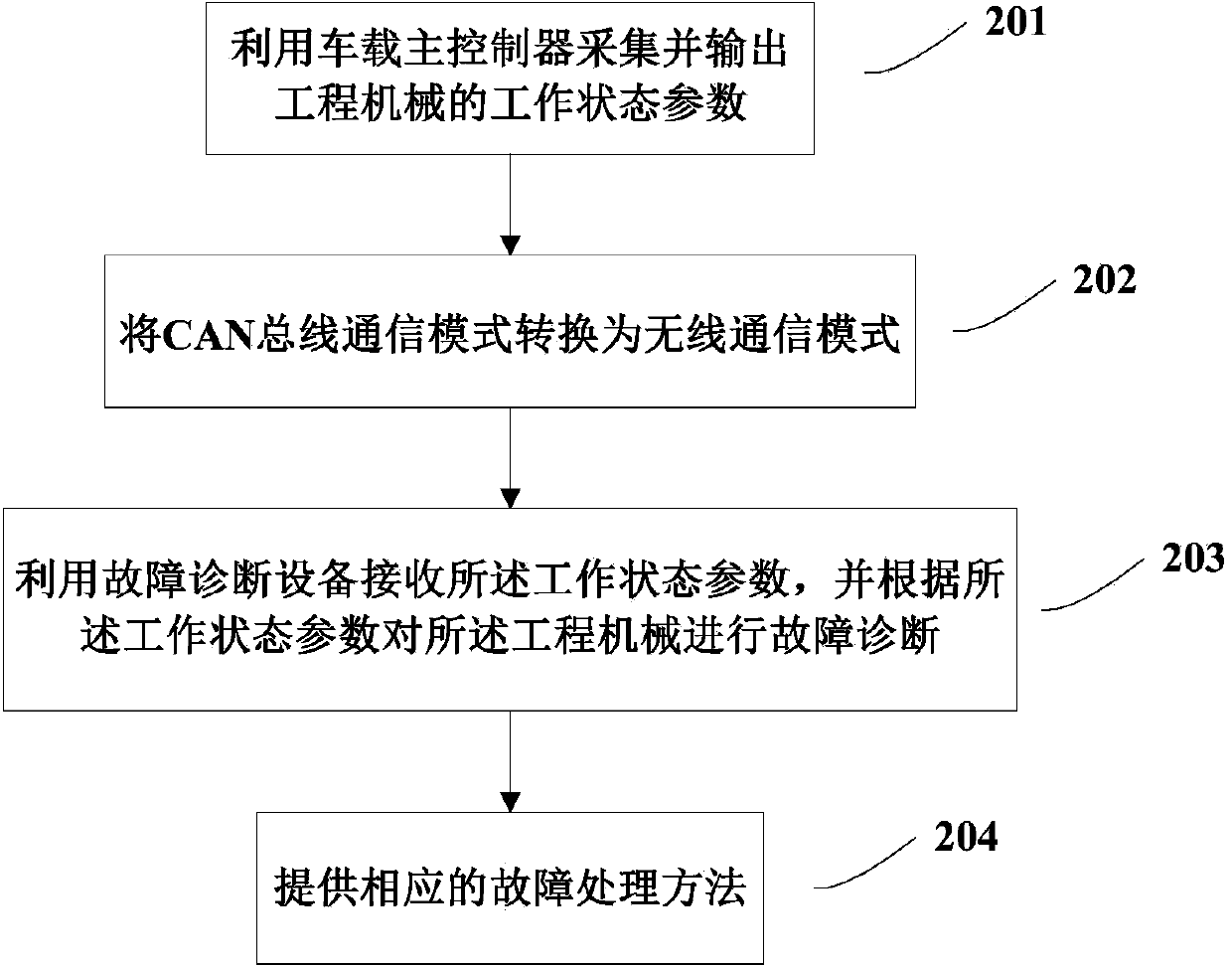

Engineering machine intelligent fault diagnosis system and method and engineering machine

InactiveCN103439944AEffective fault diagnosisLow costTotal factory controlProgramme total factory controlWork statusControl equipment

The invention discloses an engineering machine intelligent fault diagnosis system and method and an engineering machine. The engineering machine intelligent fault diagnosis system comprises a vehicle-mounted main controller and a fault diagnosis device, wherein the vehicle-mounted main controller is used for collecting and outputting work state parameters of the engineering machine, and the fault diagnosis device is used for receiving the work state parameters and carrying out fault diagnosis on the engineering machine according to the work state parameters. By means of the technical scheme, the vehicle-mounted main controller inside a cab in the engineering machine can be directly used for collecting the work state parameters for the fault diagnosis, a single-chip microcomputer or other control devices are not required to be additionally arranged for collection, the cost is low, the development period is short, the fault diagnosis can be effectively carried out on the engineering machine, the maintenance level is improved, and the machine-stop losses are reduced.

Owner:ZOOMLION HEAVY IND CO LTD

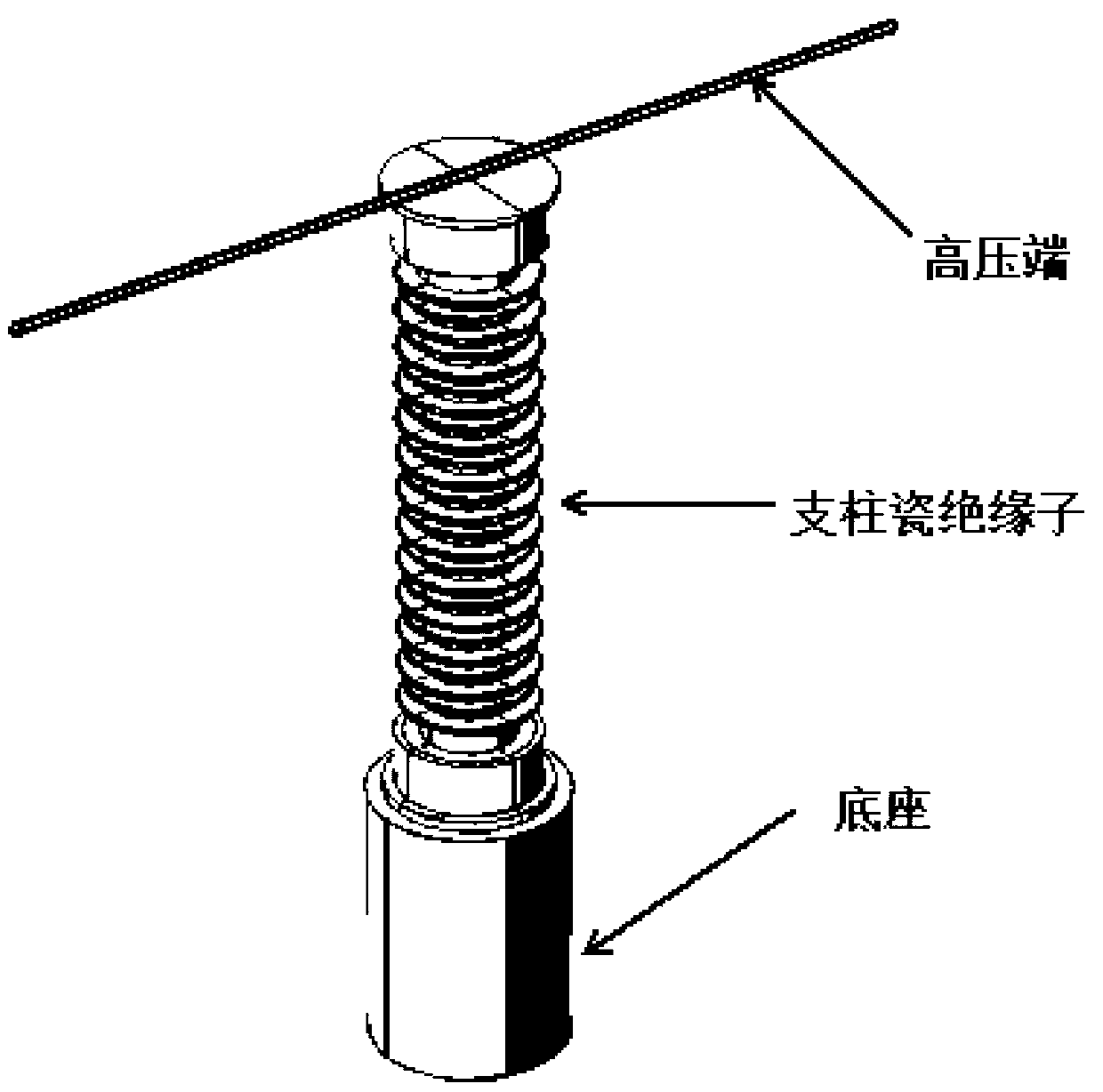

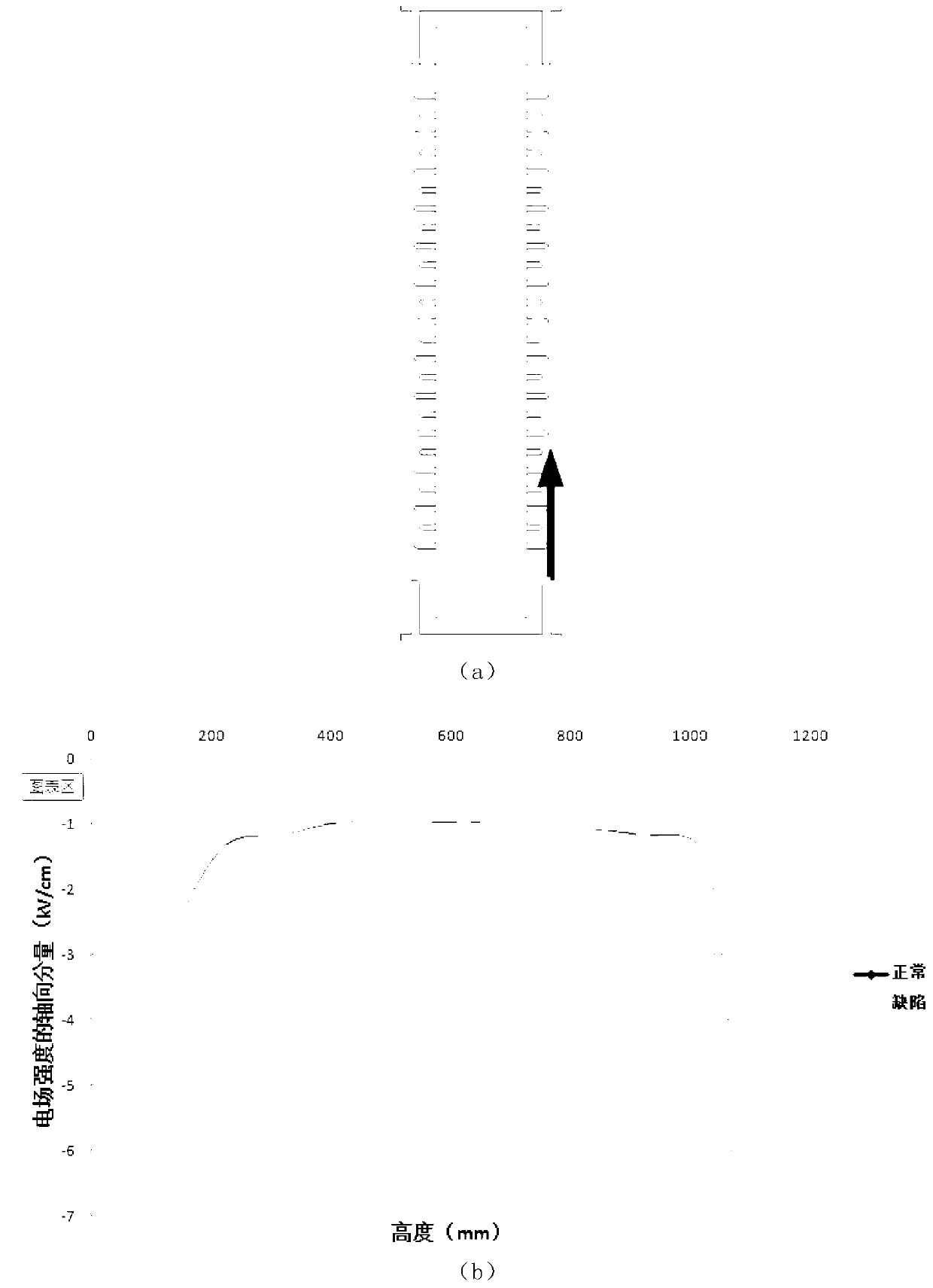

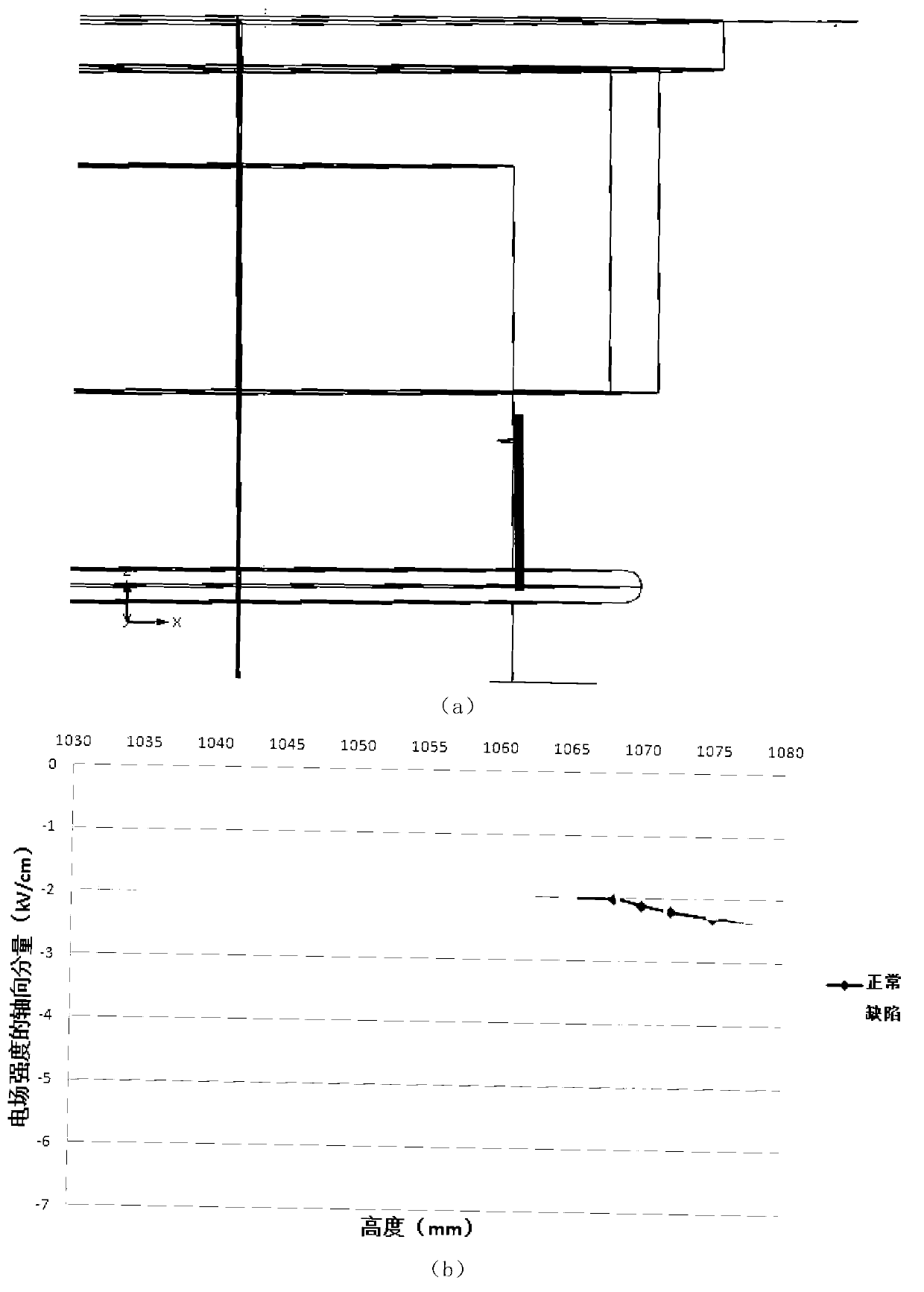

Method for detecting crack defect of in-service strut porcelain insulator

InactiveCN103344694AImprove maintenance levelGuaranteed uptimeMaterial analysis by electric/magnetic meansMeasurement deviceElectrical devices

The invention discloses a method for detecting a crack defect of an in-service strut porcelain insulator, belonging to the technical field of online monitoring and condition-based maintenance of electrical equipment. The method comprises the following steps of: determining the quantity of to-be-measured points and selecting a measuring device according to the size of a tested element; measuring a potential value aiming at a frequently-broken part of the strut porcelain insulator; according to the potential value, calculating an axial component of an electric field intensity, drawing a curve diagram; according to the electric field curve diagram, locating a defect, analyzing the deterioration degree and obtaining a conclusion. According to the method, maintenance is carried out purposefully, the maintenance level can be improved so that equipment runs more safely and reliably; and the inventory level of replacement parts, and the cost required by replacing parts and maintaining the parts is reduced. The method is used as a new supplement of the online detection method for the strut porcelain insulator, thus the method of condition-based maintenance is perfected. The method has the advantages of high resolution, high sensitivity and the like for detecting cracks on the surface of the strut porcelain insulator, and can be widely applied to the detection of the strut porcelain insulator in high-voltage alternating-current and direct-current transmission and transformation projects.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

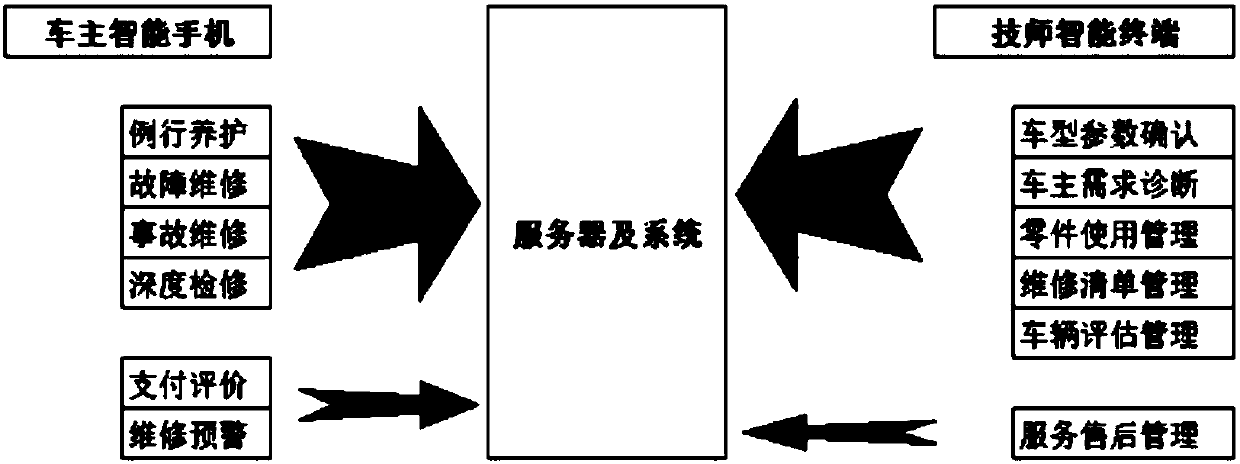

Automobile maintenance early warning system and early warning method

InactiveCN108021121AReduce incidenceReduce failureElectric testing/monitoringRepair shopMedical record

The invention discloses an automobile maintenance early warning system, which comprises a vehicle owner intelligent mobile terminal, a repair shop technician intelligent terminal and a server. The vehicle owner intelligent mobile terminal includes a vehicle owner maintenance and repair business demand module and a vehicle owner business payment and evaluation module. The repair shop technician intelligent terminal includes a repair shop technician business diagnosis and quotation module, a repair shop technician maintenance record module, a repair shop technician part management module and a service after-sales management module. The server includes a maintenance business big data analysis and arraignment module. According to the invention, through the intelligent terminal, a vehicle ownercan directly and permanently have maintenance "medical records"; and the system of the invention can issue a maintenance early warning in an all-round way, thereby being capable of taking preventivemeasures and greatly reducing the incidence rate of failures and accidents.

Owner:苏州骏车信息技术有限公司

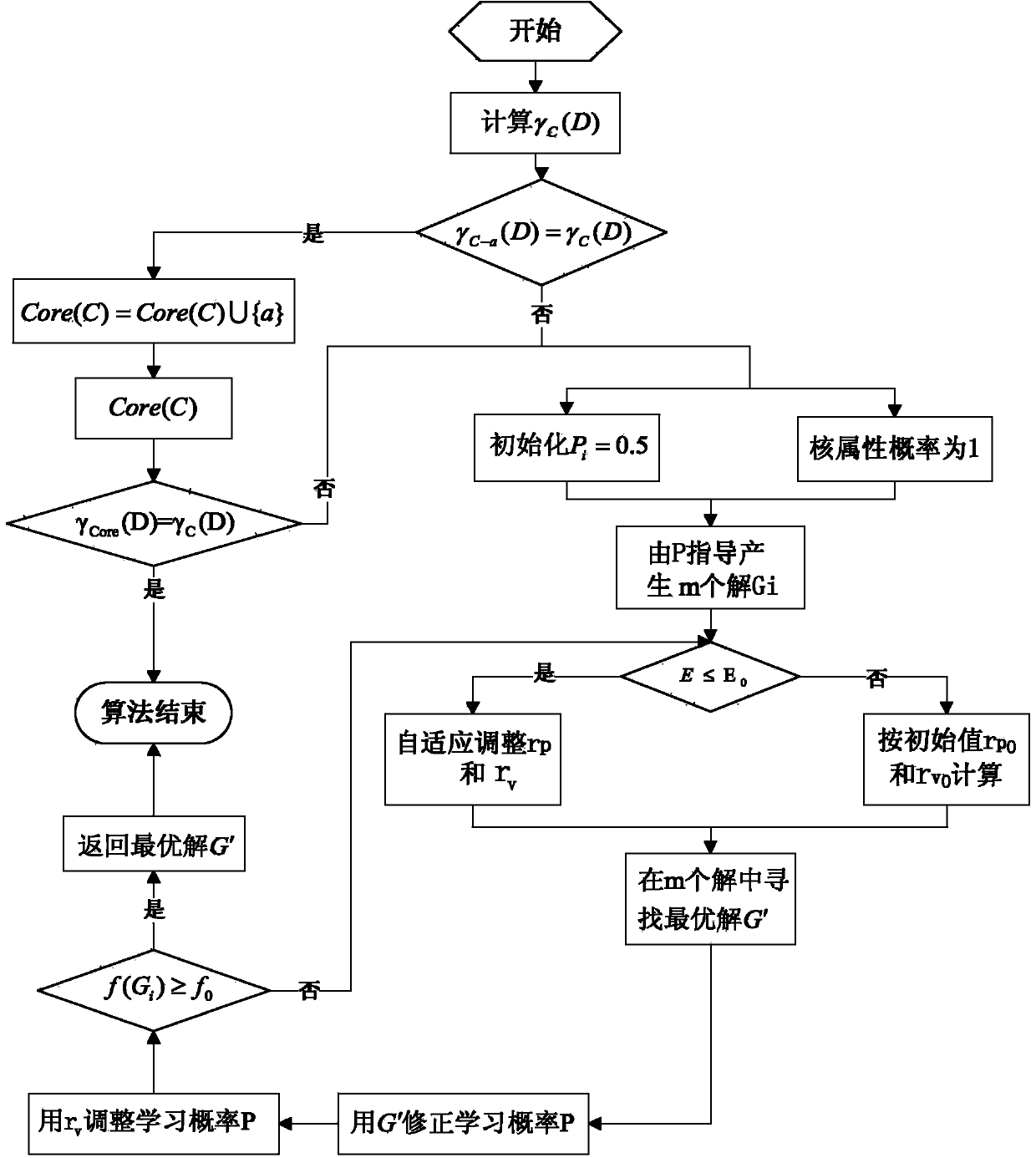

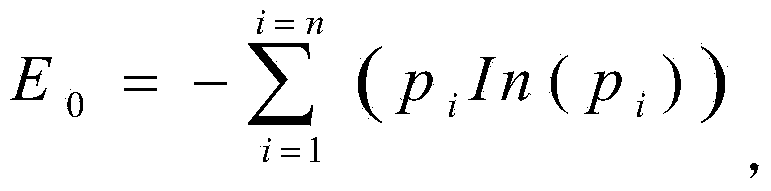

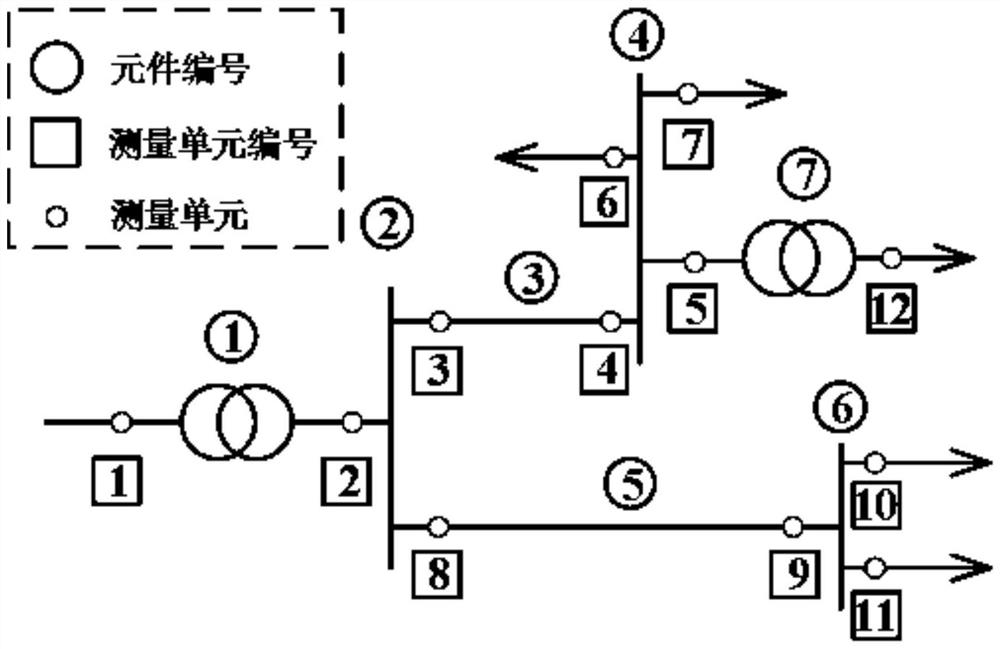

Method for building ship electric power plant fault diagnosis petri net model based on rough set

ActiveCN104182613AImprove fault diagnosis efficiencySimple and less redundantFault locationSpecial data processing applicationsElectric power systemPetri net

The invention discloses a method for building a ship electric power plant fault diagnosis petri net model based on a rough set. The method comprises the steps as follows: 1, acquiring a set of fault performance information possibly existing in each part of a ship electric power plant power system; 2, obtaining a non-redundant fault performance information set of the fault performance information set with an attribute reduction algorithm according to the rough set theory; 3, establishing a corresponding relation between each subset in the non-redundant fault performance information set and each actual fault of the ship electric power plant power system, and forming a system fault Petri net model by the corresponding relations; and 4, performing lamination, classification and coloring treatment on the fault Petri net model of the ship electric power plant power system according to the composition structure of the ship electric power plant power system. According to the invention, the fault diagnosis model can be prevented from generating larger redundancy under the condition of a large quantity of fault information, and accuracy and efficiency of the ship electric power plant fault diagnosis petri net model building are improved.

Owner:NAVAL UNIV OF ENG PLA

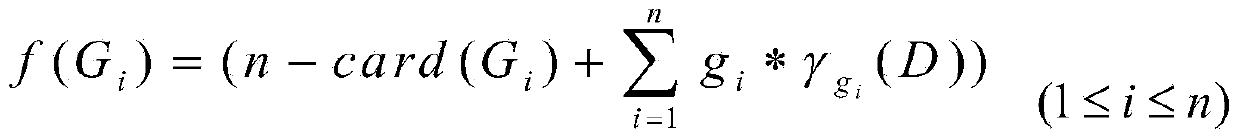

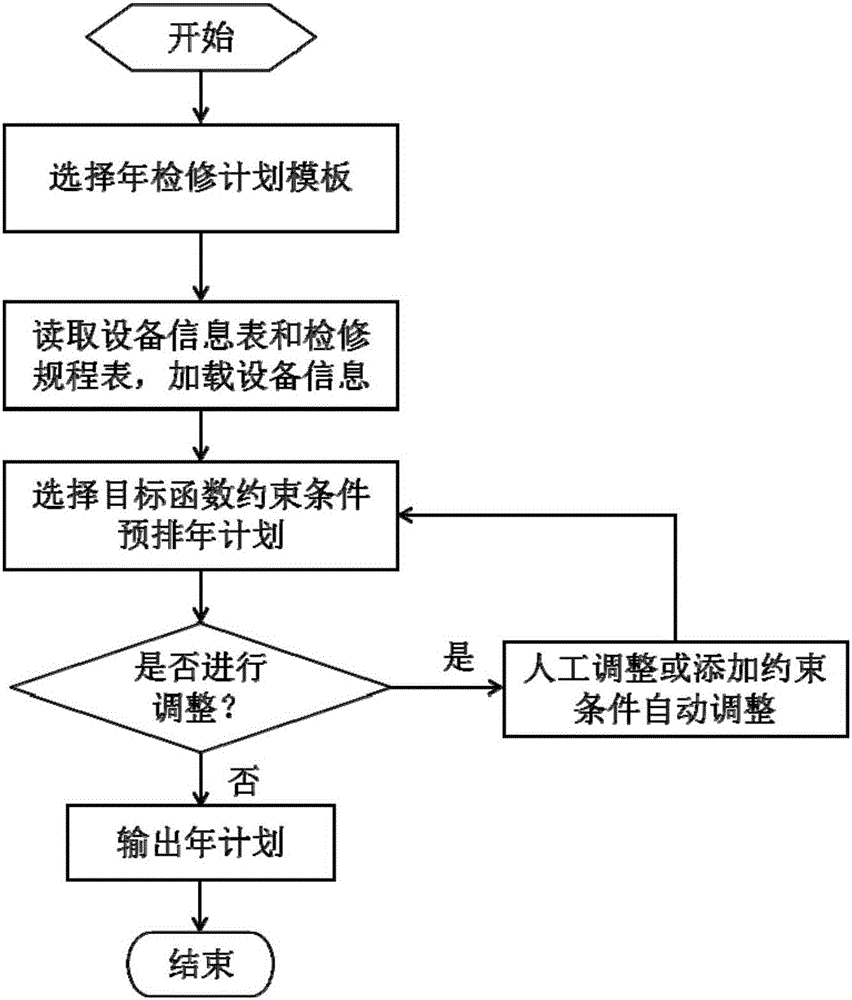

Method for automatically pre-arranging annual overhaul plan of rail transit equipment based on repair program

InactiveCN106845789AReasonable distributionImprove the level of operation managementResourcesObject functionRail transit

The invention discloses a method for automatically pre-arranging an annual overhaul plan of rail transit equipment based on a repair program. The method comprises the steps of 1, inputting an annual overhaul plan table template, an equipment information table, a historical overhaul record and a repair program table; 2, calling out the annual overhaul plan table template; 3, filling the annual overhaul plan table template: screening out all overhaul equipment belonging to a line and a profession from the equipment information table, reading overhaul information corresponding to the overhaul equipment from the overhaul table, and filling the annual overhaul plan table template with the overhaul equipment and the corresponding overhaul information; 4, establishing a target function and constraint conditions; 5, generating an initial annual overhaul plan according to the target function and the constraint conditions through the filled annual overhaul plan table template, and allocating overhaul tasks of a whole year to 12 months; and 6, auditing the initial annual overhaul plan, and taking the annual overhaul plan passing the audit as a final annual overhaul plan. Therefore, the repairability and economy of equipment overhaul are improved.

Owner:NARI TECH CO LTD +1

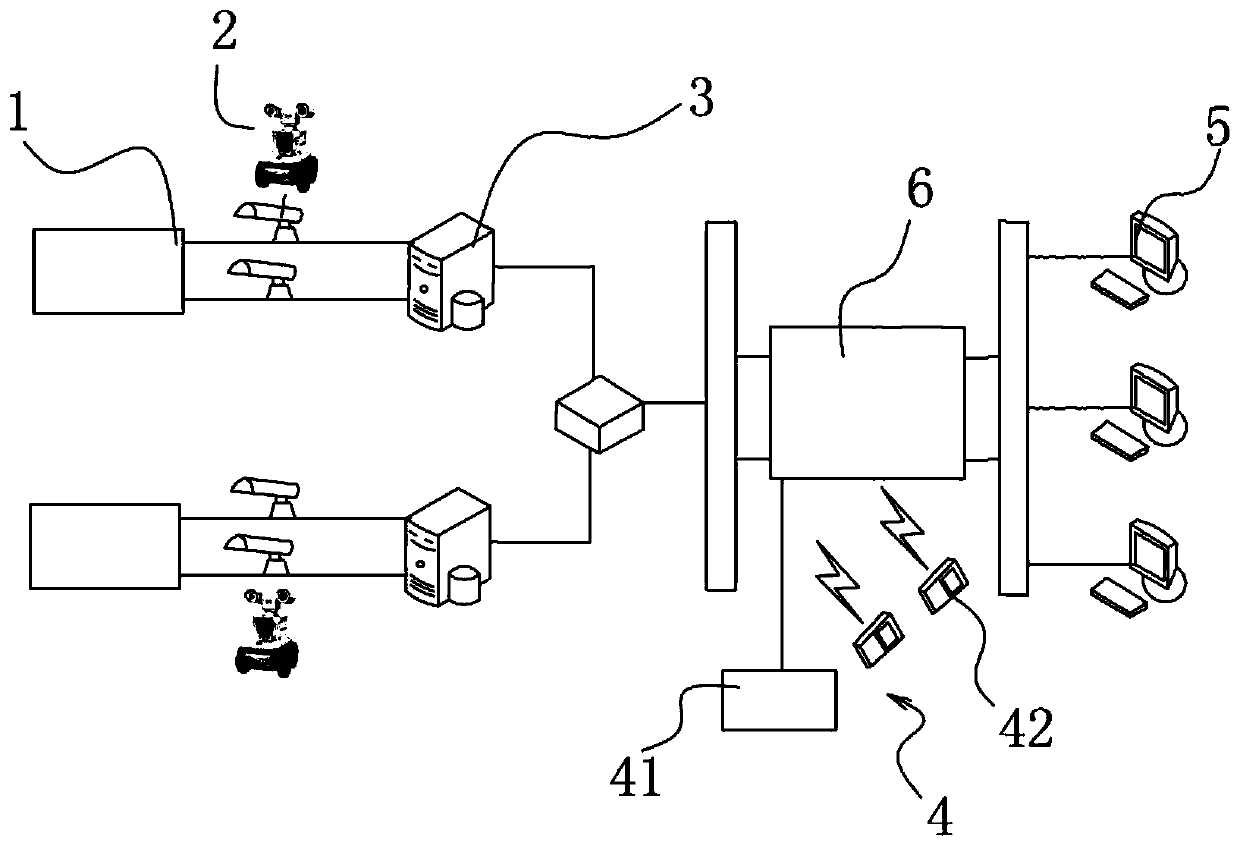

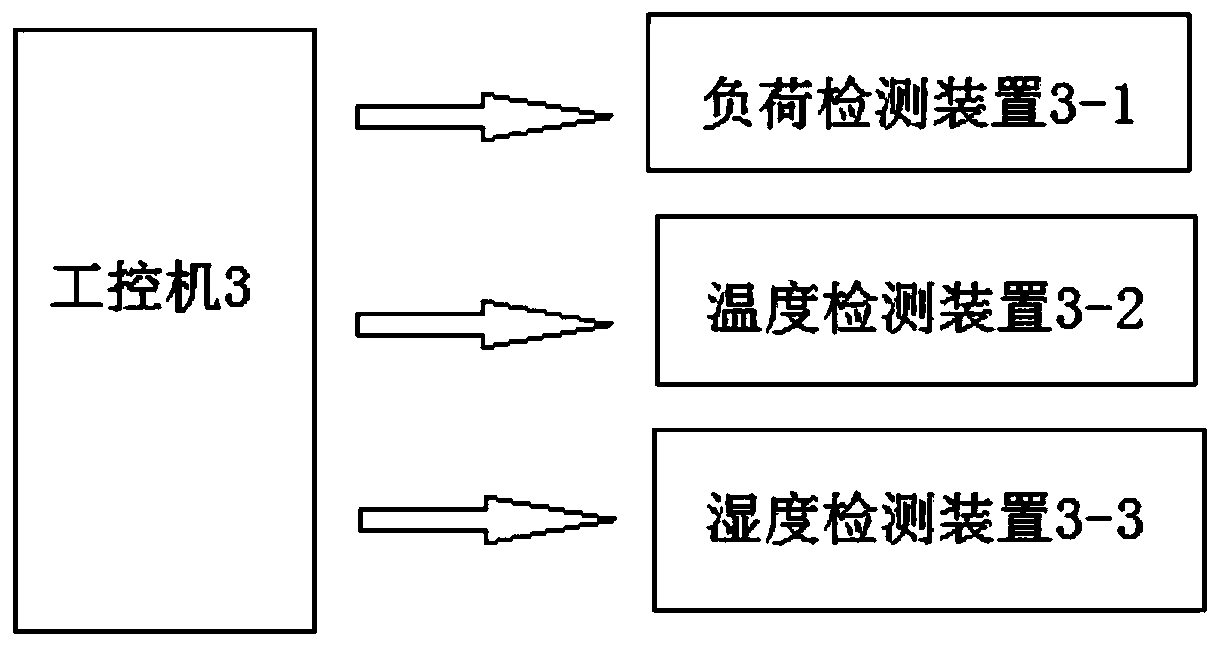

Transformer thermal fault monitoring device and method based on transformer substation inspection robot

InactiveCN111553918AGuaranteed uptimeImprove maintenance levelImage enhancementRadiation pyrometryTransformerWireless

The invention discloses a transformer thermal fault monitoring device and method based on a transformer substation inspection robot. An infrared thermal imaging camera is connected with an industrialpersonal computer in a wireless communication mode, the industrial personal computer is connected with an alarm mechanism and a monitoring terminal, and the industrial personal computer is also connected with a server for storing a transformer thermal image. The alarm mechanism comprises any one or more of a sound-light alarm device or a mobile short message receiving terminal; the industrial personal computer is further connected with a load detection device used for detecting the load of the transformer, a temperature detection device used for detecting the environment temperature and a humidity detection device used for detecting the environment humidity. The infrared imaging device is integrated on a transformer substation inspection robot platform, collected transformer substation infrared image information is identified in a non-contact monitoring mode, rapid identification and diagnosis of the parts, the degrees and the types of potential faults in the early stage of a transformer are achieved, and the beneficial effects of being safe, reliable and efficient are achieved.

Owner:苏州求臻智能科技有限公司

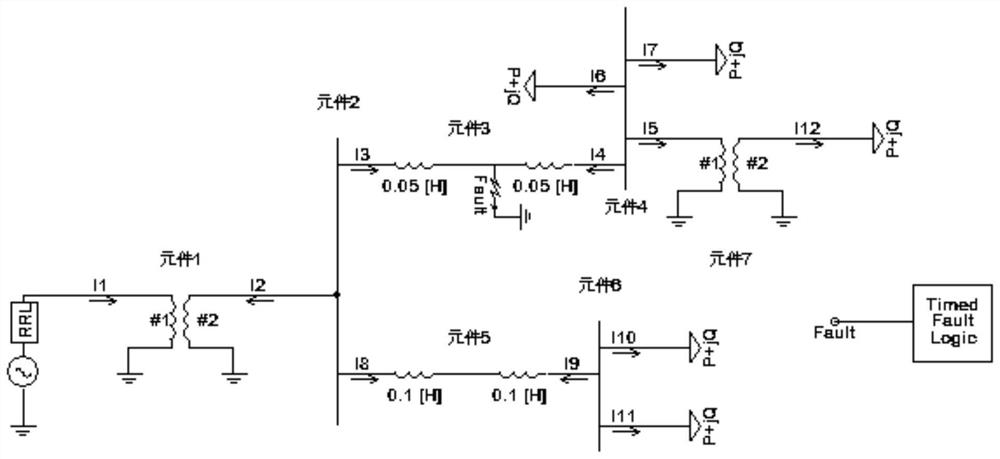

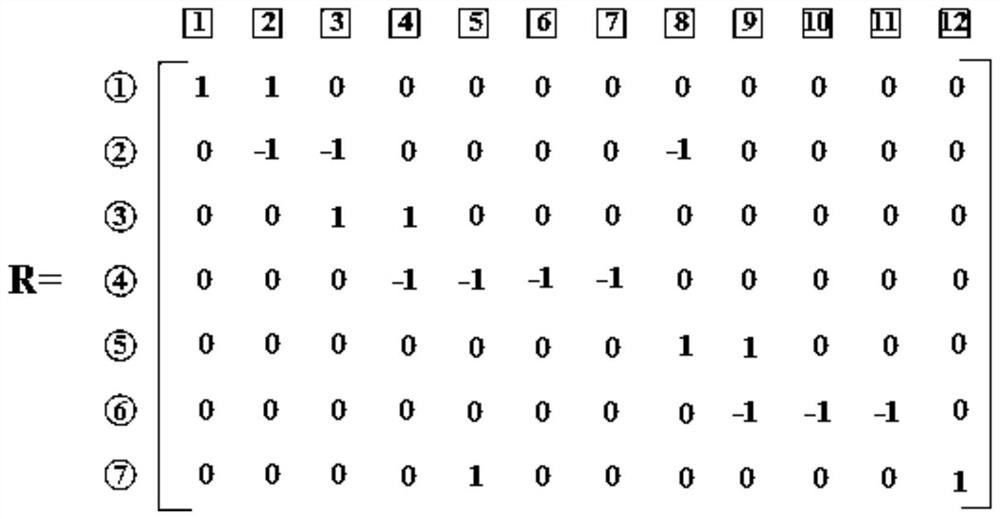

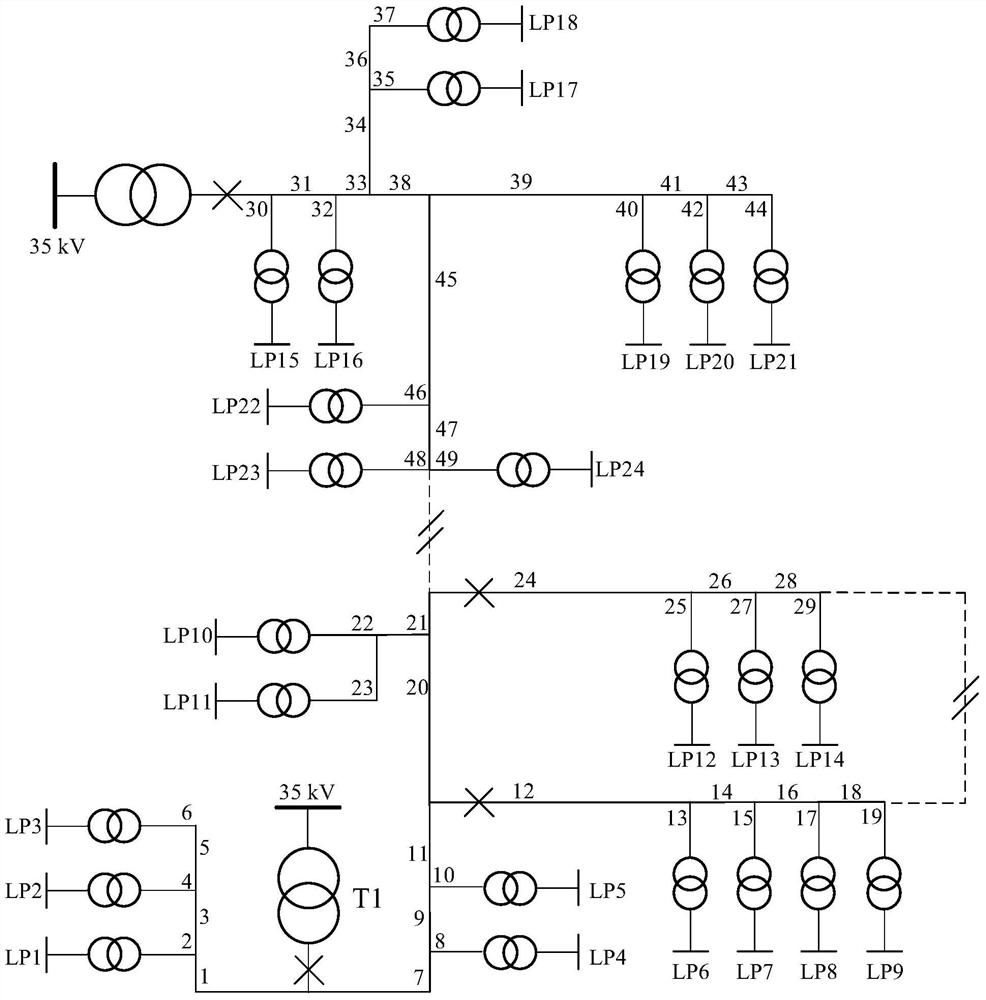

Low-voltage distribution network protection method based on wide-area measurement information and medium

ActiveCN111884346AImprove maintenance levelAccurately determine the fault locationEmergency protective circuit arrangementsFault location by conductor typesDistribution gridTransformer

The invention discloses a low-voltage distribution network protection method based on wide-area measurement information and a medium, and relates to the field of power systems and automation thereof.The invention aims at the defects of fault identification and positioning of the existing power distribution network, and the technical problem of insufficient reliability of the existing power distribution network on-line monitoring and protection method is solved by utilizing a current differential principle. The method comprises the steps of: constructing a topological structure incidence relation matrix R, a measurement unit remote control function on-off matrix B, a transformer transmission coefficient correction matrix D, a measurement voltage matrix U and a measurement current matrix I;forming a fault position research criterion; positioning a fault position on an element; determining a fault phase, and constructing an associated circuit breaker tripping strategy after the fault onthe basis of the remote control function on-off matrix B . The fault location in the power distribution network can be accurately judged, and the operation maintenance level of the power distributionnetwork is improved.

Owner:STATE GRID SICHUAN ELECTRIC POWER CORP ELECTRIC POWER RES INST

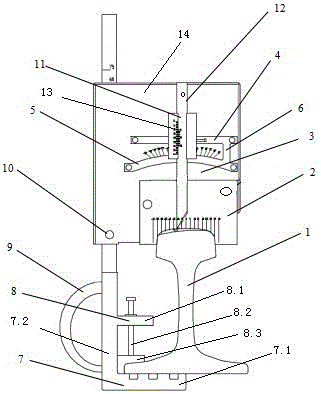

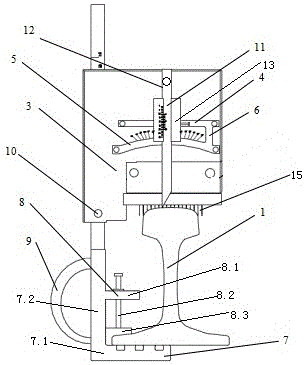

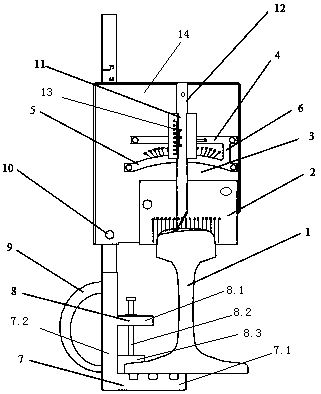

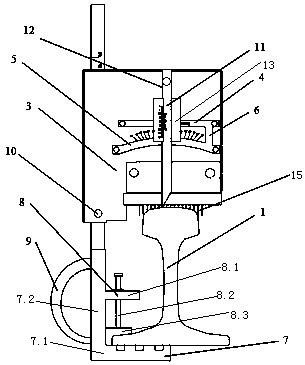

Rail head silhouette measuring instrument

ActiveCN107433960AStrengthen conservationImprove maintenance levelRailway auxillary equipmentRailway profile gaugesRail profileMeasuring instrument

The invention discloses a rail head silhouette measuring instrument, and relates to the technical field of steel rail repair and maintenance. The rail head silhouette measuring instrument comprises a positioning device, a fixing device for fixing a steel rail and a measuring device. The fixing device is arranged at the lower portion of the positioning device. The measuring device is arranged at the upper portion of the positioning device. The measuring device comprises a slide way arranged on a fixed plate, a ruler and a telescopic probe. The ruler slides on the slide way through a slider. The fixed plate can slide up and down and is connected with the positioning device. The transverse probe is arranged at the lower end of the fixed plate and can be meshed with and fixed to the upper end of a rail head silhouette. A standard template is arranged and fixed at the position, corresponding to the probe, of the fixed plate. The grinding amount required by the steel rail and the difference value between the ground steel rail profile and the designed profile can be rapidly measured on working site, the repair and maintenance level of the steel rail is improved, and work efficiency is improved.

Owner:SHIJIAZHUANG TIEDAO UNIV

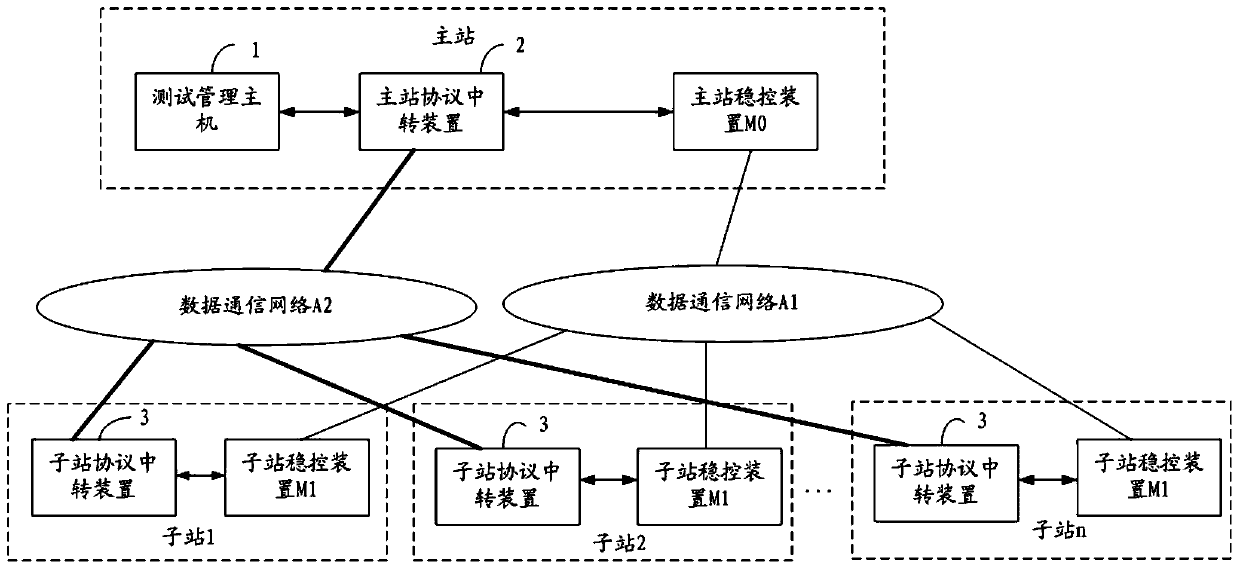

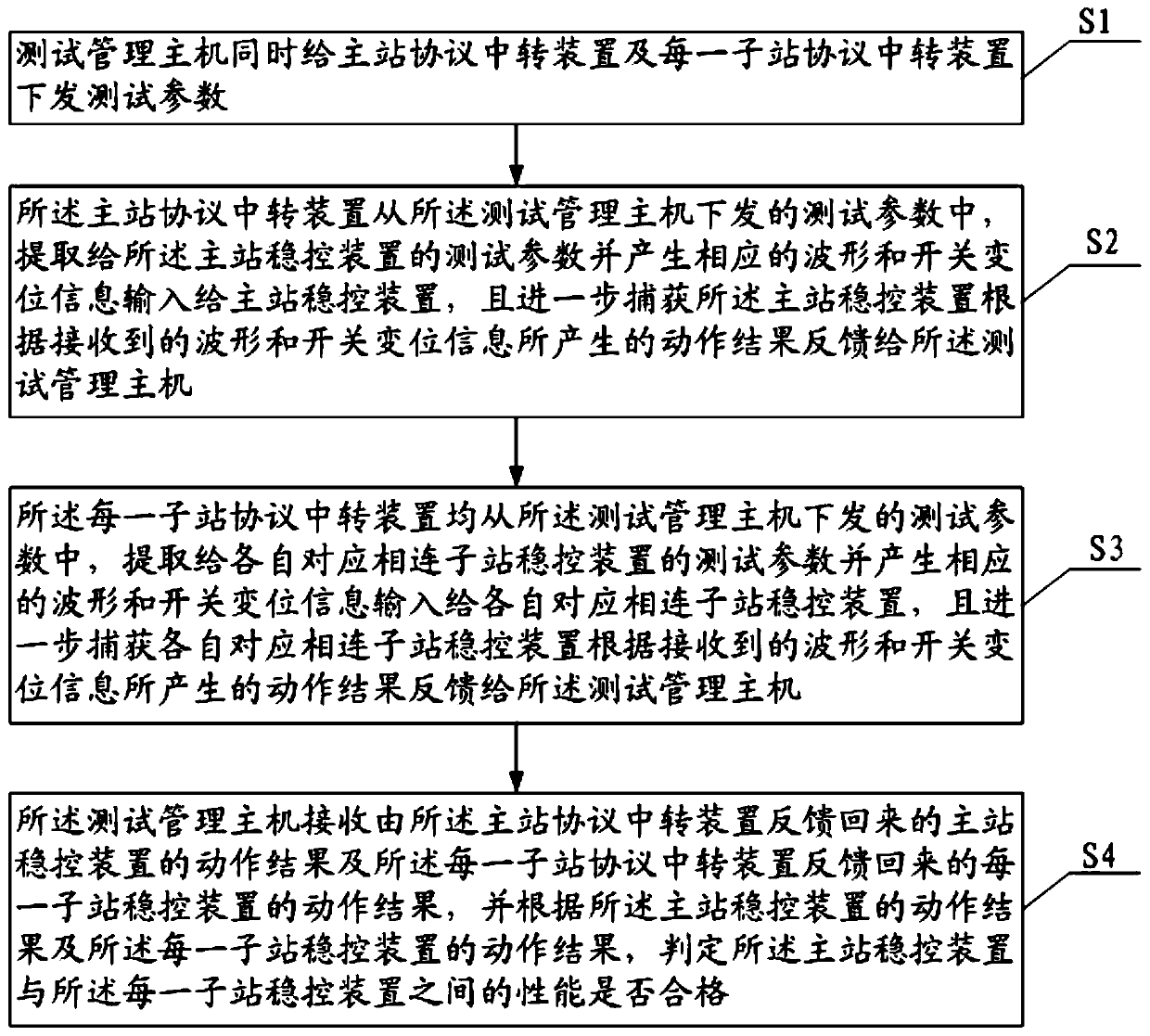

Test platform for wide-area joint debugging of interstation stable control device and implementation method of test platform

PendingCN110658804ATroubleshoot automated testing issuesImprove efficiencyProgramme controlElectric testing/monitoringPrimary stationTest management

The invention provides a test platform for a wide-area joint debugging of interstation stable control device. The test platform is matched with a master station stable control device and a plurality of sub-station stable control devices interconnected with the master station stable control device in a wide-area way. The test platform comprises a test management host, a master station and a plurality of sub-station protocol transfer devices, wherein the test management host communicates with the master station stable control device by a master station protocol transfer device and is further interconnected with each sub-station protocol transfer device in a wide-area way by the master station protocol transfer device according to another data communication network, each sub-station protocoltransfer device is directly connected with the corresponding sub-station stable control device, and the test management host is used for simultaneously issuing a test parameter to the master station and each sub-station protocol transfer device and receiving action results of the master station and each sub-station stable control device fed back by the master station and each sub-station protocoltransfer device to judge whether performance between the master station stable control device and each sub-station stable control device is qualified or not. According to the test platform provided bythe invention, the problem of automatic test for wide-area joint debugging of the interstation stable control device can be solved in site, so that the site working efficiency and the maintenance level are improved.

Owner:SHENZHEN POWER SUPPLY BUREAU

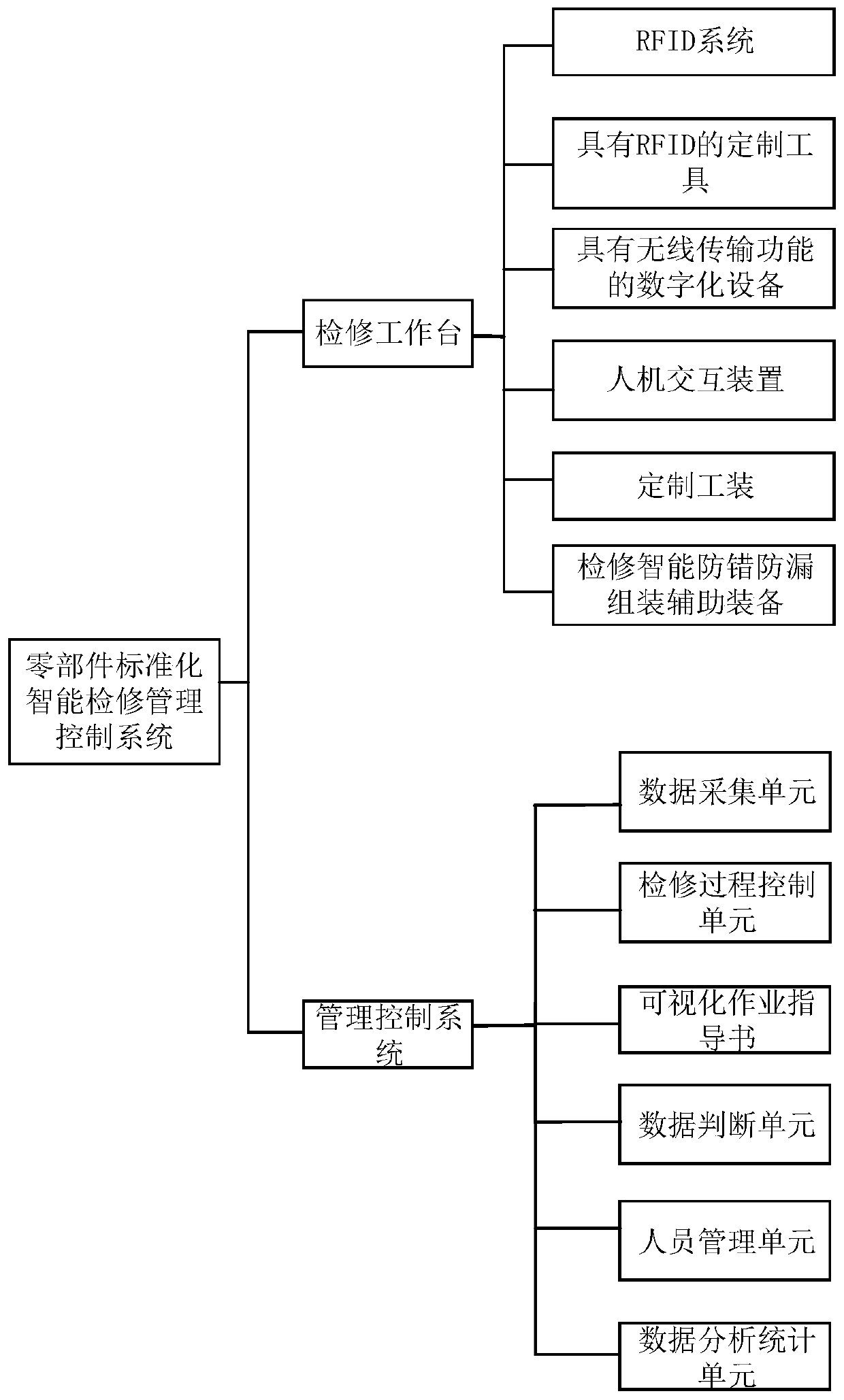

Standardized intelligent maintenance management control system for parts

ActiveCN109784767ASelf-repairImprove maintenance levelCo-operative working arrangementsResourcesEngineeringHuman–computer interaction

The invention discloses a standardized intelligent maintenance management control system for parts, and belongs to the technical field of maintenance control of parts. The system comprises at least one maintenance workbench and a management control system. The maintenance workbench comprises a customization tool with an RFID function, an RFID system, man-machine interaction equipment, digital equipment with an infinite transmission system, maintenance intelligent error-proof and leakage-proof assembly auxiliary equipment and a customization tool. The management control system comprises a process control unit, a visual operation instruction, a data acquisition unit, a data judgment unit, a personnel management unit and a data analysis and statistics unit. Monitoring and control of the partmaintenance process can be achieved, it is guaranteed that maintenance of the parts is executed according to the standardized process, meanwhile, work of operators can be monitored, all data in the maintenance process can be recorded, and standardized value maintenance and life cycle management of the parts are achieved.

Owner:睿惟智(上海)科技有限公司

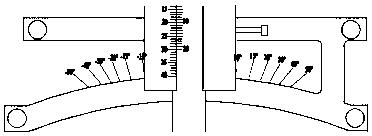

Double-stage spraying roadbed material maintenance device

InactiveCN106087630AImprove maintenance levelWide spreadRoadwaysSoil preservationWater sourceReduction drive

Disclosed is a double-stage spraying roadbed material maintenance device. One end of a water inlet pipe is connected with a water source. The other end of the water inlet pipe is connected with a high-pressure water pump. A waterway passing the high-pressure water pump is connected with a rubber pipe. The rubber pipe is connected with a grading water pipe fixed to a rotary shaft. The bottoms of two sets of hydraulic jacks are fixed to a rack. The extending ends of the hydraulic jacks are connected with the bottoms of sliding plates correspondingly. An output shaft of a driving motor is connected with the rotary shaft through a speed reducer. The other end of the rotary shaft is connected with the middles of the sliding plates through bearings. The grading water pipe is provided with a first stage spraying head and a second stage spraying head. According to the double-stage spraying roadbed material maintenance device, the grading water pipe, the first stage spraying head and the second stage spraying head are used for distributing pumped-in high-pressure water flow in a shunted mode, the distributing range is larger, the distributed water quantity is larger, and thus the maintenance level of roadbed materials can be promoted effectively.

Owner:BEIJING UNIV OF TECH

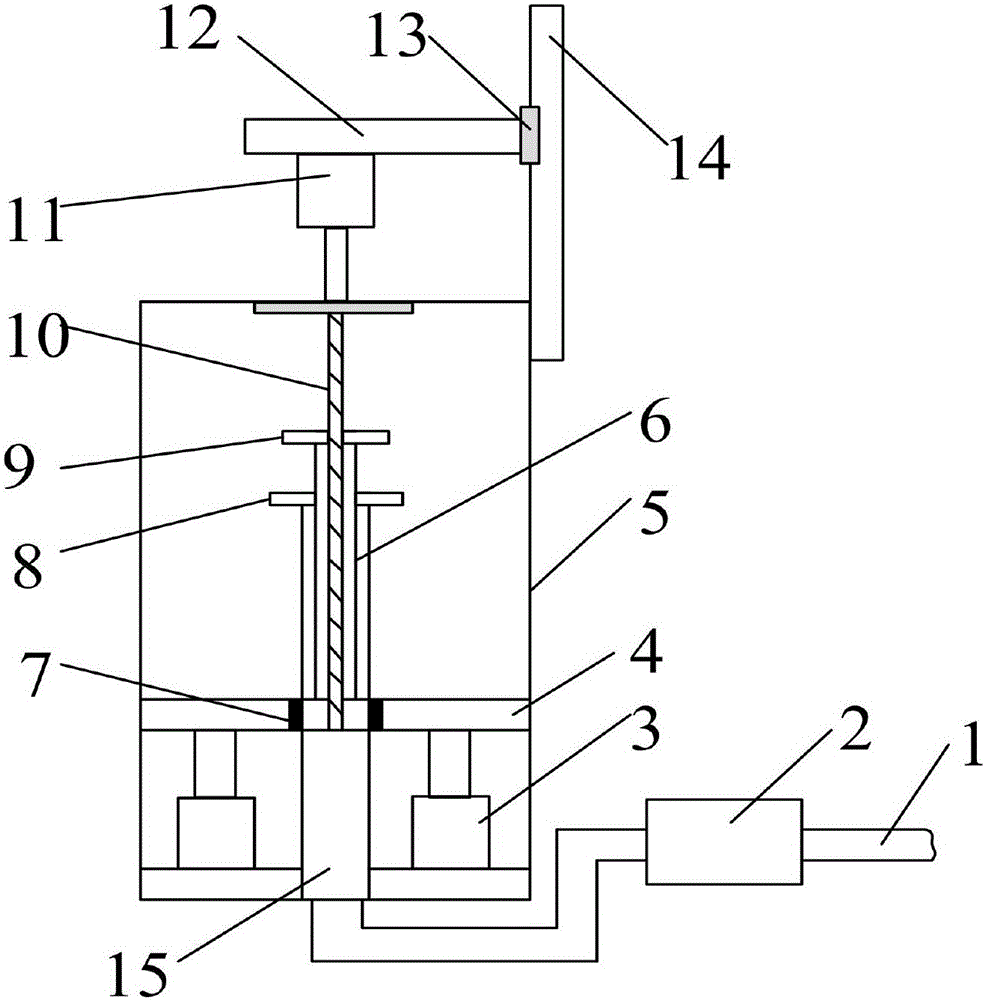

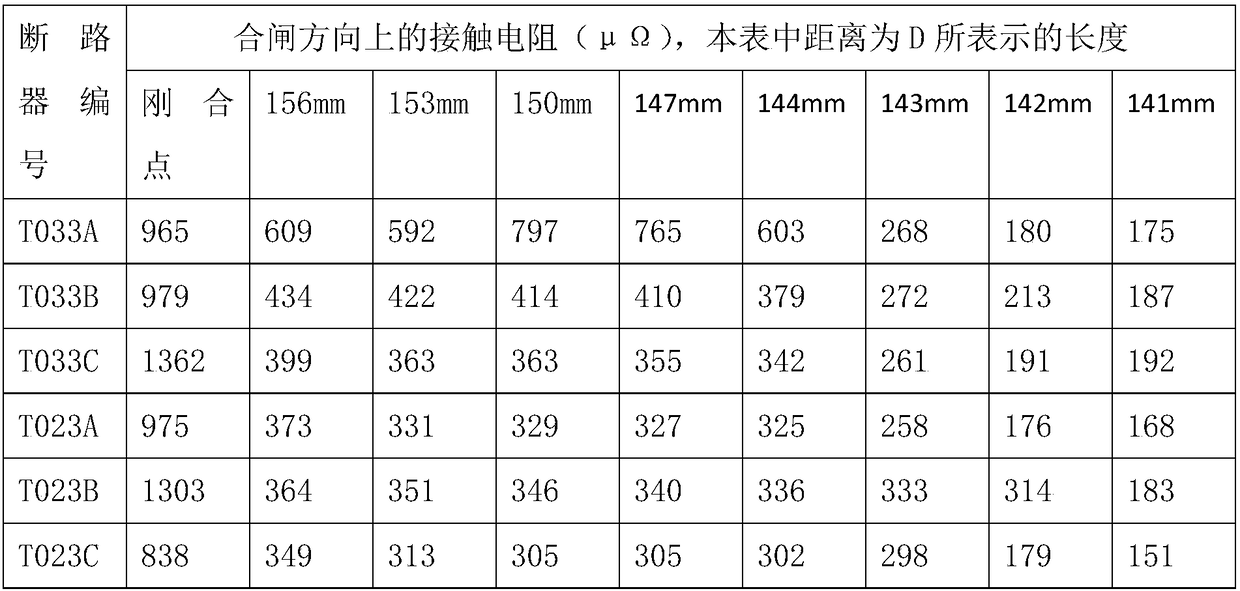

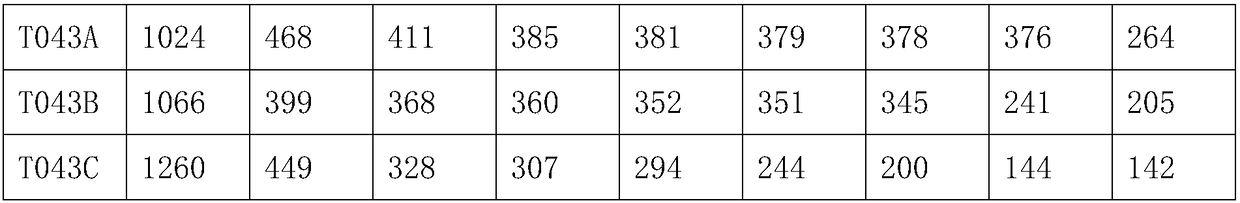

Detection method for loose defects of arc contact of extra-high voltage circuit breaker

InactiveCN108490347AFind loose defectsImprove maintenance levelCircuit interrupters testingElectrical resistance and conductanceEngineering

The invention relates to a detection method for loose defects of an arc contact of an extra-high voltage circuit breaker. The detection method comprises the following steps: (1) carrying out micro-distance movement on a circuit breaker contact by virtue of a slow division and combination manner during measurement; (S2) carrying out resistance measurement on multiple points in the route of the arccontact under a static state; (S3) carrying out state quantity significant difference analysis and calculation on a measurement result obtained in the step (S2); and (S4) judging whether the arc contact has the loose defects according to a calculation result in the step (S3). Compared with the prior art, the detection method has the advantages of relatively high accuracy, wide popularization valueand the like.

Owner:SHANGHAI MUNICIPAL ELECTRIC POWER CO

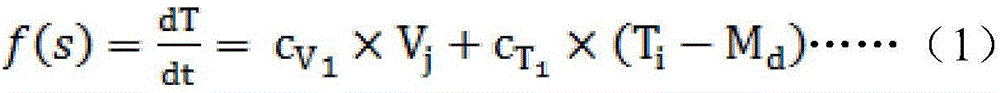

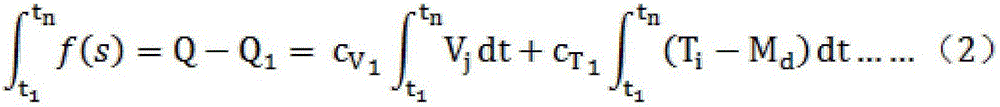

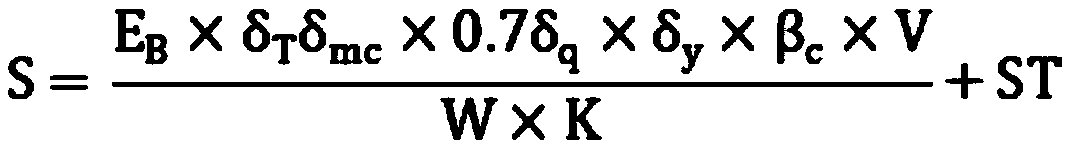

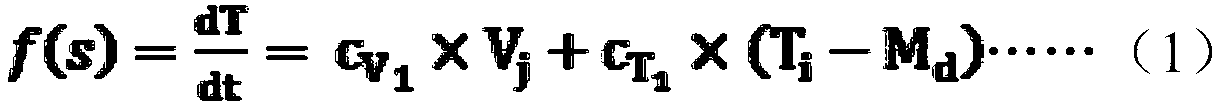

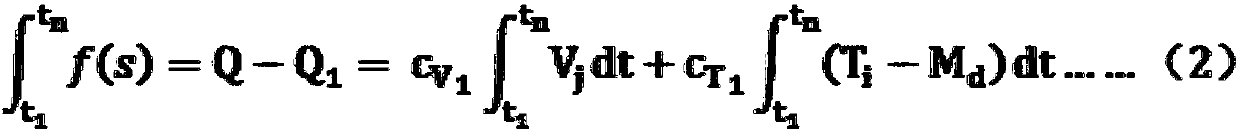

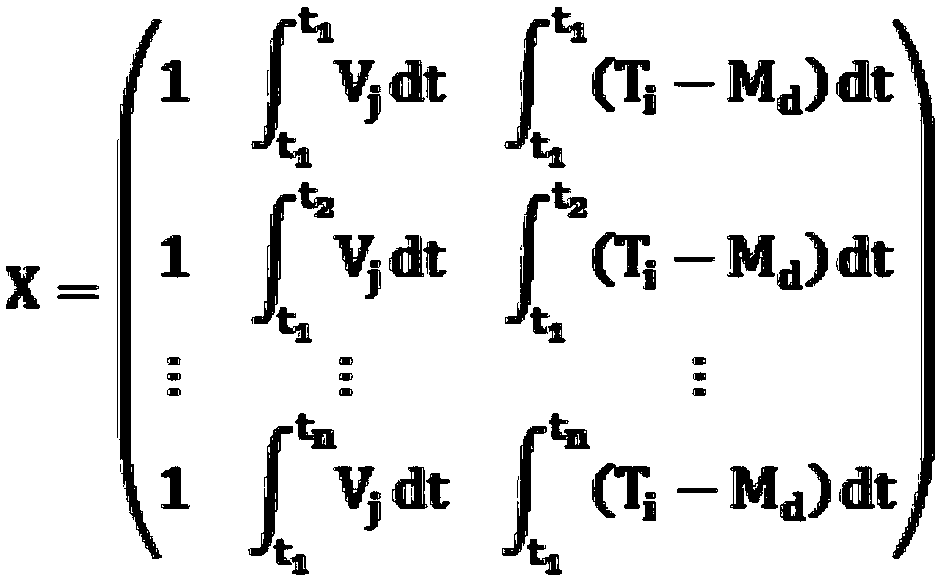

A method for evaluation and early warning for train axle properties based on mathematical models

ActiveCN106528940ARealize qualitative judgmentEfficient maintenanceGeometric CADSpecial data processing applicationsHigh speed trainSelf recovery

The invention provides a method for evaluation and early warning for train axle properties based on mathematical models and belongs to the field of methods for evaluation and early warning of high speed train axle properties. The method comprises the steps of establishing an axle temperature variation mathematical model for axle operation in each of the latest 30 days, and obtaining a group of parameters for evaluating the axle properties with respect to each model; performing smoothing processing on each group of parameters, and performing abrupt change detection and trend detection for the axle properties based on the smoothed property parameters. The qualitative method can assist train maintainers in accurately and reliably judging whether axle temperature alarm signals belong to short-period false alarms capable of self-recovery, and further provide important reference bases for maintenance decisions thereof.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

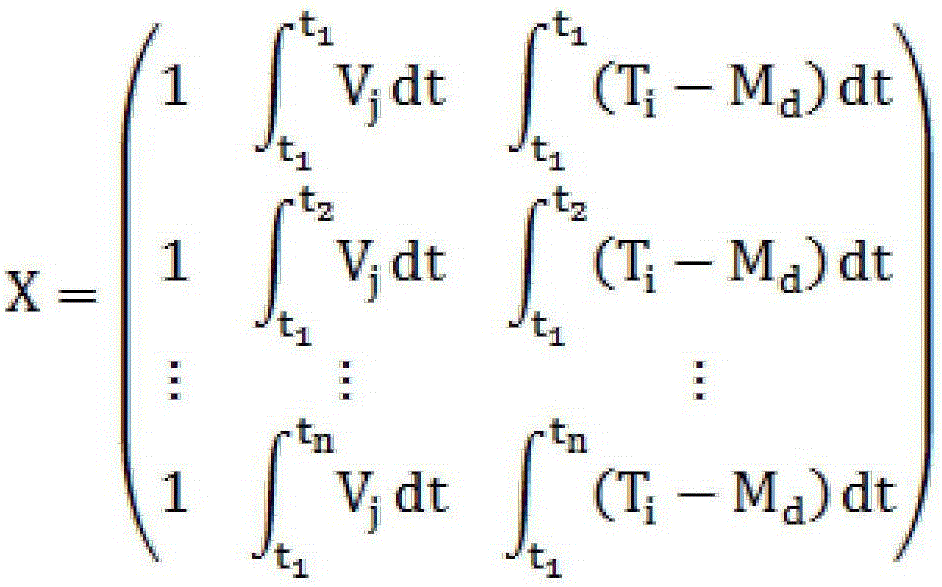

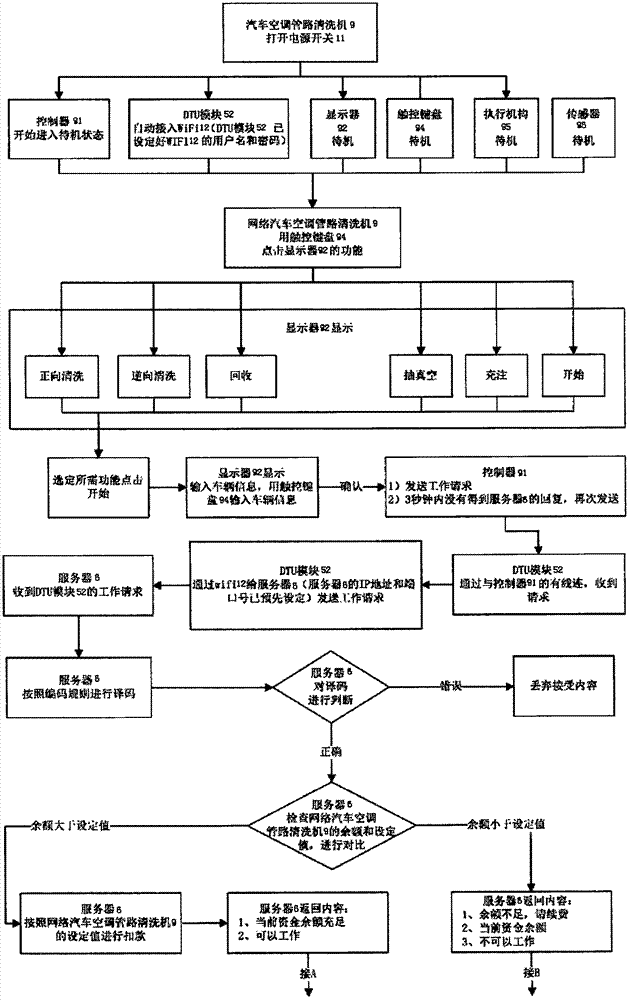

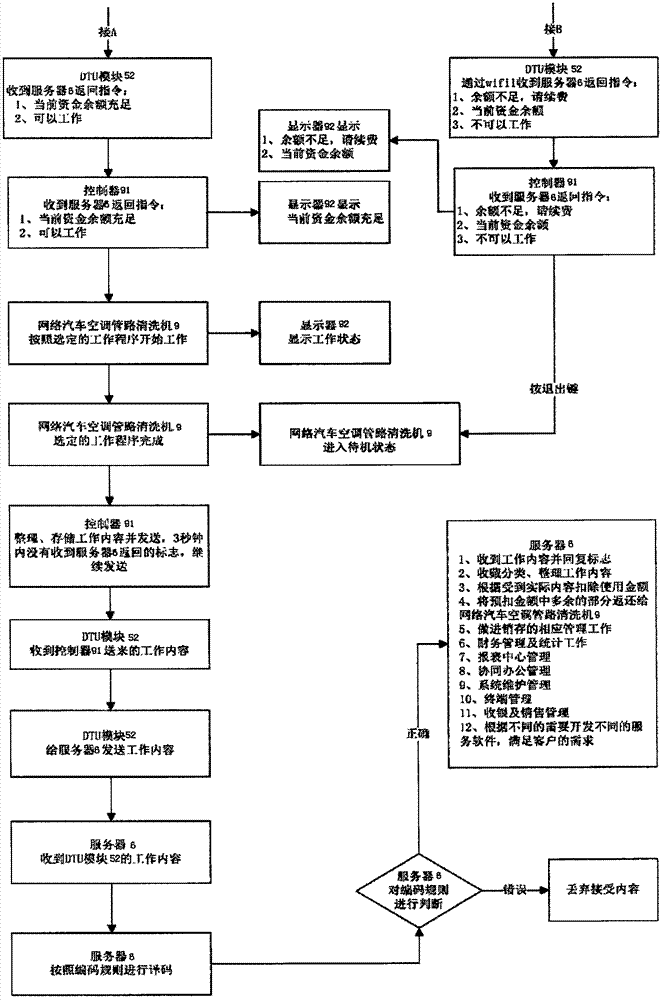

Automobile maintenance equipment network management system

PendingCN106878413AImprove the level ofIncrease credibilityData processing applicationsTransmissionServicing equipmentPower switching

Owner:蒋宇昕

Monitoring method and monitoring system for transformer overheating fault

InactiveCN103278244BGuaranteed uptimeImprove maintenance levelRadiation pyrometryCircuit arrangementsSystems designTransformer

The invention belongs to the technical field of electrical equipment monitoring and relates to a monitoring method and a monitoring system for an overheat fault of a transformer. The technical problems that traditional monitoring methods and monitoring systems in the prior art are not reasonable enough and the like are solved by the invention. The monitoring system comprises the following steps: A, thermal image acquisition; B, image recognition processing; and C, fault diagnosis and processing. The monitoring method and the monitoring system for the overheat fault of the transformer have the advantages that acquired image information is recognized by adopting a non-contact monitoring mode to realize fast recognition and diagnose of the part, the degree the type of the early potential fault of the transformer. The monitoring method and the monitoring system for the overheat fault of the transformer have the characteristics that the safety, the reliability and the efficiency are high. Meanwhile, by utilizing the non-contact monitoring mode, a condition is provided for realizing all-weather state monitoring on the transformer on the premise that the operation of the transformer is not influenced, and therefore, the safe, stable and reliable operation of equipment is ensured, the maintenance level of the transformer is comprehensively promoted, and the maintenance cost is reduced. The system is reasonable in design, simple in structure, good in working stability and high in fault detection rate.

Owner:苏州求臻智能科技有限公司

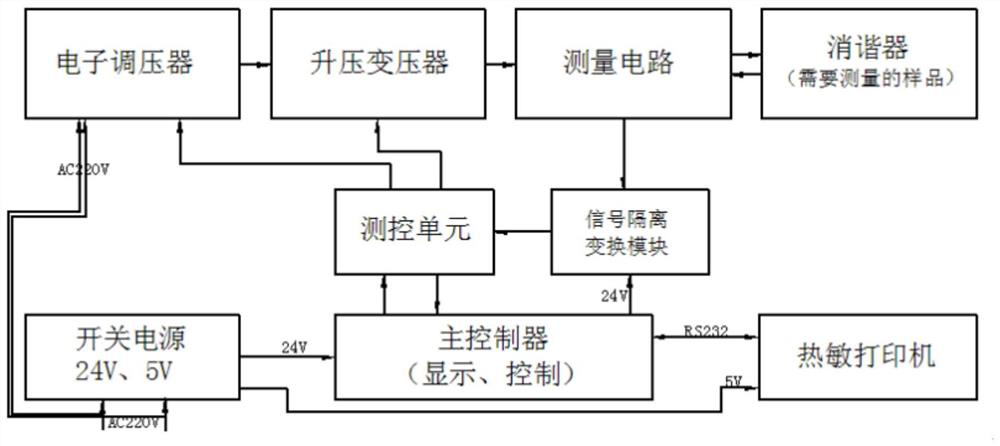

Full-automatic nonlinear resistance type resonance eliminator test system

InactiveCN113466595AVolt-ampere characteristics maintainedLimit voltage acrossResistance/reactance/impedenceElectrical testingNumerical controlComputer printing

The invention discloses a full-automatic nonlinear resistance type resonance eliminator test system, which comprises an electronic voltage regulator, a boosting transformer, a measuring circuit, a resonance eliminator, a measurement and control unit, a signal isolation conversion module, a switching power supply, a main controller and a thermal printer; the working process of the full-automatic non-linear resistance type resonance eliminator test system is as follows: voltage output by the numerical control module passes through the resonance eliminator, the main controller automatically records the voltage and calculates the real-time resistance value of the resonance eliminator, and the printer automatically prints the voltage, current and resistance of the system. According to the full-automatic non-linear resistance type resonance eliminator test system, a resonance eliminator power frequency current and voltage parameter verification method is adopted, a high-voltage sampling signal isolation transformation technology is combined, a volt-ampere characteristic curve graph is drawn while fault prediction is performed on a running resonance eliminator, and the test system adopts a segmented variable parameter measure, so that the resonance eliminator can still maintain the original volt-ampere characteristic in a normal working current section.

Owner:STATE GRID HUBEI ELECTRIC POWER CO XIAOGAN POWER SUPPLY CO

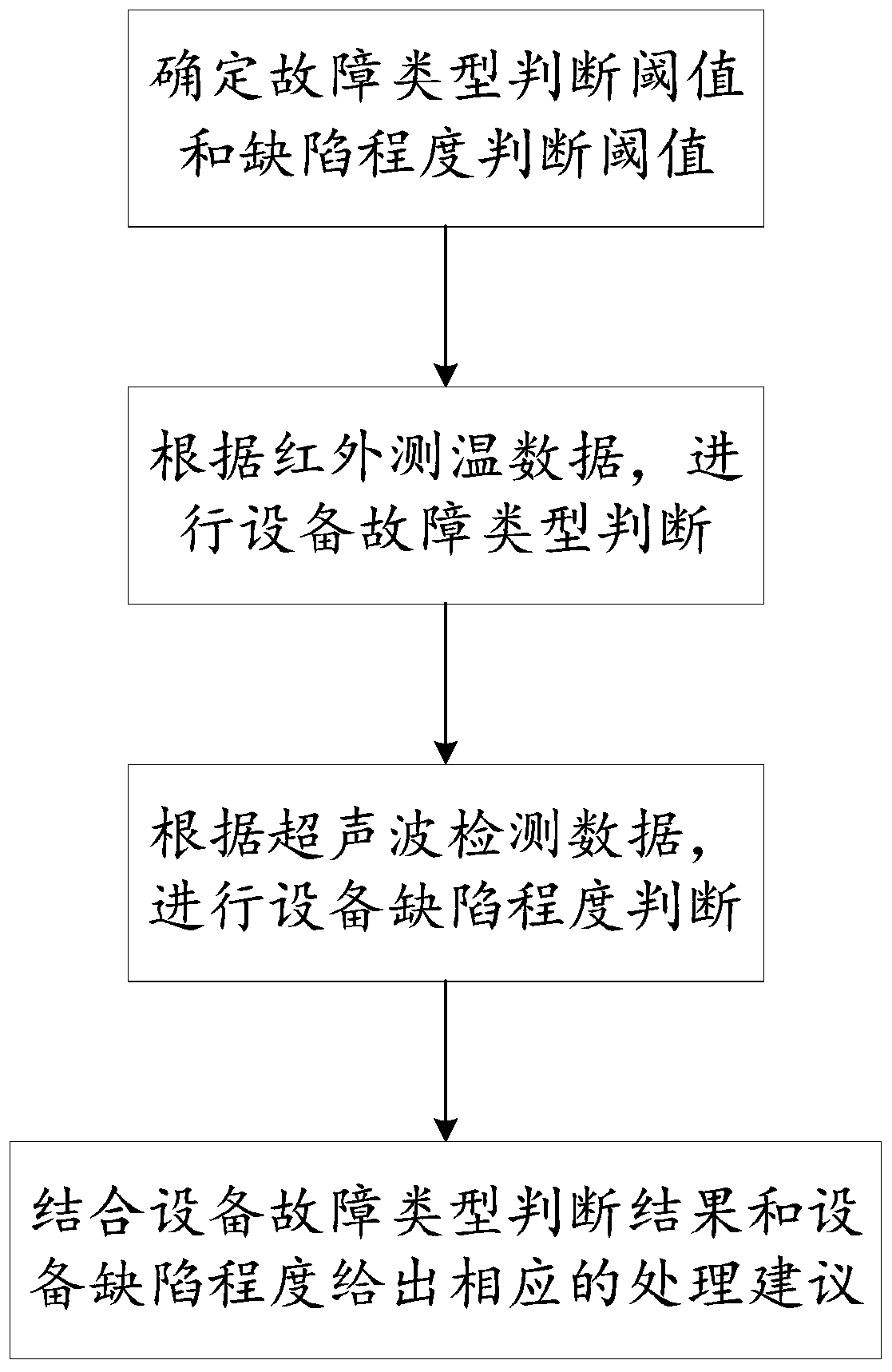

Method and system for improving online fault detection accuracy rate of overhead line structures

InactiveCN110243479AEfficient detection meansImprove discoveryRadiation pyrometryTesting using acoustic measurementsTransformerUltrasonic testing

The invention provides a method and a system for improving online fault detection accuracy rate of overhead line structures. In combination with infrared temperature measurement and ultrasonic testing technology, potential faults of the overhead line structures are discovered in time, health information of each overhead line and each transformer substation is collected through online detection, an information standing book is established scientifically to qualitatively and quantificationally help managerial personnel to grasp health condition of equipment operation in time, simultaneously, a maintenance schedule is established scientifically by operation and maintenance personnel through complete and accurate information, and potential safety hazards are eliminated as soon as possible.

Owner:STATE GRID SHANDONG ELECTRIC POWER CO JINING CITY RENCHENG DISTRICT POWER SUPPLY CO +1

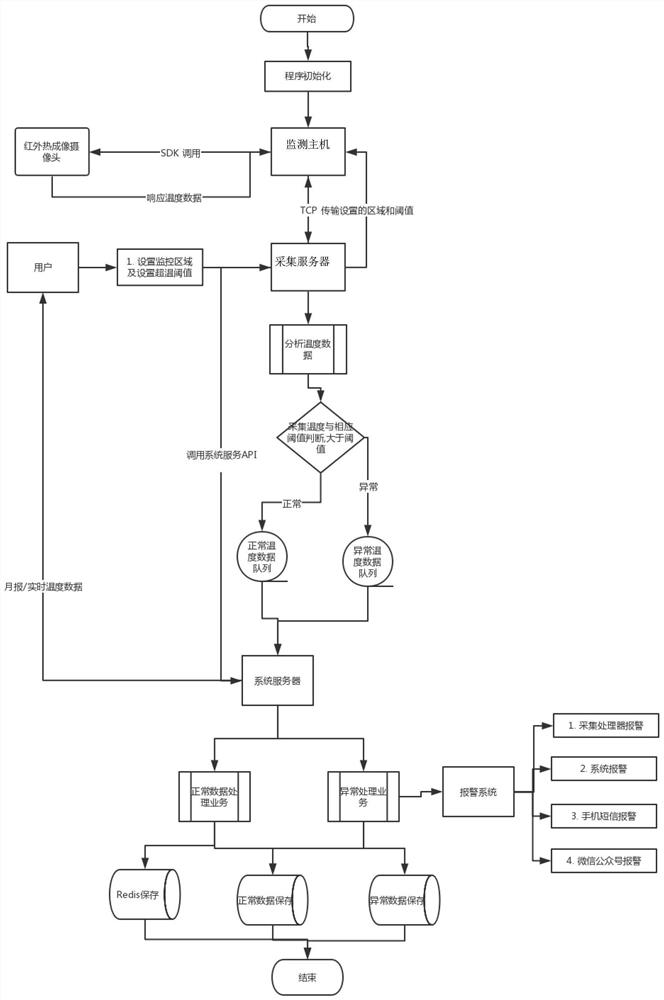

Thermal imaging online monitoring method and system for electrical equipment

InactiveCN112097919AImprove maintenance levelIntelligent online temperature monitoringPyrometry using electric radation detectorsProcess engineeringTemperature monitoring

The invention discloses a thermal imaging online monitoring method and system for electrical equipment, and the method comprises the steps: collecting thermal imaging pictures of different positions of the electrical equipment through employing a plurality of thermal imaging cameras, and setting at least one monitoring region and a corresponding overtemperature threshold value for each position; amonitoring host acquires temperature data of each monitoring region in the thermal imaging picture and uploads the temperature data to an acquisition server; the acquisition server analyzes the temperature data, compares the temperature data with the corresponding overtemperature threshold, and reports a comparison result and the temperature data to a system server; and the system server stores the temperature data and judges whether to give an alarm according to the comparison result. All-weather, multi-region and intelligent online temperature monitoring can be realized, safe, stable and reliable operation of equipment is ensured, the maintenance level of the electrical equipment is comprehensively improved, and the operation and maintenance cost is reduced.

Owner:厦门市美亚睿进电力科技有限公司

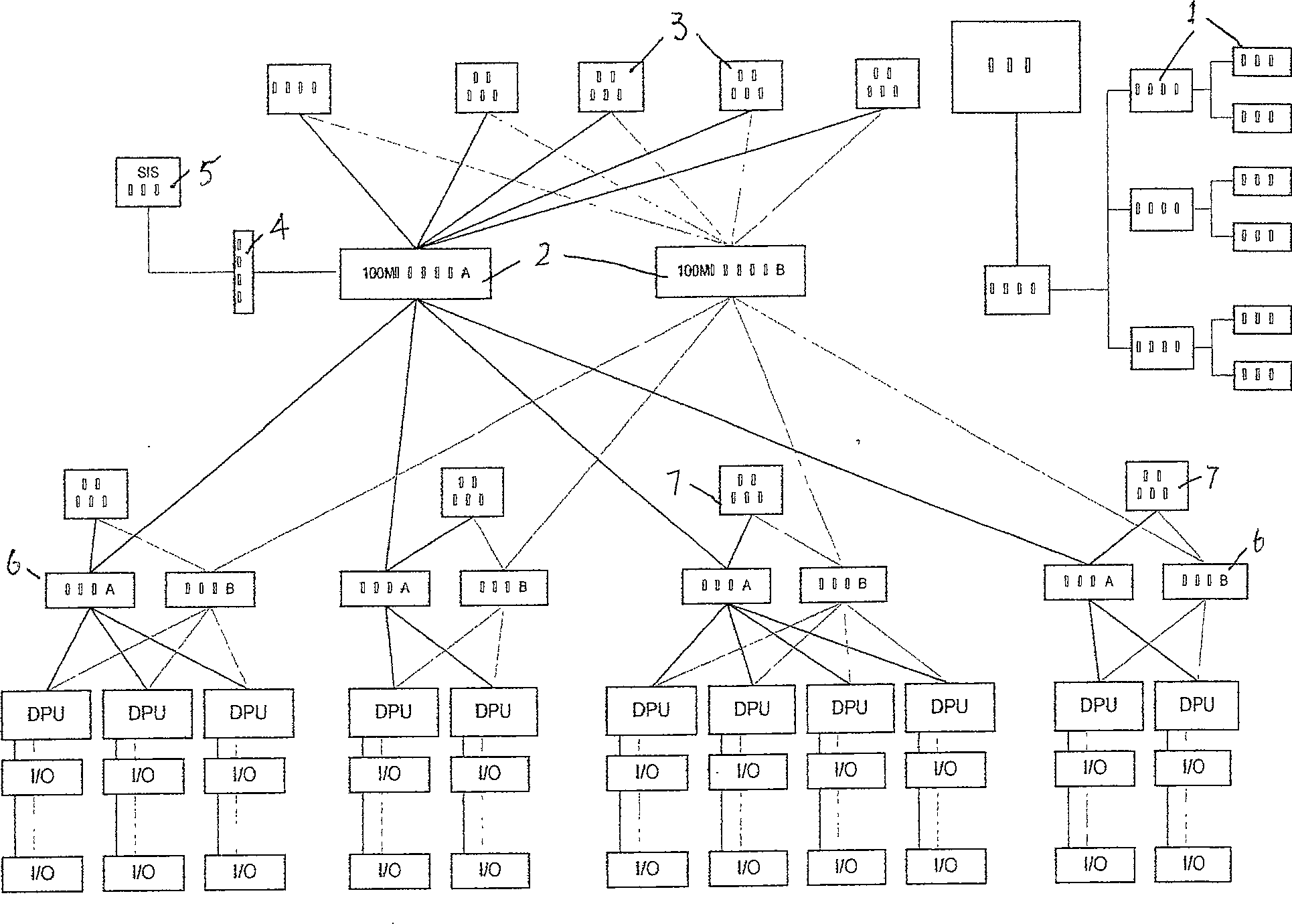

Auxiliary workshop centralized control method for electricity generating enterprise

InactiveCN100498616CControl designRaise the level of monitoringElectric testing/monitoringTotal factory controlIndustrial EthernetElectricity

The invention discloses an integral concentration control method of plant management and control, which is characterized by the following: programming the concentration control and management of operation, monitor and management equipment in the coal handling, ash removal and water carbureting auxiliary workshop; setting the concentration control chamber of auxiliary workshop; controlling the integral PLC or DCS unit in each control chamber of auxiliary workshop to do concentration management; accomplishing the concentration control and management through network control; setting four control points of control chamber, water carbureting, coal handling and ash in the auxiliary chamber. The network structure is allocated in each control chamber of auxiliary workshop, which adapts hybrid topology structure; the auxiliary workshop adapts concentration star topology structure; the PLC or DCS concentration control network adapts industrial Ethernet. The system control power, controller and network all apply redundant allocation.

Owner:南京科远智慧能源投资有限公司

General fault detecting and maintenance method for equipment

InactiveCN103617576BRealize accumulationAchieve sharingError detection/correctionSpecial data processing applicationsMaintenance strategySimulation training

Owner:NANJING UNIV +1

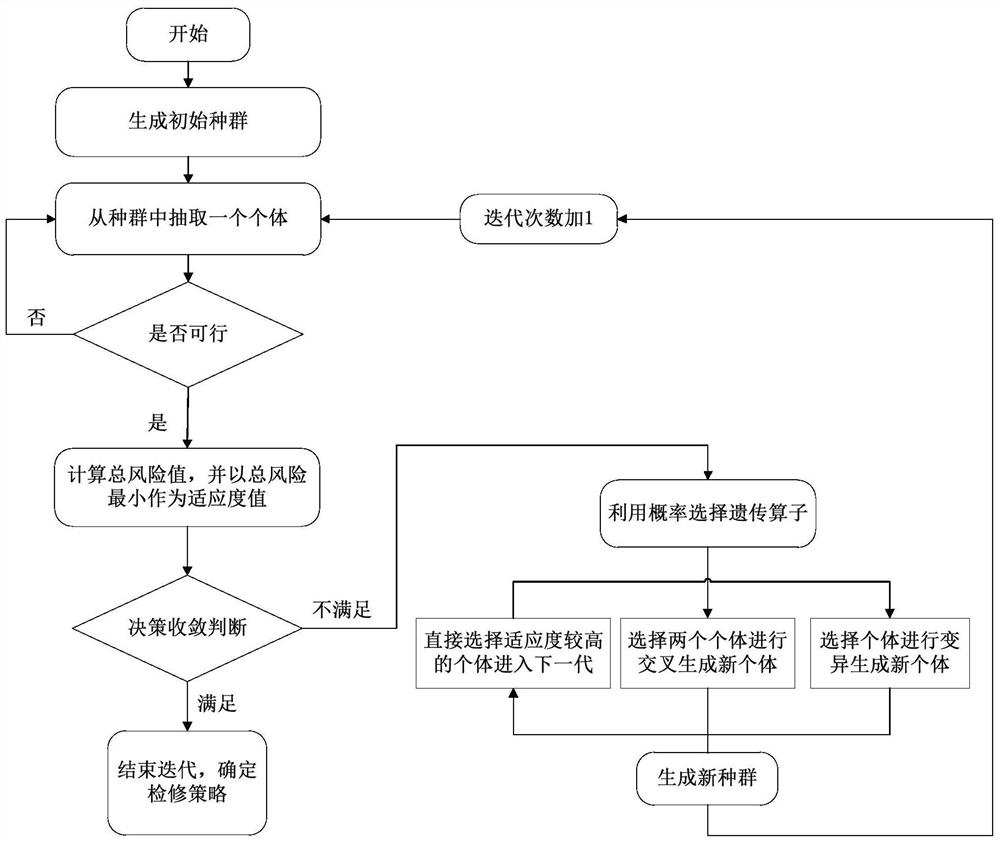

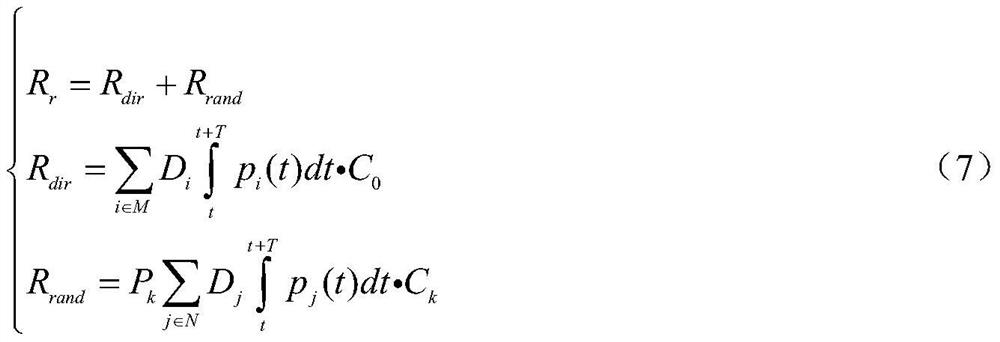

An optimal maintenance method for 10kv distribution transformers considering the risk of power grid operation

ActiveCN107563536BComprehensive and thoughtful optimization and maintenanceGuaranteed uptimeForecastingSystems intergating technologiesFailure rateDistribution transformer

The present invention is a 10kV distribution transformer optimization maintenance method considering the operation risk of the power grid. The method includes: calculating the failure rate of the 10kV distribution transformer; calculating the individual risk loss of the 10kV distribution transformer maintenance and the risk loss of the power grid operation; The objective function of transformer maintenance and the corresponding constraints; complete the optimal maintenance of 10kV distribution transformer. The method for optimizing the maintenance of 10kV distribution transformers provided by the present invention, which considers the operation risk of the power grid, improves the operation, maintenance and maintenance level of the distribution transformers, prevents and reduces the probability of failures, and reduces the waste of maintenance resources.

Owner:CHINA ELECTRIC POWER RES INST +2

A rail head profile measuring instrument

ActiveCN107433960BStrengthen conservationImprove maintenance levelRailway auxillary equipmentRailway profile gaugesRail profileMeasuring instrument

The invention discloses a rail head profile measuring instrument, which relates to the technical field of rail repair and maintenance; it includes a positioning device, a fixing device for fixing the rail, and a measuring device; the fixing device is arranged at the lower part of the positioning device, and the measuring device is arranged at the positioning device The upper part; the measuring device includes a slideway, a ruler and a retractable probe arranged on the fixed plate. The scale slides on the slideway through the slider, and the fixed plate can slide up and down. The fixed plate is connected with the positioning device, and a horizontal row of probes Set at the lower end of the fixed plate; a horizontal row of probes can match and fix the upper end of the rail head profile; there is also a standard template, which is fixed on the fixed plate at the position corresponding to the probes; it can be quickly measured on the job site The amount of grinding required for the rail and the difference between the polished rail profile and the designed profile can improve the maintenance and repair level of the rail and improve work efficiency.

Owner:SHIJIAZHUANG TIEDAO UNIV

Wearable auxiliary device for aircraft maintenance

InactiveCN102795349BAvoid misuseImprove maintenance levelInput/output for user-computer interactionAircraft maintainanceHead movementsMicrocontroller

The invention belongs to wearable auxiliary equipment for aircraft maintenance in the field of the maintenance of aviation machines. The wearable auxiliary equipment comprises a wearable computer, a head motion detector which contains a helmet, an inertial sensor with a gyroscope or a gyroscope of the helmet, a microcontroller and a communication circuit, a camera, a monocular display, earphones, a microphone and a power supply. According to the wearable auxiliary equipment, the head wearable camera is arranged additionally to take pictures and record videos for reference on conditions of maintenance sites and the like, and an operation request is sent by using voice and is confirmed or denied in modes of nodding and shaking a head, so that the auxiliary equipment for maintenance has the characteristics that a comprehensive function is high, the auxiliary equipment can be maintained without manual operation, the conditions (such as failure phenomena and maintenance results) of the maintenance sites and the like can be photographed and recorded accurately and objectively at any time to analyze failure and track the maintenance results subsequently, the maintenance quality and the maintenance efficiency can be improved effectively, the maintenance cost can be reduced and the like.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

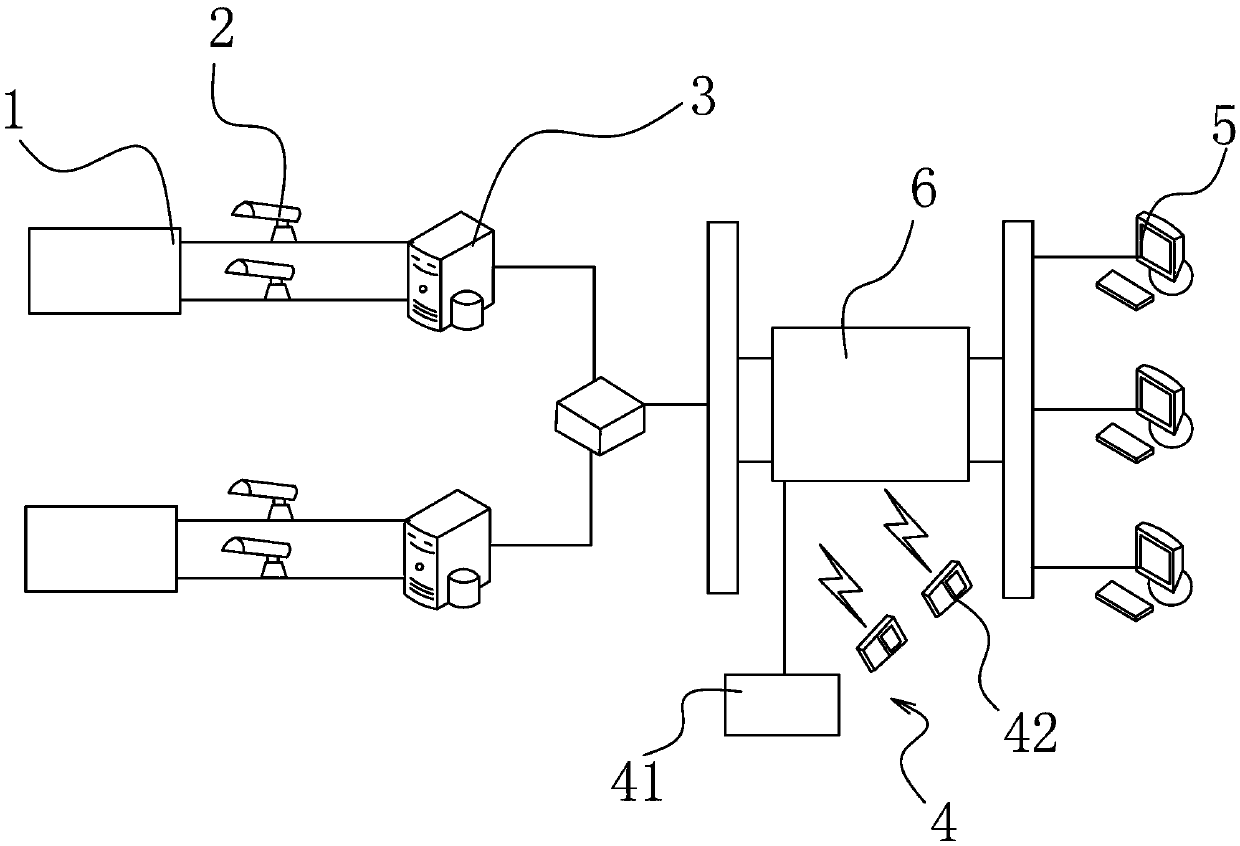

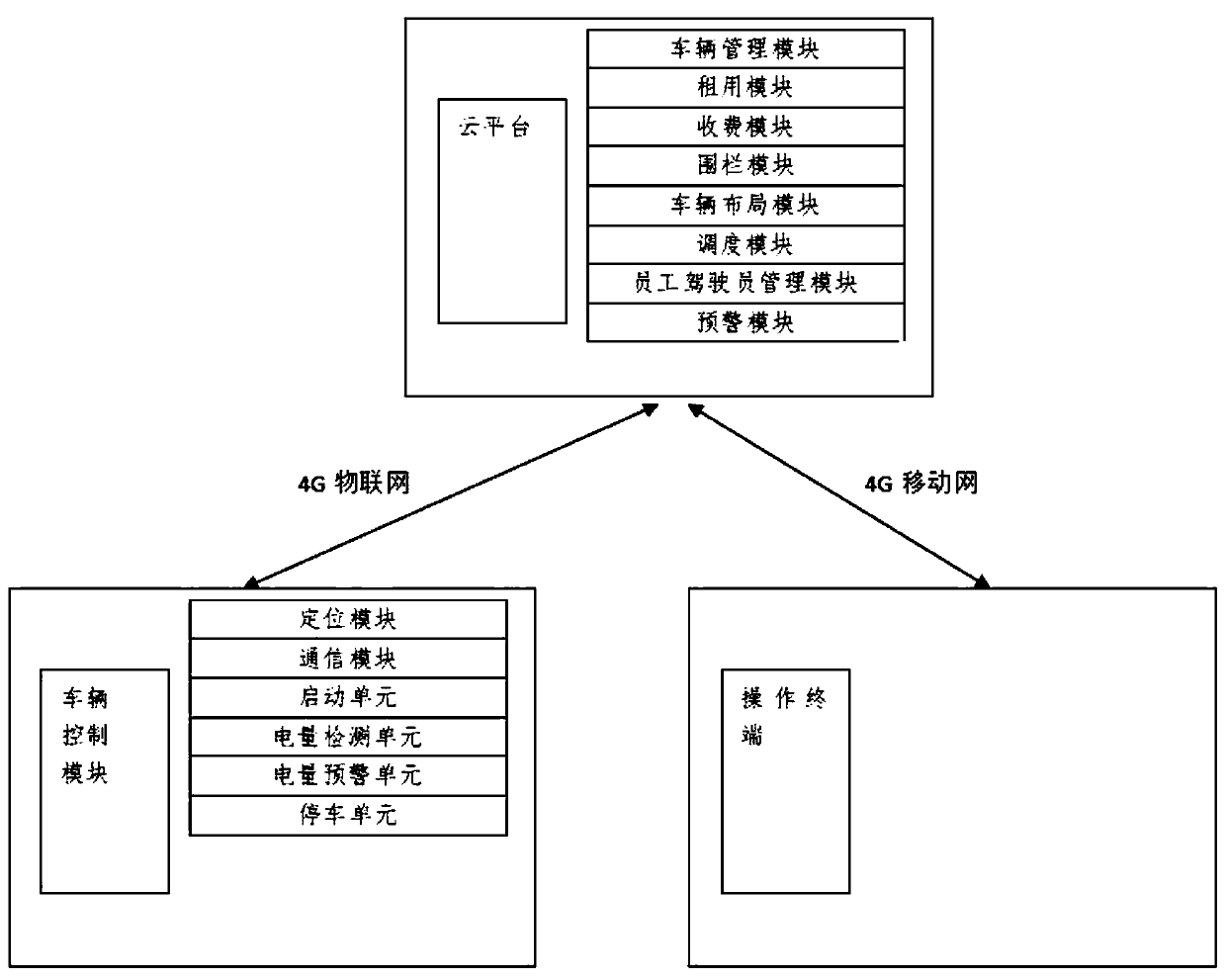

Scenic area shared battery sightseeing vehicle monitoring system

The invention discloses a scenic area shared storage battery sightseeing vehicle monitoring system which comprises a vehicle control system, a cloud platform monitoring system and an operation terminal. The vehicle control system is used for operating and controlling a vehicle. The cloud platform monitoring system is used for monitoring and managing the use state of a vehicle, the supervision of tenants and the scheduling configuration of the vehicle in a scenic spot. The operation terminal is used for realizing reservation, vehicle operation starting, process supervision and expense settlement, the vehicle control system is carried on a vehicle body, the vehicle control system is connected with the cloud platform supervision system through the Internet of Things technology, and the operation terminal is connected with the cloud platform supervision system through mobile data.

Owner:CHONGQING TECH & BUSINESS UNIV

A Method of Evaluating and Pre-warning Train Axle Performance Based on Mathematical Model

ActiveCN106528940BRealize qualitative judgmentEfficient maintenanceGeometric CADSpecial data processing applicationsMathematical modelSelf recovery

The invention provides a method for evaluation and early warning for train axle properties based on mathematical models and belongs to the field of methods for evaluation and early warning of high speed train axle properties. The method comprises the steps of establishing an axle temperature variation mathematical model for axle operation in each of the latest 30 days, and obtaining a group of parameters for evaluating the axle properties with respect to each model; performing smoothing processing on each group of parameters, and performing abrupt change detection and trend detection for the axle properties based on the smoothed property parameters. The qualitative method can assist train maintainers in accurately and reliably judging whether axle temperature alarm signals belong to short-period false alarms capable of self-recovery, and further provide important reference bases for maintenance decisions thereof.

Owner:CRRC CHANGCHUN RAILWAY VEHICLES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com