Patents

Literature

178 results about "Inventory level" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

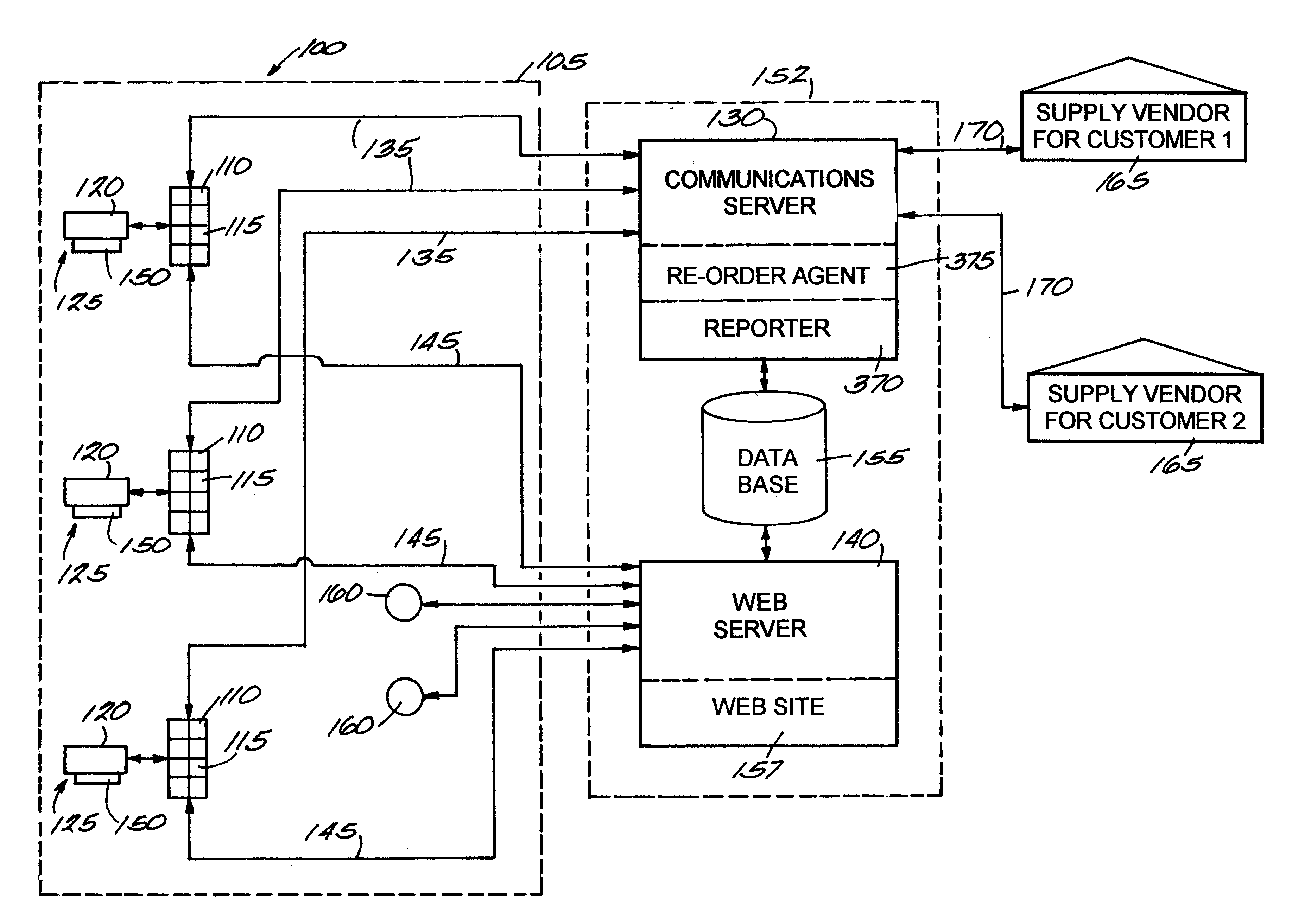

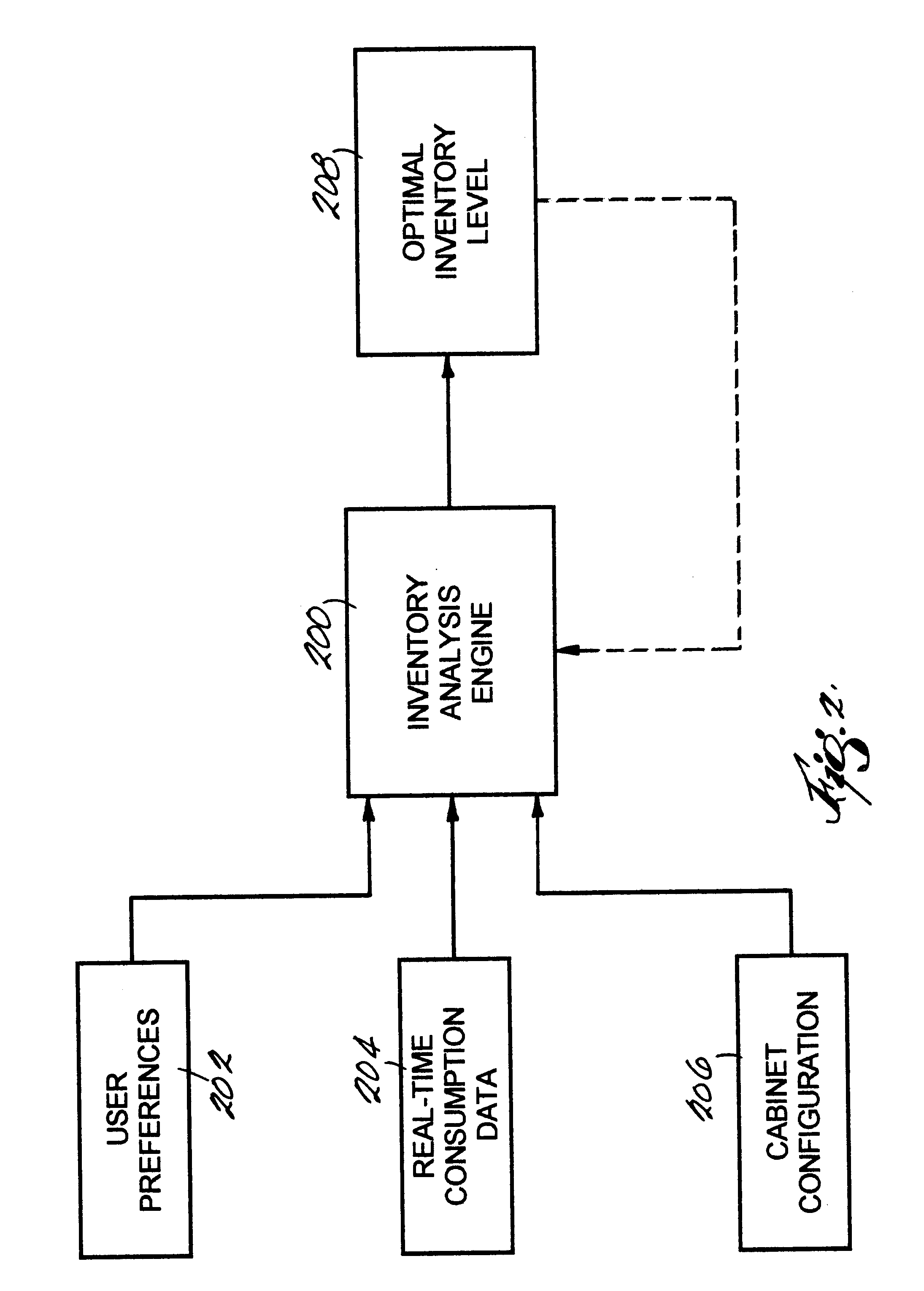

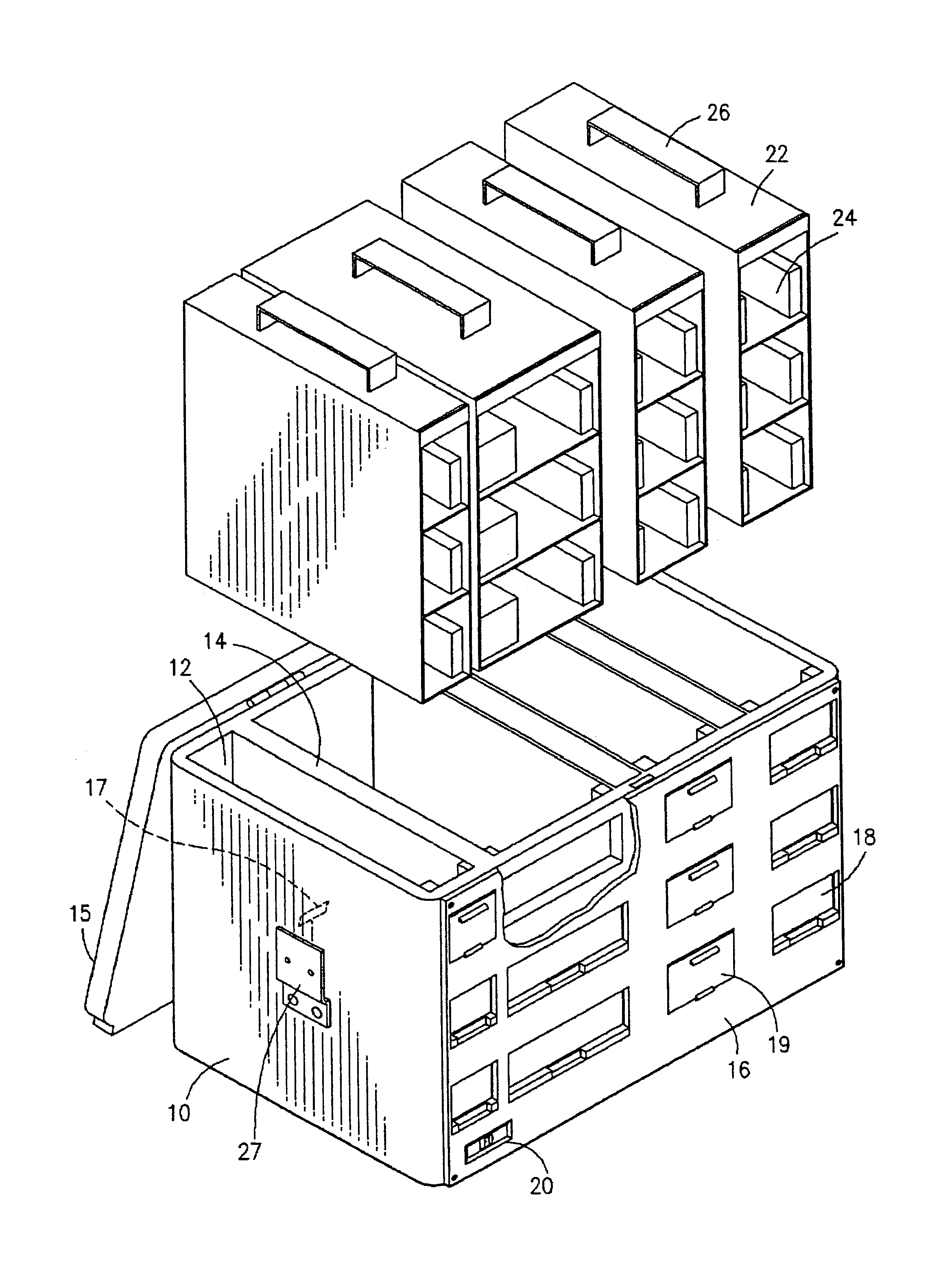

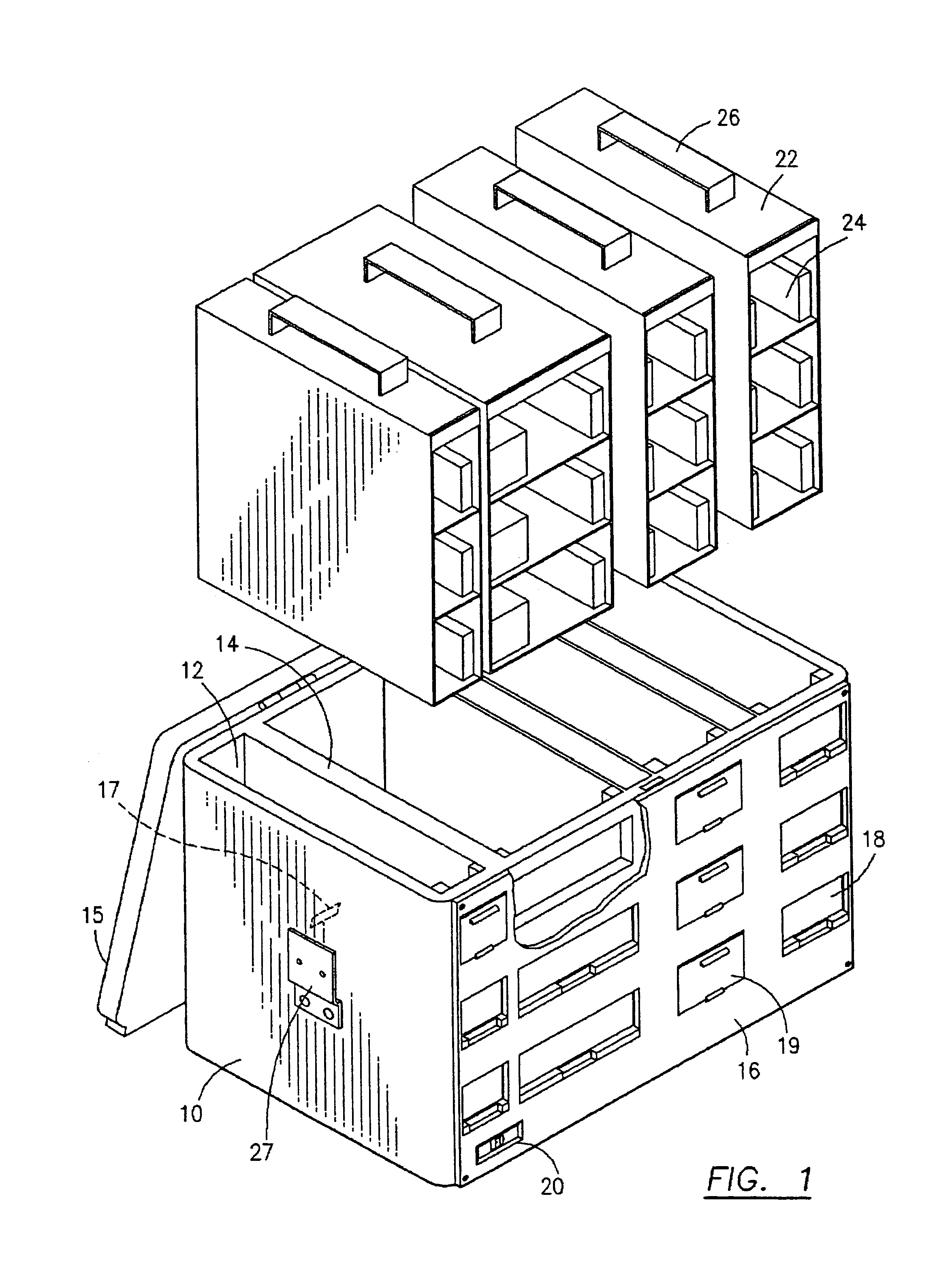

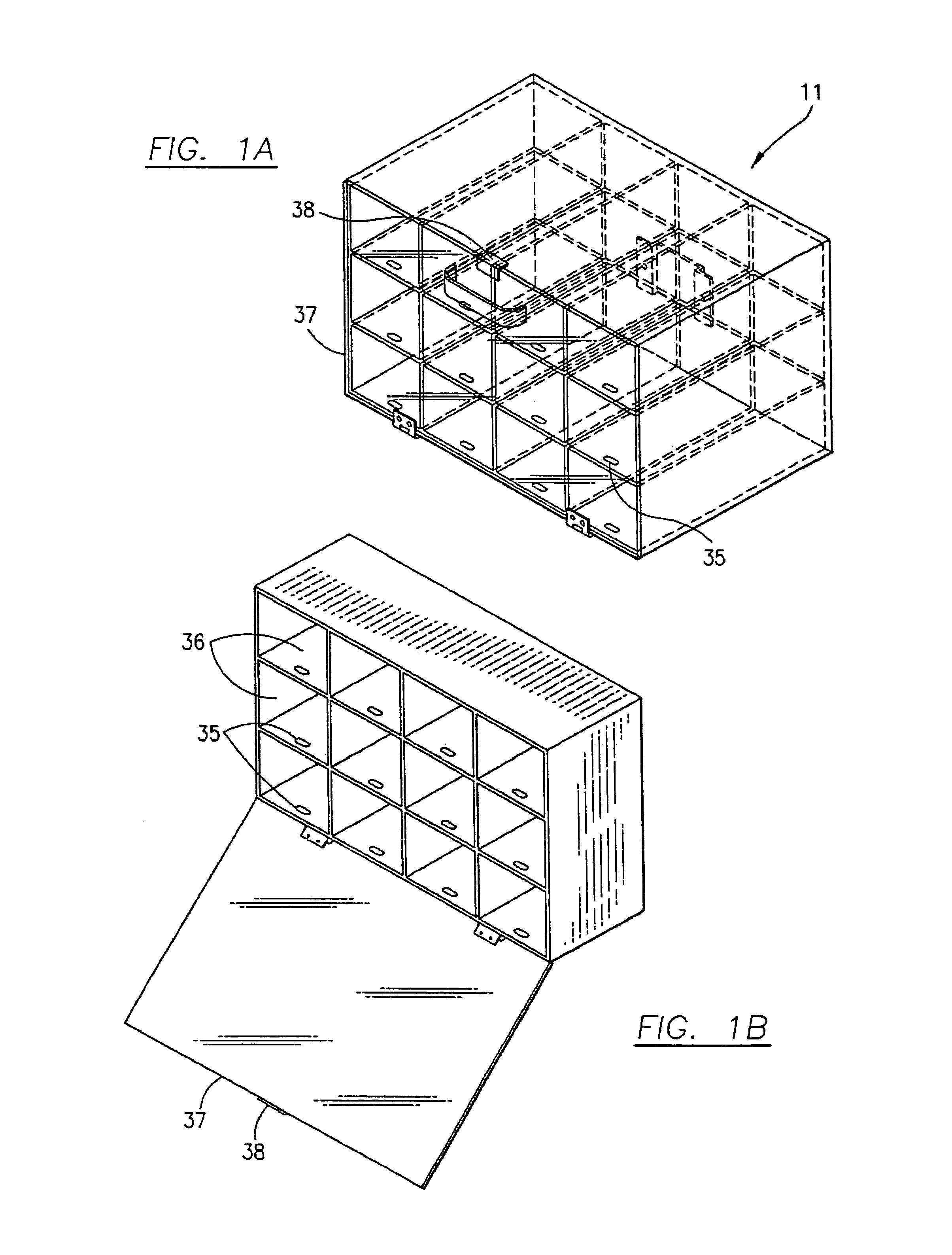

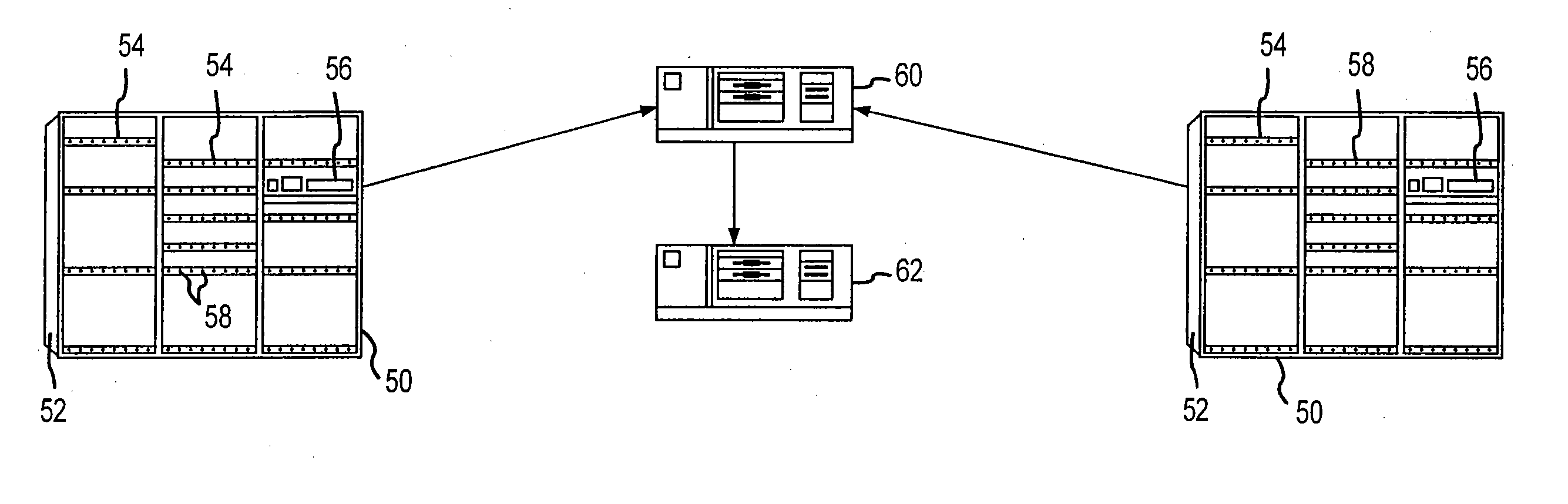

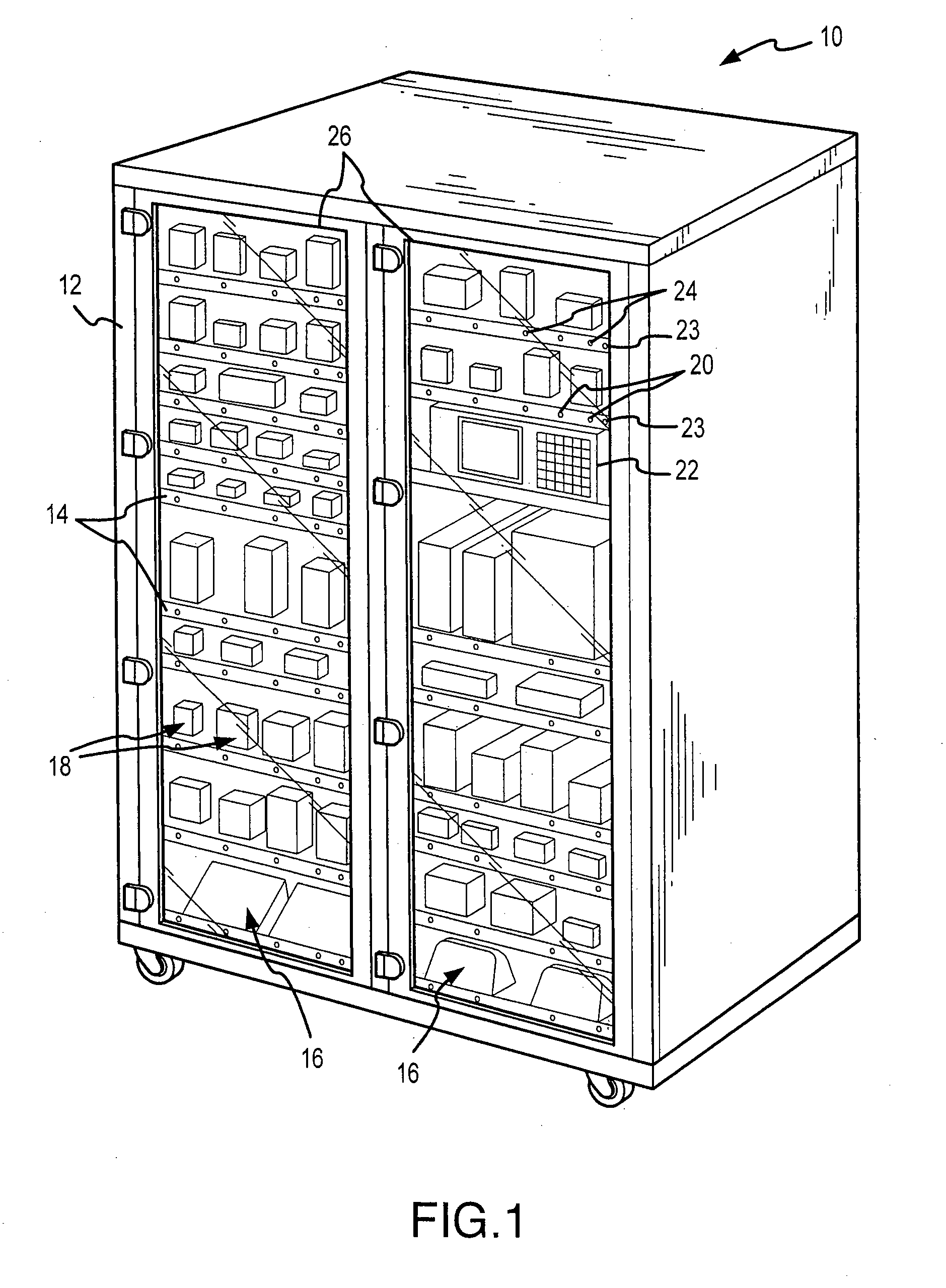

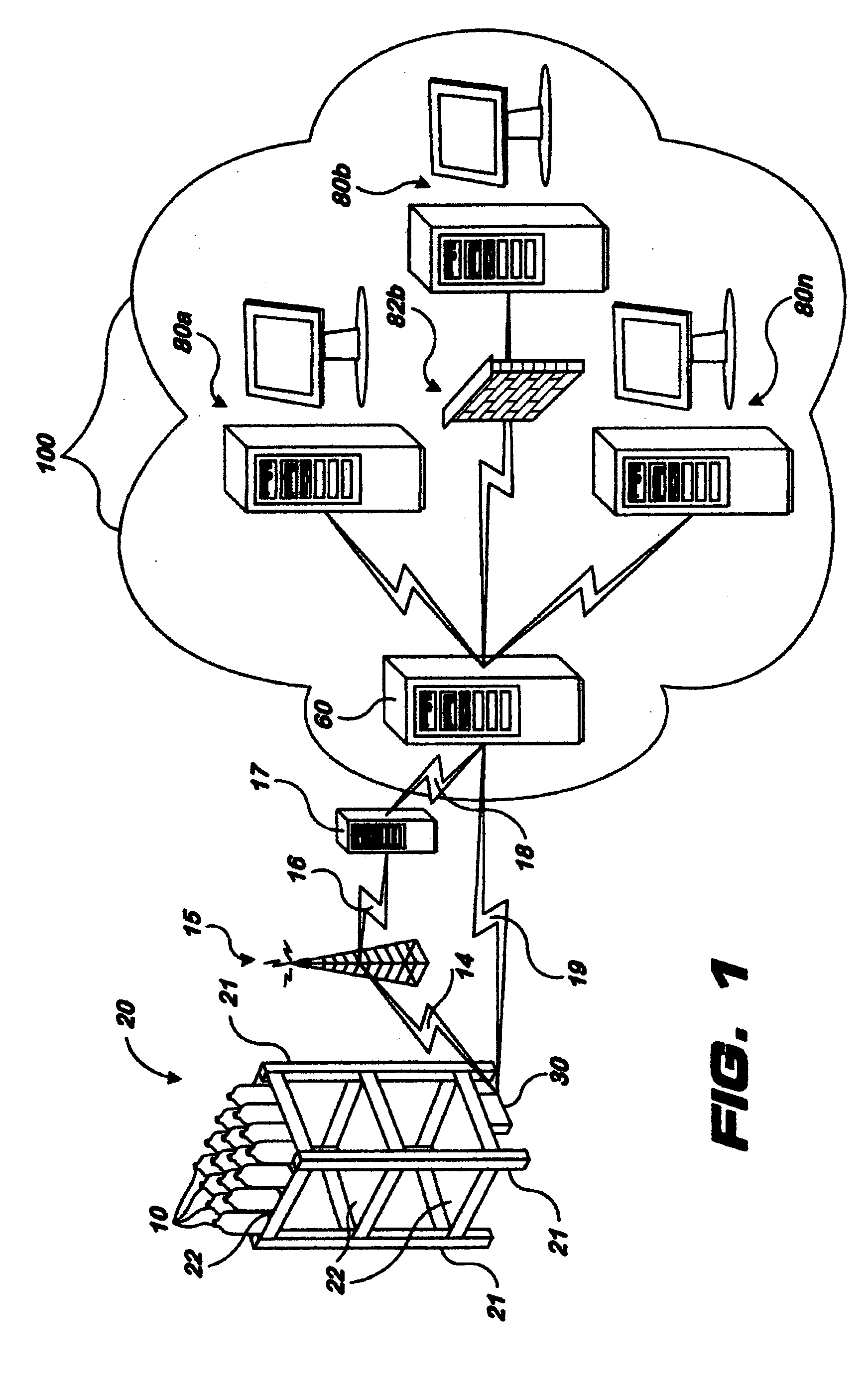

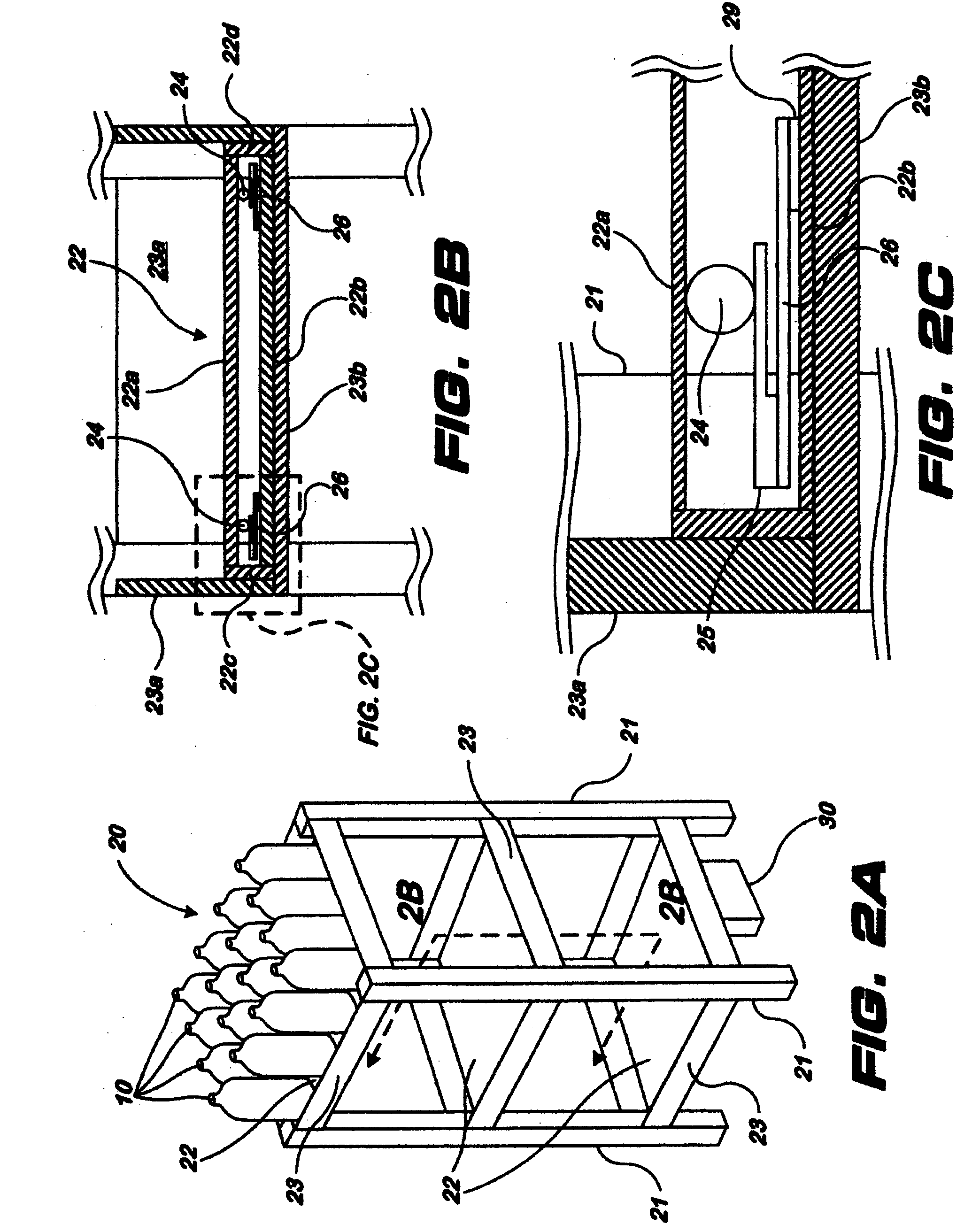

Inventory management system and method

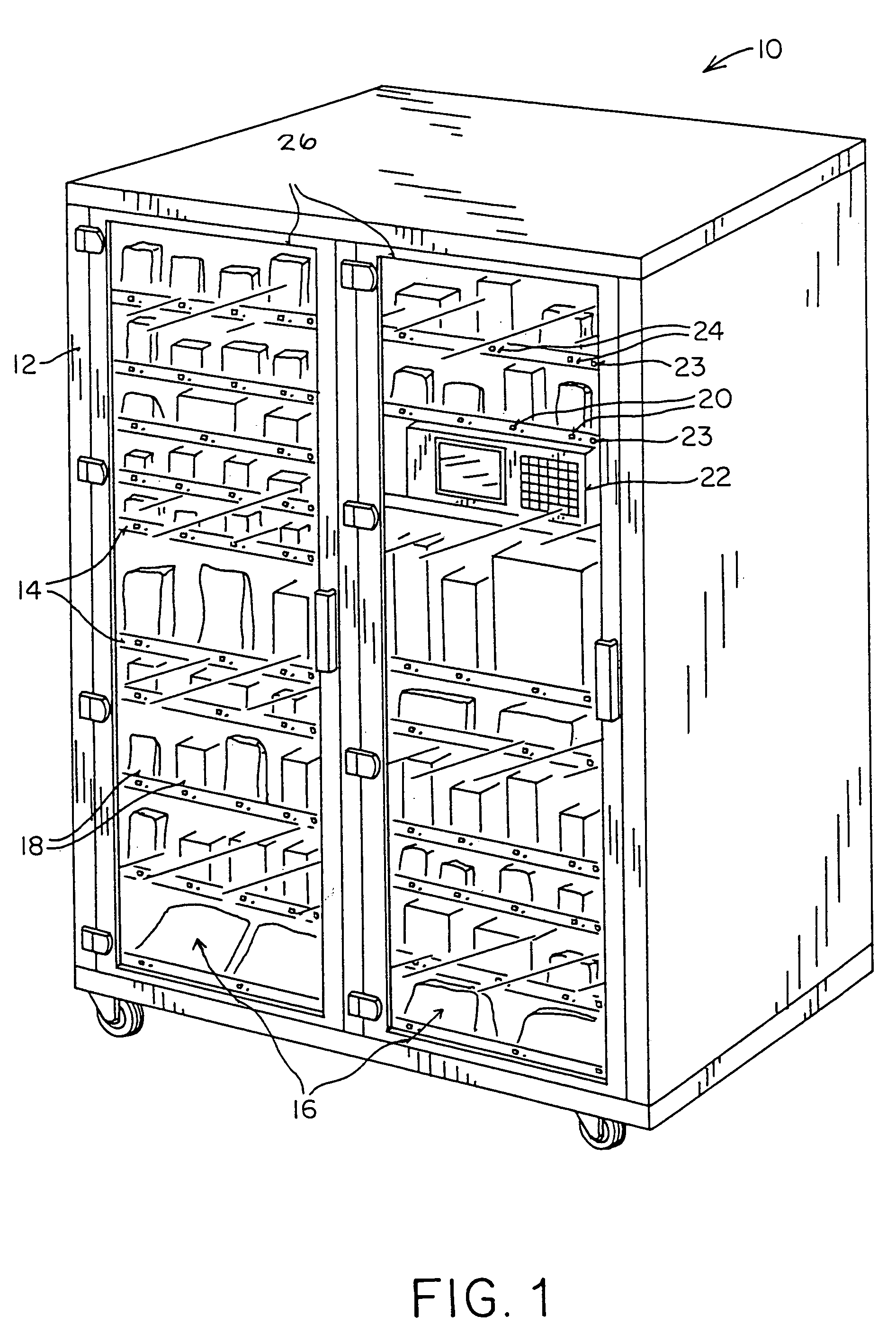

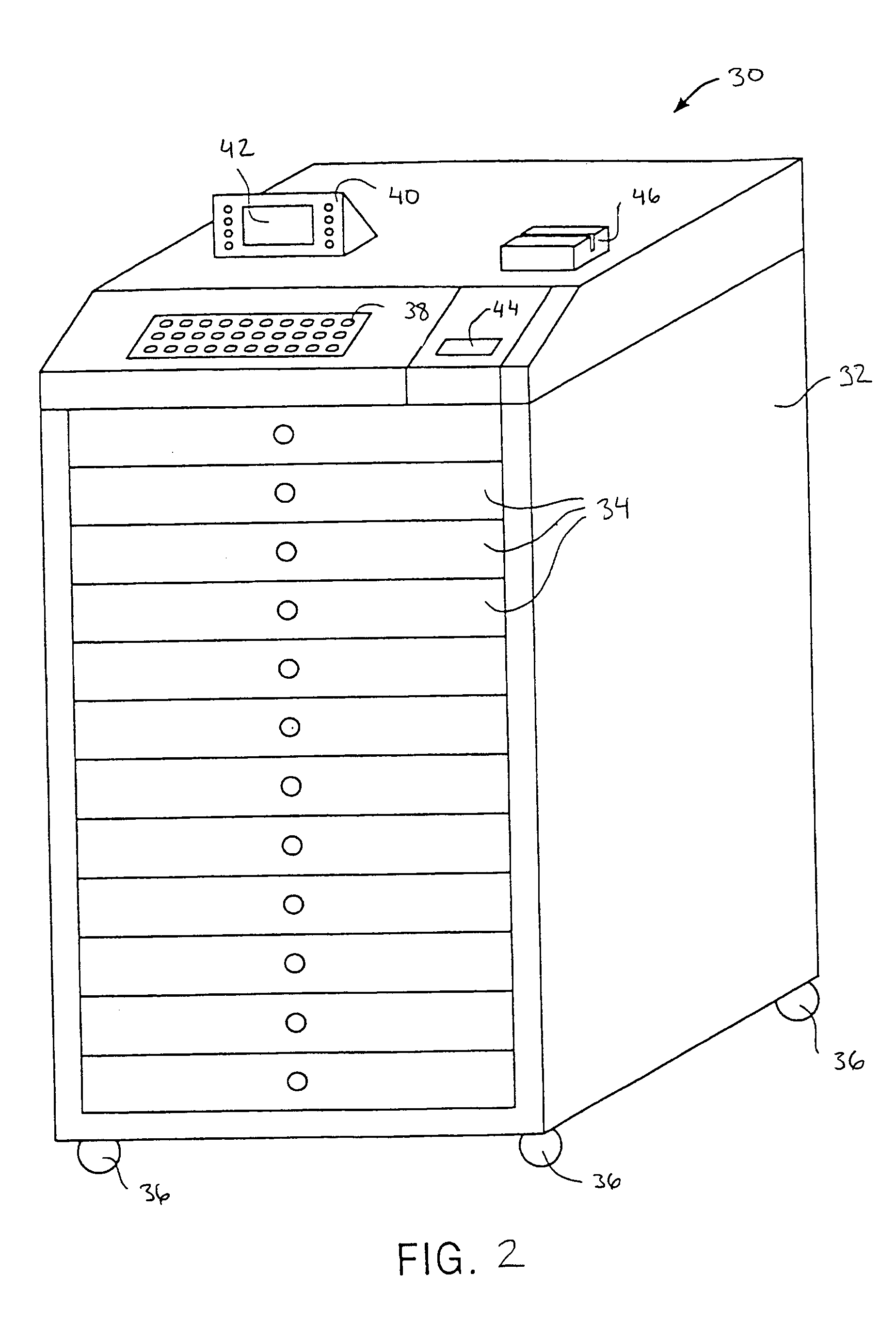

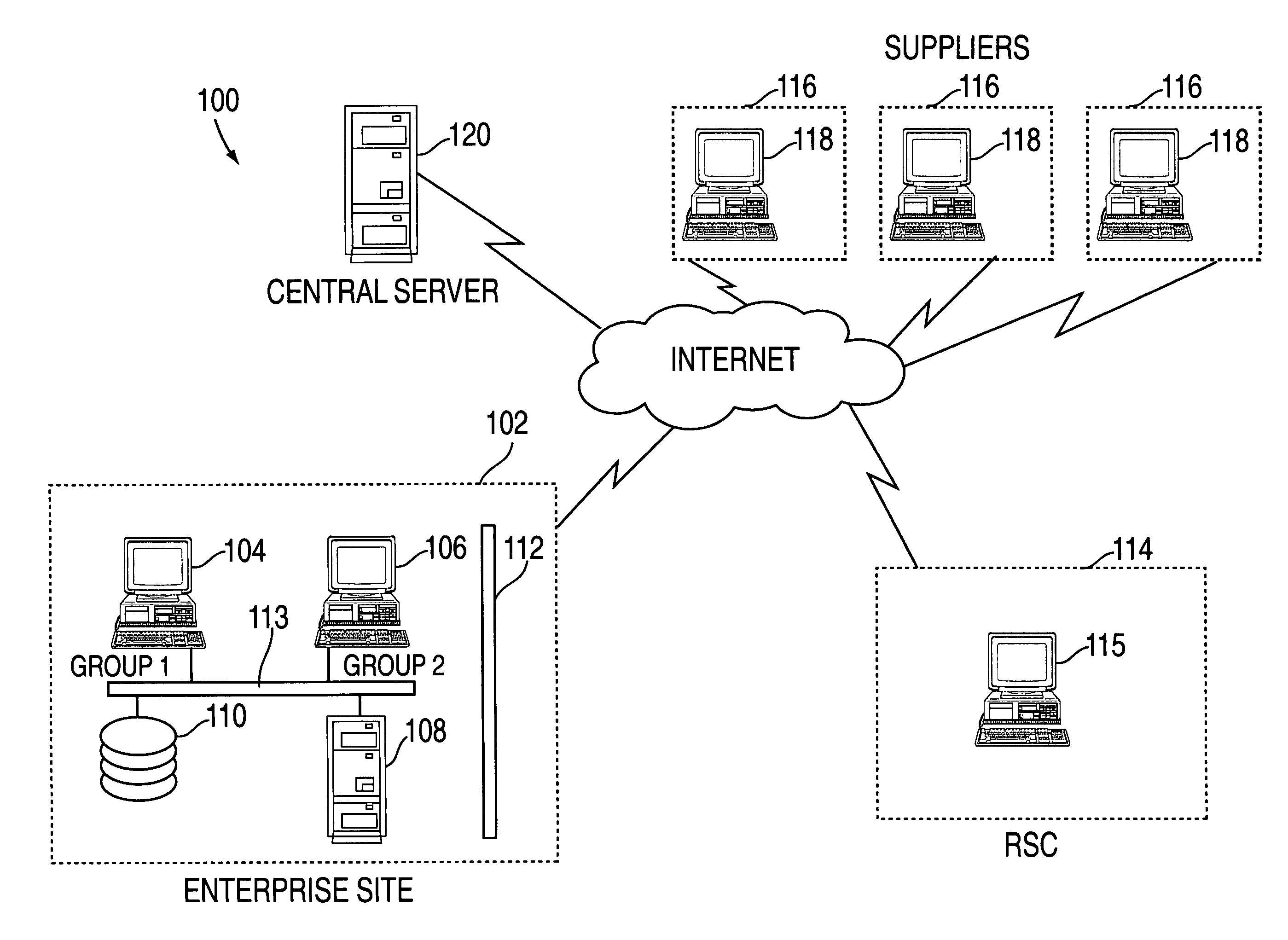

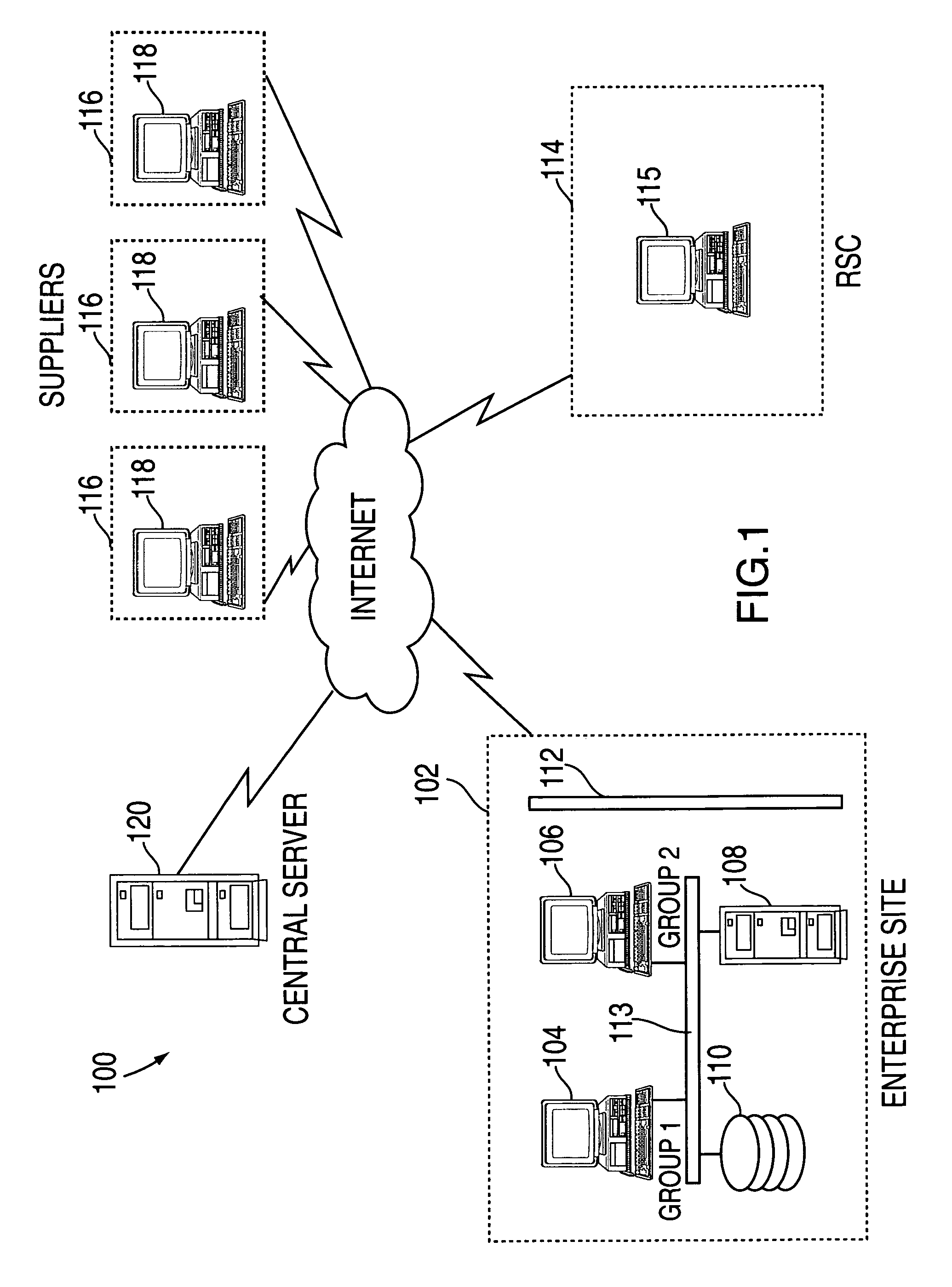

A method and system of dispensing items in a controlled manner from cabinets or similar enclosures, re-ordering the dispensed articles or items, and providing inventory and other information about the items and users in the system. The invention utilizes a distributed network and permits users to browse and search for any item across multiple enclosures from any location. The method and system can track inventory, generate administrative reports, and independently initiate orders based on aggregate inventory levels of multiple enclosures to gain the benefit of volume discounts, minimize deliveries, maximize availability of items, or generate individual orders based on specific enclosures to maintain just-in-time inventory levels. The method and system also track the removal and stocking of items through unique identification strings, so that individual access, use, and theft of items can be monitored.

Owner:SUPPLYPRO

System for inventory management

ActiveUS20050168345A1Electric signal transmission systemsHand manipulated computer devicesSecurity MeasurePurchasing

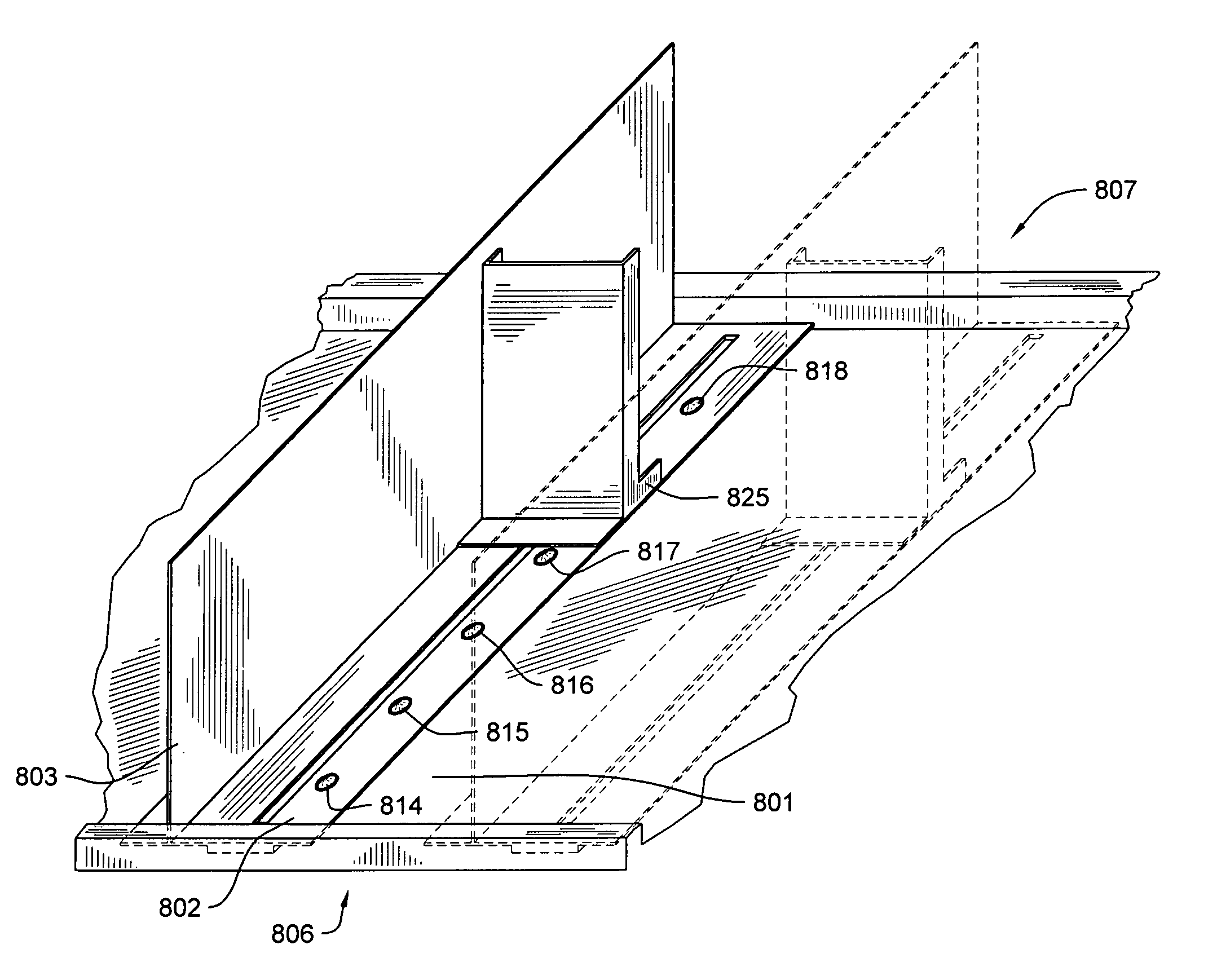

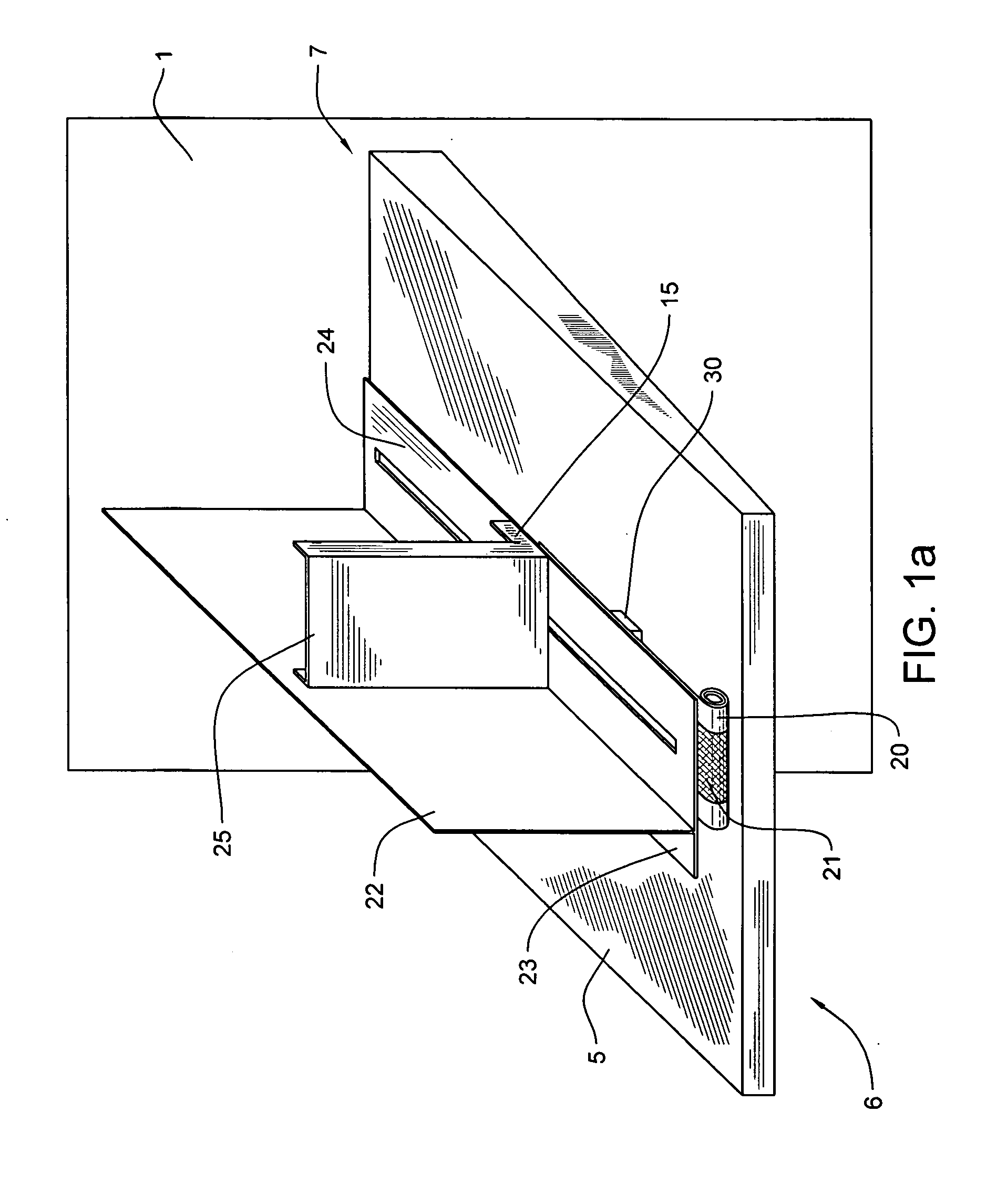

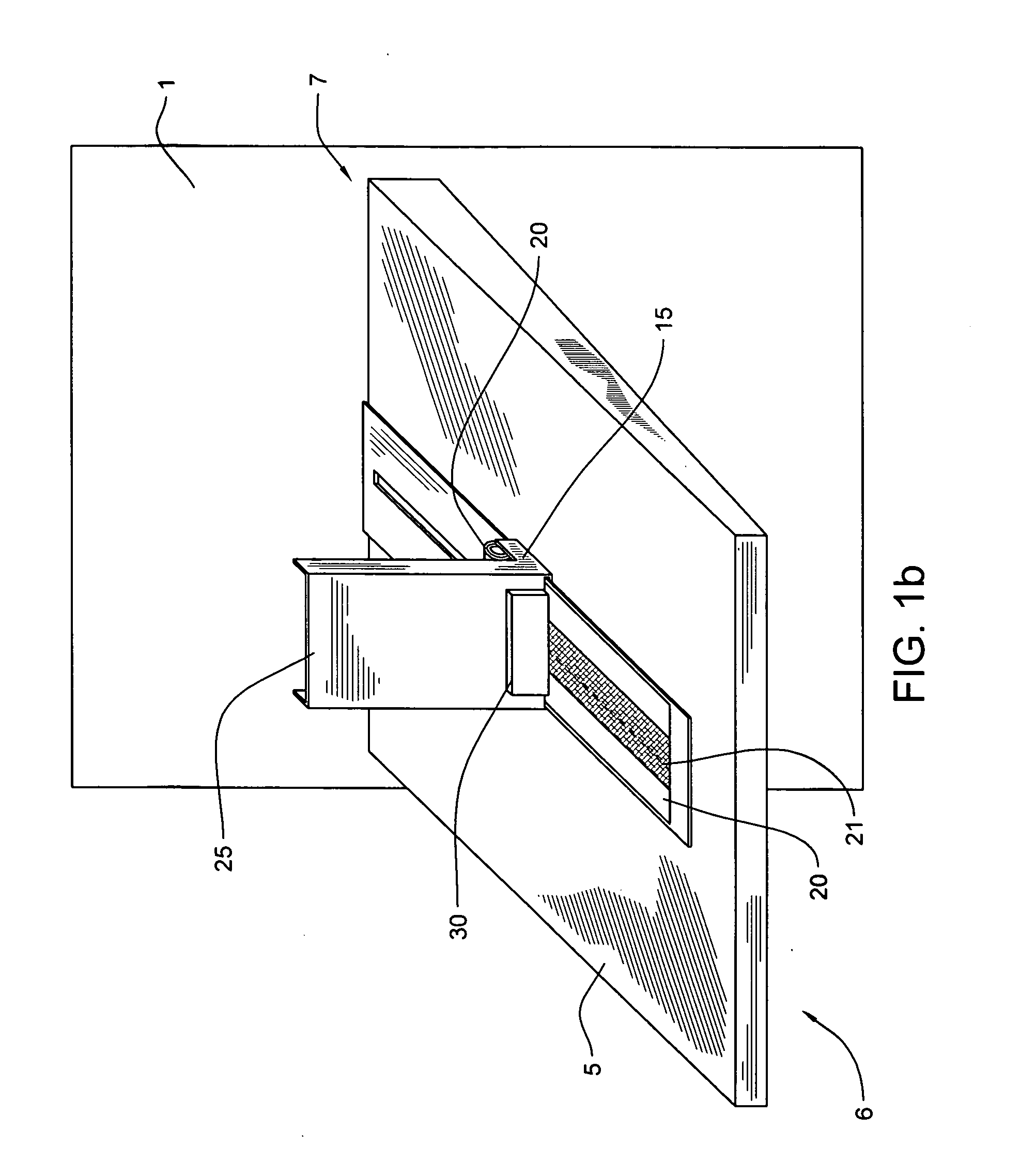

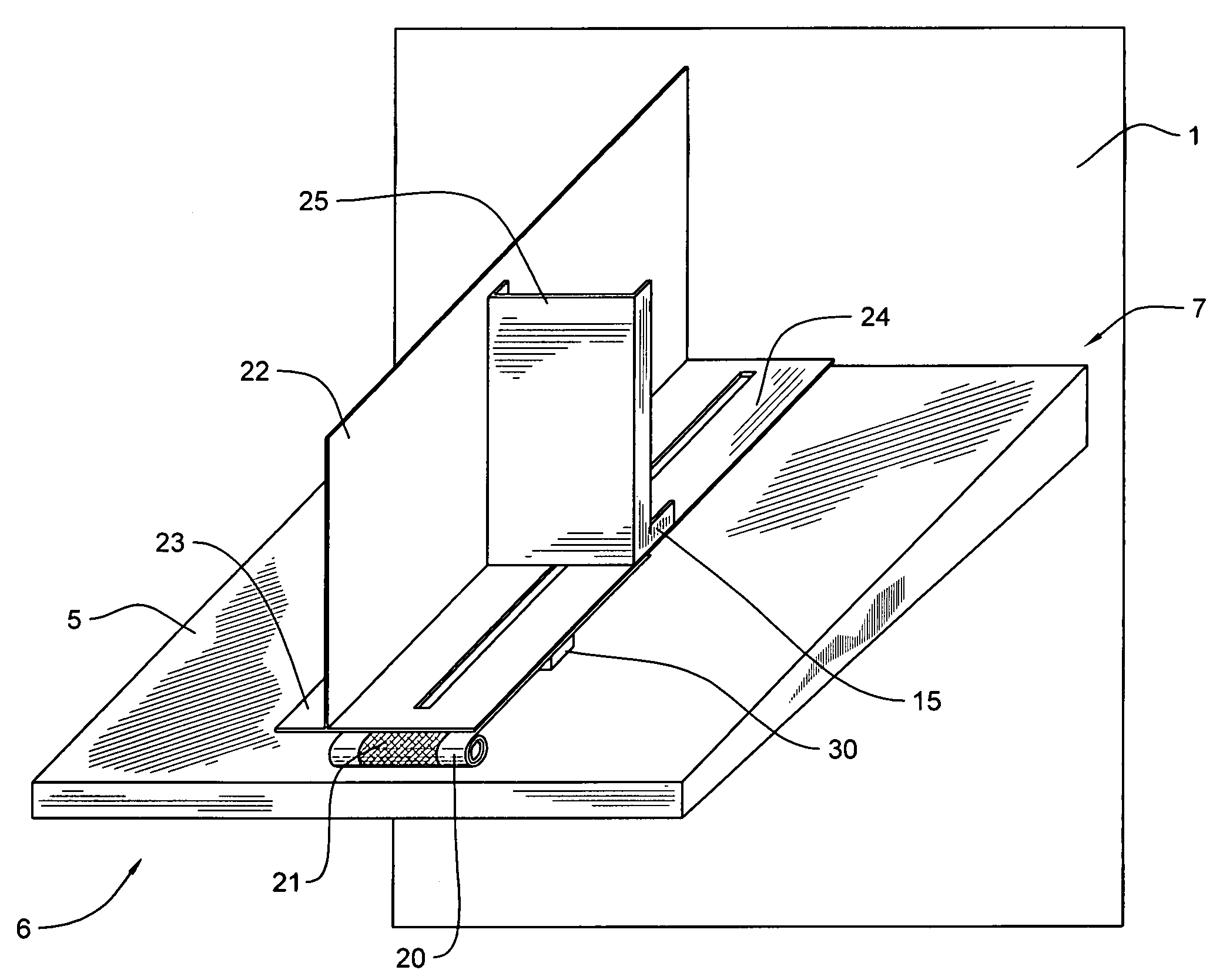

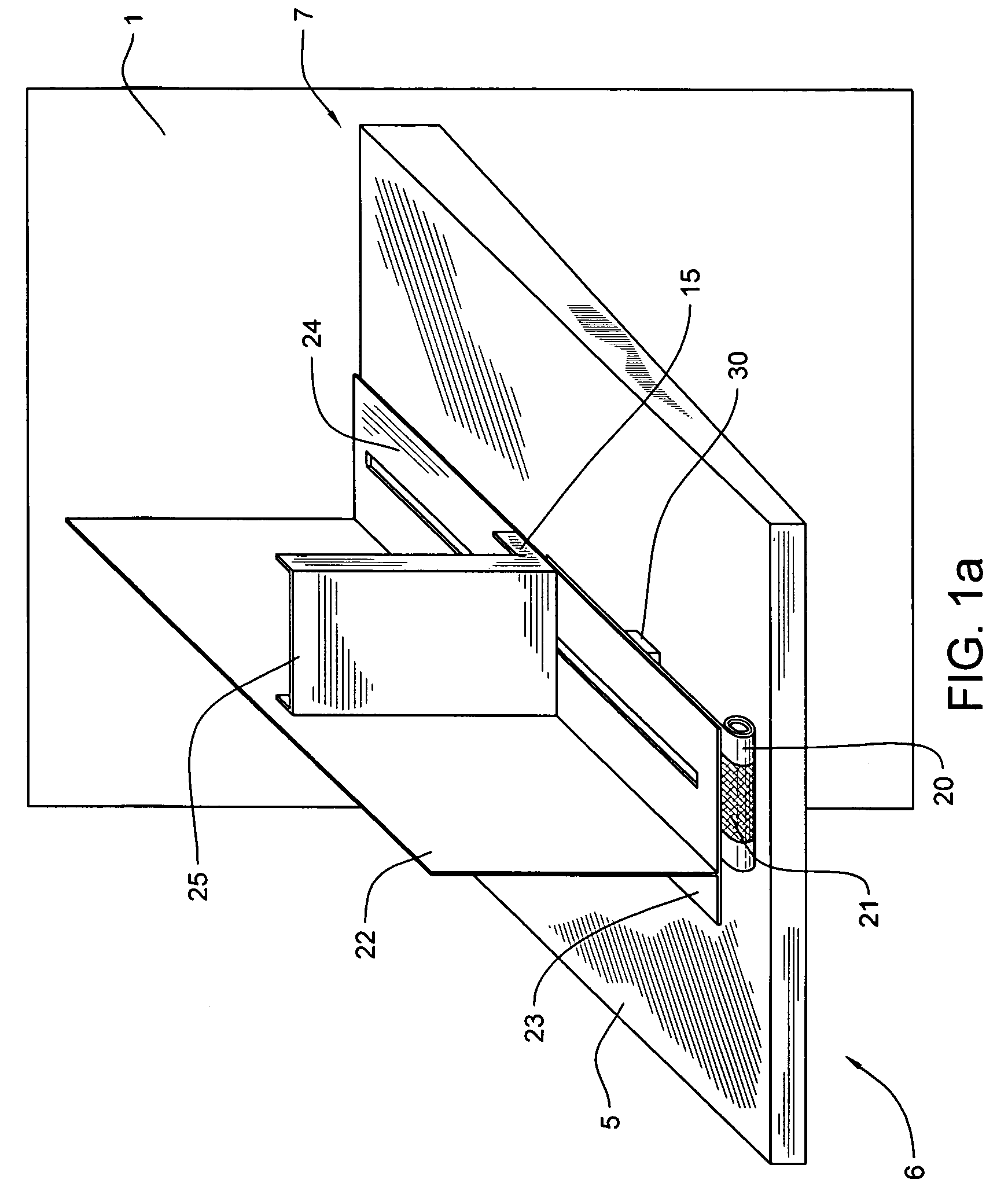

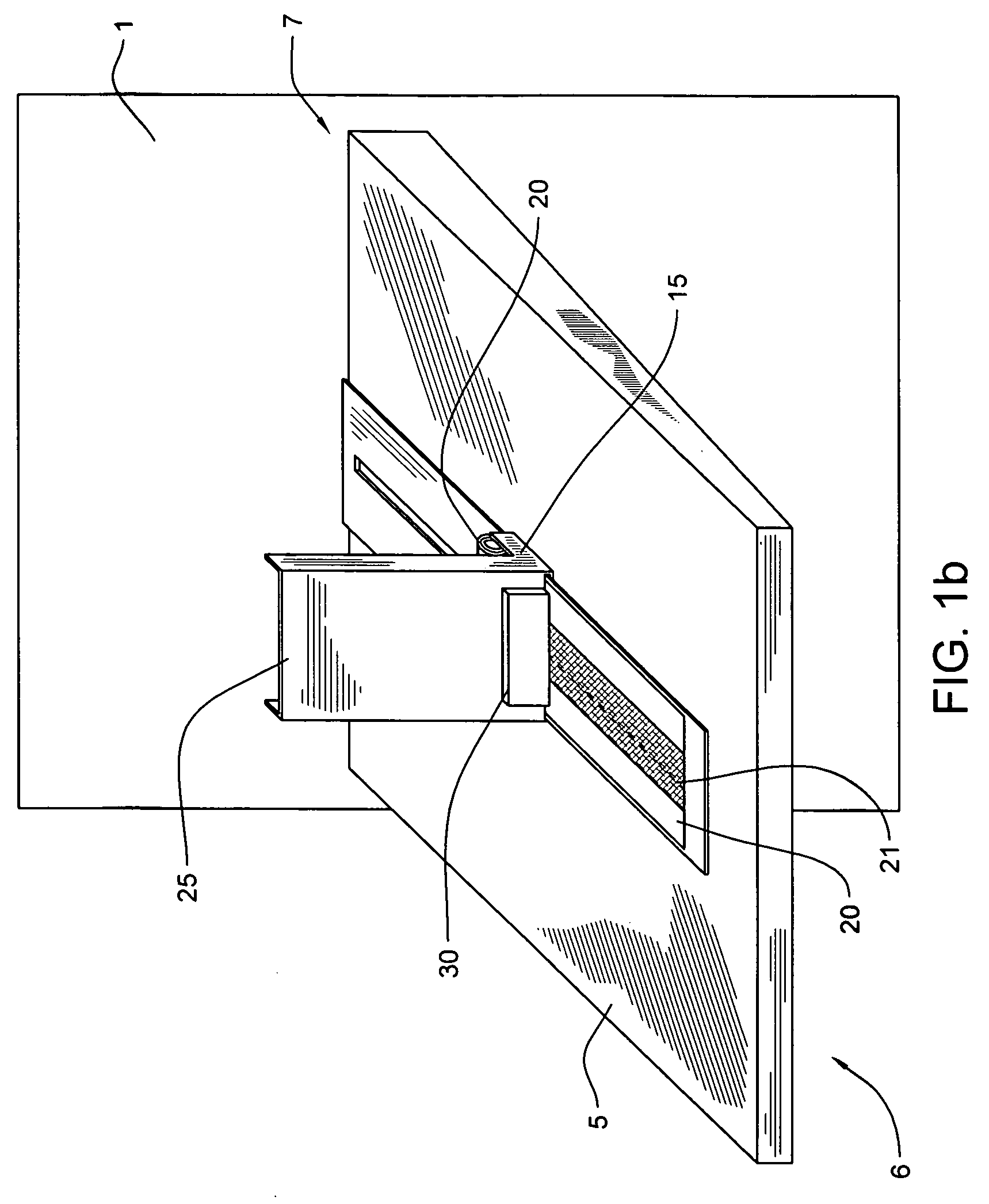

The present invention relates to a system for tracking product on a shelf. In an embodiment, an indicia strip is placed on a self coiling sheet, and a sensor is configured to read the indicia strip. The data on the indicia strip corresponds to the location of a pusher assembly. In an embodiment, a store computer can use the data regarding the location of the pusher assembly to determine the amount of inventory on the shelf. In an embodiment, the store computer can automatically order additional inventory based on the levels of inventory on the shelf. In an embodiment, a deviation from normal customer purchasing habits can be used to prompt security measures so as to reduce the possibility of product theft.

Owner:RTC IND

System for inventory management

ActiveUS7792711B2Electric signal transmission systemsHand manipulated computer devicesSecurity MeasurePurchasing

Owner:RTC IND

Method and apparatus for managing demand and inventory

InactiveUS20040068451A1Increase salesDecrease stockSpecial data processing applicationsMarketingComputer scienceInventory level

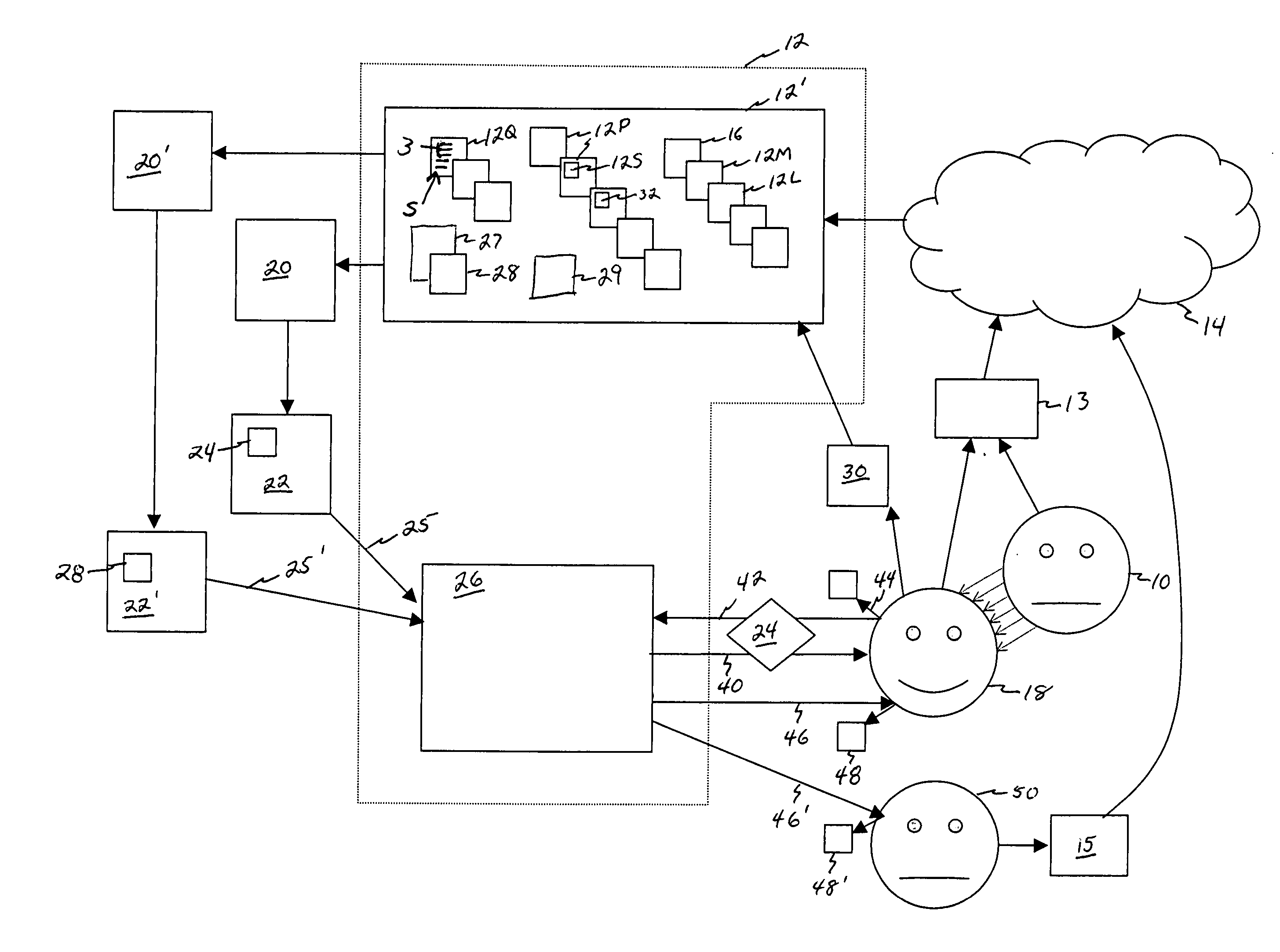

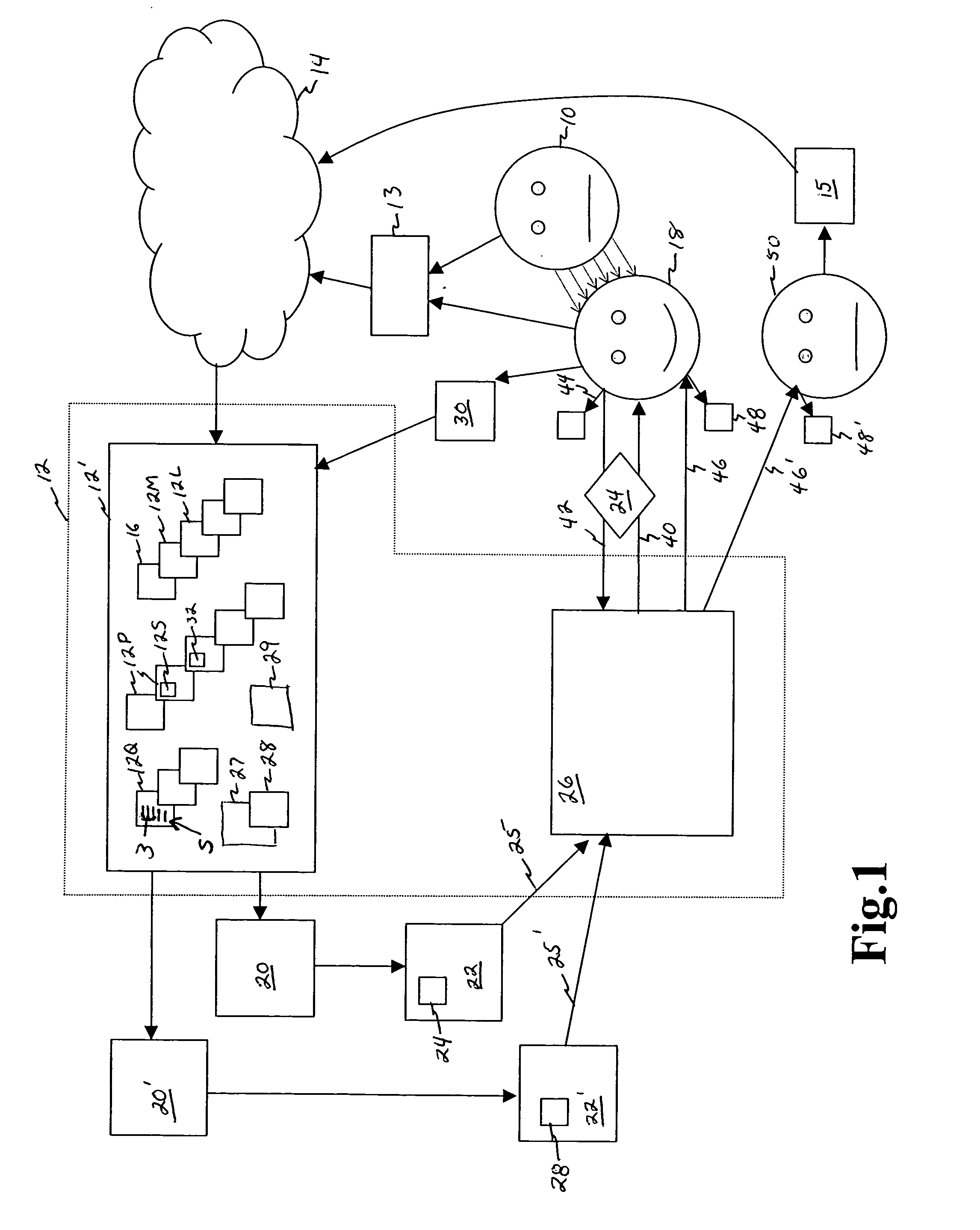

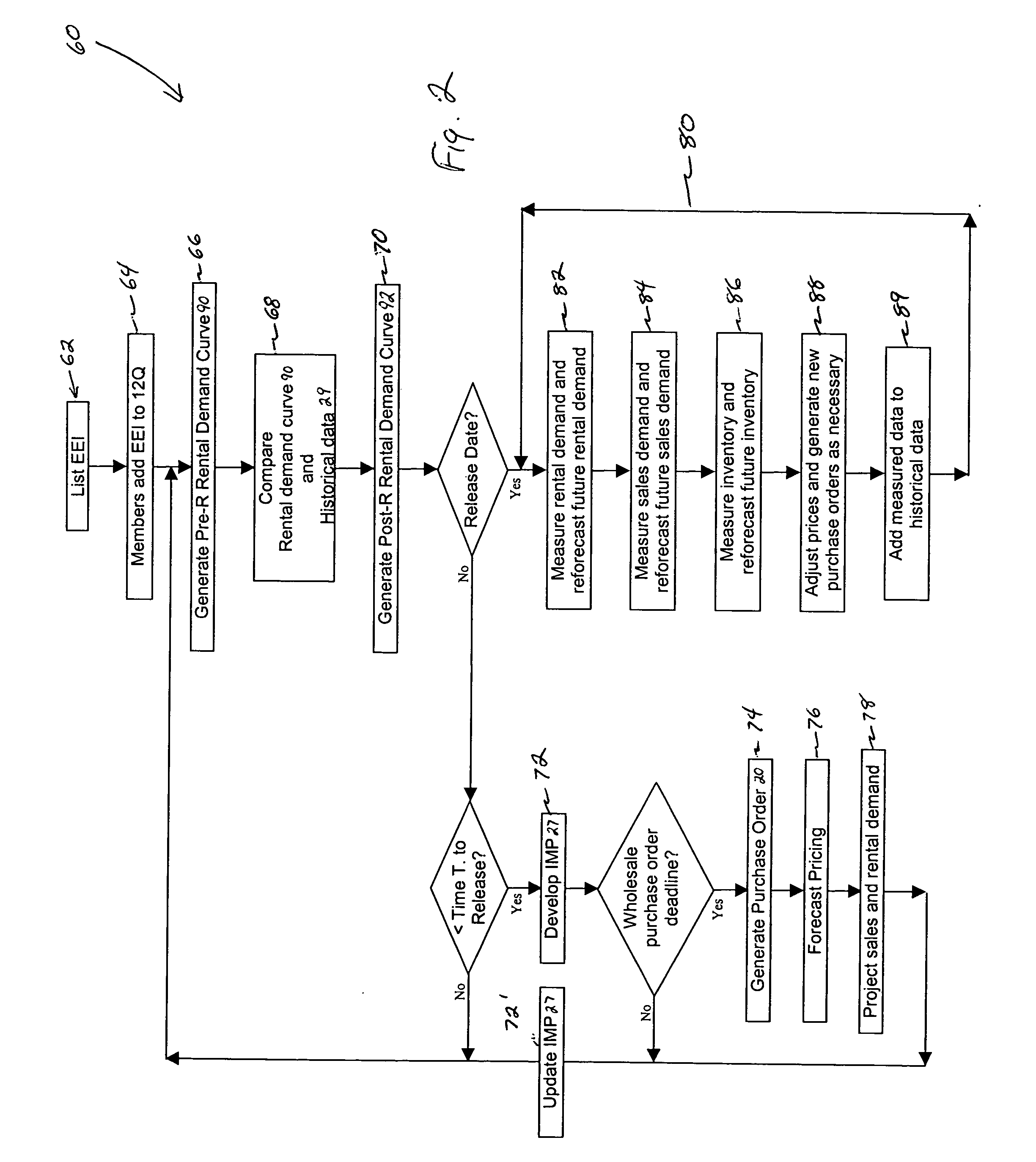

The present invention is directed to a method and system for managing the inventory level of, and the distribution of, electronic media rental units, including but not limited to videogame discs, musical compact disks, or movie VCD / DVDs. More specifically, preferred embodiments of the present invention forecasts future rental and sales demand for a given electronic media, such as a videogame, prior to the release of that electronic media to the general public. The forecast is based on the pre-release demand of the electronic media in that the future rental and sales demand is estimated from the rental and sales demand of previously released electronic media having similar pre-release demand. Furthermore, the preferred embodiments of the present invention allows registered members of a rental user group to keep rented units of the electronic media for a purchase price, which is dynamically controlled to minimize rental shortage and maximize profits.

Owner:GAMEFLY

Systems and methods for purchasing, invoicing and distributing items

InactiveUS7072855B1Hand manipulated computer devicesDigital data processing detailsInvoicePurchasing

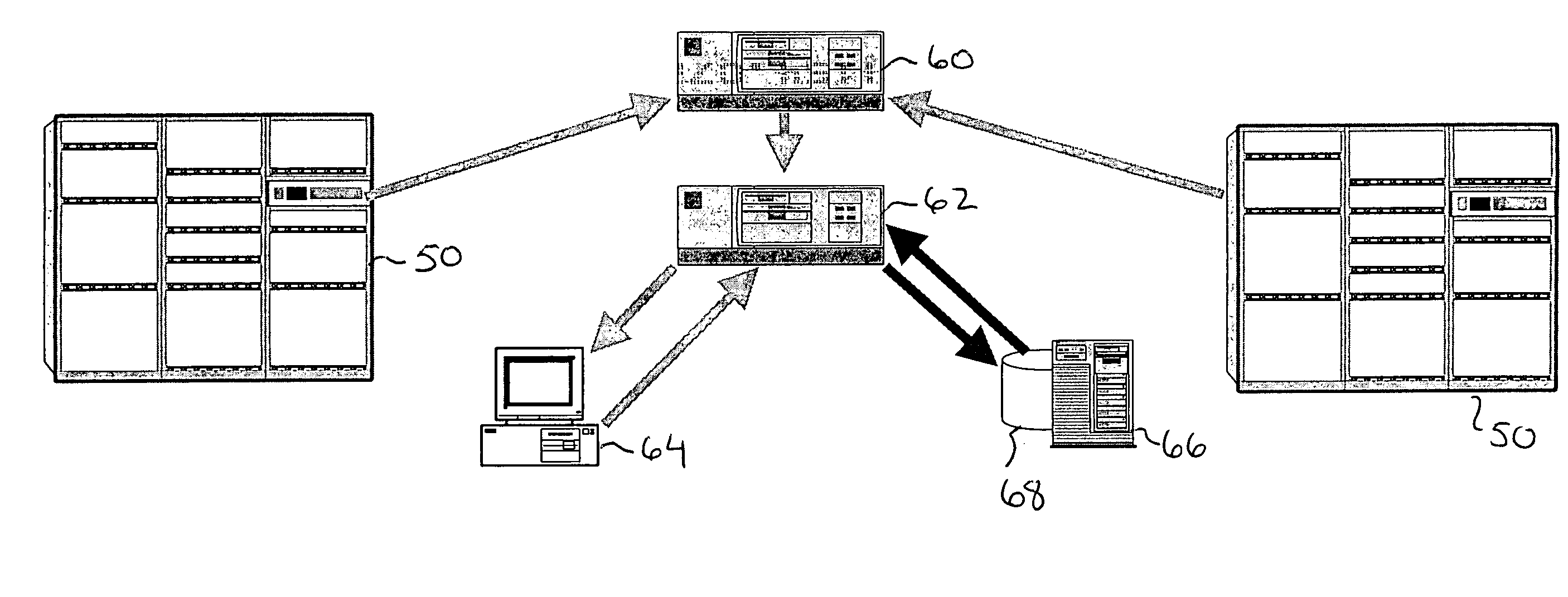

A method for supplying items to dispensing units that hold at least one type of item and a record of inventory levels comprises periodically sending restocking information from the dispensing units over a network to a server computer. Ordering information is generated for the items to be restocked based on the restocking information. The ordering information is electronically sent to one or more supplier computers to order items to be restocked into the dispensing units.

Owner:NEXIANT

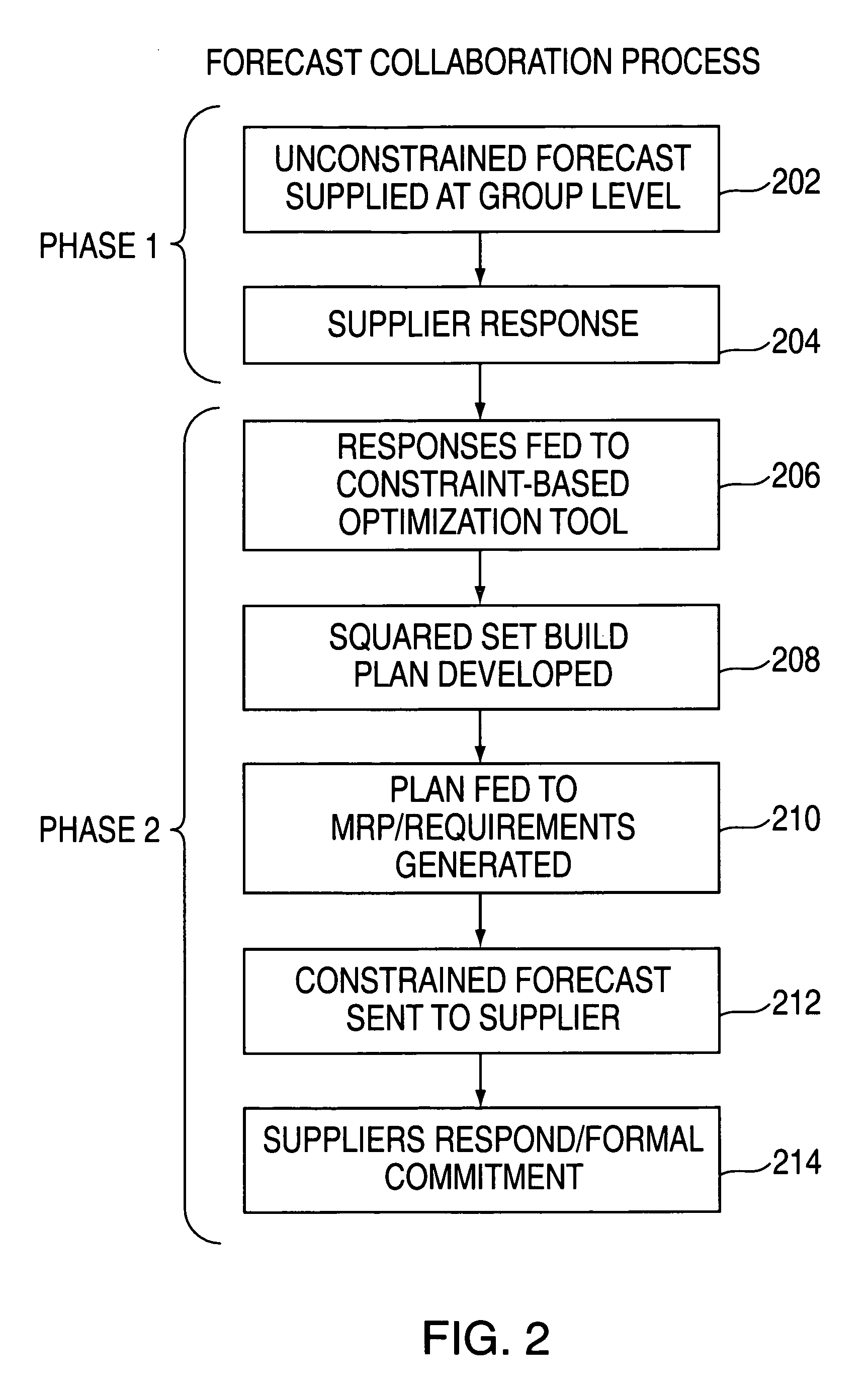

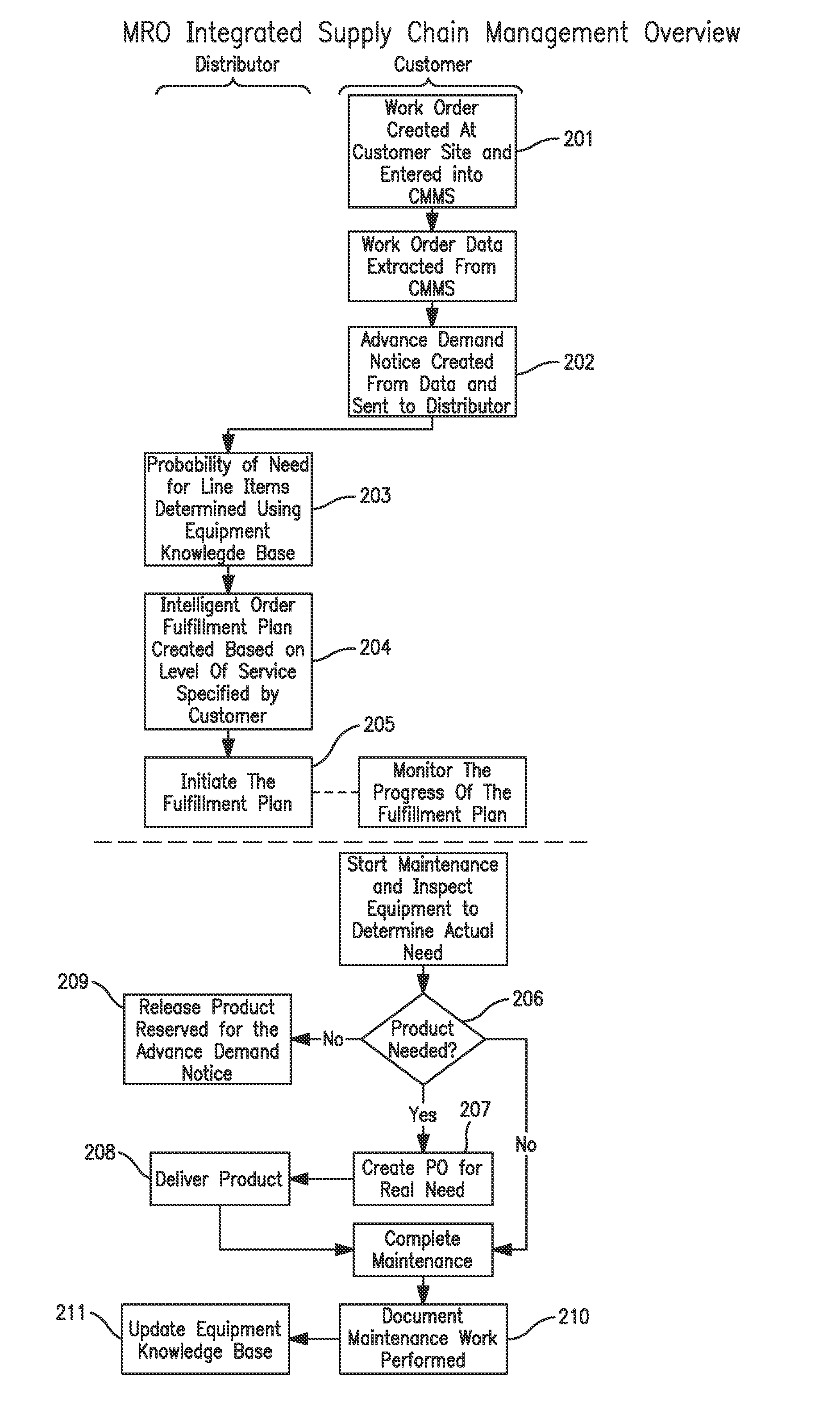

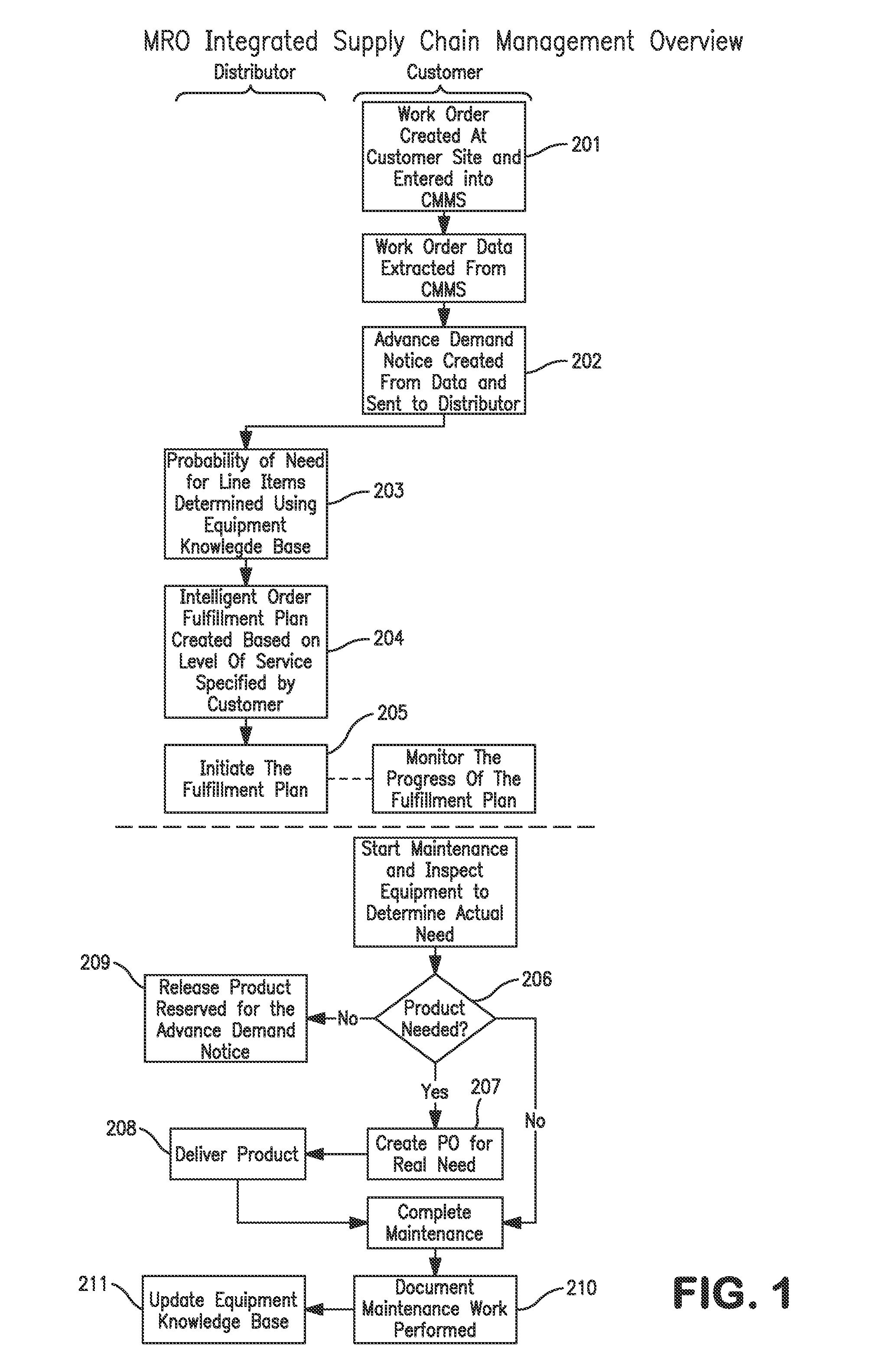

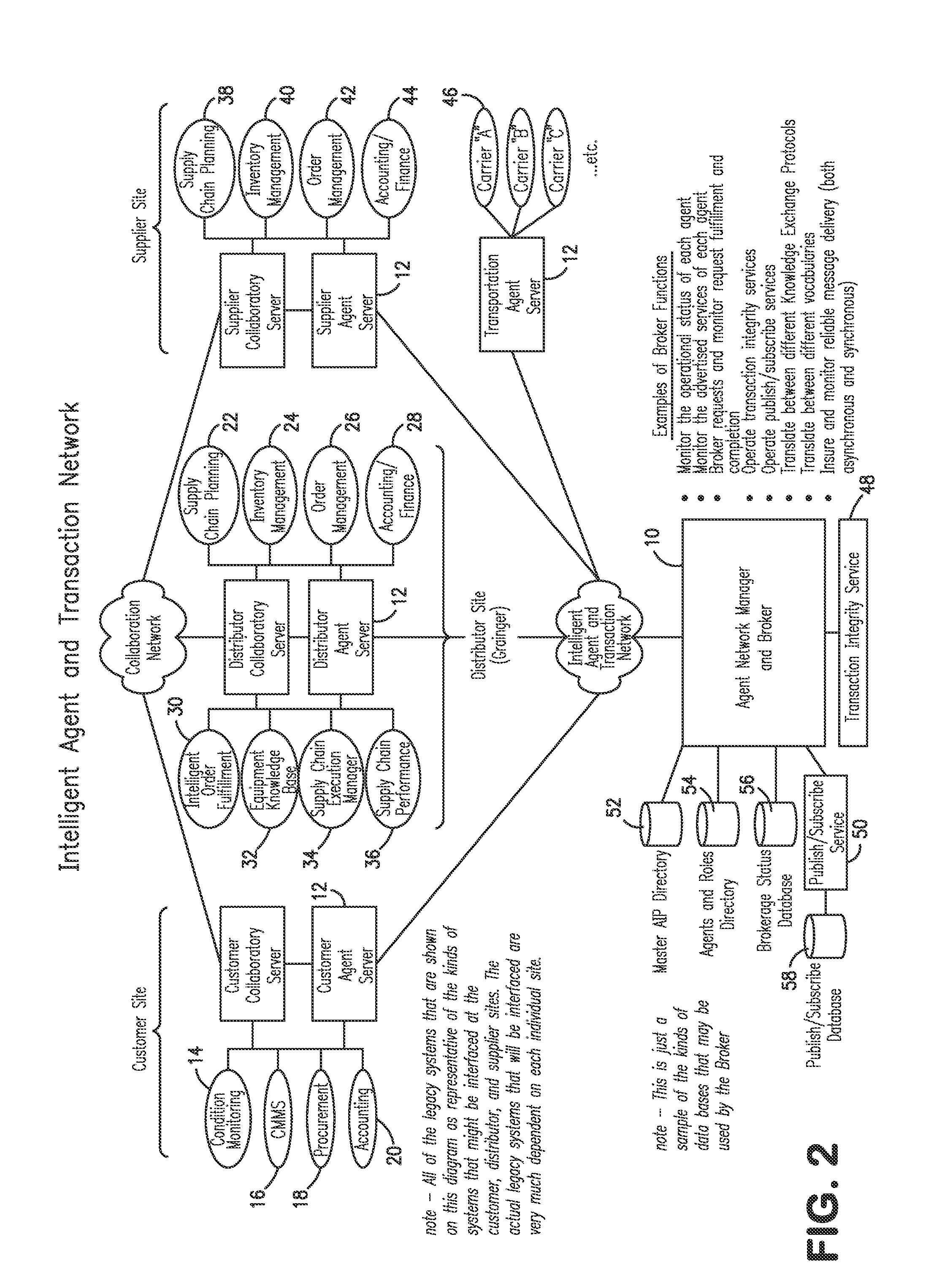

Network-based supply chain management method

InactiveUS7904350B2Reduce deliveryHand manipulated computer devicesResourcesEngineeringInventory level

Owner:INT BUSINESS MASCH CORP

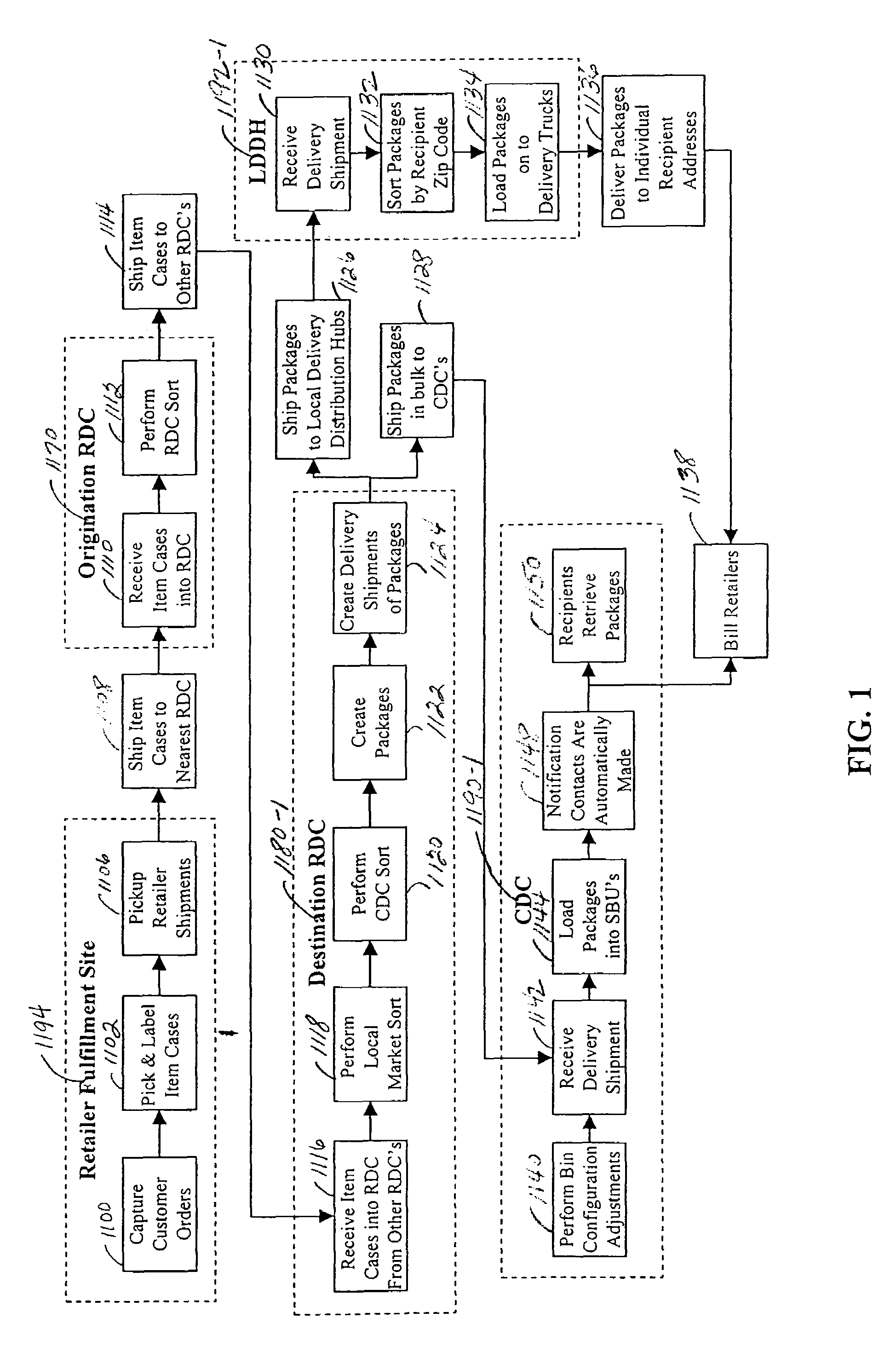

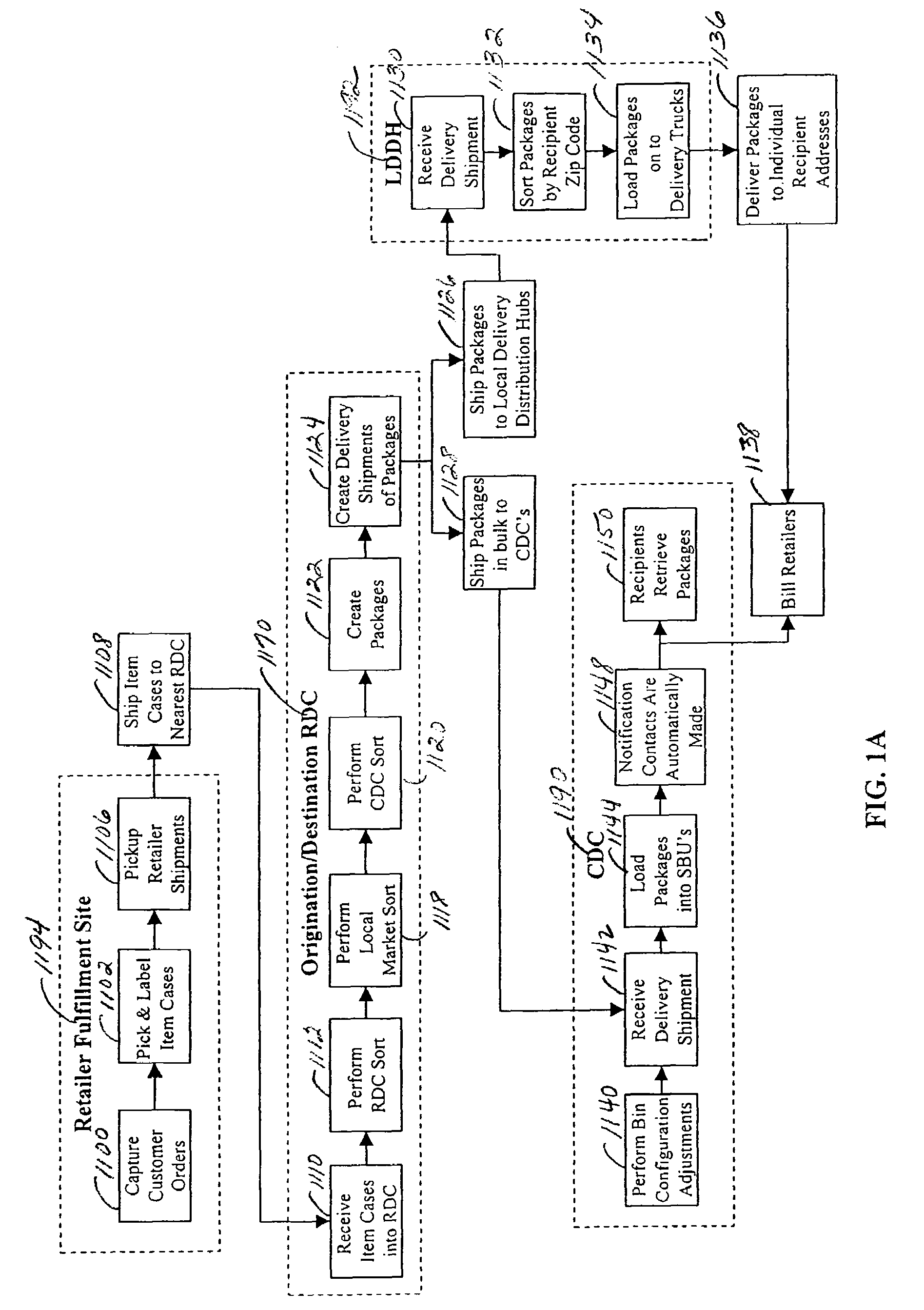

Method and system for efficient package delivery and storage

InactiveUS7653457B2Authentication is convenientEfficient deliveryAcutation objectsDigital data processing detailsComputer scienceInventory level

A method and system for efficient package delivery in bulk to pickup locations for recipients in which items ordered by different customers from one or more different retailers, suppliers, manufacturers, and the like can be sorted within and picked from an on-hand inventory at a distribution center and packed into a package for delivery to a specific pickup location for a specific recipient. A replenishment order for items to replace the on-hand inventory at the distribution center can be made to a fulfillment location to maintain inventory levels defined for an item at a distribution center. The items to replenish the on-hand inventory at the distribution center can be shipped in bulk from a fulfillment location in containers organized by item identifier. The items can be sorted at a different distribution center, still organized within containers of all the same item identifier, to reach the distribution center placing the replenishment order for the items.

Owner:BREAKTHROUGH LOGISTICS CORP

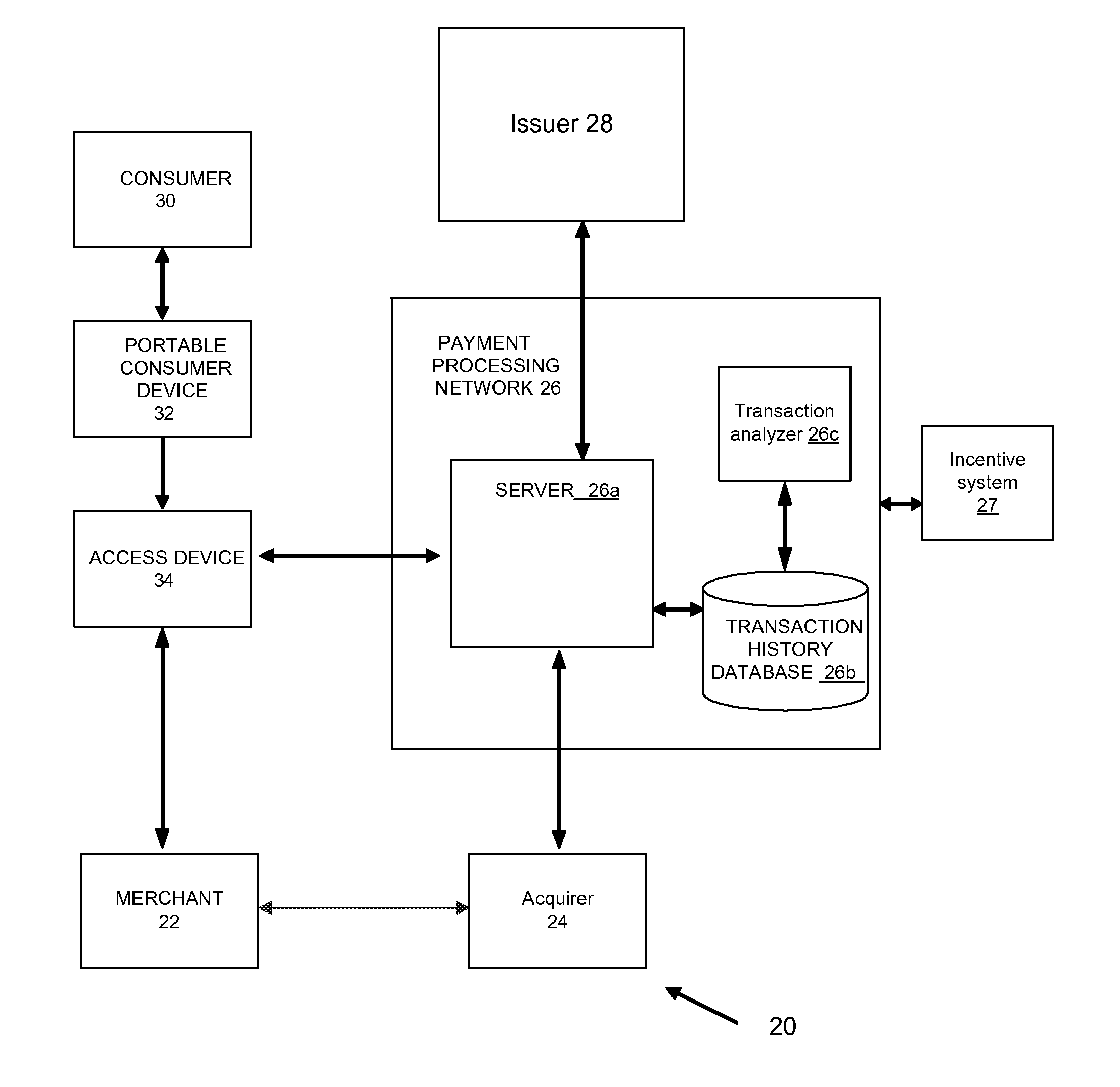

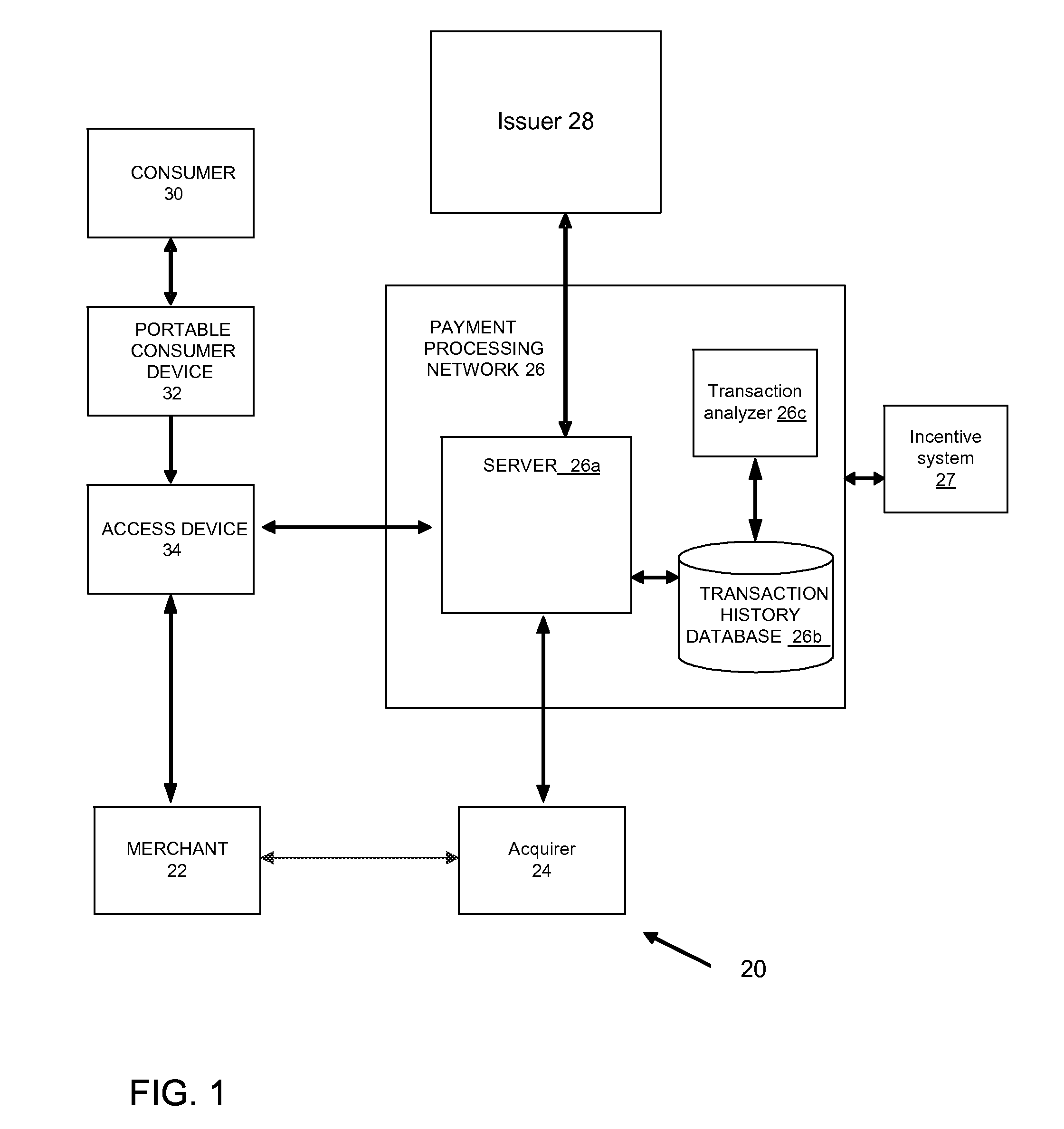

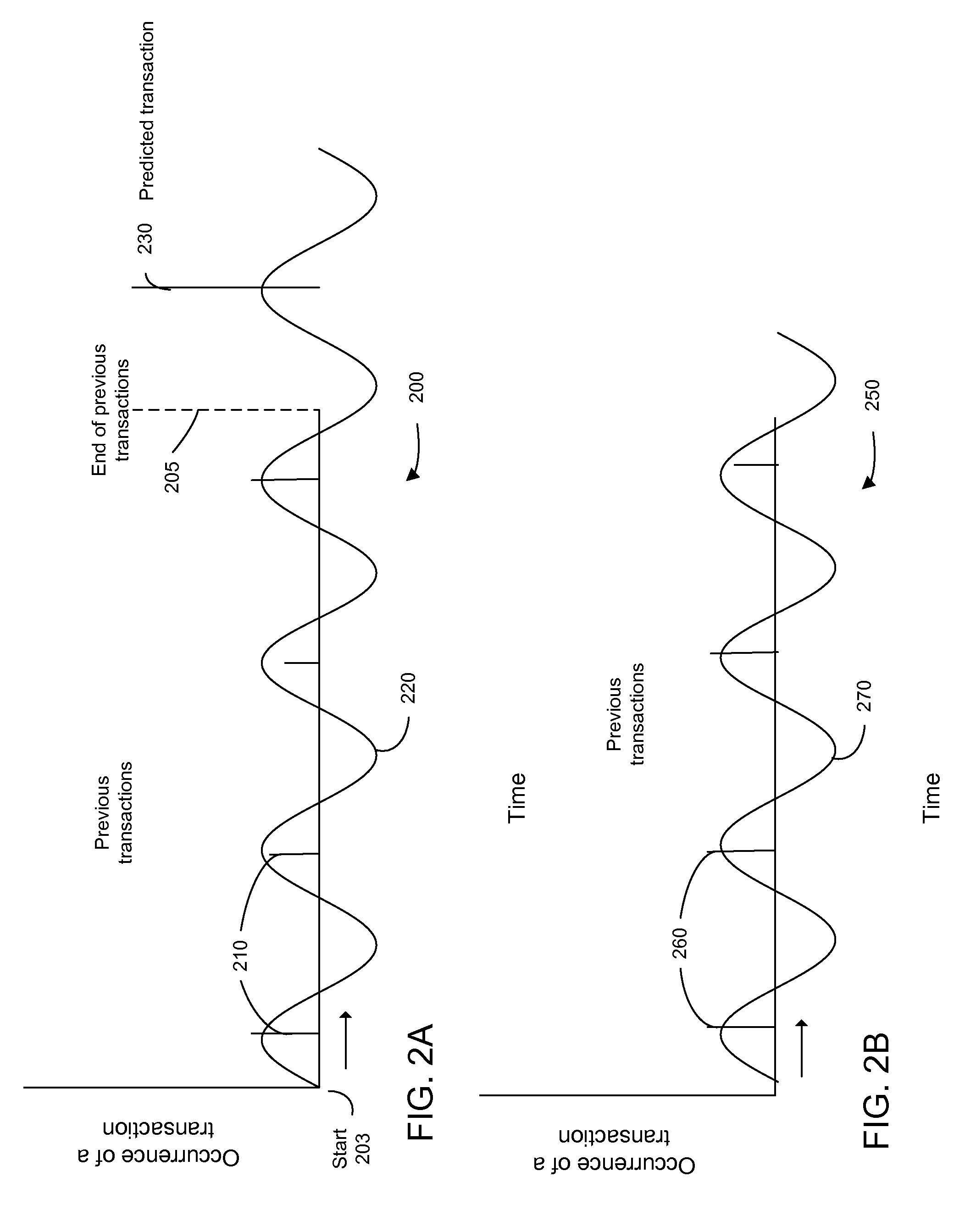

Demographic analysis using time-based consumer transaction histories

InactiveUS20100280881A1Improve accuracyMarket predictionsBiological neural network modelsStatistical analysisData mining

Systems, apparatus, and methods for determining groups of similar consumers and for identifying a trend in consumer behavior are provided. Likelihoods of a transaction being initiated at various times by one consumer can be calculated based on previous transactions of the consumer. The likelihoods for different consumers can be used to determine a group of similar consumers as a demographic. The likelihoods of a transaction being initiated at various times by a consumer of a demographic (or other entity) can be used to forecast trends (such as a demand for a product) and make business decisions, such as for marketing campaigns, inventory levels (e.g. at particular stores or for all stores), pricing, and store locations. Such likelihoods when focused to a particular category of transactions can provide even greater accuracy.

Owner:FAITH PATRICK +2

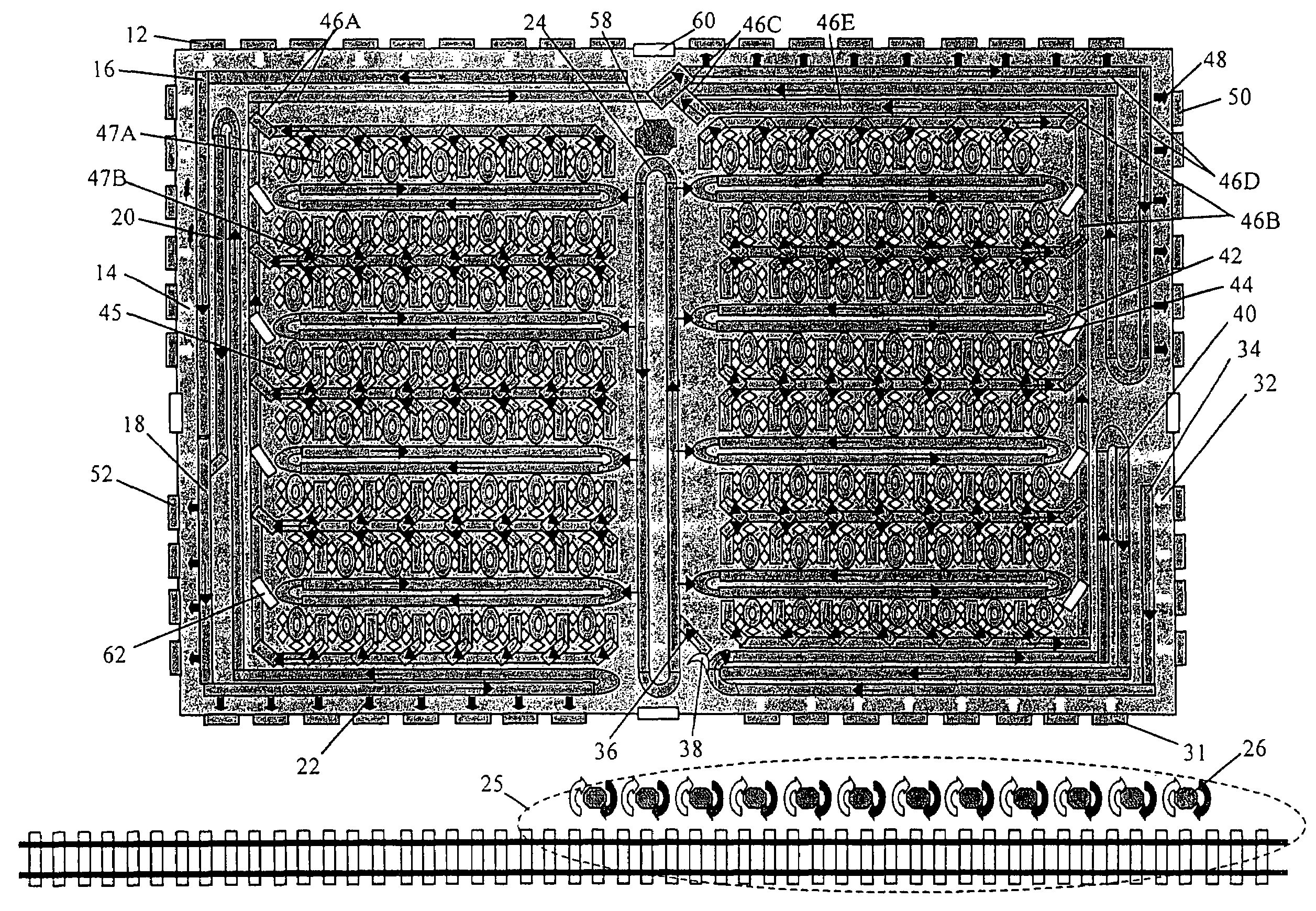

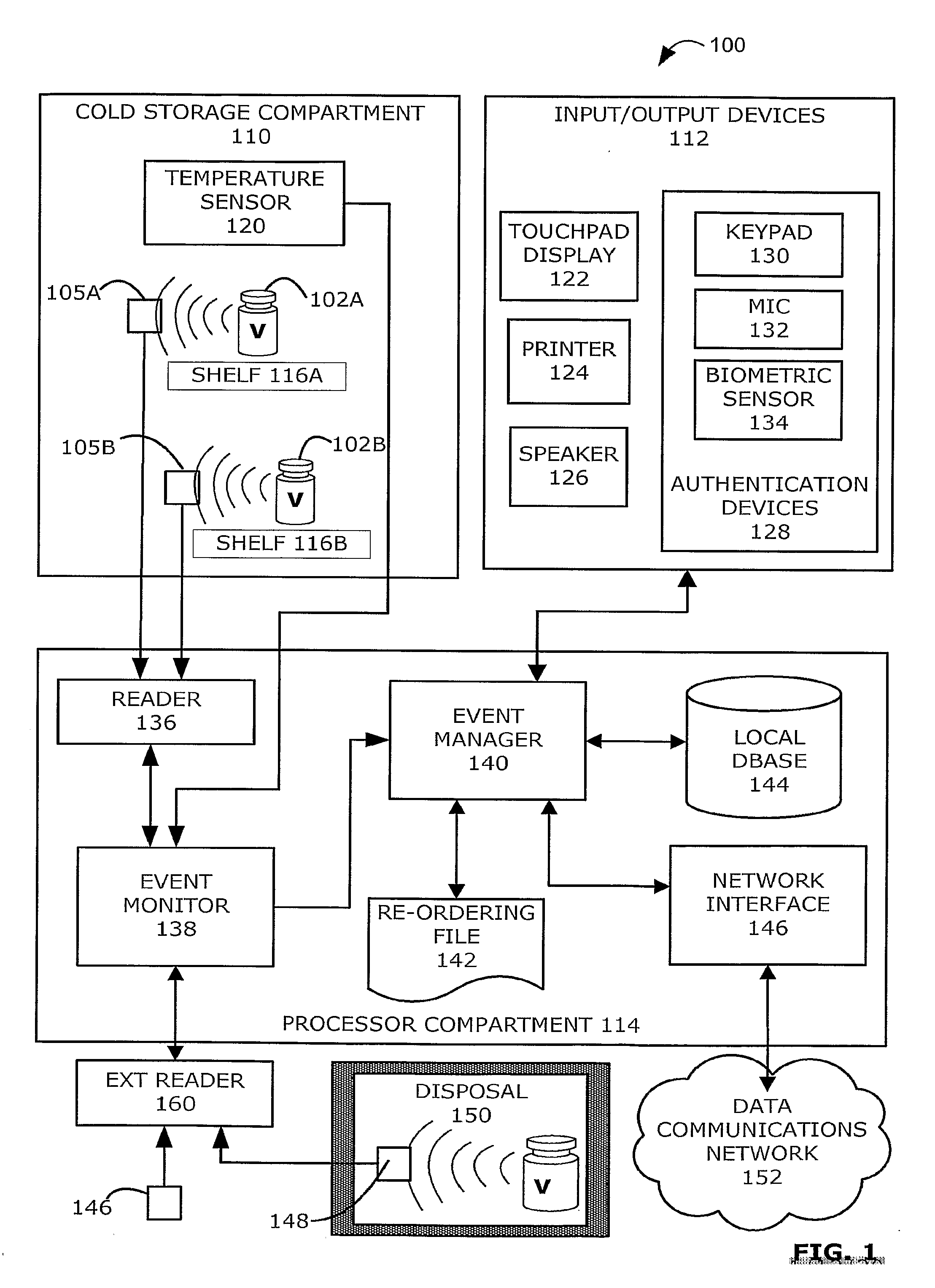

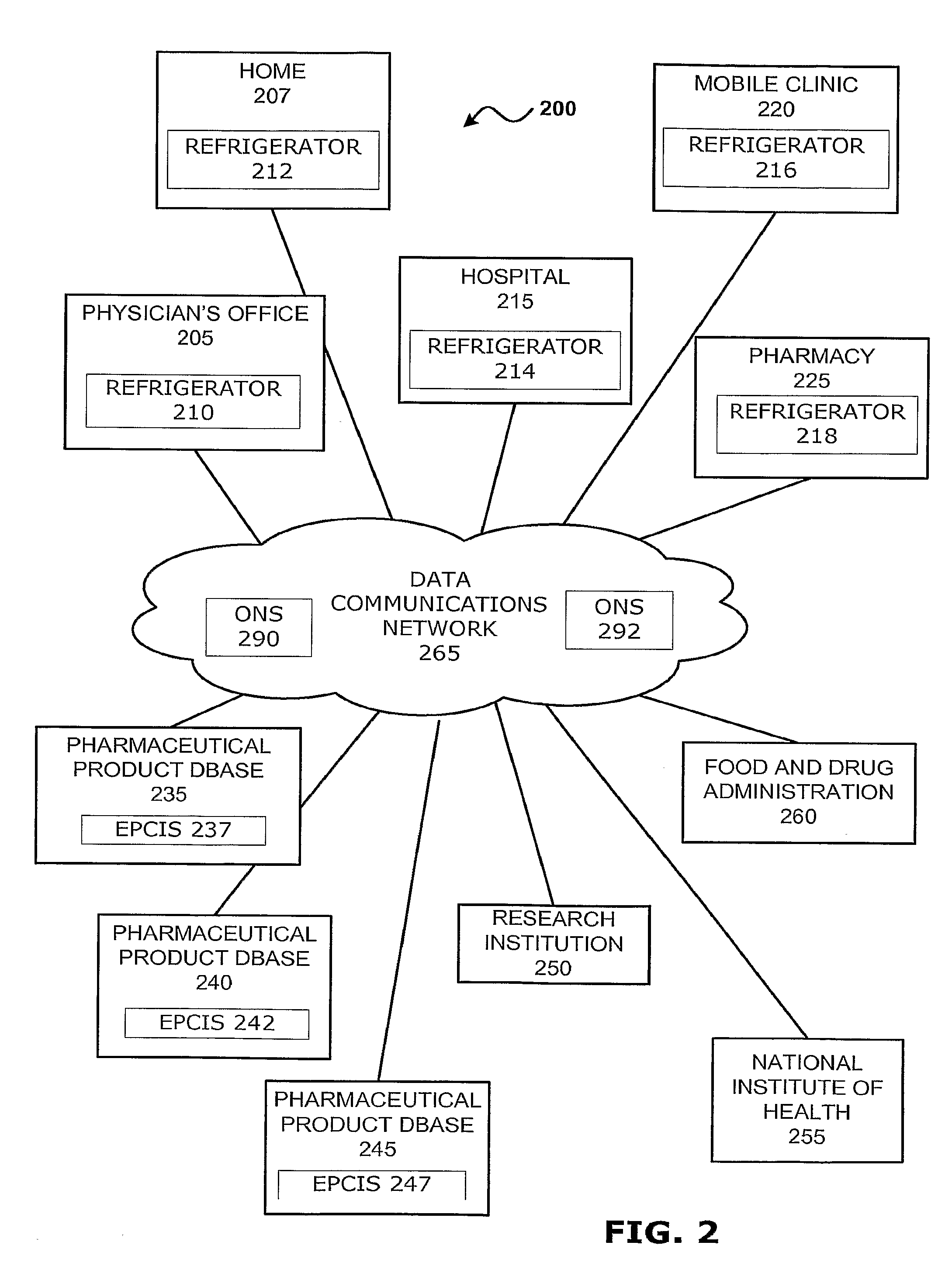

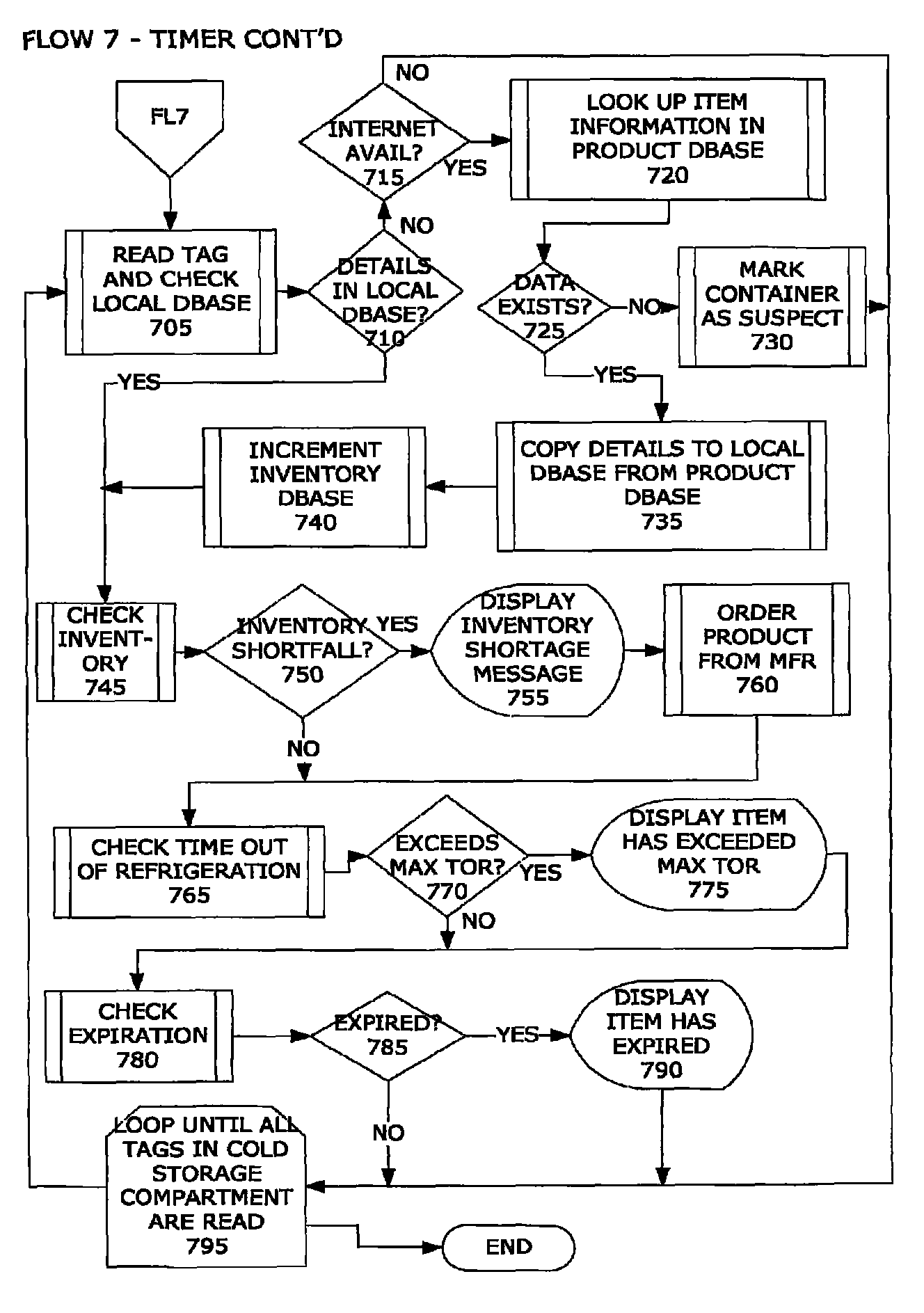

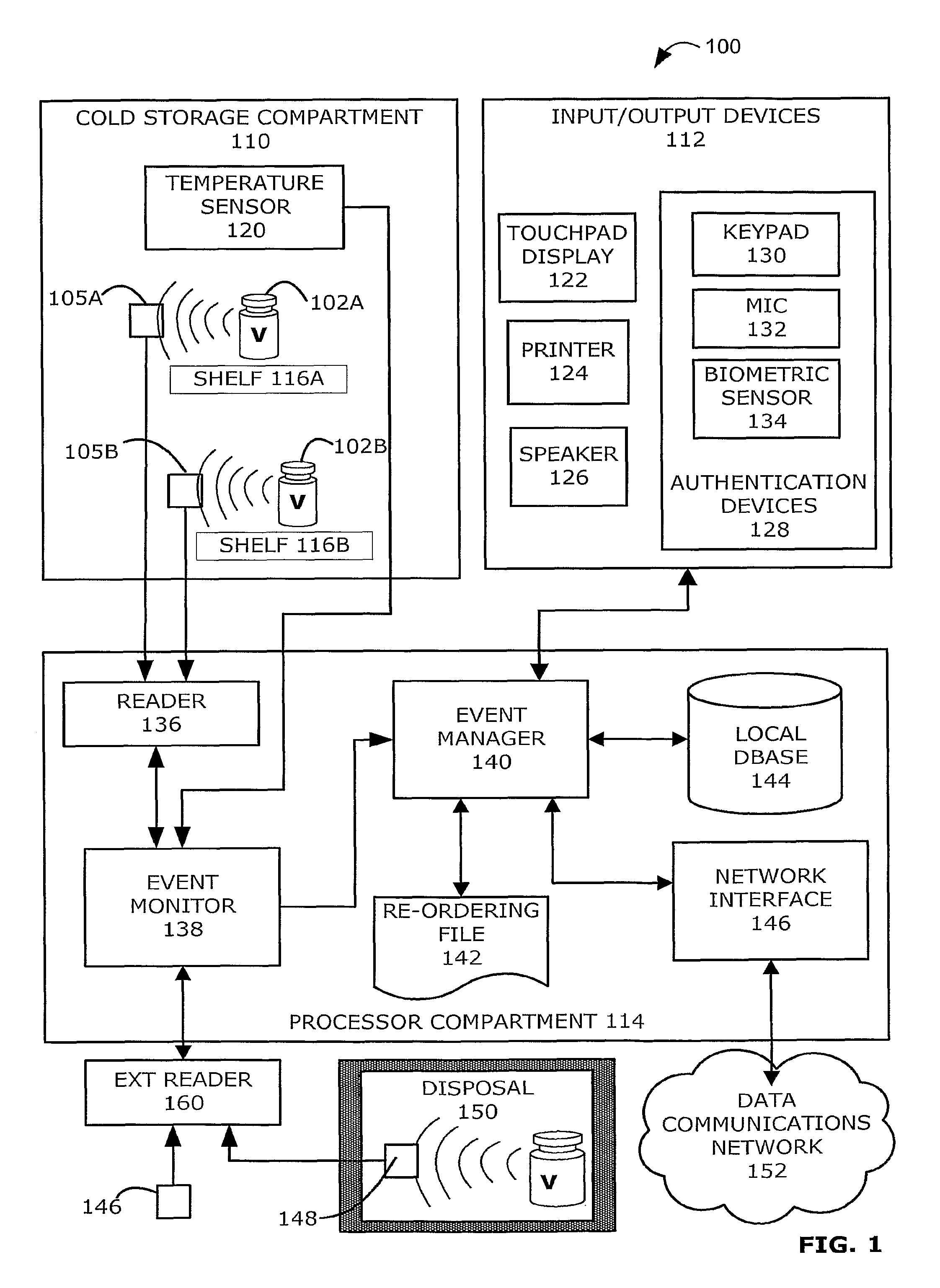

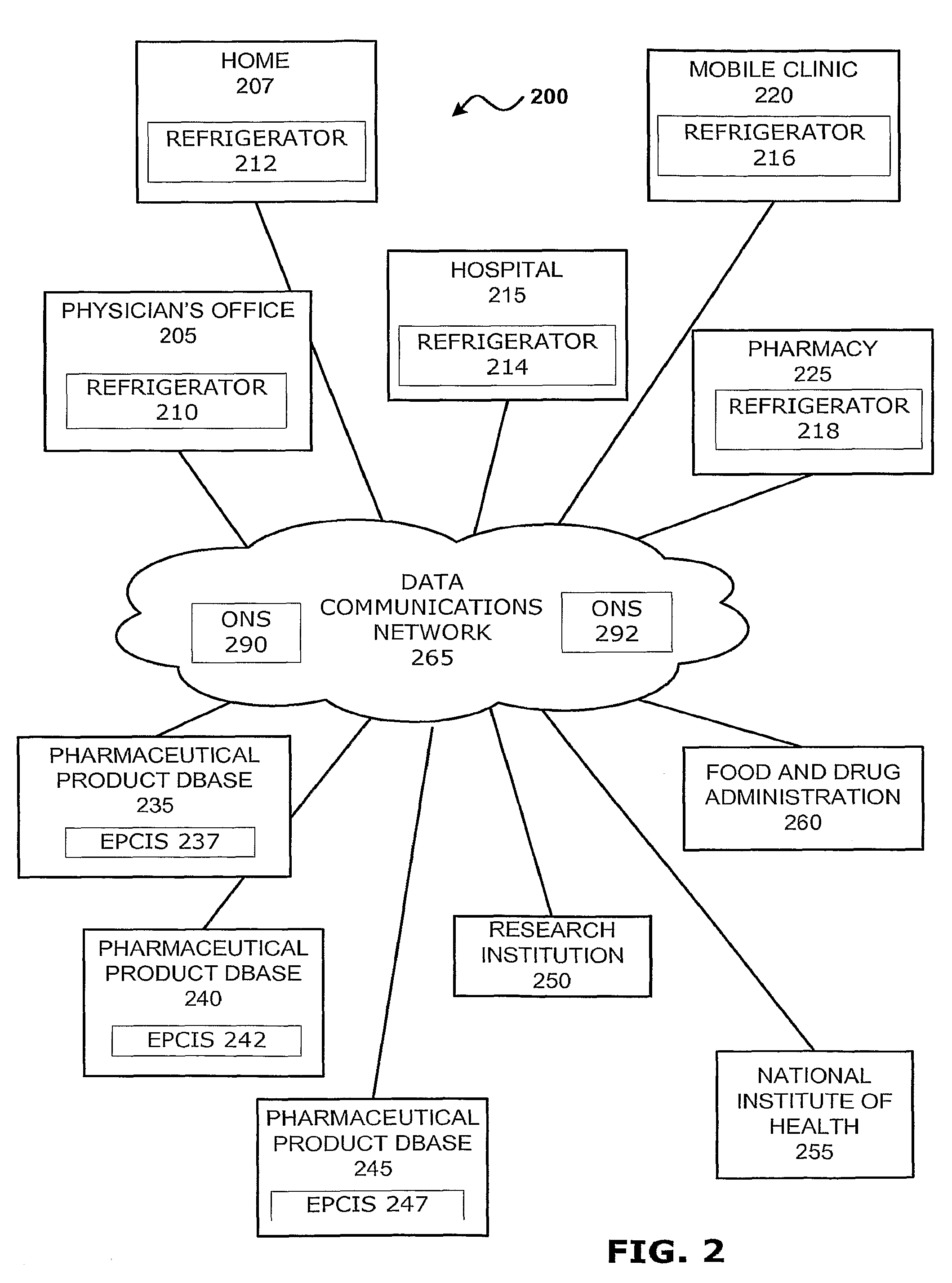

Intelligent Refrigerator for Storing Pharmaceutical Product Containers

Intelligent refrigerator system for storing pharmaceutical product containers, such as vials, ampules, syringes, bottles, medication tubes, blister packs and cartons, at the point of dispensing. Embodiments of the invention use product identification technology, such as radio-frequency identification (RFID) tags and readers, to uniquely identify containers as they are added to or removed from the cold storage compartment of the refrigerator, and automatically retrieve from a local or remote database a variety of details associated with the containers and their contents, such as manufacturing data, expiration dates, time out of refrigeration, inventory levels, safety information, usage statistics, known contraindications and warnings, etc. If the details indicate that there is a problem with a particular pharmaceutical (e.g., that it is counterfeit, expired, suspect, spoiled, recalled or almost depleted), then a message or warning is automatically delivered to a human operator via an attached output device, such as a display screen, speaker or printer. Embodiments of the invention may also be configured to monitor and report temperature faults, power failures and other anomalies associated with the refrigerator or cold storage compartment.

Owner:MERCK SHARP & DOHME LLC

Portable dispensing device for refreshments and sundries

ActiveUS7418311B1Increase salesReadily availableLighting and heating apparatusCoin-freed apparatus detailsPaymentEngineering

A portable dispensing system comprising a vending machine including an upper snack-holding portion, an intermediate beverage-holding portion, a lower refrigeration portion, contained within a housing that fits within the basket of a golf cart. The snack-holding portion and the beverage-holding portion occupy a common cabinet being separated by an insulating wall, allowing a refrigeration mechanism within the refrigeration portion to refrigerate the beverage-holding portion without refrigerating the snack-holding portion. The cabinet is disposed above the basket within the golf cart, and may be provided with a pair of belts for fastening the dispensing system to the golf cart. Within the snack-holding portion, snacks are held in a plurality of snack-holding bins, with similar snacks being stored in a single bin, separated from one another by sliding platforms. When a sliding platform is pulled away, the snack product resting atop the sliding platform is released to fall downward into a lowest position within the bin, to be retrieved by the user through a door. Within the beverage-holding portion, cans are stored in a plurality of columns to be retrieved through doors. An inventory management system is disclosed for controlling and monitoring the dispensing of refreshments and sundries. The inventory management system including a systems for electronically accepting payment, a system for monitoring inventory levels, and a system for wirelessly communicating with a remote terminal.

Owner:GOLF CONCESSIONS

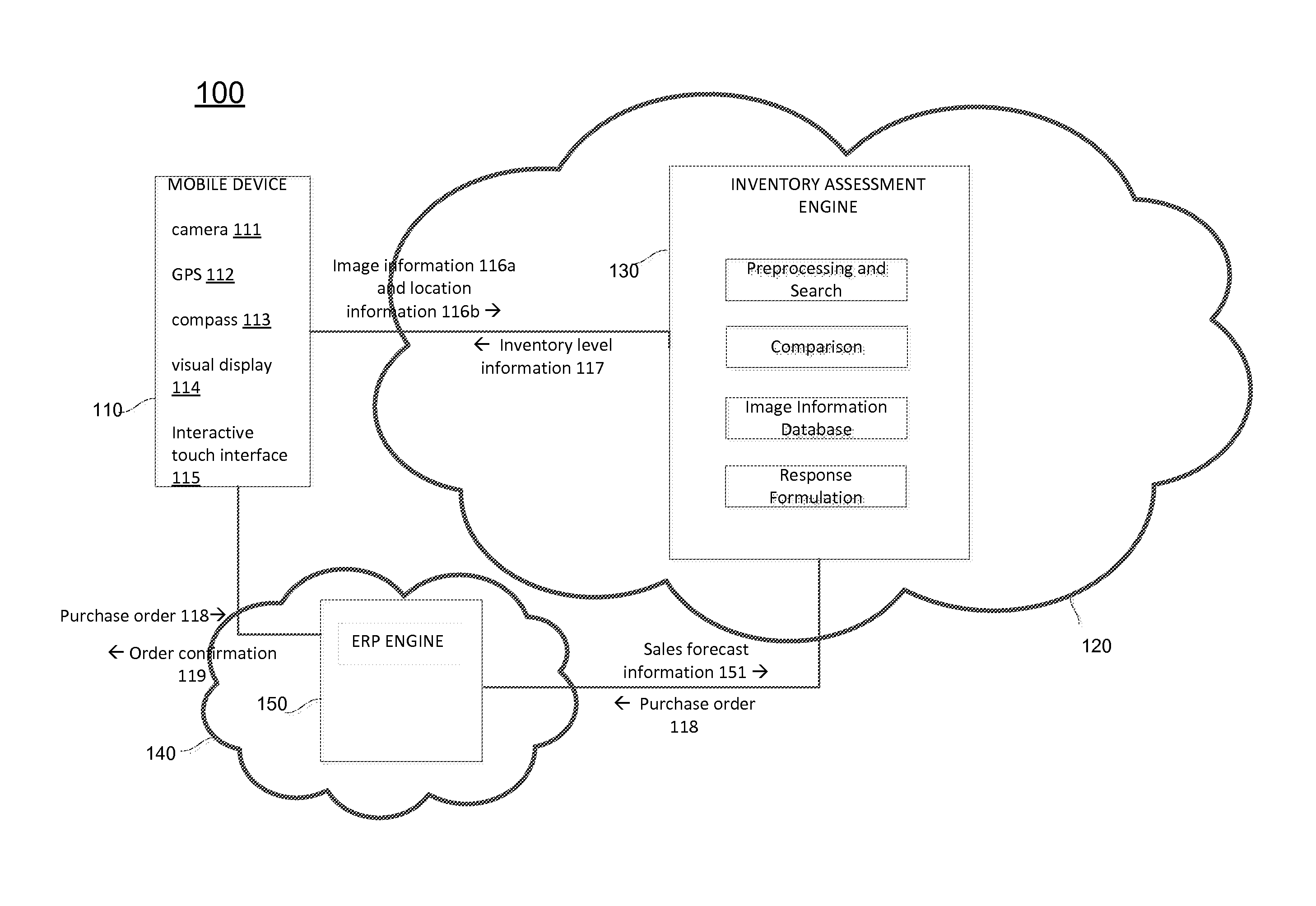

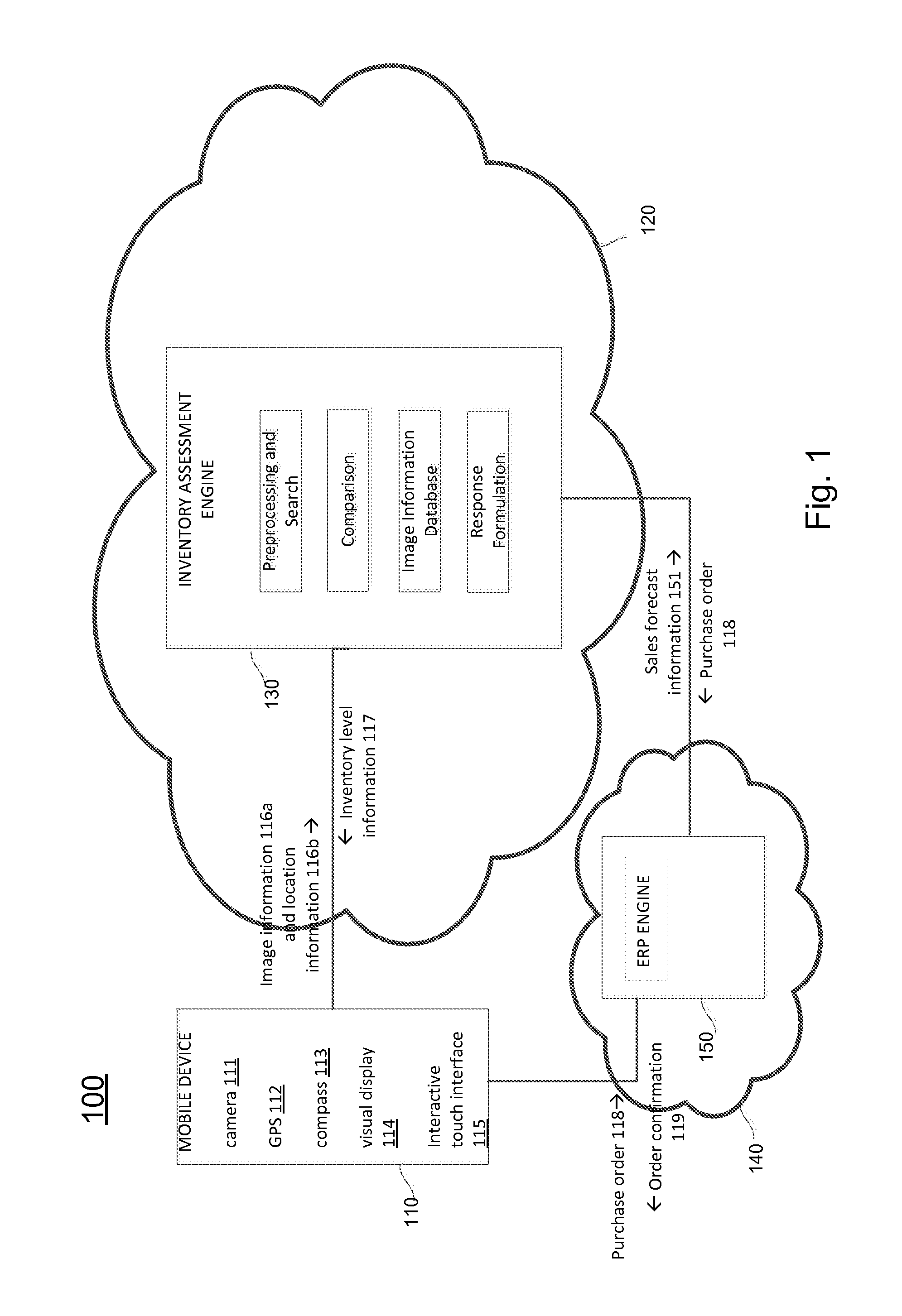

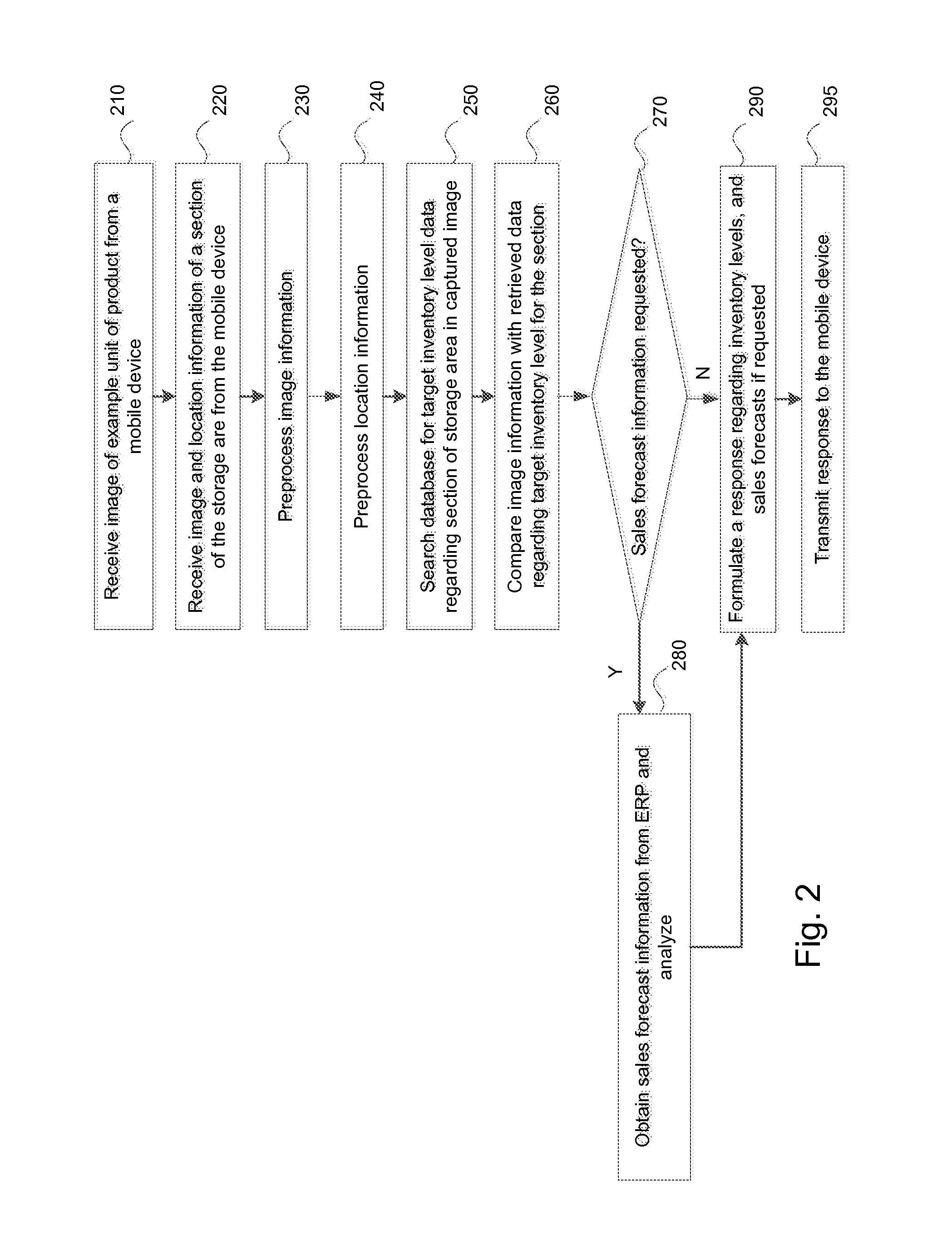

Inventory Assessment with Mobile Devices

In one embodiment, an inventory level assessment feature or service is provided for a camera-enabled mobile device such that a user of such mobile device can use the mobile device to measure inventory levels of a product in a physical location (e.g., a warehouse, a retail store or another context) pictured in one or more captured images from such device. Among other things, as the user points the mobile device's camera at one or more sections of the physical location, data relating to the captured image or images of such sections of the physical location are transmitted to and processed by a remote inventory assessment engine to determine a current inventory level of the product in the imaged section or sections.

Owner:SAP AG

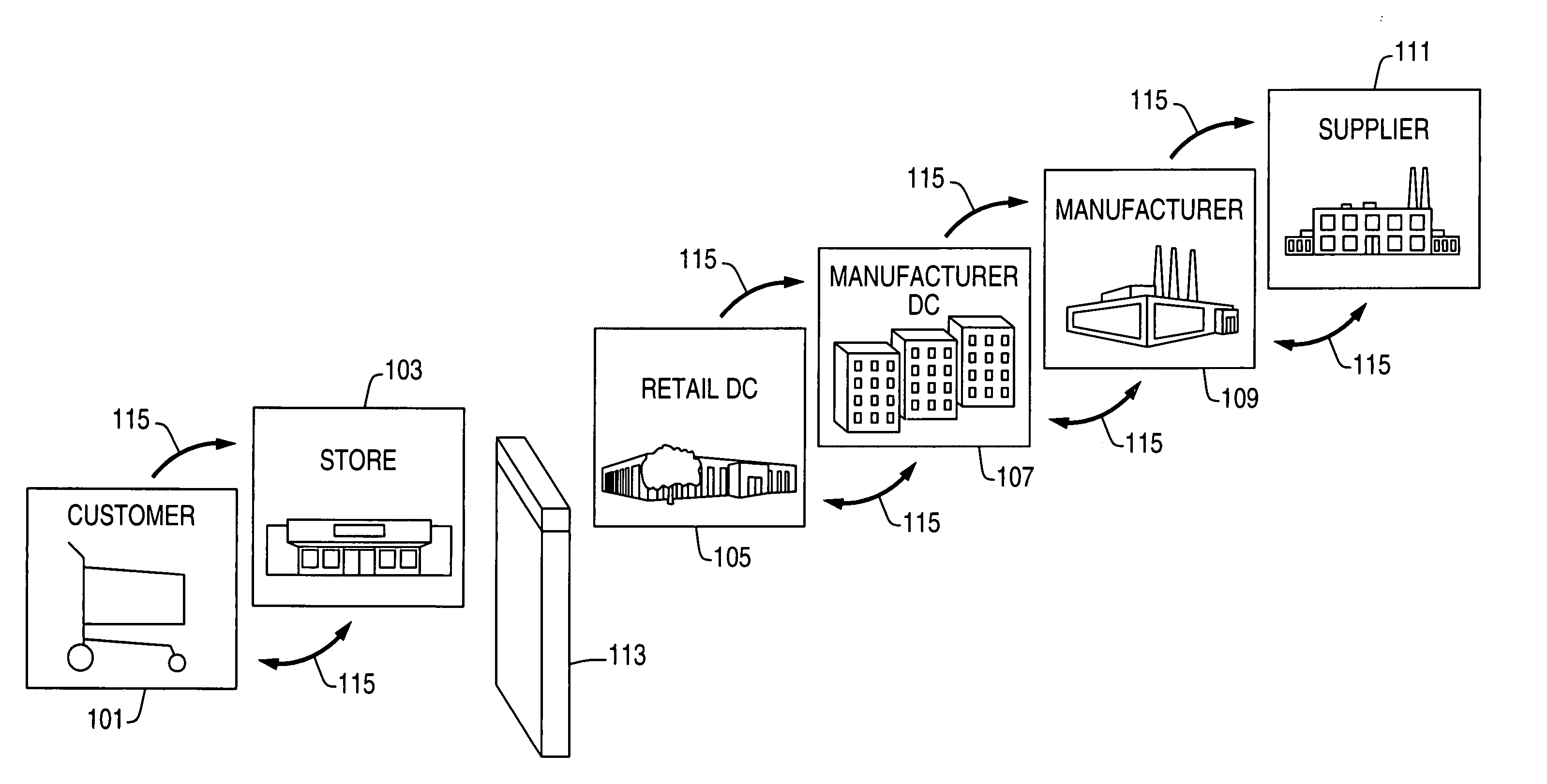

Method for managing inventory within an integrated supply chain

ActiveUS20100205044A1Maximize efficiencyMaximize profitabilityPayment architectureLogisticsOrder formInventory level

A method for managing inventory within a supply chain. The method is performed by providing forecasts of demand for items distributed within the supply chain, using the forecasts to establish base stocking levels and reorder points within the supply chain, and using the established base stocking levels and reorder points to position items within the supply chain so as to maximize efficiency and profitability when responding to an order for an item.

Owner:W W GRAINGER

Systems and methods for purchasing, invoicing and distributing items

InactiveUS20070050272A1Hand manipulated computer devicesDigital data processing detailsItem generationInvoice

A method for supplying items to dispensing units that hold at least one type of item and a record of inventory levels comprises periodically sending restocking information from the dispensing units over a network to a server computer. Ordering information is generated for the items to be restocked based on the restocking information. The ordering information is electronically sent to one or more supplier computers to order items to be restocked into the dispensing units.

Owner:OMNICELL +1

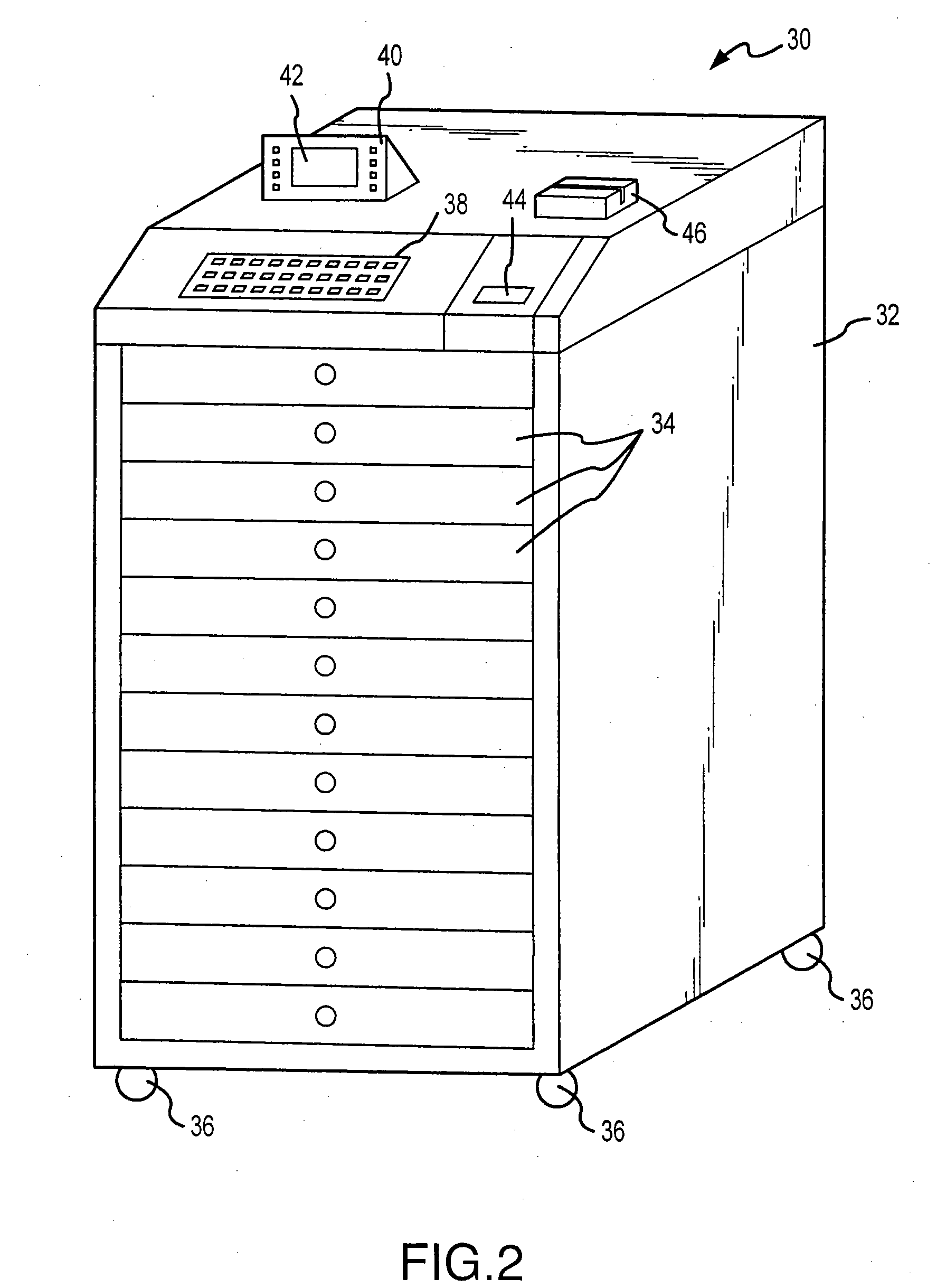

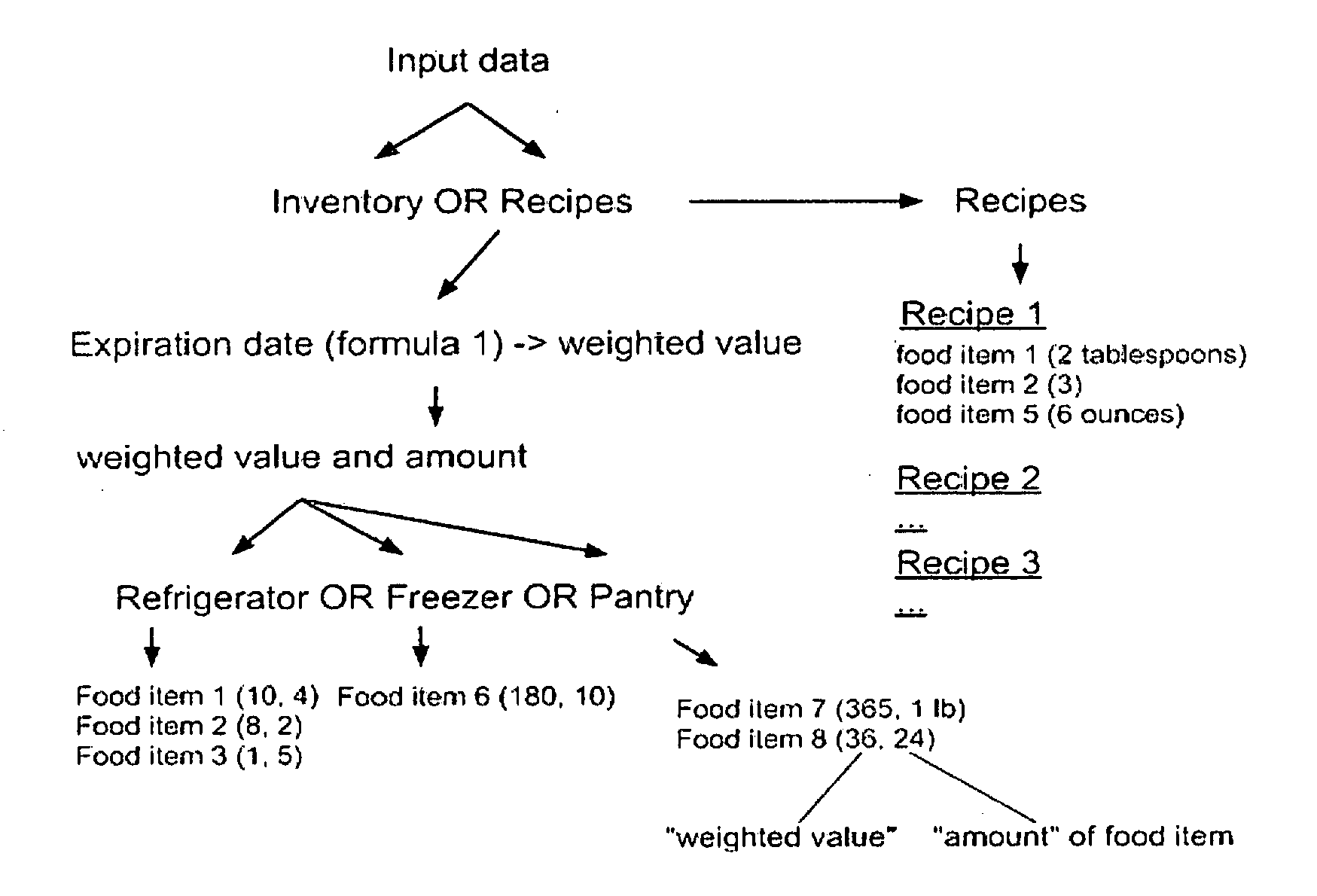

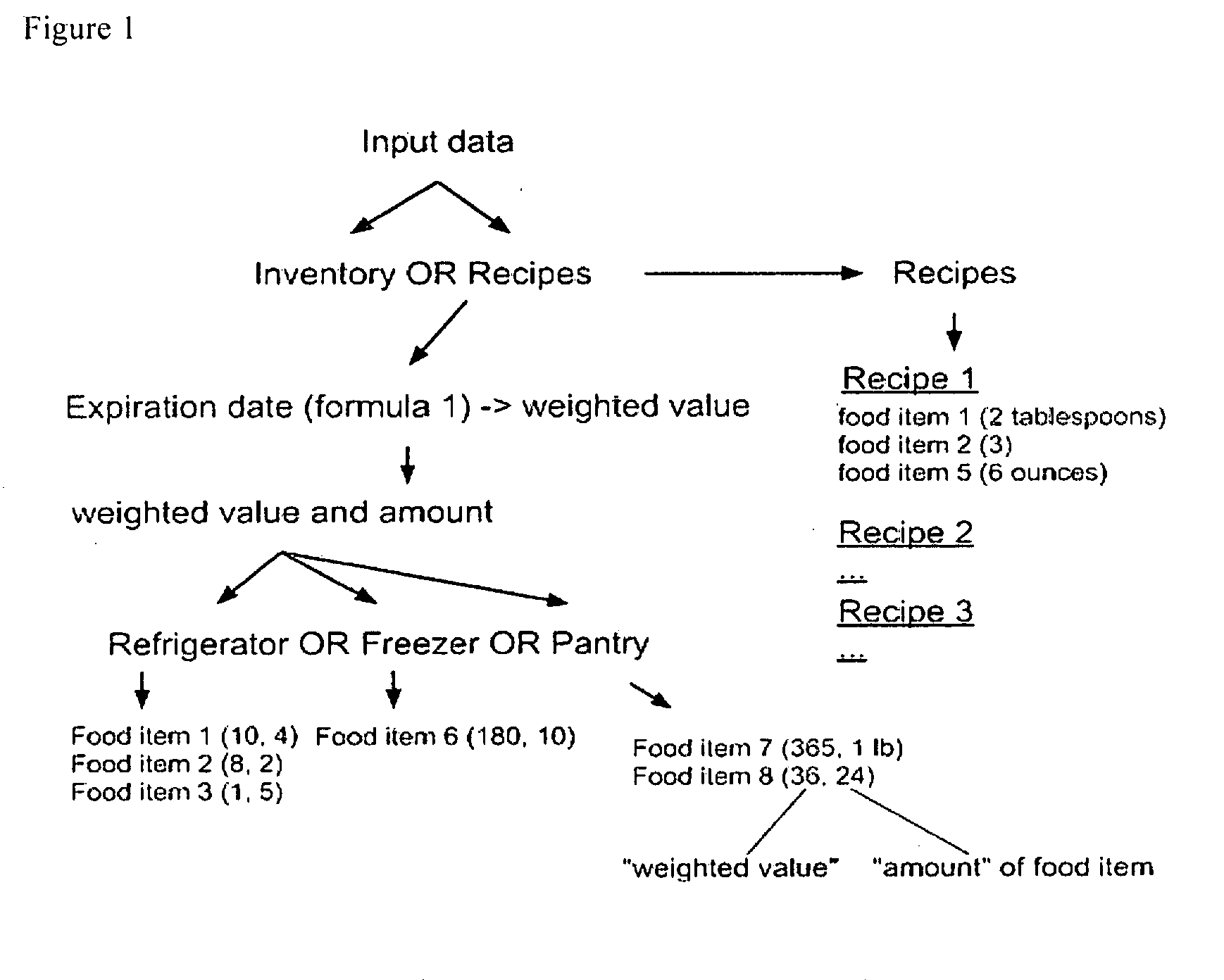

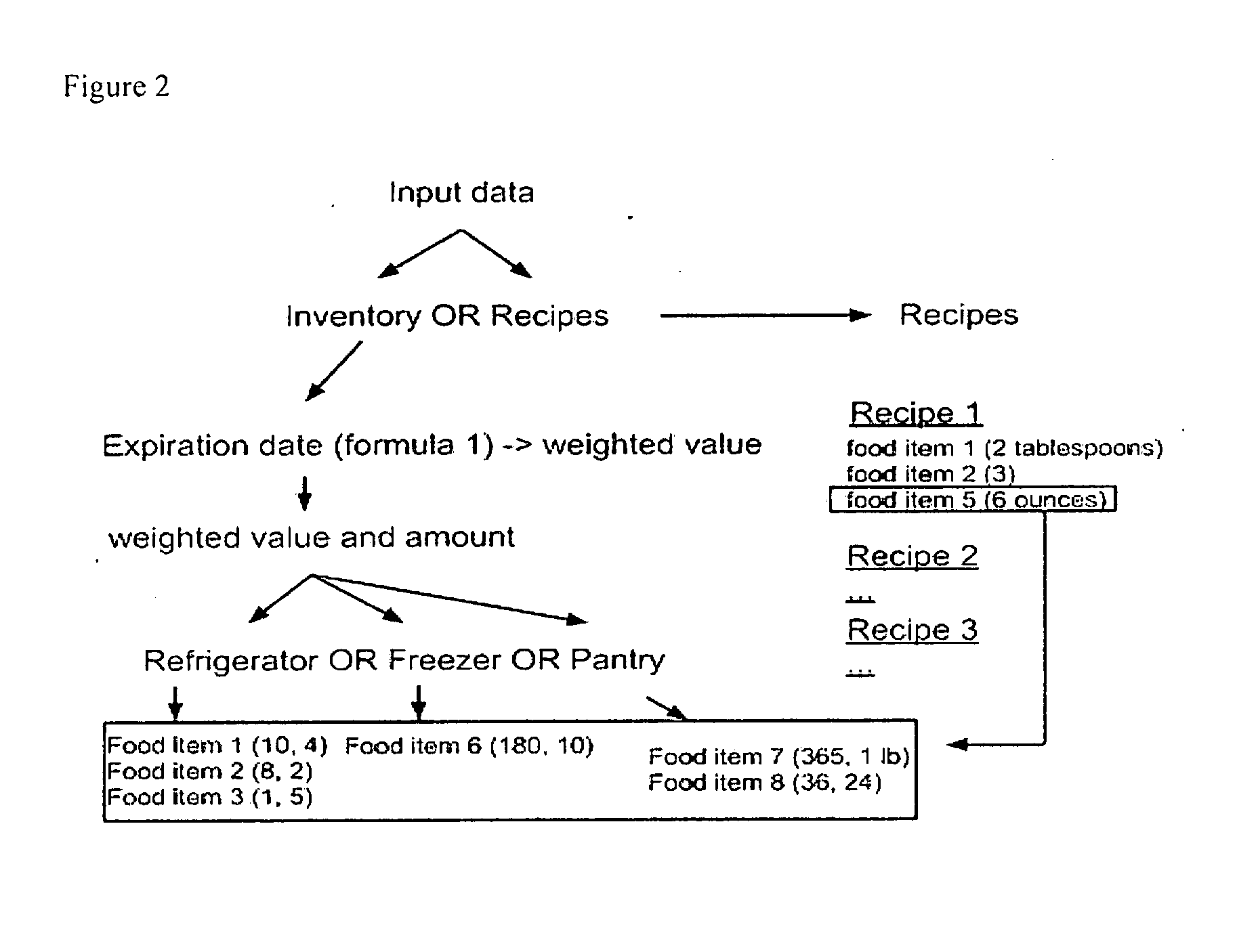

Method and Device for Expiration Date Weighted Food Inventory System and Meal Planner

InactiveUS20130138656A1Easily and accurately maintainingPrevent spoilageDigital data processing detailsMultiple digital computer combinationsEngineeringStore food

A method and device comprising a food inventory system that enables food inventory control as well as meal planning Food items are entered into a software controlled means for storing food inventory data and meal recipes. Meal planning is enabled whereby recipes are proposed based on inventory levels and / or food expiration or spoilage times, as well as nutrient and dietary information. Shopping lists are created that reflect inventory levels, recipe needs, and / or food expiration or spoilage dates.

Owner:WHEATON WENDI

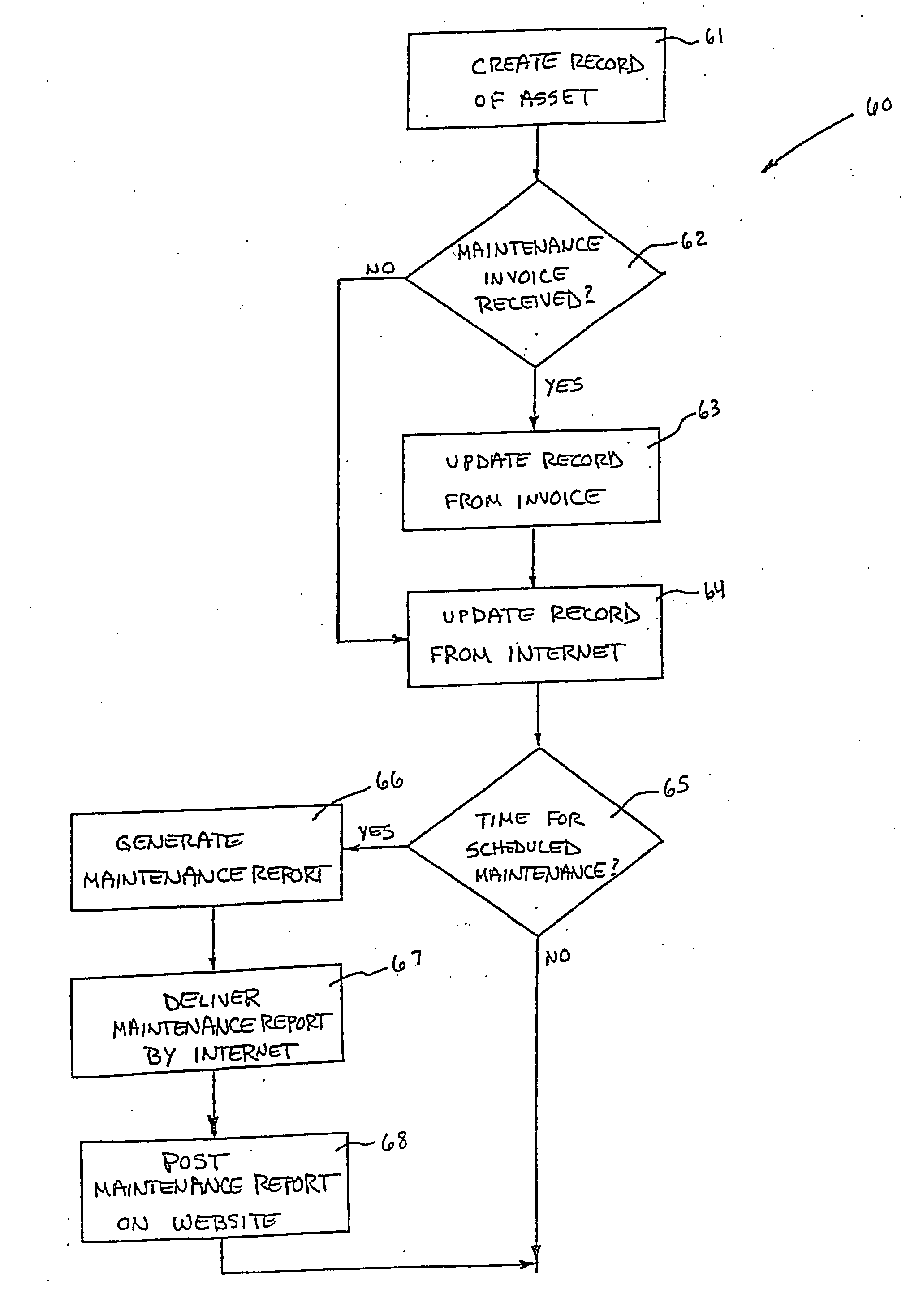

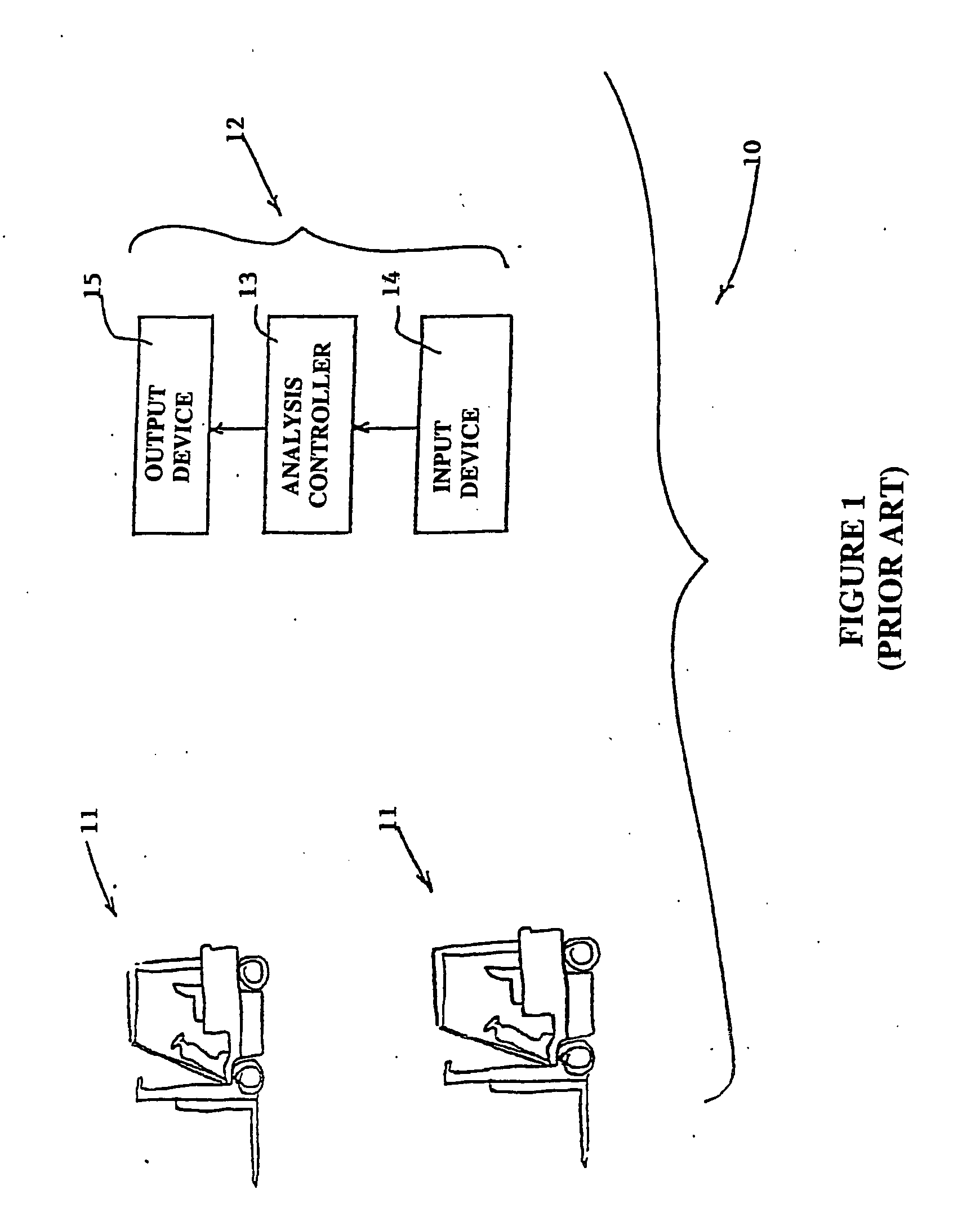

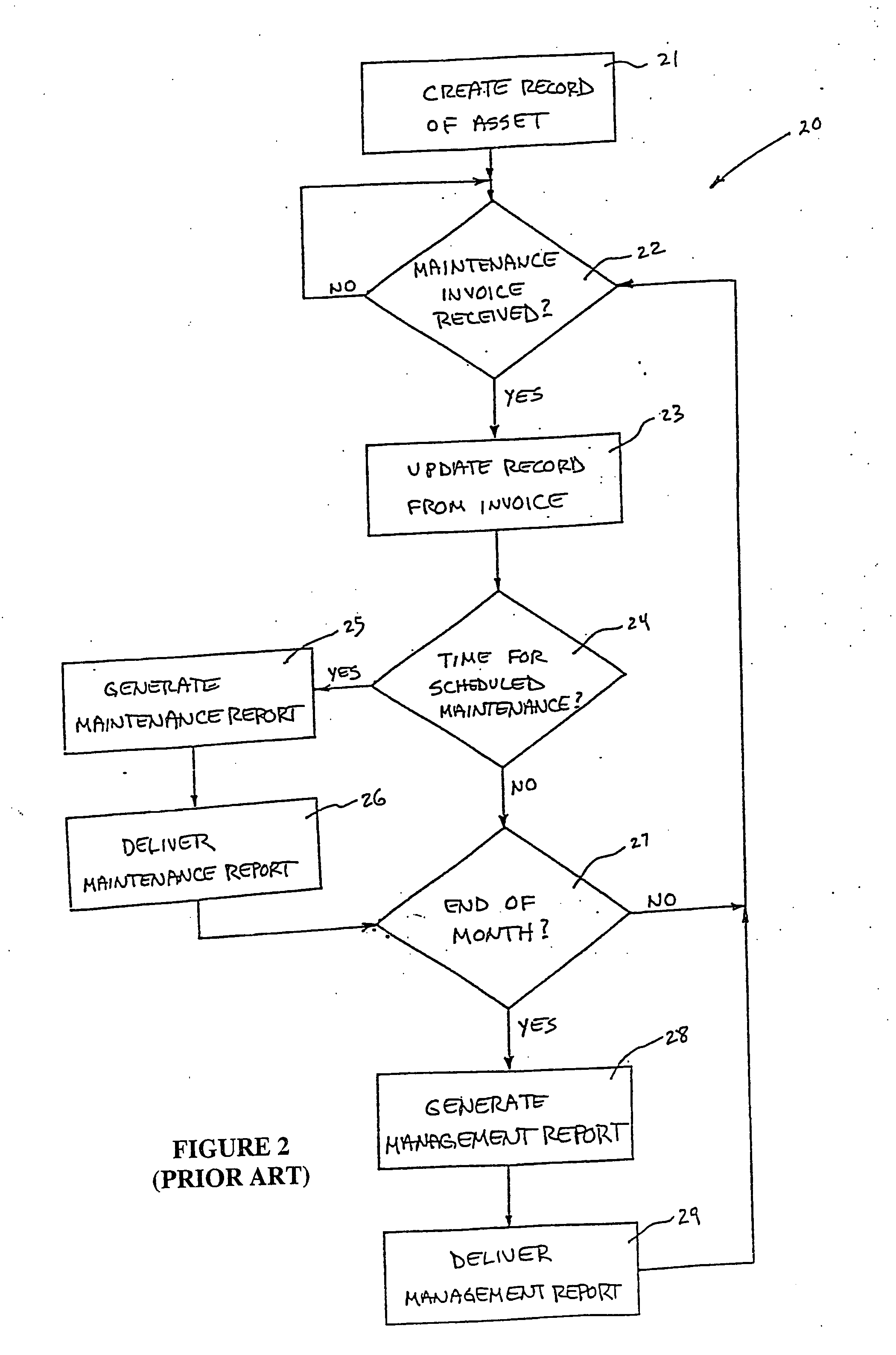

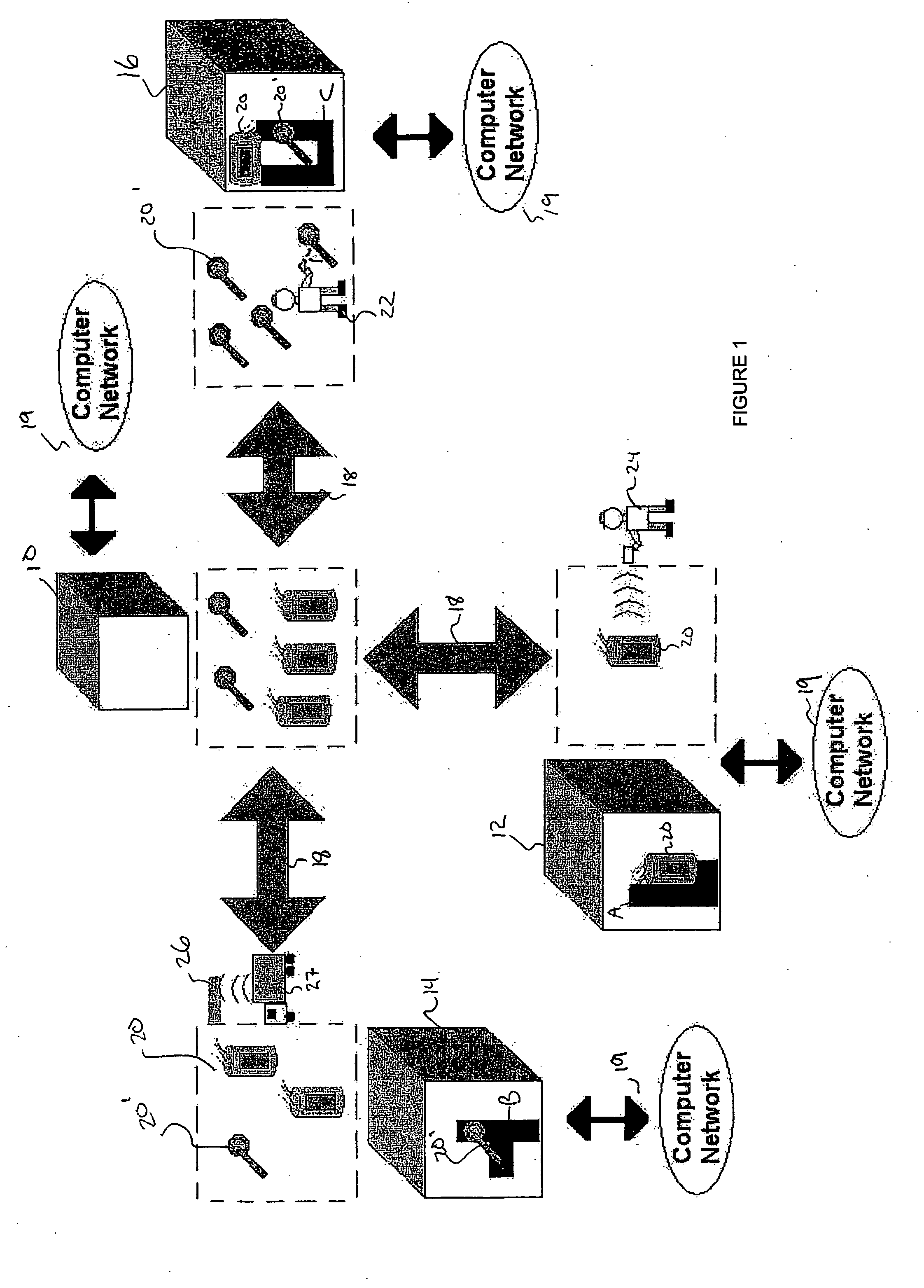

Apparatus and method for tracking and managing physical assets

InactiveUS20050131729A1Maximize productivityReduce operating costsAnimal feeding devicesTechnology managementData acquisitionIndustrial equipment

A computer based system automatically gathers, analyzes, and delivers information relating to the procurement and utilization of a plurality of such assets, such as a fleet of industrial equipment, so as to maximize productivity and to reduce operating costs and administrative burdens. Each of the assets is preferably provided with a data acquisition device for sensing and storing one or more operating characteristics associated therewith. That information can be transmitted through space to a receiver connected to a local controller for storing such information and for transmitting such information to a remote analysis system. The remote analysis system automatically updates individual records associated with each of the assets with the information received. In response to such information, the remote analysis system automatically analyzes the newly provided information and schedules maintenance as required. Information associated with the maintenance is also recorded electronically to maximize efficiency, provide historical trends, automate billing, and control inventory levels.

Owner:DANA AUTOMOTIVE SYST GRP LLC

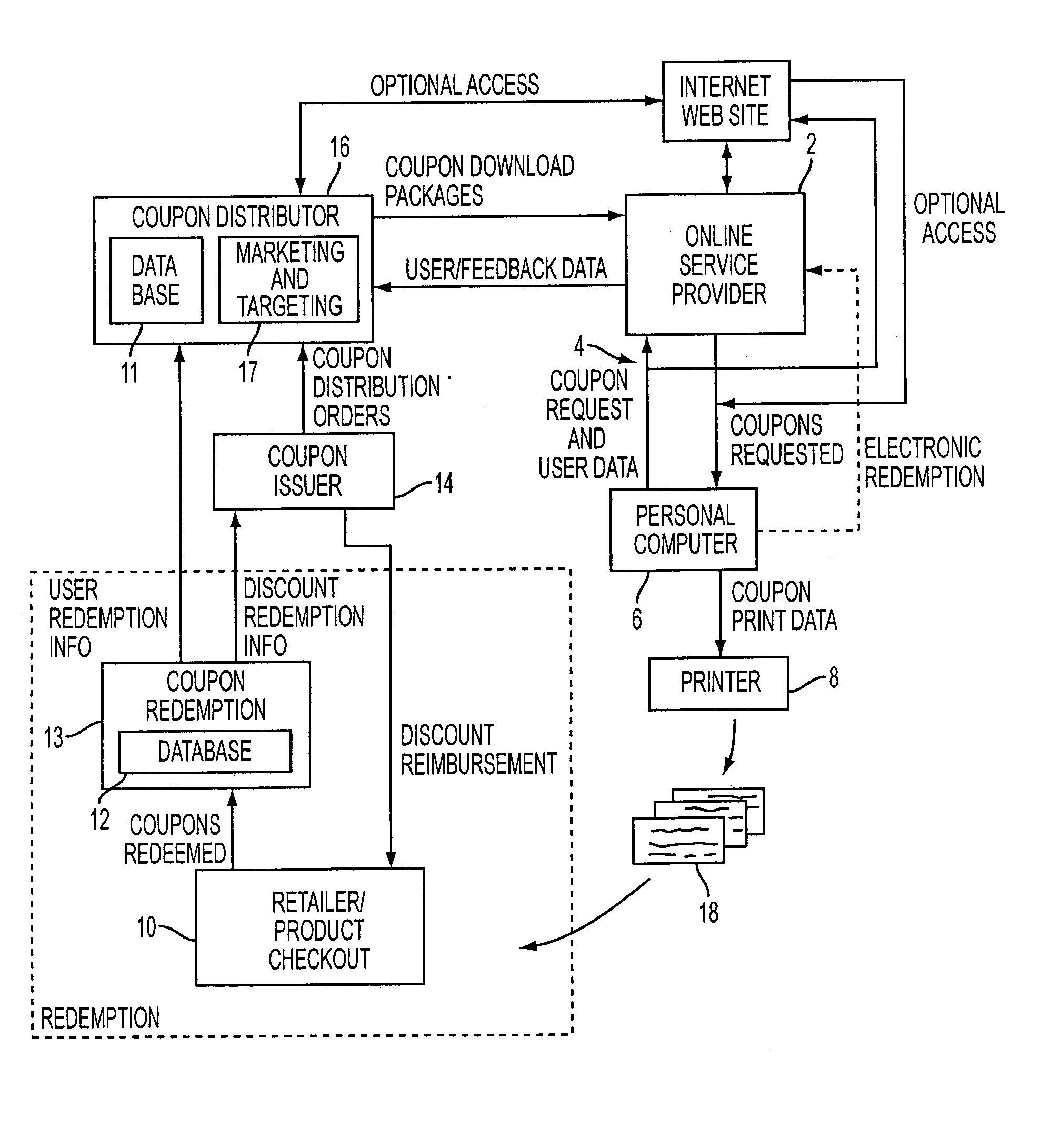

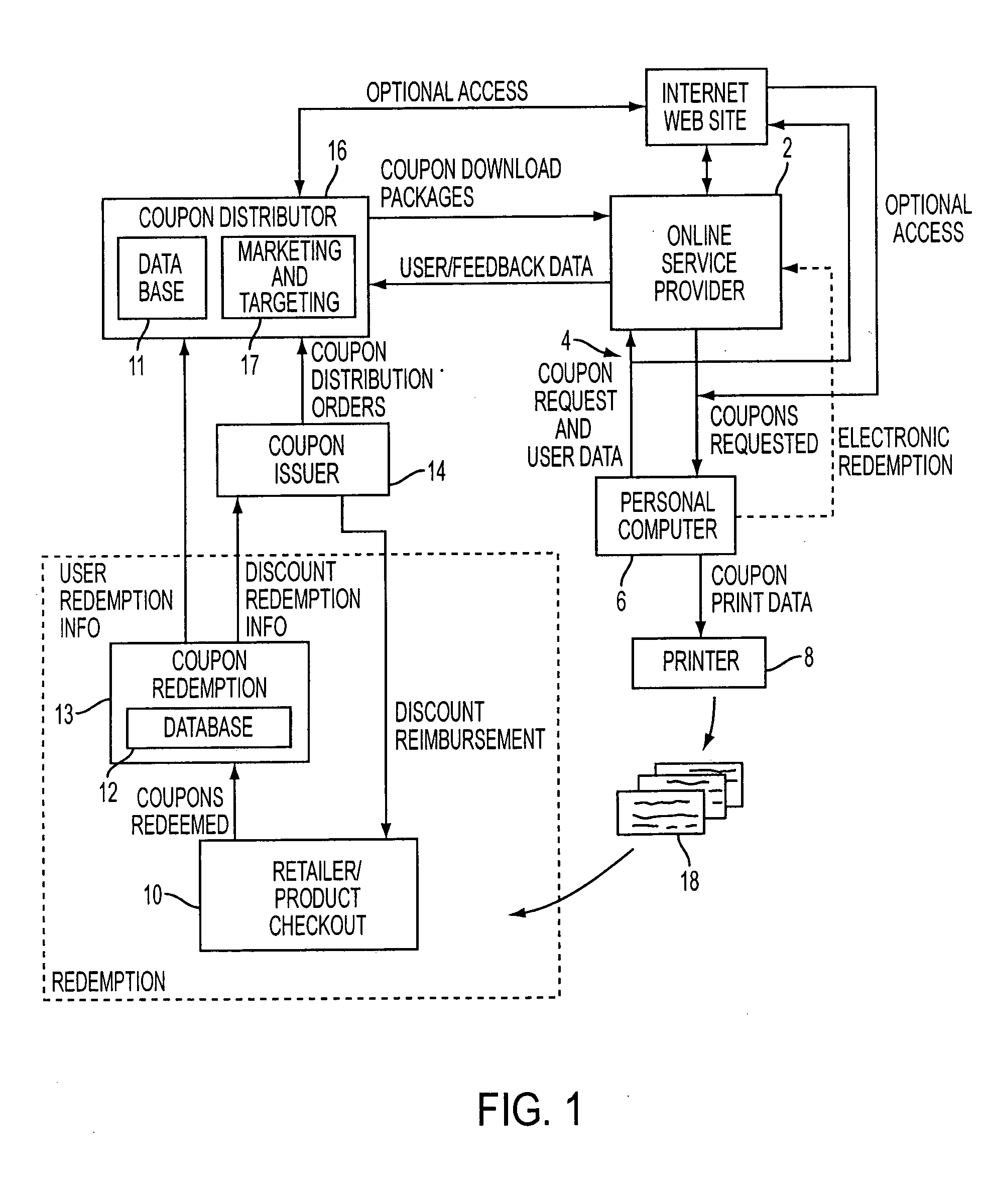

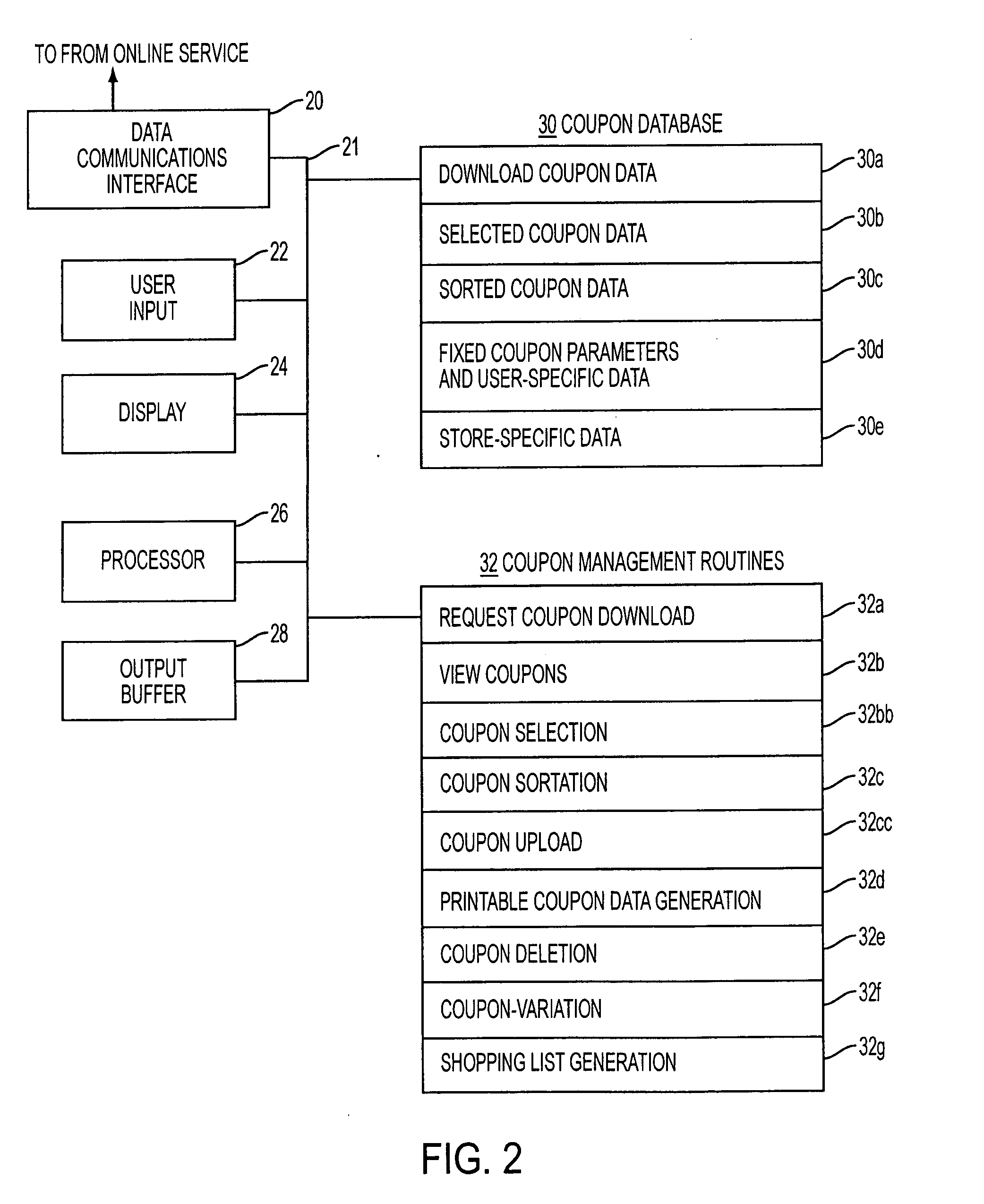

Method and system for managing inventory and promotions campaign based on redemption data

ActiveUS20050222910A1Cost-effective mannerAvoid repetitionHand manipulated computer devicesPayment architectureTransaction dataComputerized system

Provided is a method and system for the management of inventory and / or promotional campaigns associated with electronic distribution of secure money saving or discount incentives, including coupons and other marketing incentives and, in particular, to modifying a promotional campaign and / or modifying inventory levels and product ordering based on transaction data relating to coupons distributed as part of an online computer system for interactively distributing such incentives to remotely connected consumer computers.

Owner:CATALINA MARKETING CORP

Intelligent refrigerator for storing pharmaceutical product containers

Intelligent refrigerator system for storing pharmaceutical product containers, such as vials, ampules, syringes, bottles, medication tubes, blister packs and cartons, at the point of dispensing. Embodiments of the invention use product identification technology, such as radio-frequency identification (RFID) tags and readers, to uniquely identify containers as they are added to or removed from the cold storage compartment of the refrigerator, and automatically retrieve from a local or remote database a variety of details associated with the containers and their contents, such as manufacturing data, expiration dates, time out of refrigeration, inventory levels, safety information, usage statistics, known contraindications and warnings, etc. If the details indicate that there is a problem with a particular pharmaceutical (e.g., that it is counterfeit, expired, suspect, spoiled, recalled or almost depleted), then a message or warning is automatically delivered to a human operator via an attached output device, such as a display screen, speaker or printer. Embodiments of the invention may also be configured to monitor and report temperature faults, power failures and other anomalies associated with the refrigerator or cold storage compartment.

Owner:MERCK SHARP & DOHME LLC

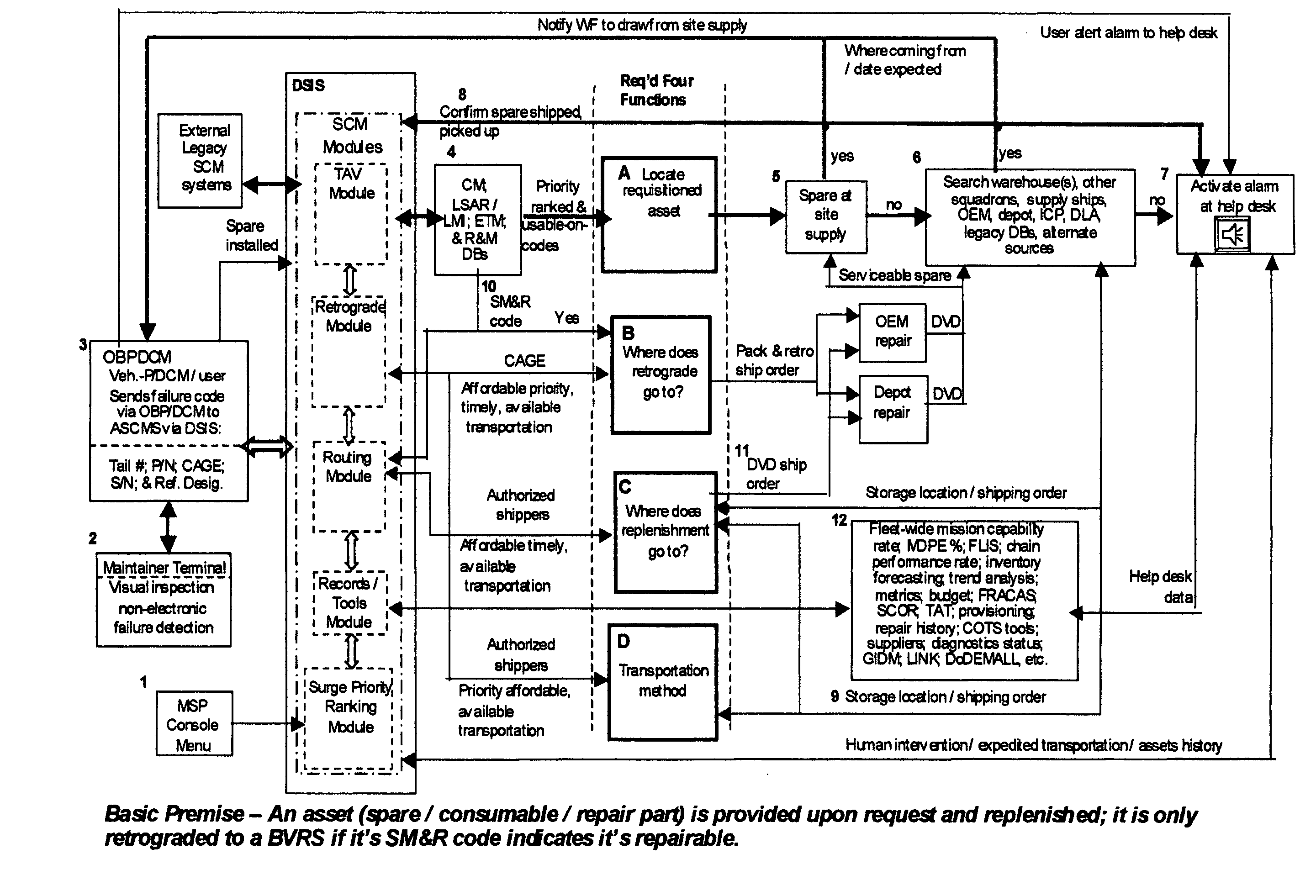

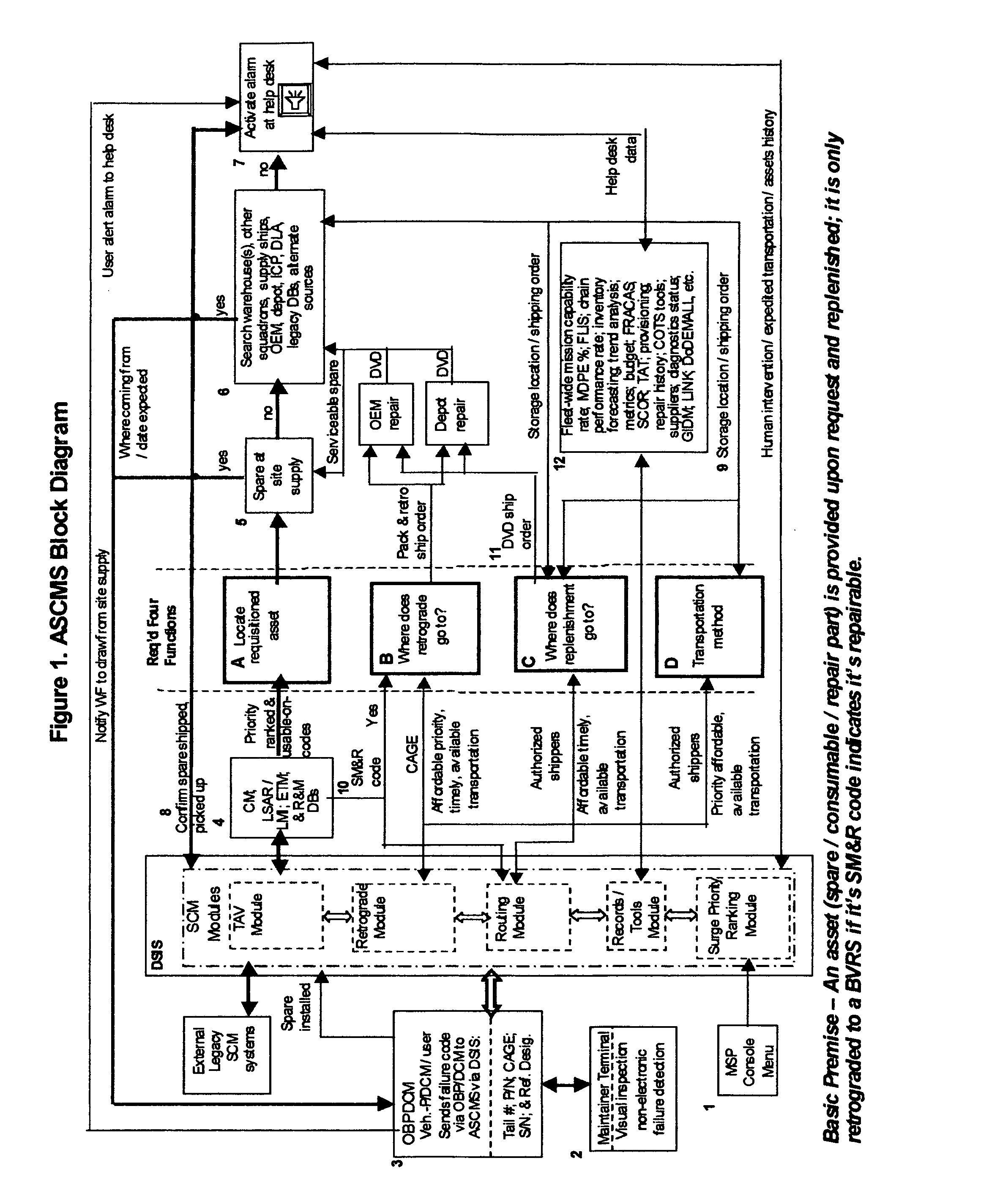

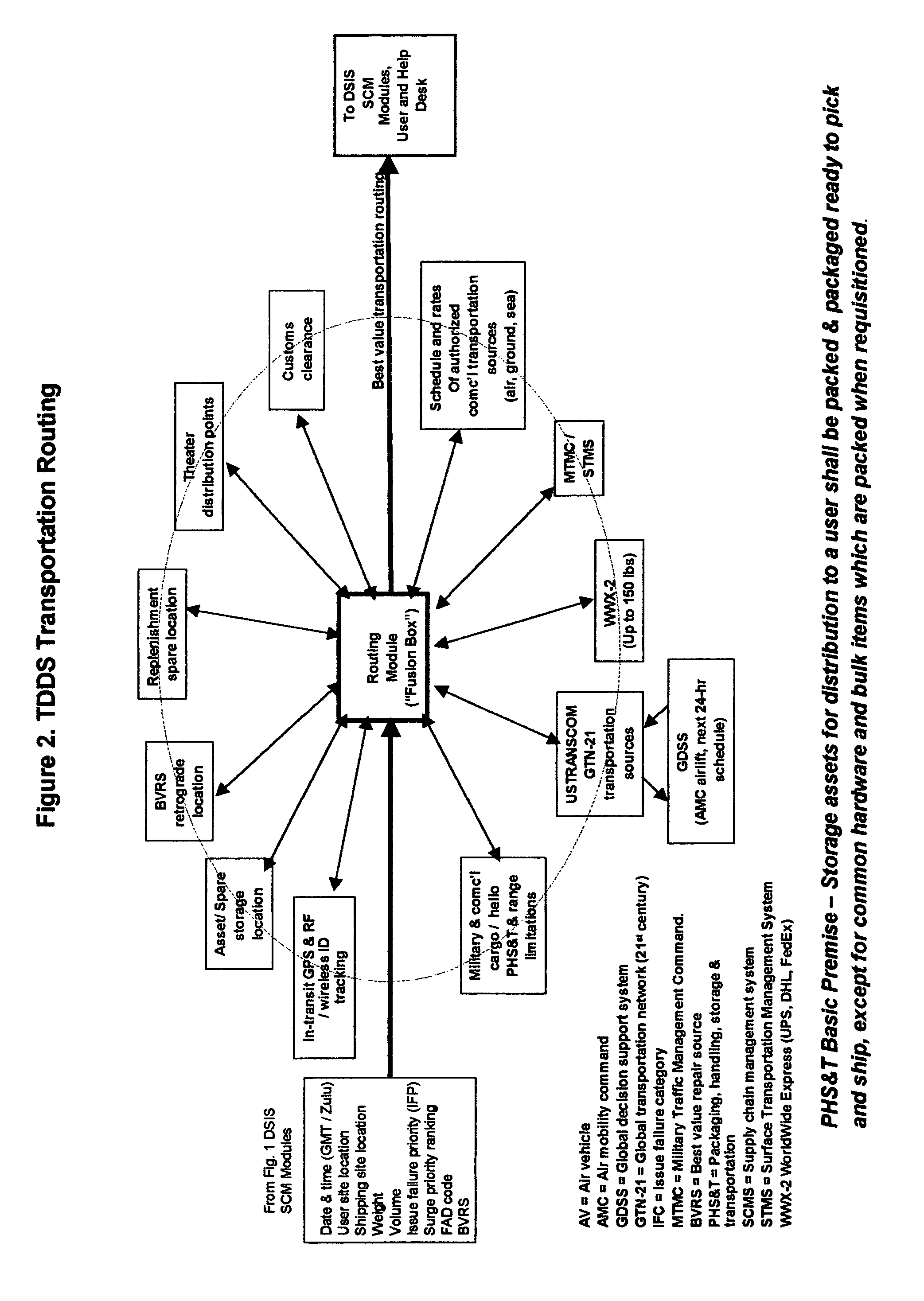

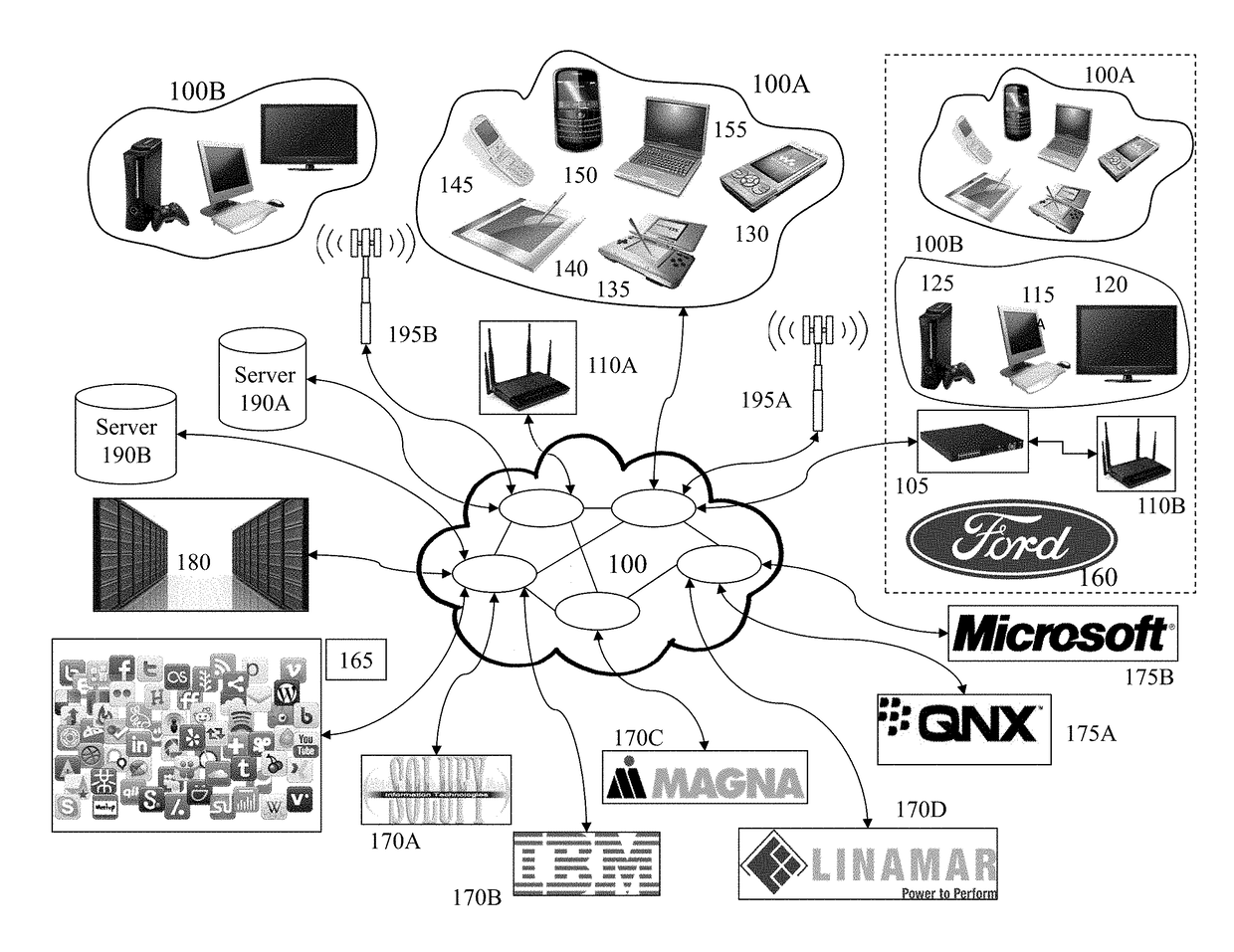

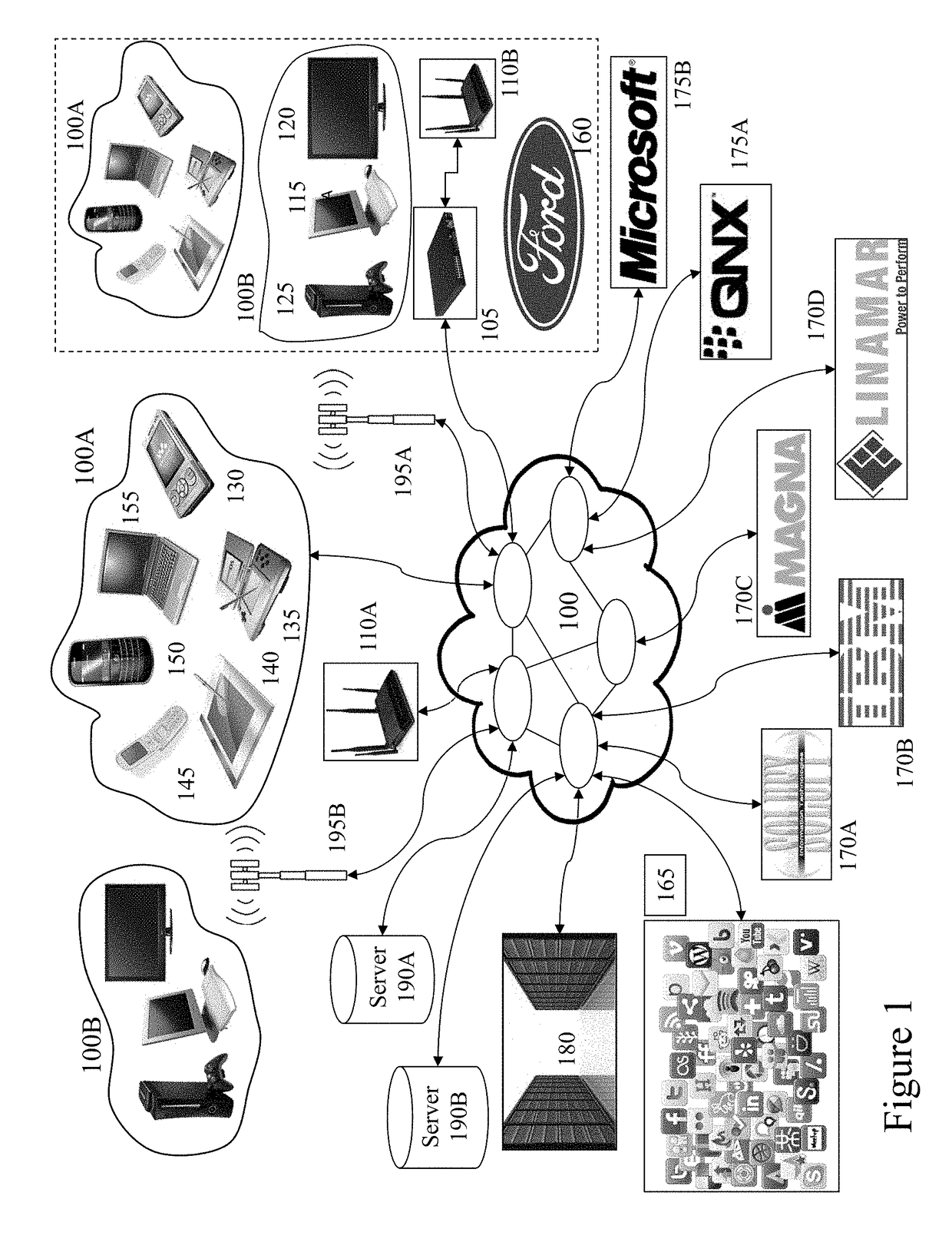

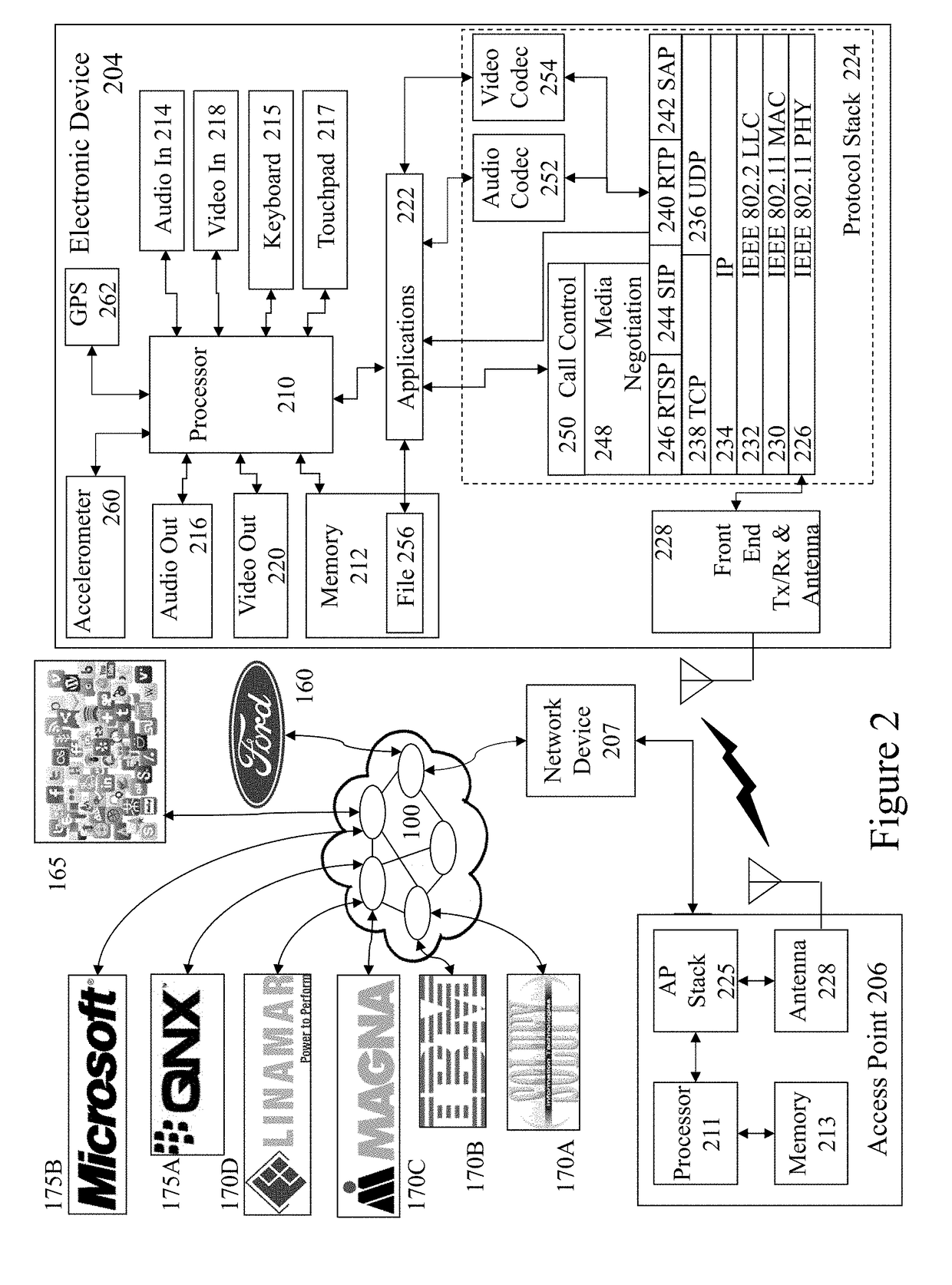

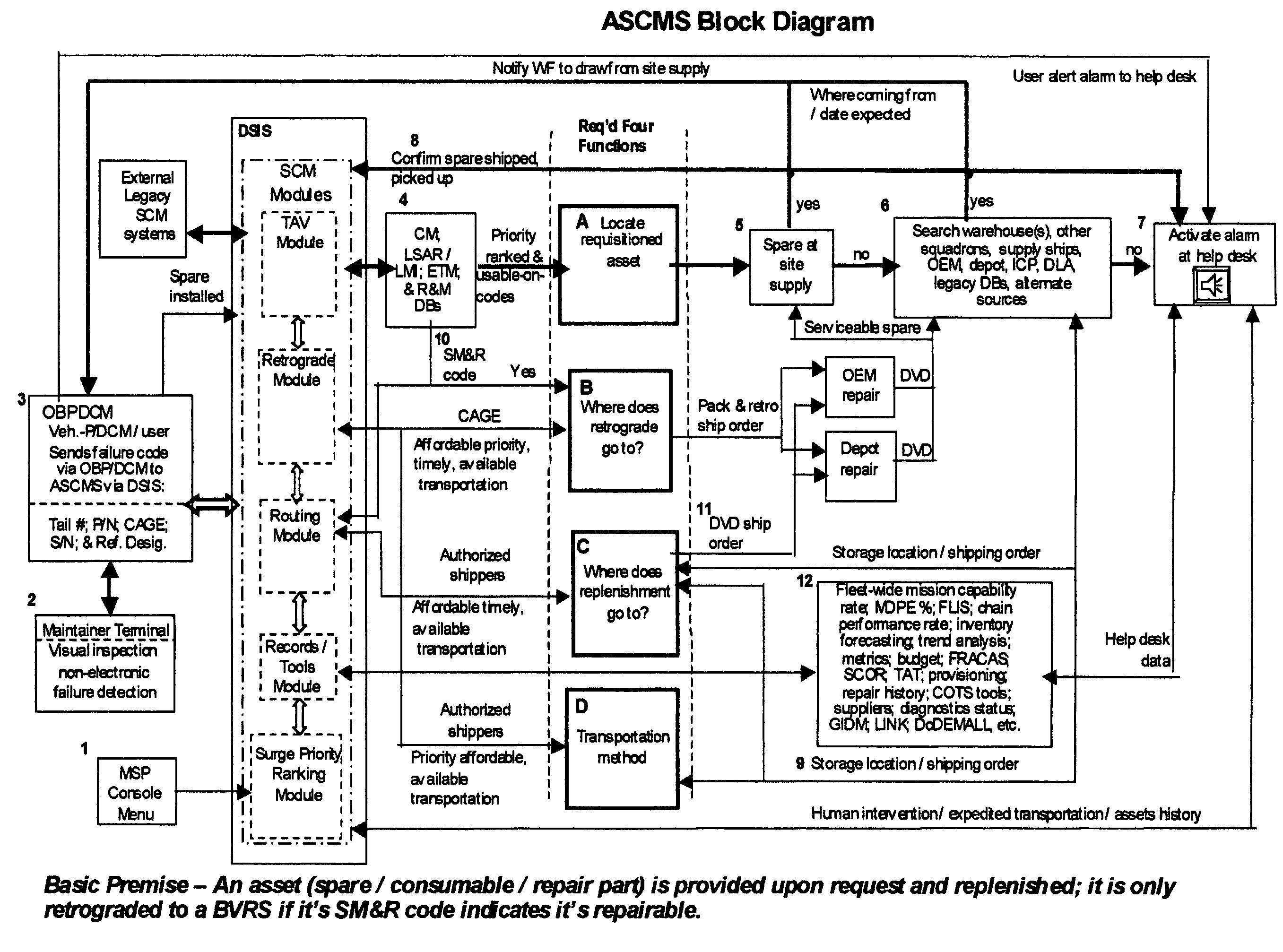

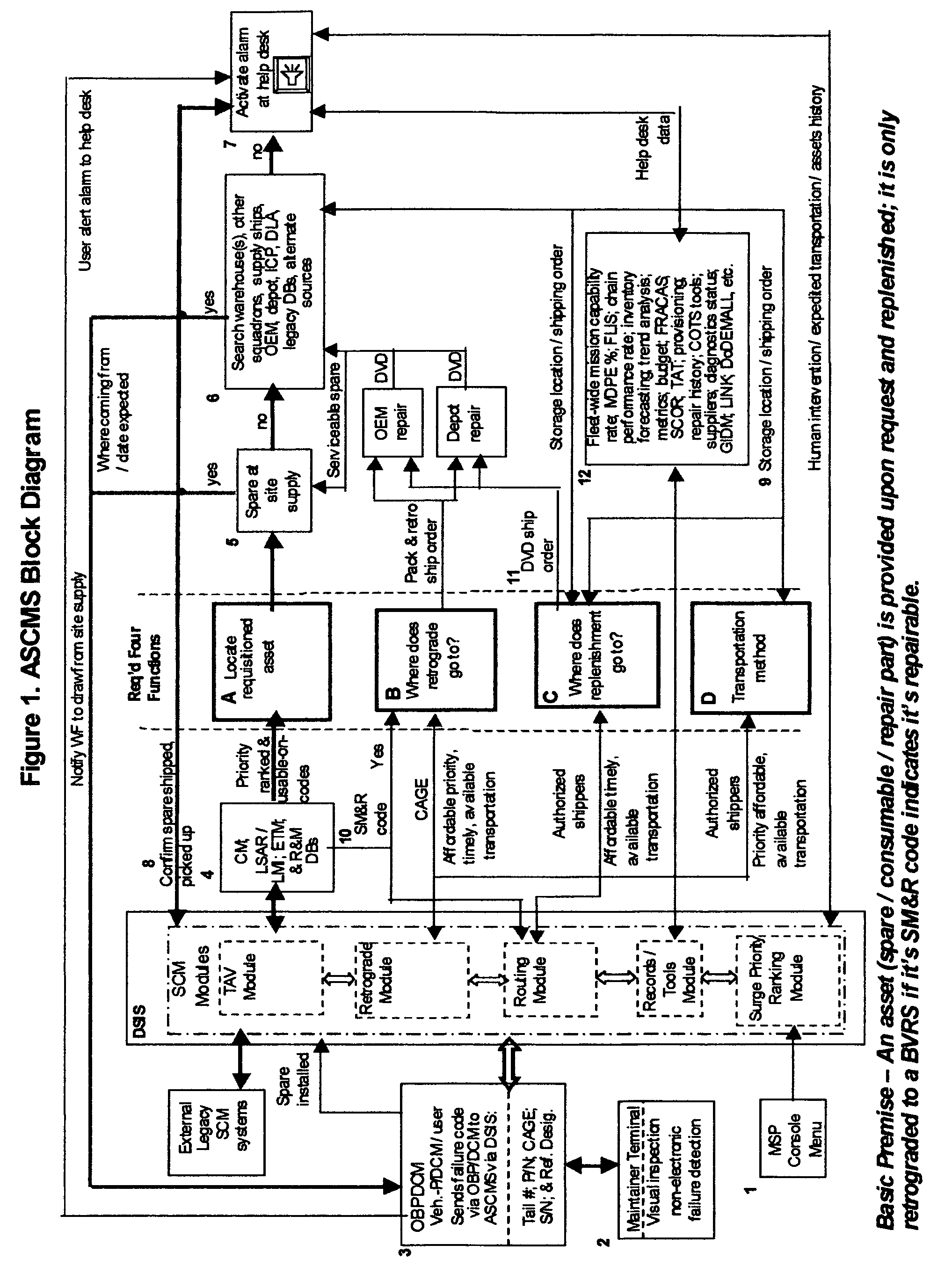

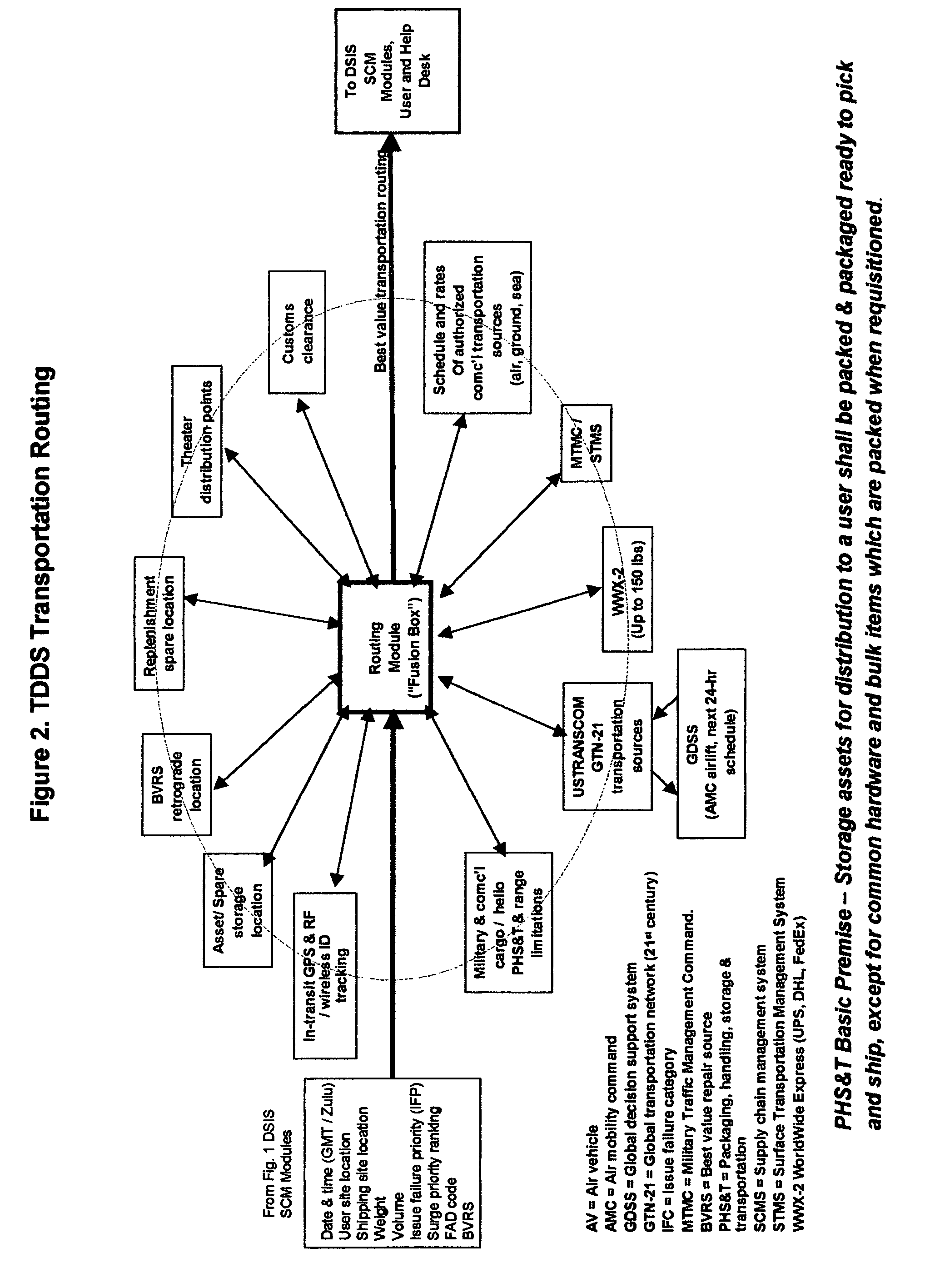

Adaptive network-centric online autonomic supply chain management system

InactiveUS20050154653A1Speeding up delivery/retrogradeIncrease supplyDigital data processing detailsResourcesMicrocontrollerOperational costs

Provided is an agile, adaptive, globally deployable online network-centric autonomic supply chain management system that when triggered by a predictive / diagnostic condition management system, without user-maintainer intervention, autonomously authorizes a complete requisitioning cycle of supply chain assets to warfighters with unprecedented criticality of speed. A requisitioning cycle is comprised of: (1) asset issue authorization to a vehicle / requester (2) retrograde [return] of repairable to depot and (3) replenishment [resupply] of drawn inventory. It also autonomically provides global total asset visibility of the asset(s) of interest and a tempo surge-priority ranking with a calm-down functions. The system operates in either default autonomic mode or a user activated semi-autonomic mode. In either mode of operation a requisition cycle is accomplished autonomically by selection of the most affordable transportation that ensures delivery of an asset to a user in accordance with contractually specified time-definite delivery standards. The system's material delivery performance effectiveness percentage rate is archived for billing purposes and monitoring system performance metrics. The system almost eliminates SCM administration personpower requirements. It accelerates the entire logistics supply pipeline, resulting in:—higher annual inventory turn-rates thus permitting inventory levels to be reduced and smaller wartime pack up kits thereby lowering lifetime total operating costs. Smaller pack up kits reduces the logistics footprint and thus the number of cargo aircraft required to deploy a unit.

Owner:KENNETH JONGEBRLOED

Project and resource planning methods and systems

InactiveUS20180053127A1Improve visualizationResourcesDigital output to display deviceInventory levelProject planning

The Kanban process-management approach establishes inventory levels at different stages in manufacturing, standardizes batch sizes and signals production / delivery of a new shipment only as a previous shipment is consumed. However, users viewing Kanban charts whilst able to view tasks by different stages within a process have little comprehension of the timing associated with the tasks individually or as a sequence nor of resource workload and availability. Accordingly, a planning and resource tool allowing disparate project planning methodologies to be combined would allow a user to view not only their tasks within a graphical user interface providing comparable features to the user friendly KanBan format but also to allow them to rapidly visualize the inter-relationship of their tasks with the overall process. Such a tool would allow for quick visual identification of issues relating to their and others workload and availability.

Owner:BOILEAU MARIO MR

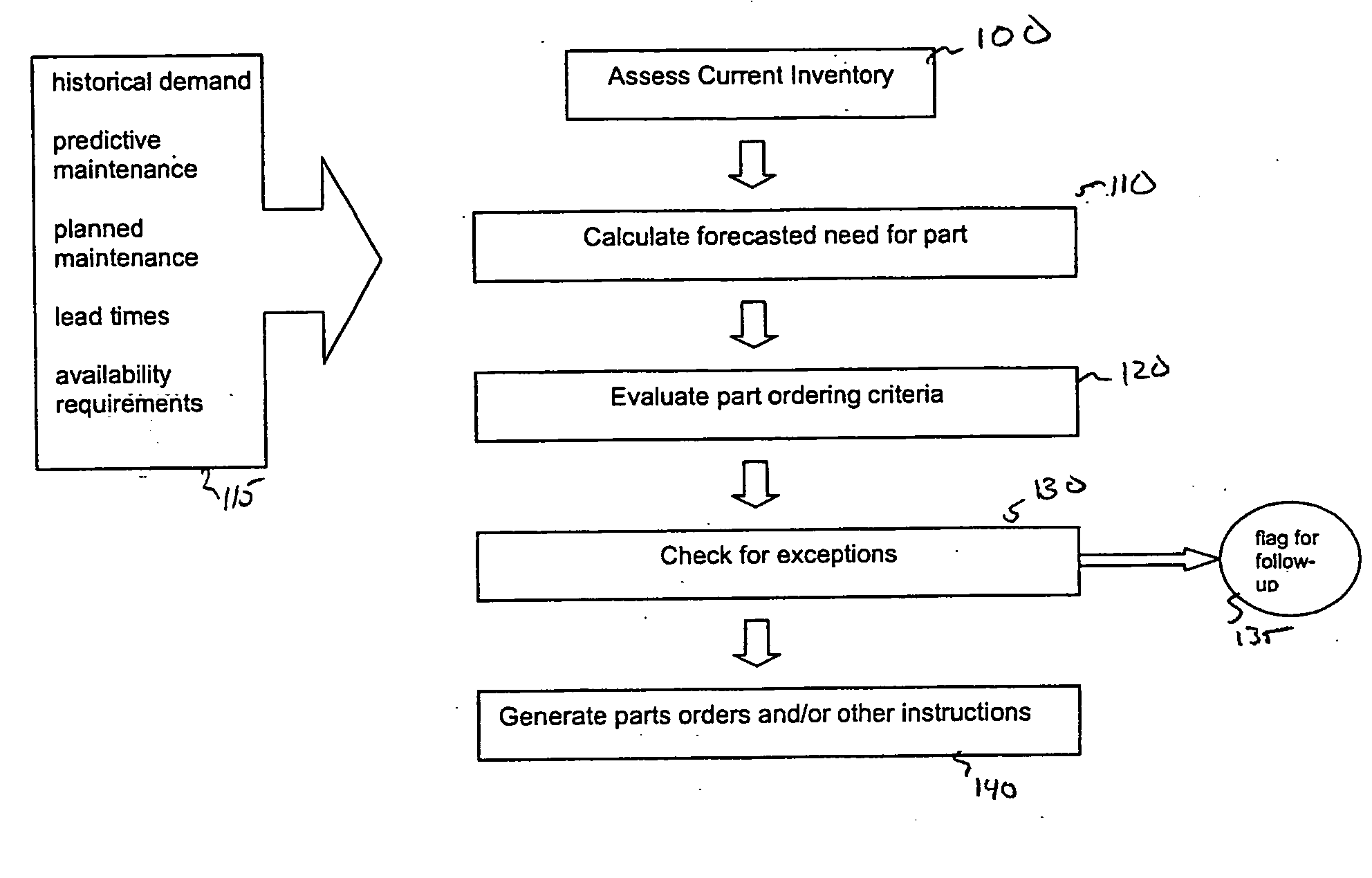

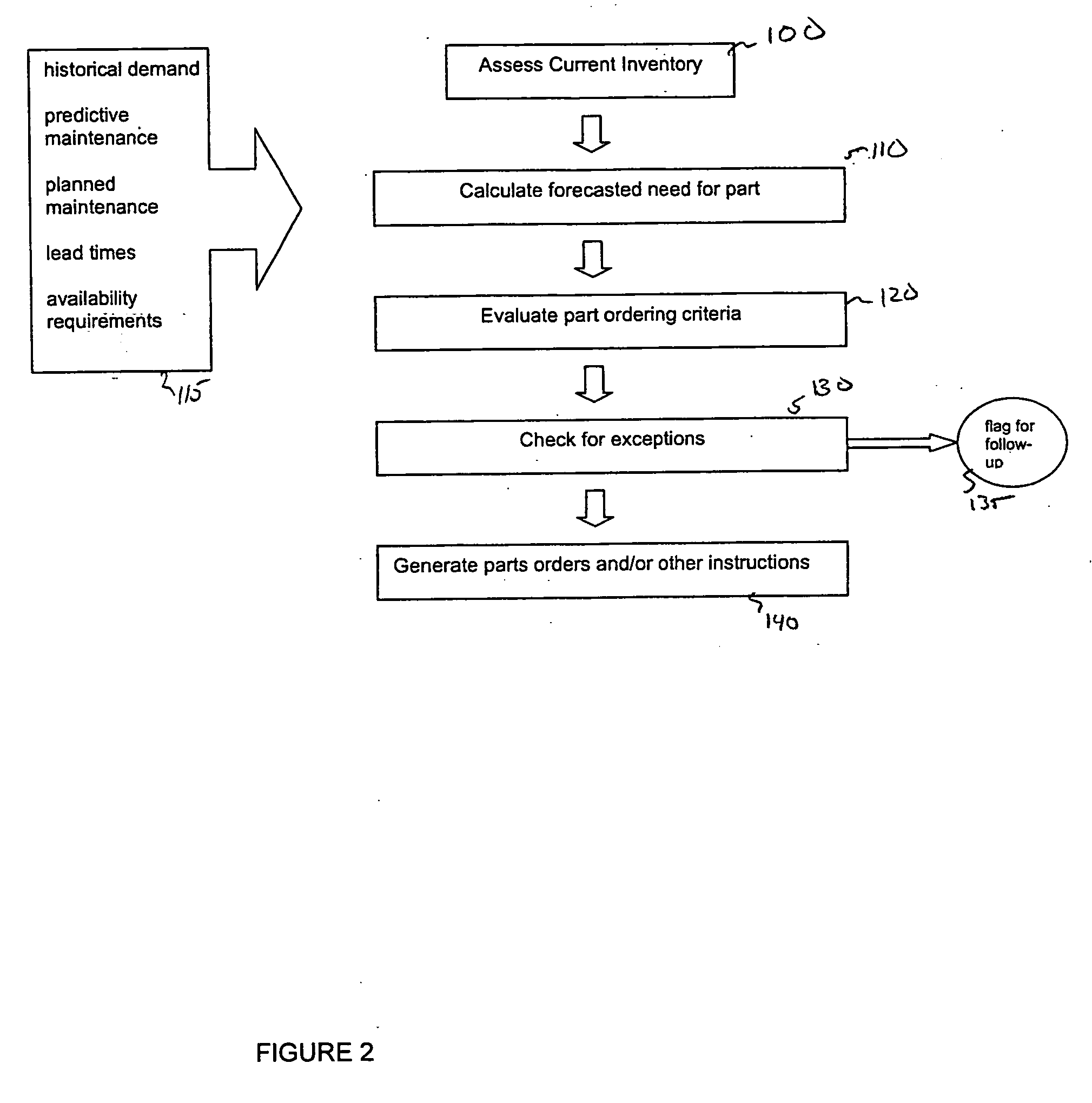

Spare parts inventory management

A method for managing spare parts and tools for a manufacturing enterprise is disclosed. Historical demand values are statistically analyzed to determine optimal stocking levels for spare parts based upon required availability percentages, parts lead times, and the statistical distribution parts demand levels. Parts stocking decisions can also be based upon planned and preventative maintenance timeframes with such parts ordered on an as-needed basis in accordance with lead times. Spare parts inventory management can utilize an enterprise-wide computer system to integrate parts demand planning with systems used for engineering and other changes to manufacturing processes and facility maintenance systems. The computer system can perform varying degrees of the parts reordering and planning process and automate certain steps while providing for decision of other issues by parts management personnel.

Owner:CALLAHAN CELLULAR L L C

Pill printing and identification

InactiveUS7059526B1Pharmaceutical product form changeCharacter and pattern recognitionPillInventory level

Method and identification system to keep track of individual pills dispensed to patients in a hospital by scanning a machine readable code assigned to each pill individually. The pills may be individually within single-pill containers. Inventory levels may be adjusted based on the scanning. Prior to dispensing the pills, a verification check may be performed.

Owner:HESS ROBERT J +1

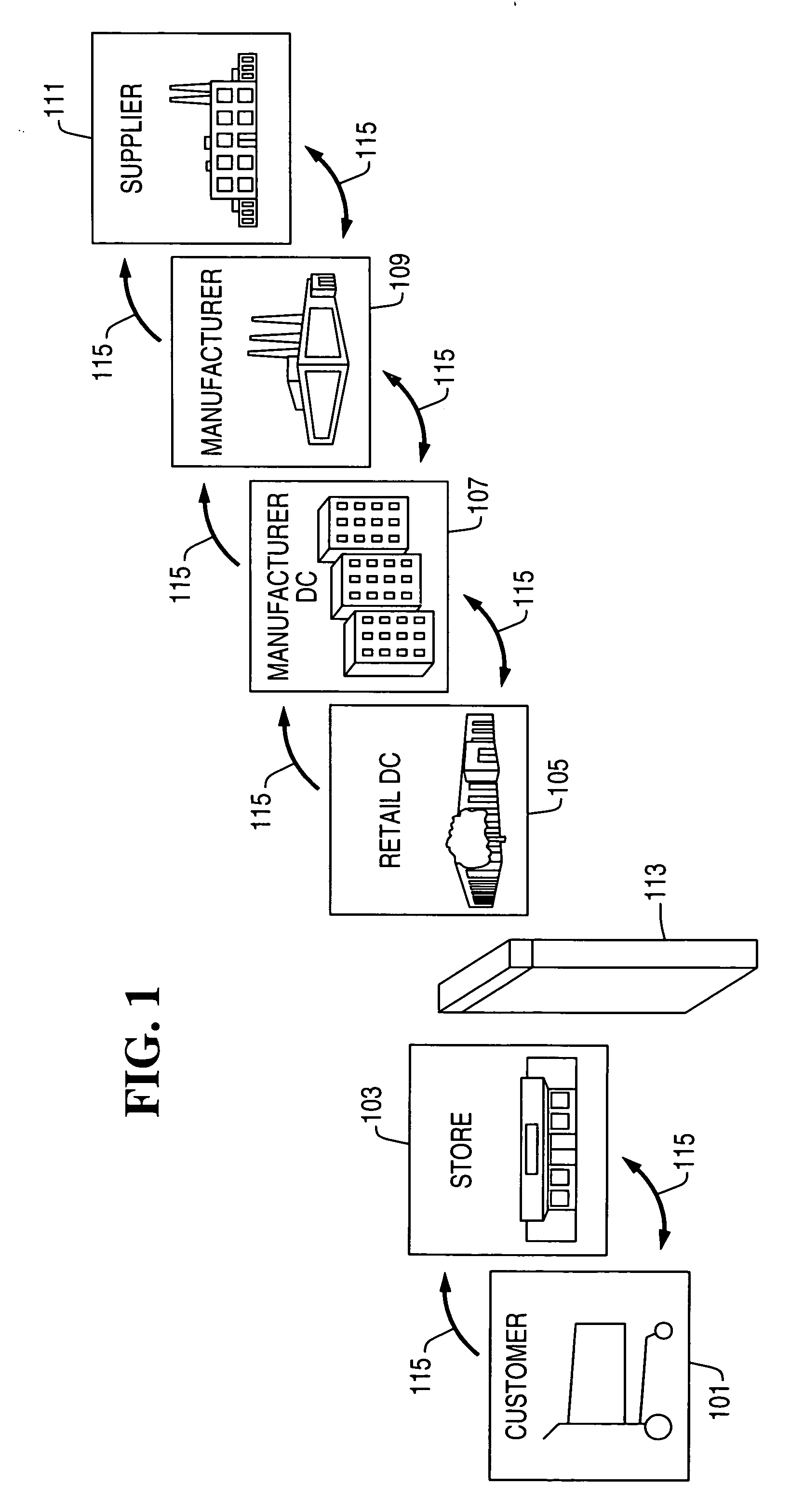

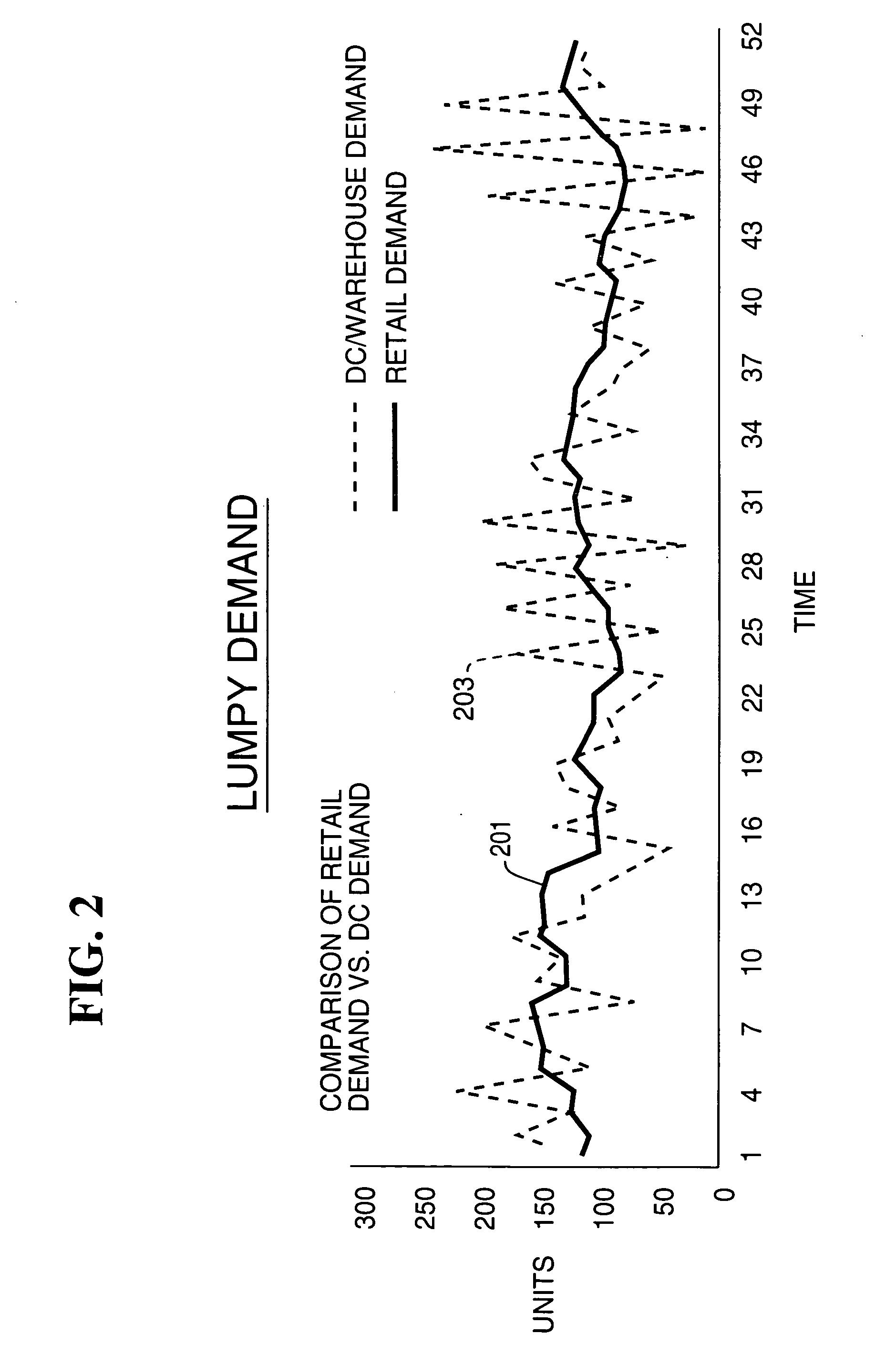

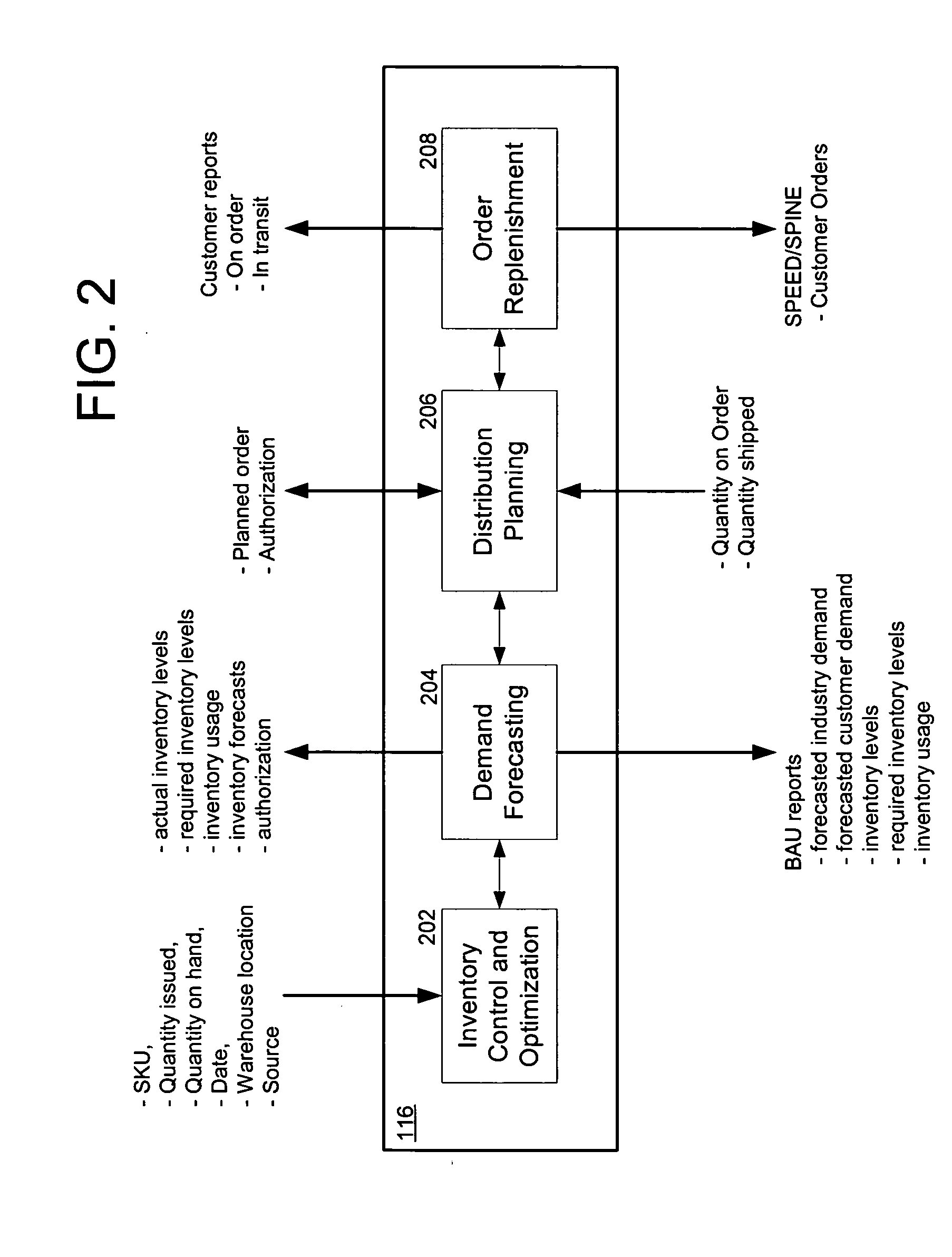

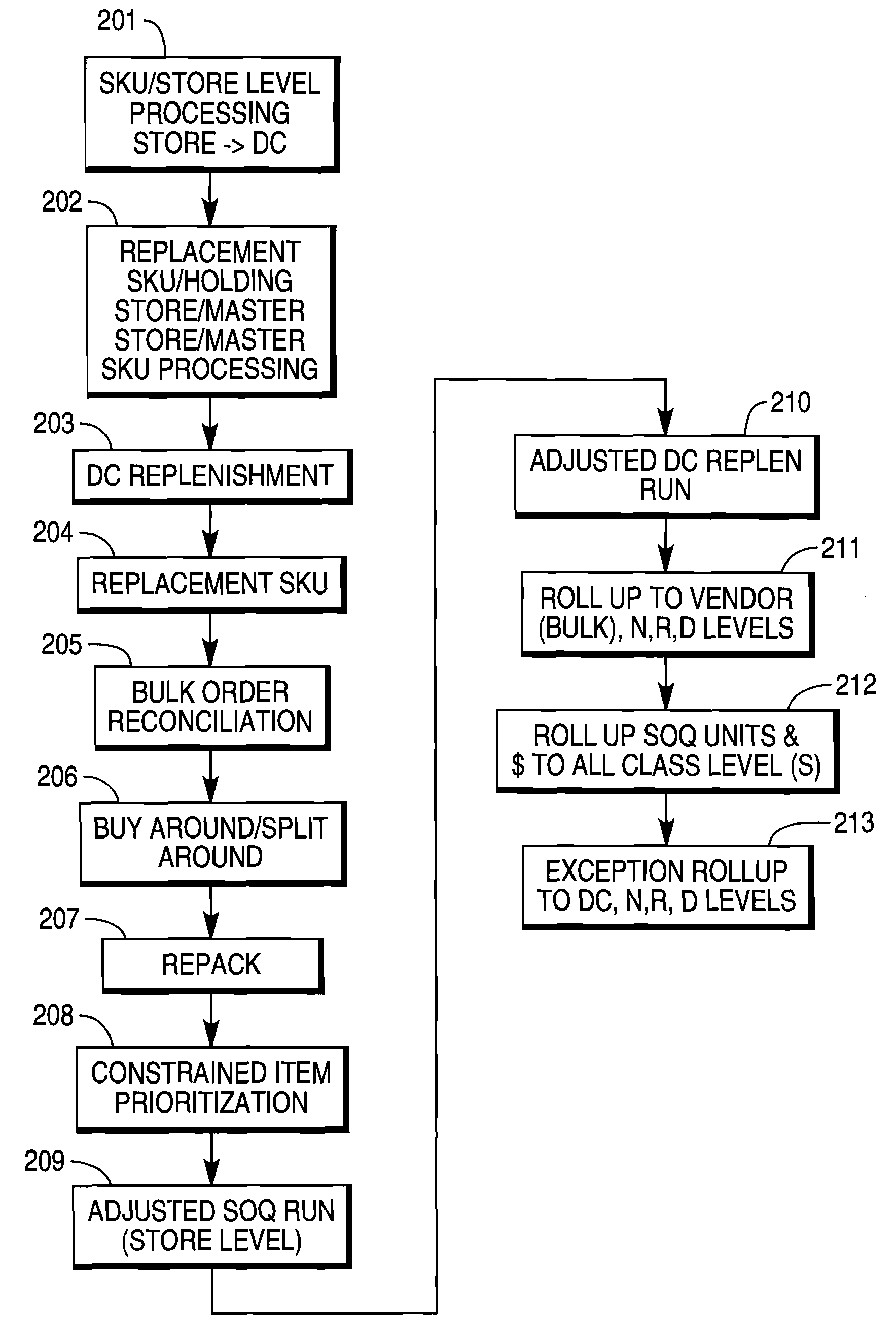

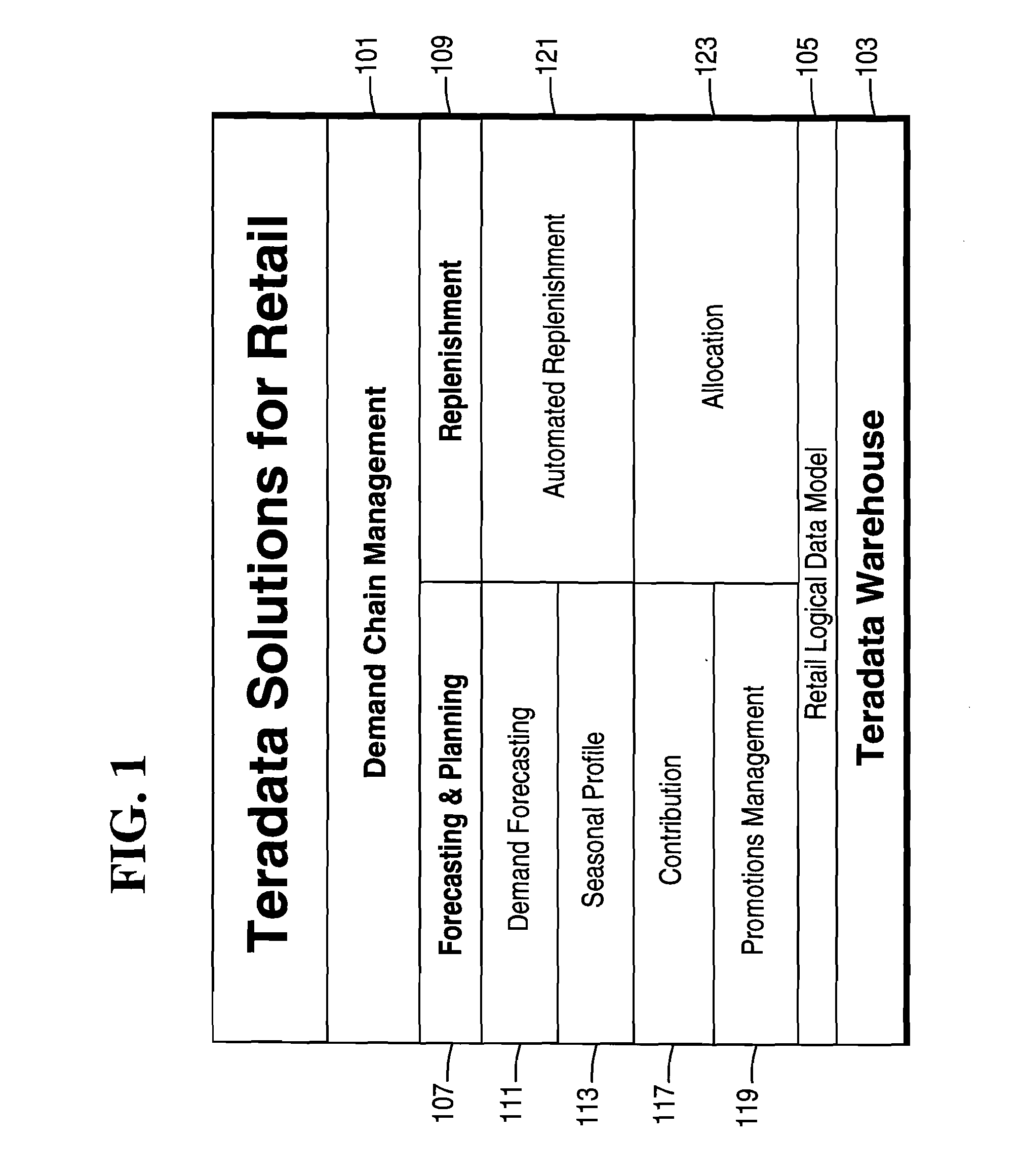

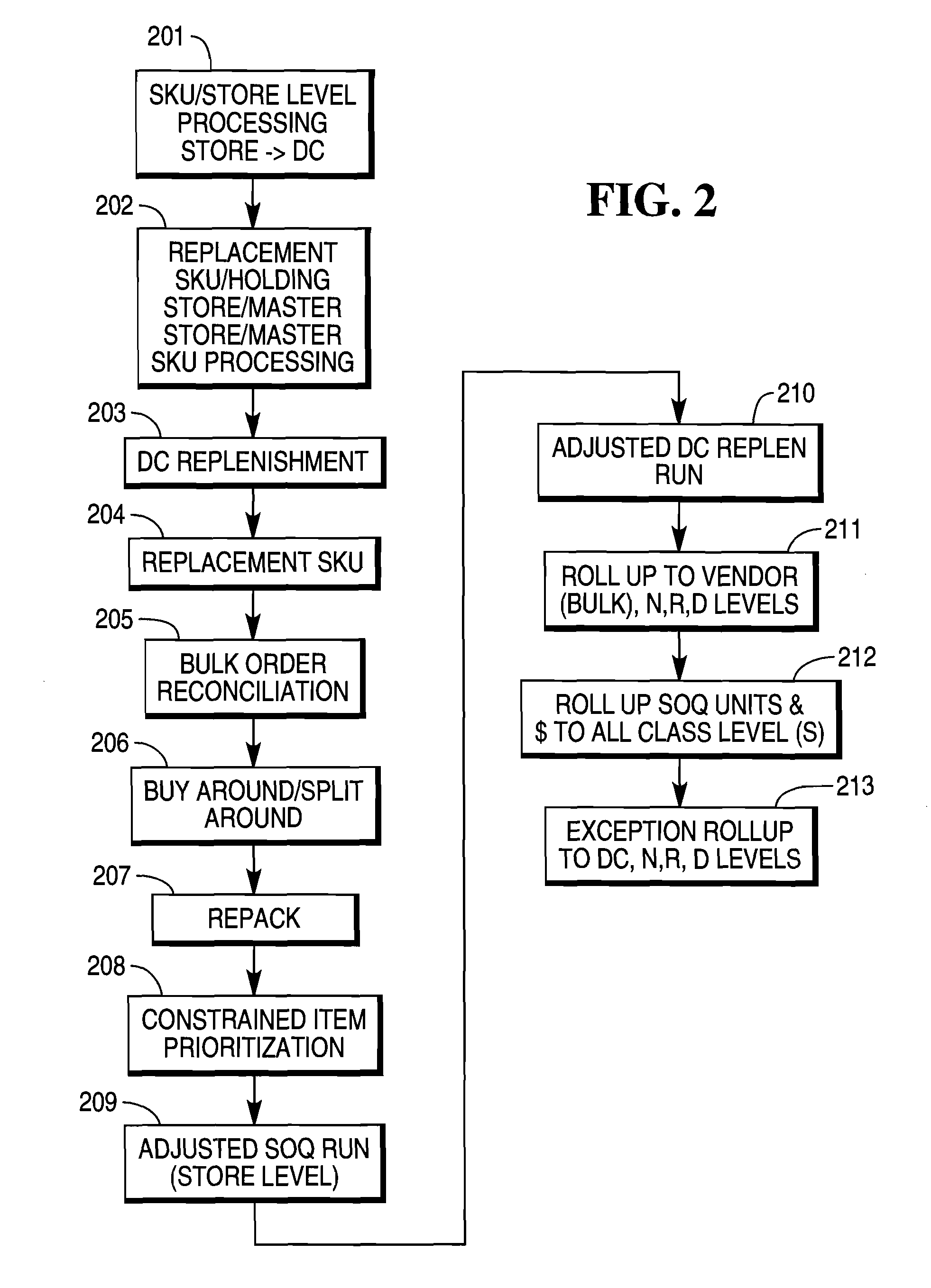

Methods and systems for synchronizing distribution center and warehouse demand forecasts with retail store demand forecasts

A method and system for forecasting product order quantities required to meet future product demands for a retail distribution center or warehouse. The method includes the steps of determining for each one of a plurality of retail stores, a long range order forecast for a product sold by said retail store; accumulating said long range order forecasts for said plurality of retail stores to generate a distribution center demand forecast for said retail distribution center; comparing said distribution center demand forecast with current and projected future inventory levels at said distribution center of said product; and determining from distribution center demand forecast and said current and projected future inventory levels suggested order quantities necessary for maintaining a minimum inventory level sufficient to meet said distribution center demand forecast for said product.

Owner:TERADATA US

Adaptive network-centric online autonomic supply chain management system

InactiveUS7225981B2Speeding up delivery/retrogradeIncrease supplyDigital data processing detailsResourcesOperational costsOperation mode

Owner:KENNETH JONGEBRLOED

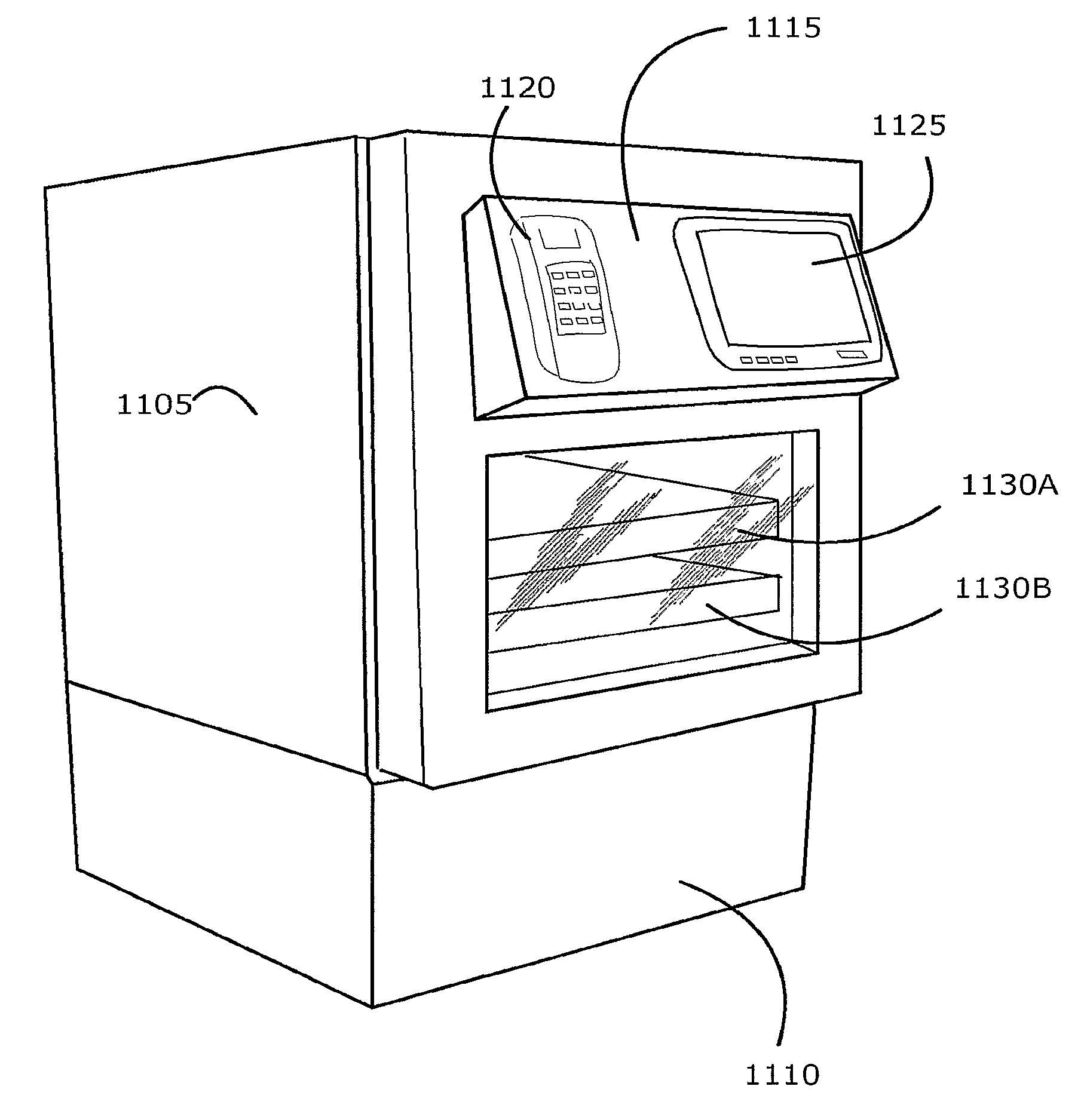

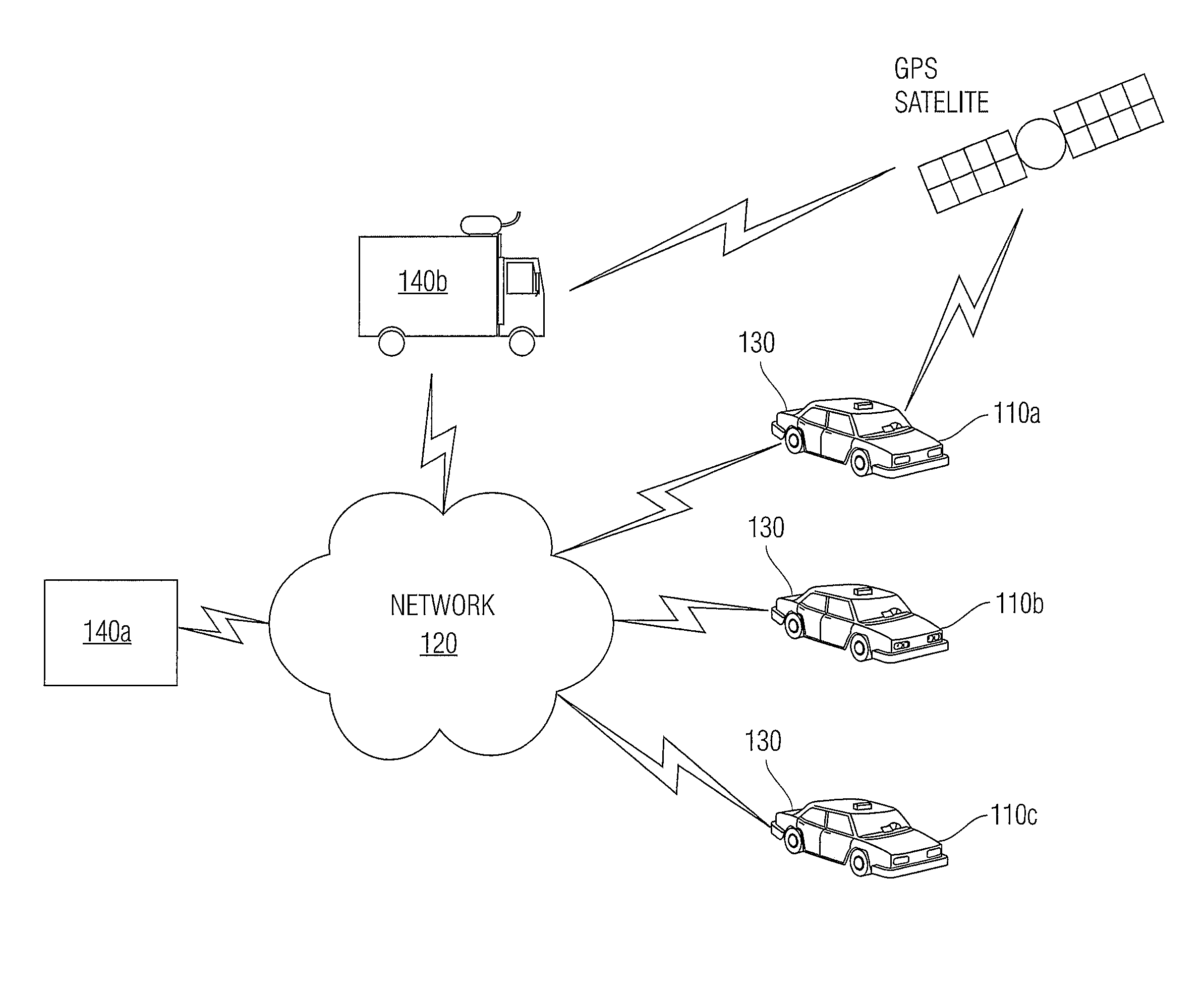

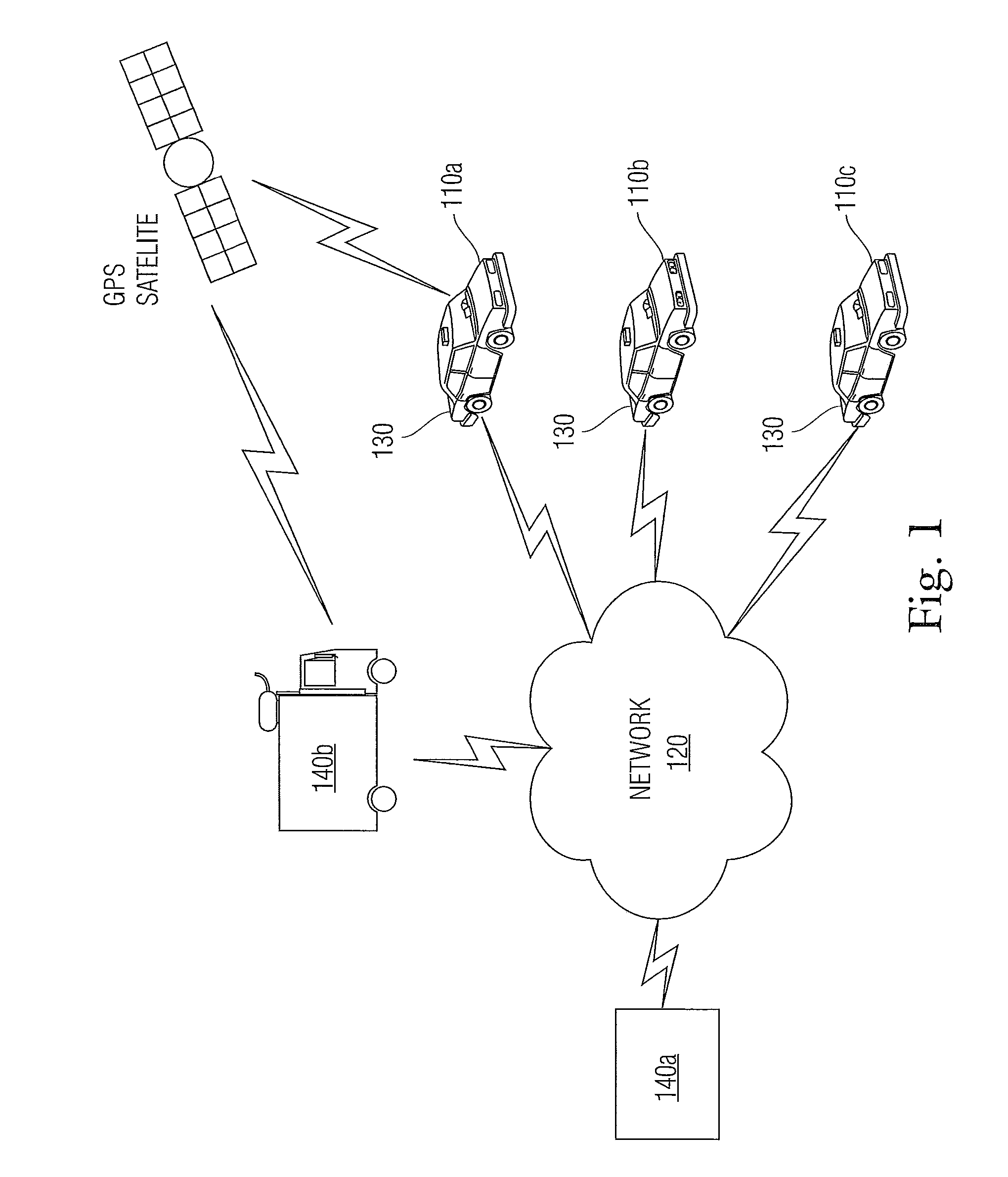

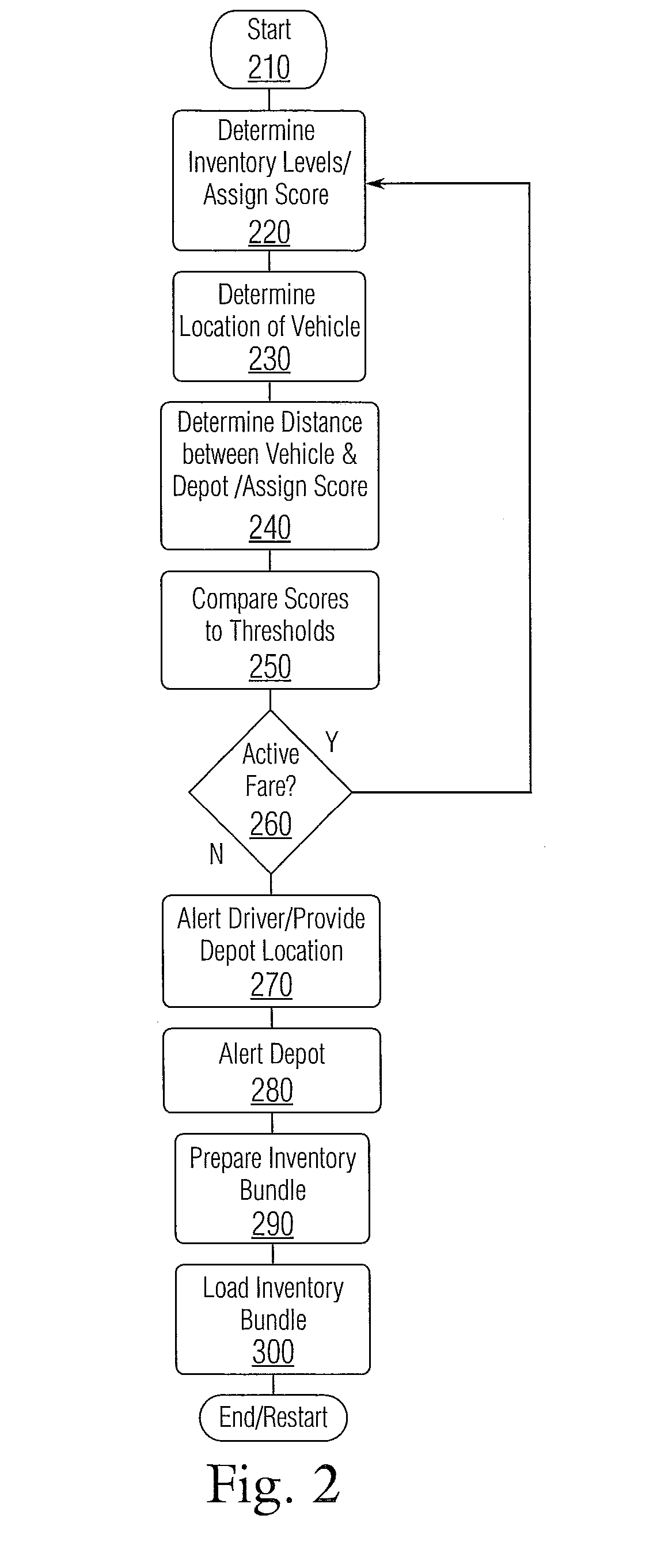

Inventory management system for mobile vending machines

A system and method for managing inventory levels in mobile vending machines is disclosed. Mobile vending machines, such as those located in passenger vehicles for hire, change their location as a result of the passenger vehicle for fire driving to and from passenger destinations. The present system provides for monitoring the inventory levels of the vending machine, the distance from an inventory replenishment depot, and whether or not the vehicle currently has a fare. The system can direct vehicle's driver to proceed to a replenishment depot if the distance and inventory levels are within a threshold and the vehicle does not currently have a fare. The vending machine inventory can be replenished via the use of cartridges preloaded with inventory.

Owner:US VENDICAB CORP

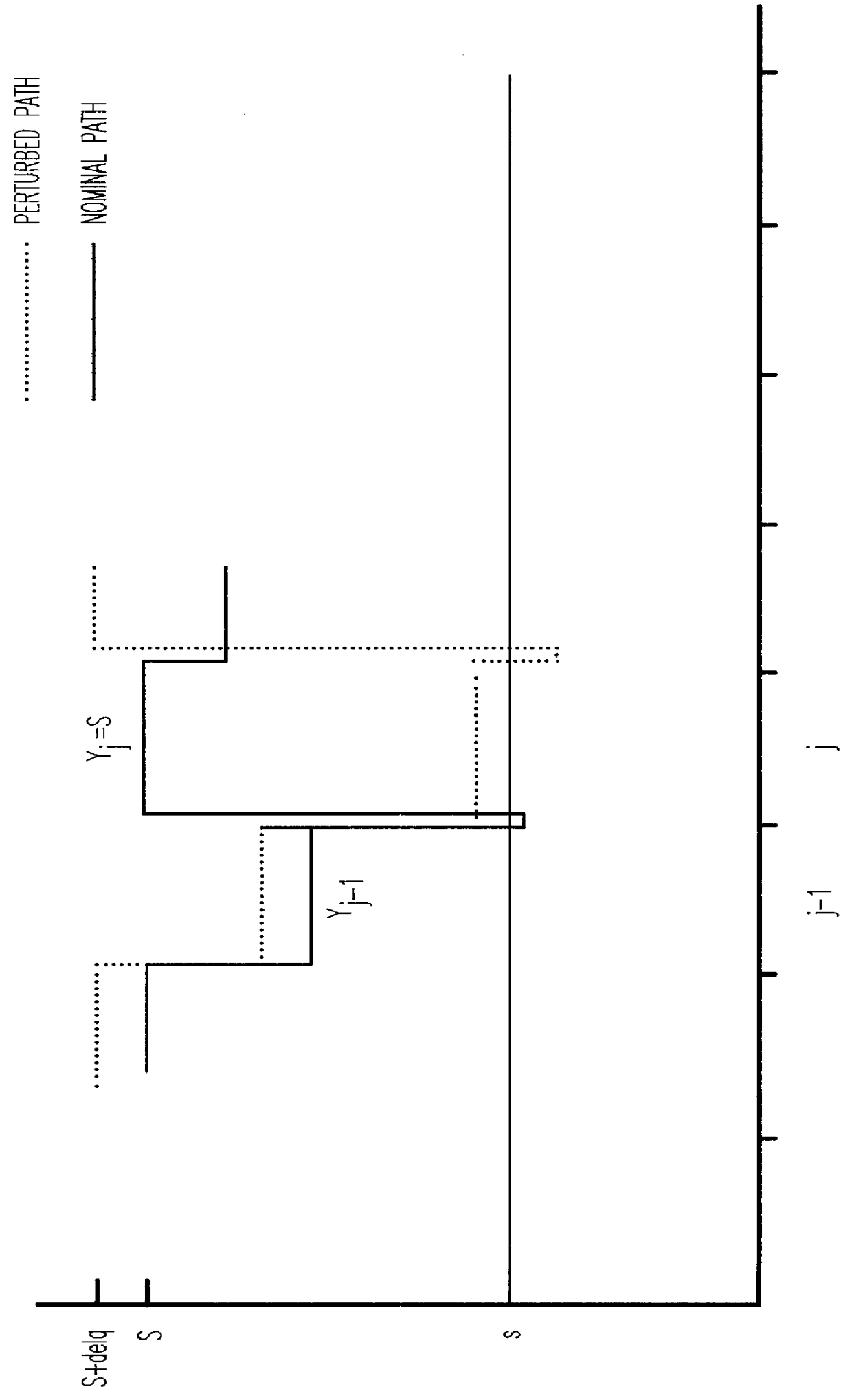

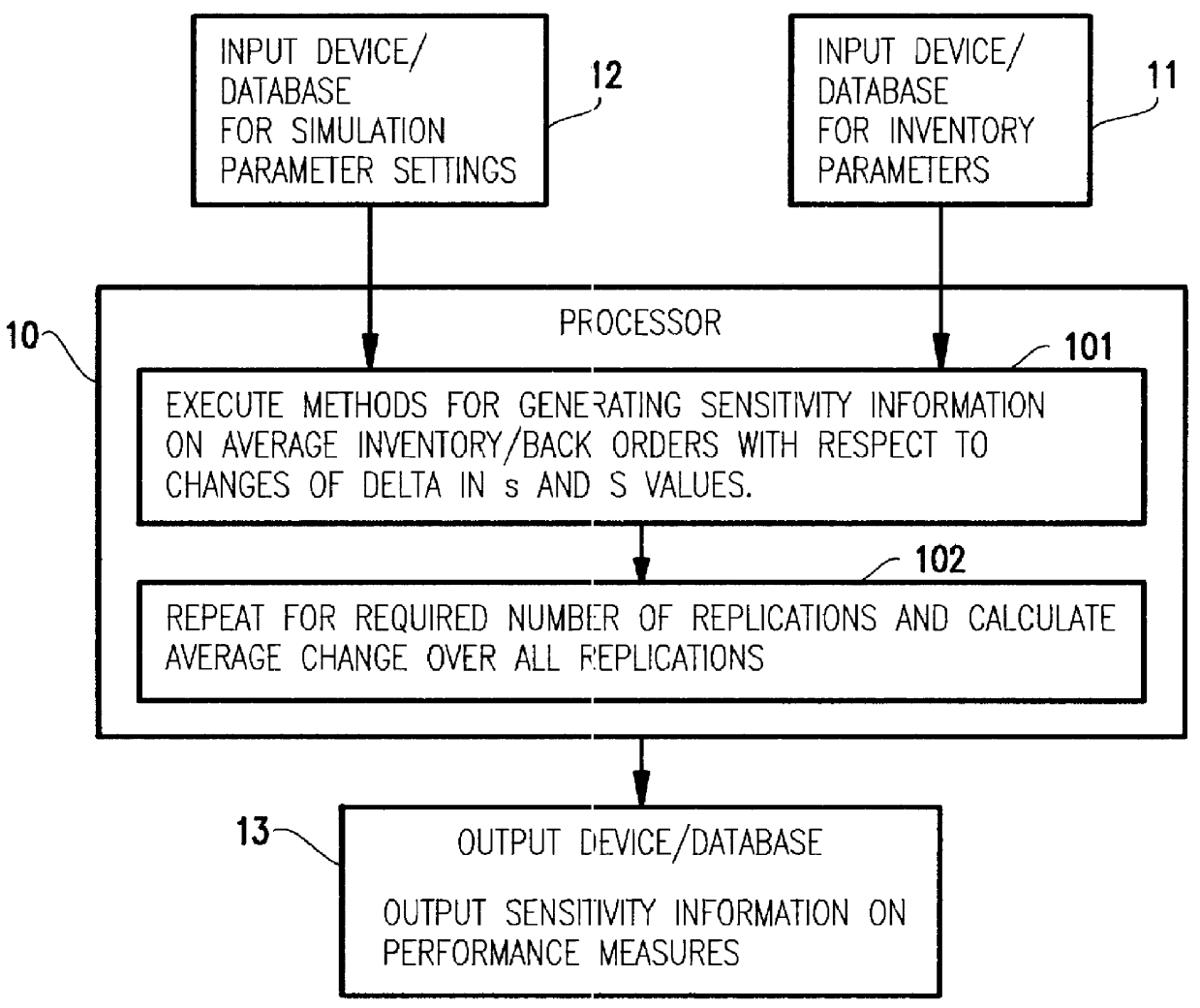

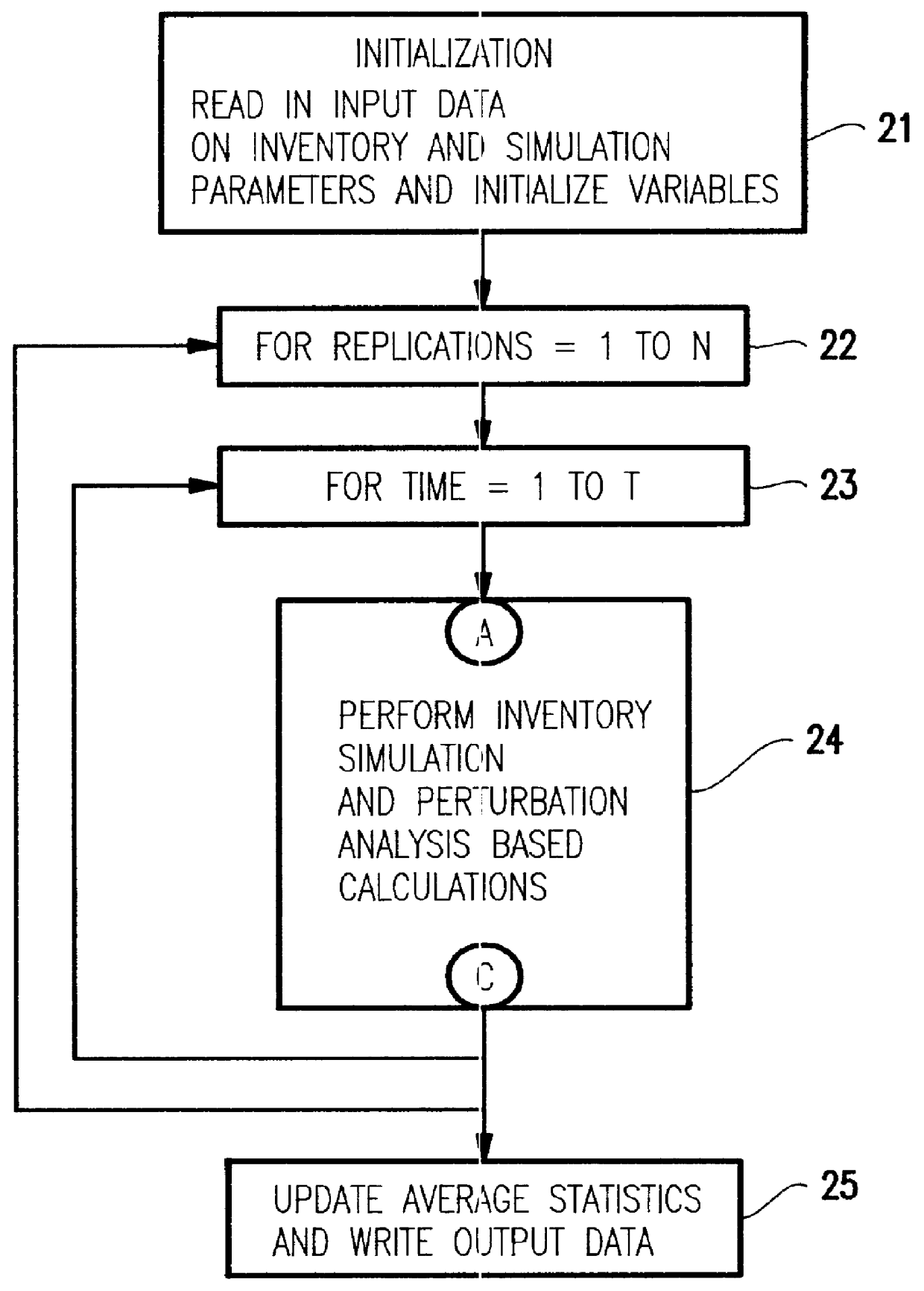

Method to provide sensitivity information for (R,s,S) inventory systems with back-ordered demand

Sensitivity information about the average back-ordered sales and inventory levels of a back-order (R,s,S) inventory system is generated with respect to the two decision variables s and S. This information is used for what-if analysis and optimization of the decision variables s and S. The computer implemented algorithm provides sensitivity of both average inventory levels and average back orders with respect to changes in s and q (where q=S-s), for a back-order inventory simulation for any specified demand distribution. Further, the sensitivity information provided by the algorithm is exact when compared to a finite-difference simulation for the case of both discrete and continuous, stationary and non-stationary demands. A finite difference estimate of the sensitivity is obtained by running two simulations where the parameter in question (s or S) differ by a chosen small number, and then calculating the resulting difference in the performance measure of interest, in this case average inventory and back orders.

Owner:IBM CORP

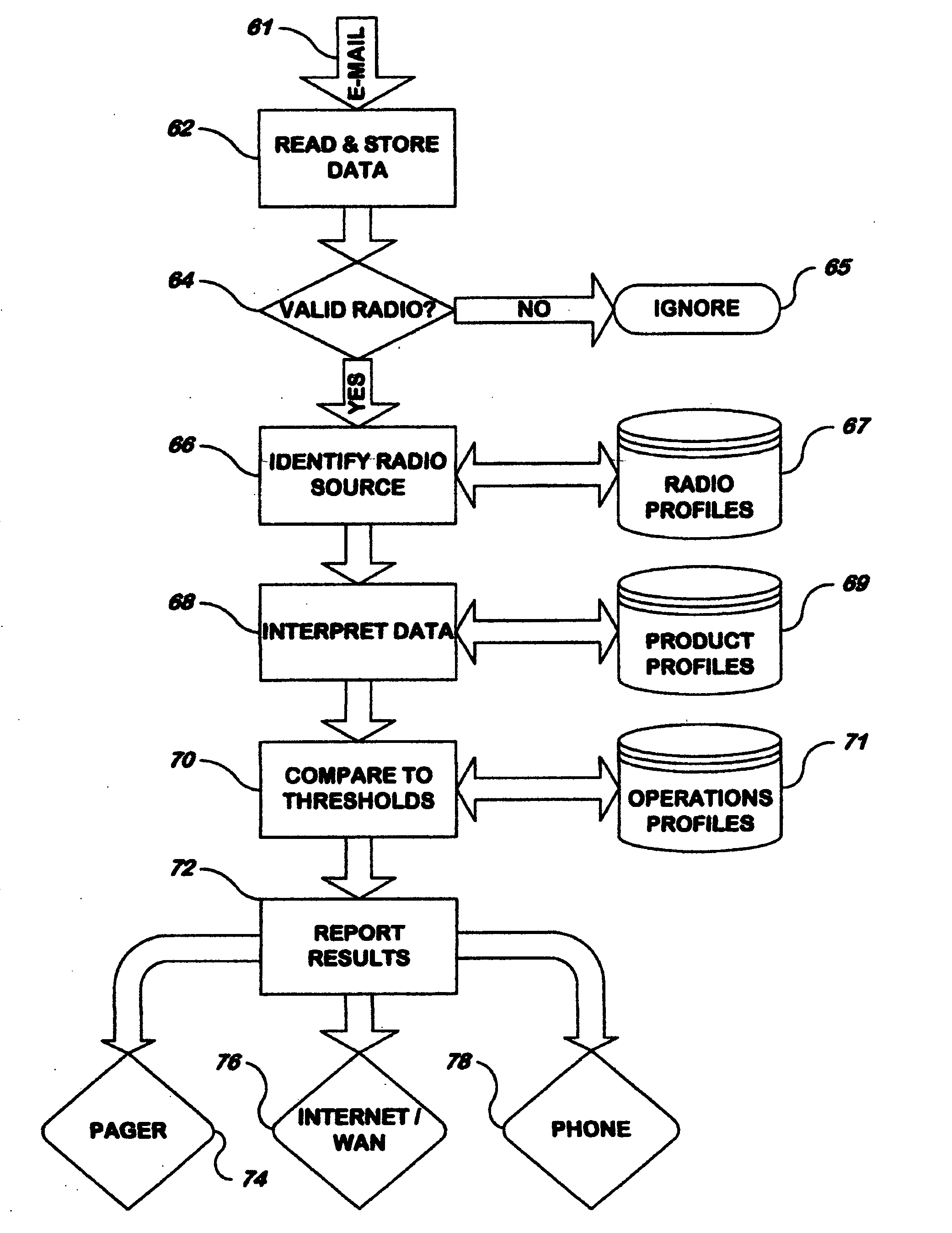

System and method for sensing and analyzing inventory levels and consumer buying habits

InactiveUS20050086133A1Easy to installHighly configurableSpecial data processing applicationsTransceiverEngineering

The invention relates to a system and methods for sensing and analyzing inventory levels and consumer buying habits. The system includes a sensor pad that can be easily installed on a display shelf by simply resting the panel on the shelf. Sensors are mounted inside the sensor pad that are hardwired to circuitry collectively called a smart hub. The hub is a programmable device with an integrated paging transceiver for communicating with a remotely located server that is managed by the inventory sensing service provider. The hub periodically transmits a report, which is highly configurable, to the service provider's server, preferably as a text message over the paging network, which arrives at a service provider's server after being converted to an e-mail. This server converts the information in the reports into inventory data and stores this data in a database that customers of the inventory service can access remotely. The server also generates reports reflecting inventory data and consumer purchasing behavior for the various display racks equipped with a smart hub.

Owner:STAR TECH INNOVATIONS

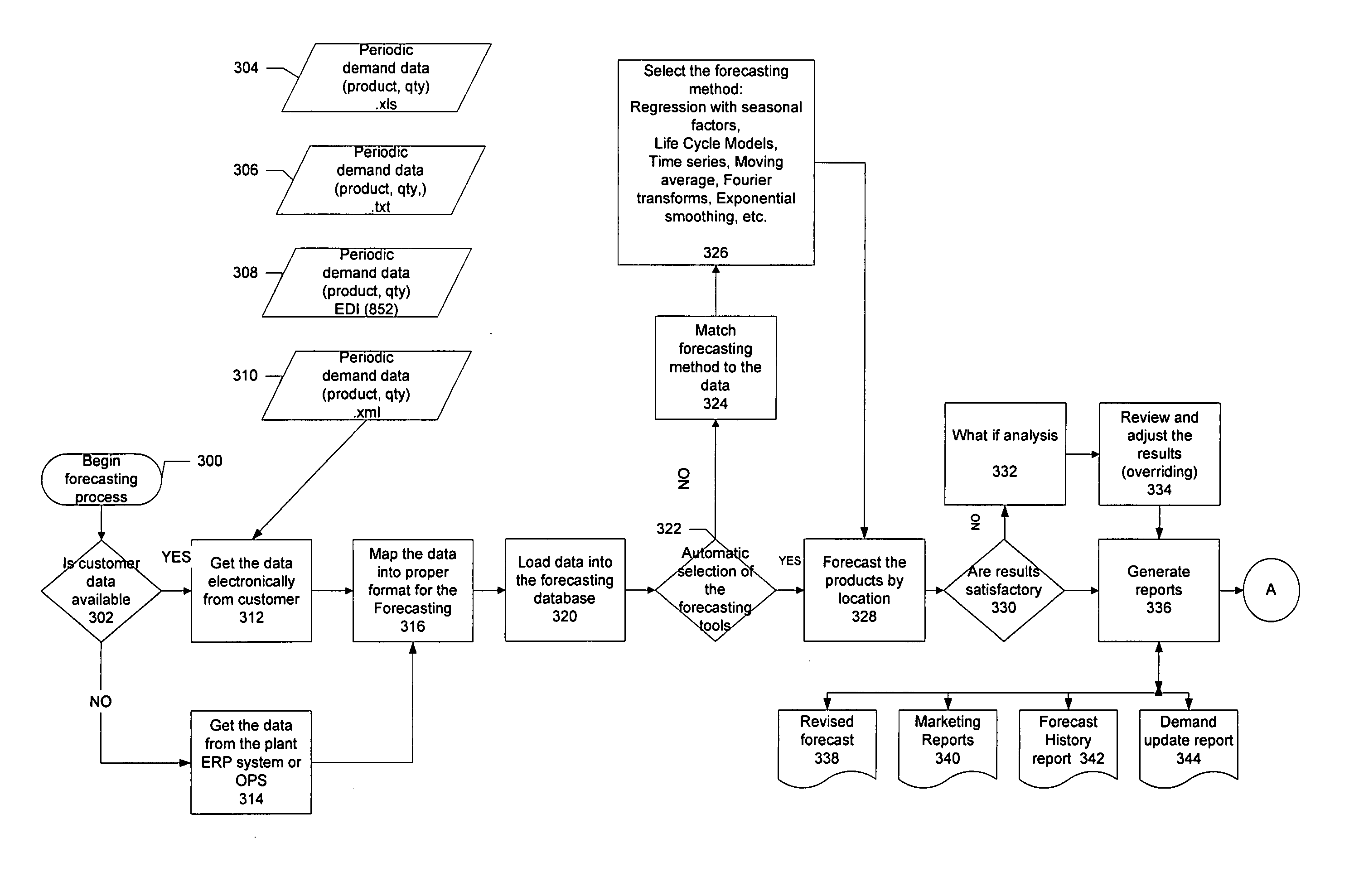

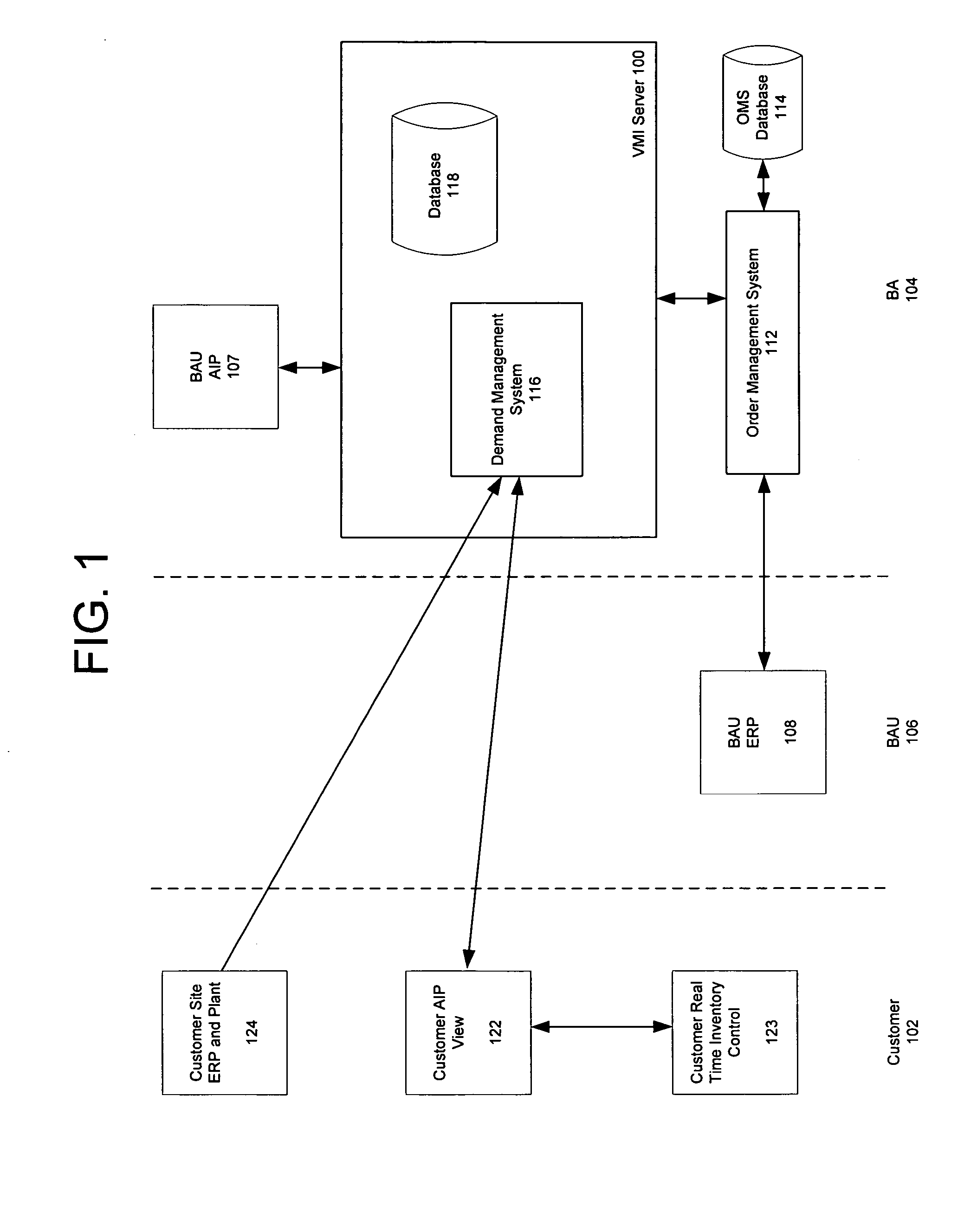

Demand and order-based process flow for vendor managed inventory

Methods of demand and order-based inventory management of a customer facility in a vender managed inventory environment. The methods include receiving and entering a customer purchase order for a product. The order is scheduled and materials are requesting to complete the order. Next, the product is manufactured and shipped to the customer facility. Customer inventory levels are monitored by a vendor to determine if the customer inventory is below a threshold value. If the customer inventory is below the threshold value, a request is sent by the vendor to the customer facility for the issuance of a customer purchase order for additional units of the product to maintain the customer inventory above the threshold level.

Owner:ABB RES LTD

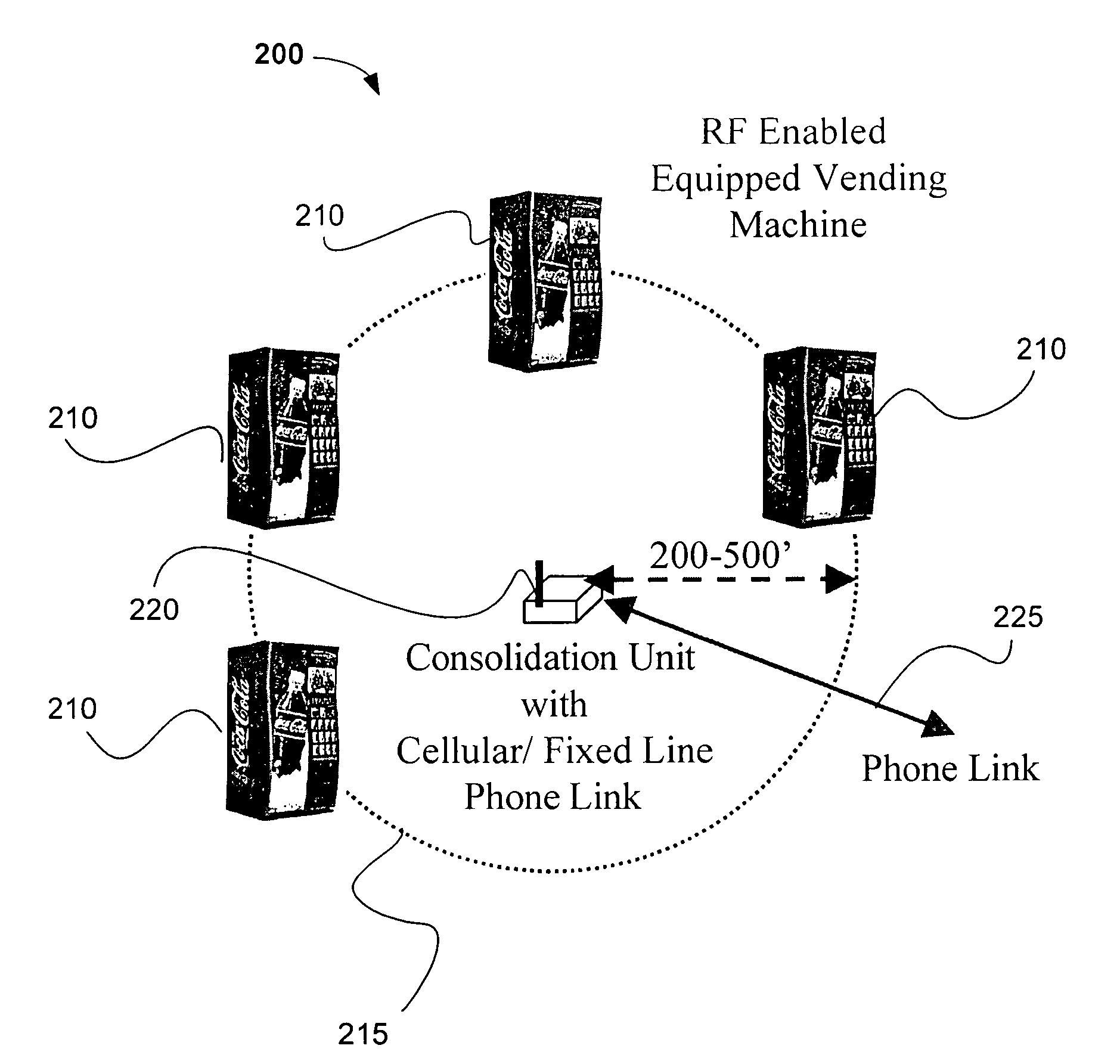

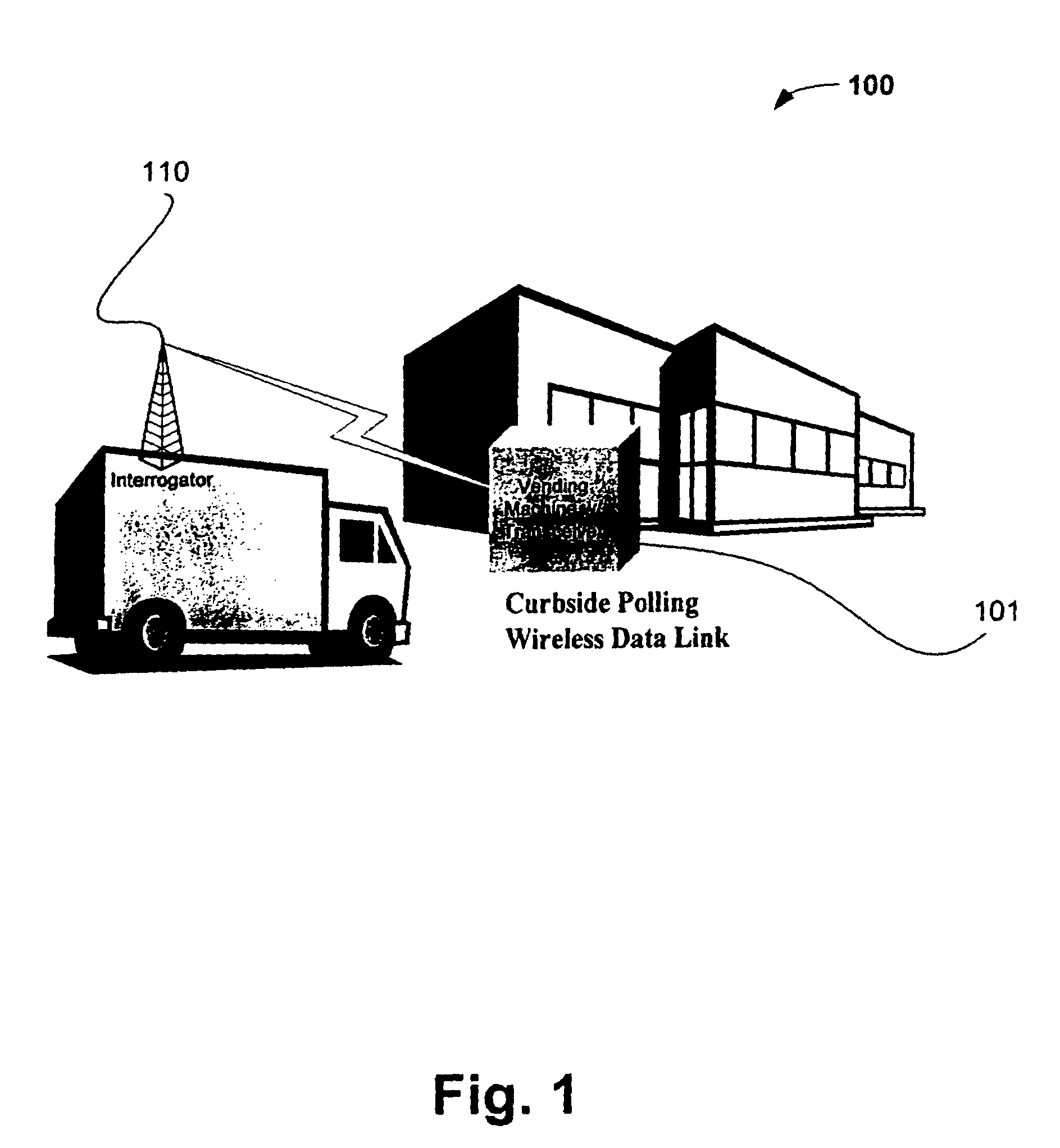

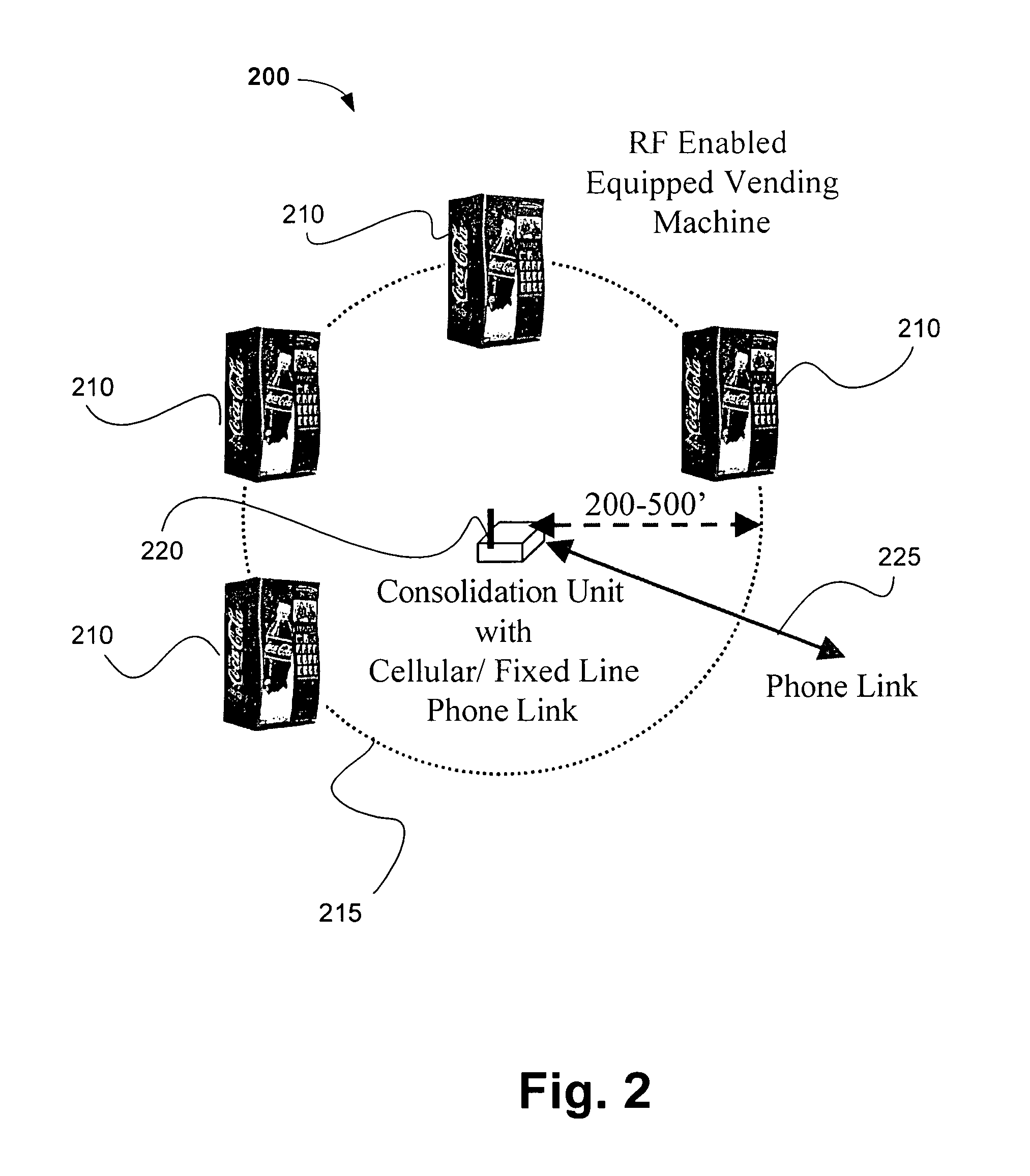

Wireless vending communication systems

InactiveUS7253729B2Coin-freed apparatus detailsRadio/inductive link selection arrangementsWireless mesh networkWireless transceiver

A system includes a plurality of vending machines communicating wirelessly with a centralized consolidation unit. The consolidation unit communicates via a pre-established communications network, such as a wired or wireless telephone network with a data collection center. A method of polling a vending machine having a wireless transceiver includes sending a first wireless signal to the wireless transceiver of the vending machine, the first signal soliciting a status response from the vending machine, and receiving a second wireless signal from the transceiver of the vending machine, the second signal including the status response which includes information pertaining to a status of the vending machine. The status information may pertain to an inventory level, money deposits, maintenance status or security status of the vending machine.

Owner:RF CODE

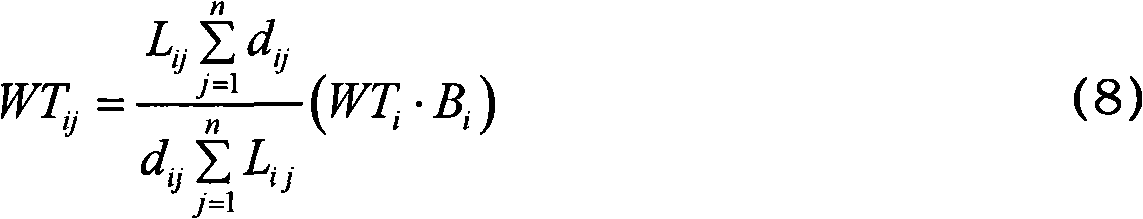

Method for predicting spare part demand in equipment manufacturing process

InactiveCN101853448AEasy to adjustThe calculation result is accurateForecastingMean time to repairPredictive methods

The invention discloses a method for predicting spare part demand in an equipment manufacturing process. The method comprises the following steps of: 1, directly acquiring an achieved availability (Aa) index, mean time between failures (MTBF), mean time to repair (MTTR) and mean preventive maintenance time (MPMT) of equipment; 2, acquiring mean waiting time (WT) of system level spare parts; 3, distributing the WT of the system level spare parts and acquiring waiting time WTi of a subsystem; 4, acquiring the waiting time WTij of each of line replaceable unit (LRU) level products which form the subsystem by a Dephi distribution method; 5, acquiring a spare part out-of-stock expected value EBOij and an inventory level sij of the LRU; and 6, acquiring a spare part fill rate according to the inventory level sij. A quantitative relation between spare part waiting time and equipment availability is established and spare part planning is always performed based on a user demand and a manufacturing requirement. Due to the combination of an equal distribution method and a Dephi method, the method has high flexibility and can be suitable for various stages of engineering development.

Owner:BEIHANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com