Washing device control method and washing device

The technology of washing equipment and control method is applied in the direction of washing machine control device, tableware washing machine/rinsing machine, washing device, etc., which can solve the problems such as solenoid valve stuck, achieve easy maintenance, realize self-maintenance, and improve satisfaction Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

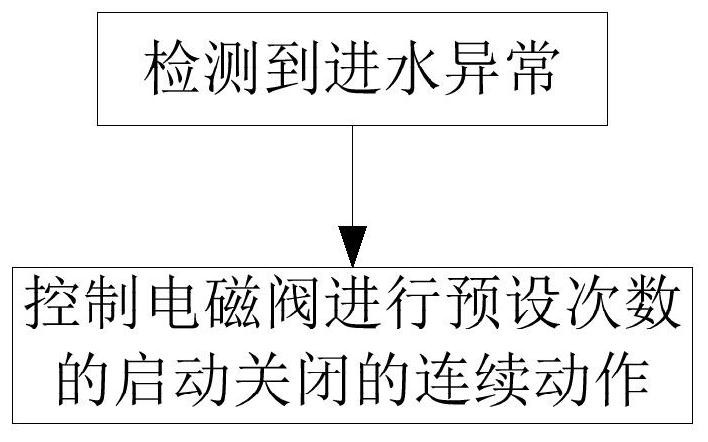

[0033] figure 1 It is a flow chart of a washing equipment control method provided in Embodiment 1 of the present invention. The method for controlling washing equipment provided in this embodiment is used in a scenario where the washing equipment performs washing tasks. The washing device control method provided in this embodiment can be executed by the main control board of the washing device, and the main control board can be realized by software and integrated in the washing device. The washing device control method provided in this embodiment can be automatically executed after the user puts in the laundry and presses the start button after the washing device is powered on.

[0034] A method for controlling washing equipment provided in this embodiment specifically includes: when abnormal water inflow is detected, controlling the solenoid valve to perform a continuous action of starting and closing, and performing the above actions for a preset number of times.

[0035] ...

Embodiment 2

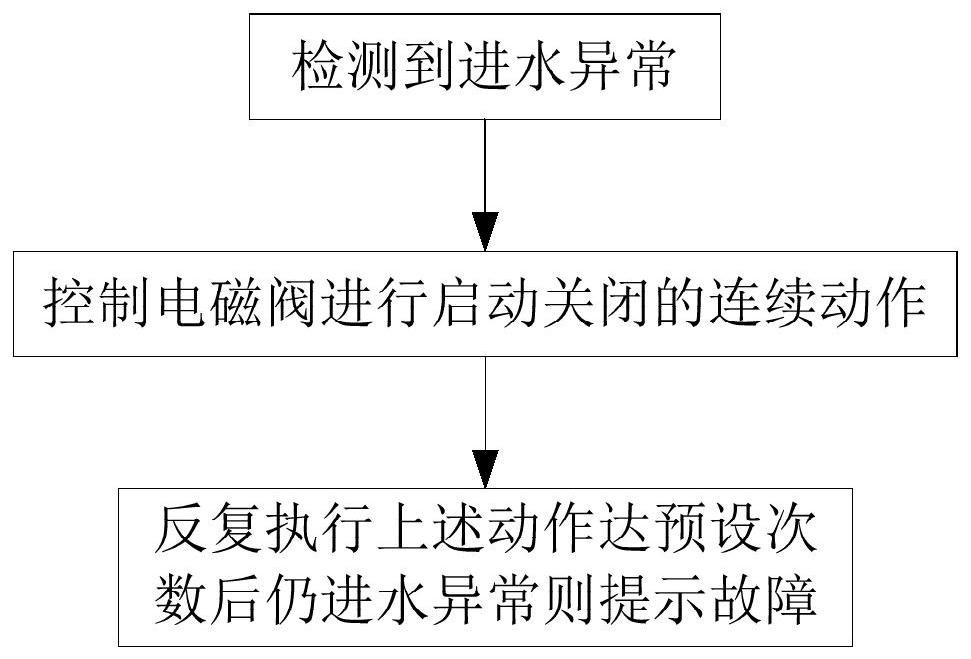

[0040] figure 2 It is a flow chart of a washing equipment control method provided in Embodiment 1 of the present invention. The method for controlling washing equipment provided in this embodiment is used in a scenario where the washing equipment performs washing tasks. The washing device control method provided in this embodiment can be executed by the main control board of the washing device, and the main control board can be realized by software and integrated in the washing device. The washing device control method provided in this embodiment can be automatically executed after the user puts in the laundry and presses the start button after the washing device is powered on.

[0041] A method for controlling washing equipment provided in this embodiment specifically includes: when abnormal water inflow is detected, the solenoid valve is controlled to perform a continuous action of starting and closing, and if the above actions are repeated for a preset number of times and...

Embodiment 3

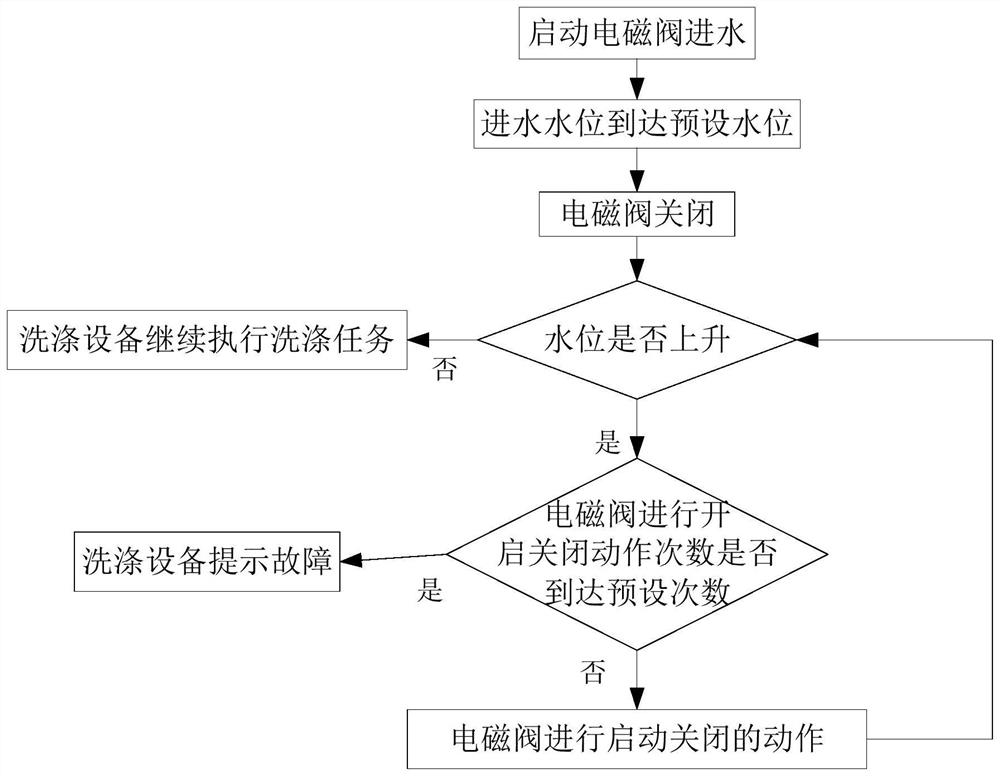

[0051] In this embodiment, the washing device control method provided in this embodiment may be automatically executed after the start button of the washing device is triggered. The washing equipment control method provided in this embodiment specifically includes:

[0052] The washing equipment is filled with water to the preset water level; after the solenoid valve is closed, it is regularly judged whether the water level has risen; if so, the solenoid valve will start and close the continuous action.

[0053] It should be noted that every time the solenoid valve performs a continuous action of starting and closing, it should be judged whether the water level has risen, so as to prevent the electromagnetic valve from being shortened due to excessive opening and closing of the solenoid valve. Limiting the abnormality of water inflow after performing the above actions for a preset number of times is to prevent the solenoid valve from being unable to flush out the small particl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com