Method for predicting spare part demand in equipment manufacturing process

A forecasting method and technology of development process, applied in forecasting, instrumentation, data processing applications, etc., can solve problems such as difficulty in obtaining input data for spare parts forecasting, difficulty in engineering operation of spare parts forecasting method, etc., and achieve simple and easy-to-understand methods with great flexibility , the effect of accurate calculation results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0075] Taking a certain type of aircraft as an example, take the three subsystems of the aircraft, avionics system, power system, and power system, and the LRU of the avionics system is radar, altimeter, and integrated display; the LRU of the power system is the engine, speed control device; the LRU of the power system is the main power supply, auxiliary power supply, and backup power supply.

[0076] Step 1: Obtain the accessibility index A of the aircraft a , mean time between failures MTBF, mean time to repair MTTR and mean time to preventive maintenance MPMT, as shown in Table 4:

[0077] Table 4 Values of aircraft input parameters

[0078] parameter

[0079] Step 2: Obtain the average waiting time WT of system-level spare parts;

[0080] Put the input data in Table 1 into formula (1) to get the average waiting time of aircraft spare parts WT=0.15h.

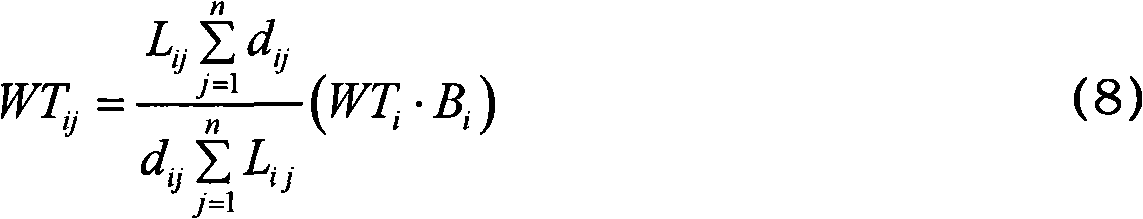

[0081] Step 3: Allocate the average waiting time WT of system-level spare parts, and obtain the average wait...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com