Standardized intelligent maintenance management control system for parts

A technology for management and control of parts and components, applied in computer parts, data processing applications, instruments, etc., can solve problems such as real-time control of parts and components maintenance process, and achieve the effect of improving the level of maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

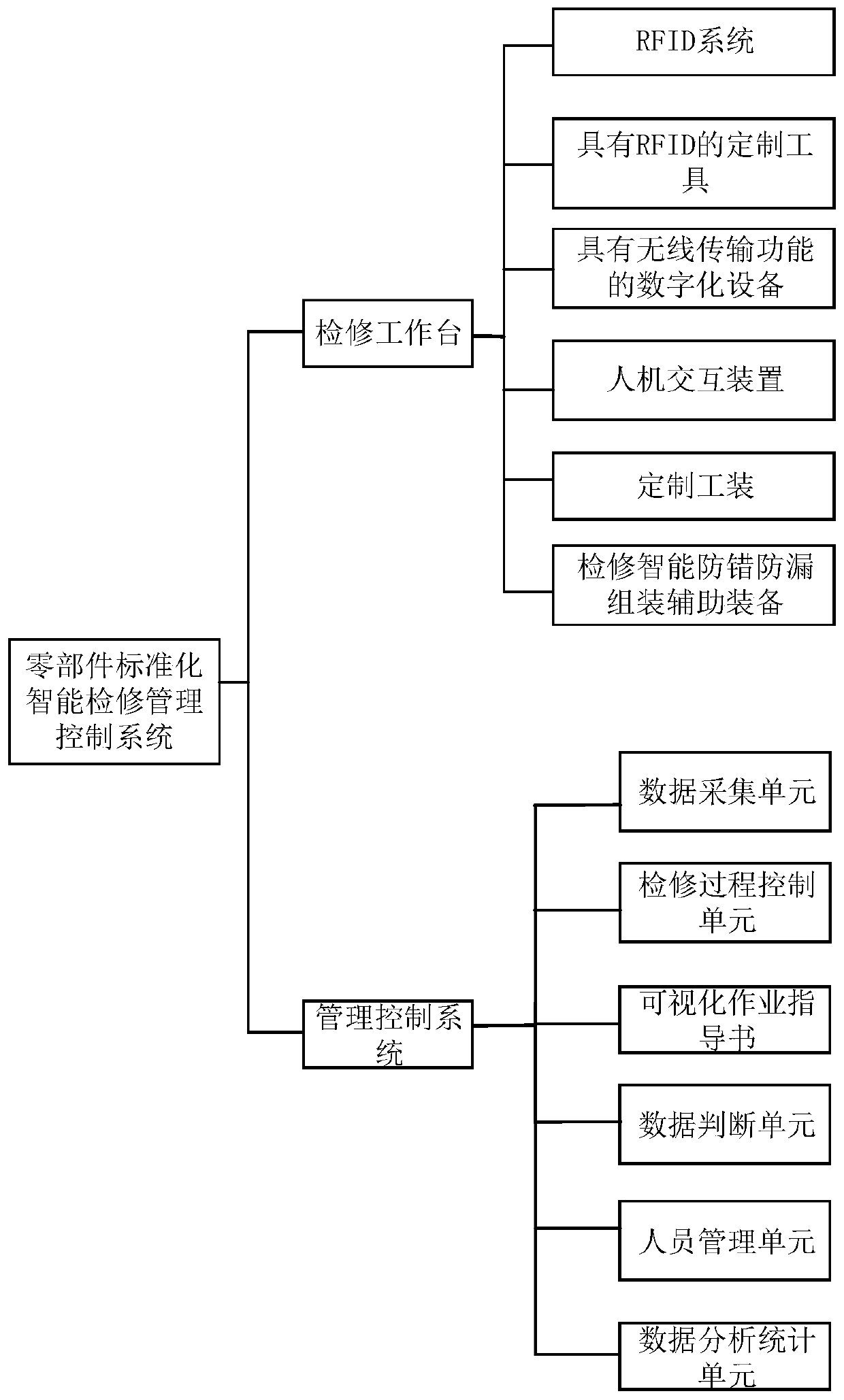

[0036] This embodiment provides a standardized intelligent maintenance management and control system for parts, such as figure 1 As shown, the system includes at least one maintenance workbench and a management control system. The maintenance workbench includes customized tools with RFID function, RFID system, human-computer interaction equipment, digital equipment with wireless transmission function, customized tooling and maintenance intelligent error-proofing Missing assembly auxiliary equipment, management and control system includes data acquisition unit, process control unit, visual work instructions, data judgment unit, personnel management unit and data analysis and statistics unit.

[0037] Furthermore, the human-computer interaction equipment provides an operating environment for the management control system.

[0038] Further, parts maintenance includes parts dismantling, parts measurement and parts assembly. Among them, parts maintenance needs to establish tasks i...

Embodiment 2

[0052] This embodiment has the same inventive concept as Embodiment 1, and on the basis of Embodiment 1, a method for using a standardized intelligent management and control system for parts is provided for repairing parts. Before starting work, all maintenance tools are hung on the corresponding positions on the panel.

[0053] Specifically, component disassembly includes the following steps:

[0054] (11) The operator turns on the computer and enters the login interface of the management control system. The operator enters the account number and password on the screen. After confirmation by the system, the operator enters the task selection interface of the management control system and selects a new dismantling task. In addition, the data acquisition unit in the management control system reads the information of the operator in the employee card hanging at the specified position in the upper right corner of the panel, and the data judging unit judges whether the operator ow...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com