Solder ball positioning and parameter identification method for ball grid array pin chip

A ball grid array and parameter recognition technology, which is applied in image data processing, instrumentation, calculation, etc., can solve the problems of low recognition accuracy, slow recognition speed and poor robustness of BGA chip solder balls

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

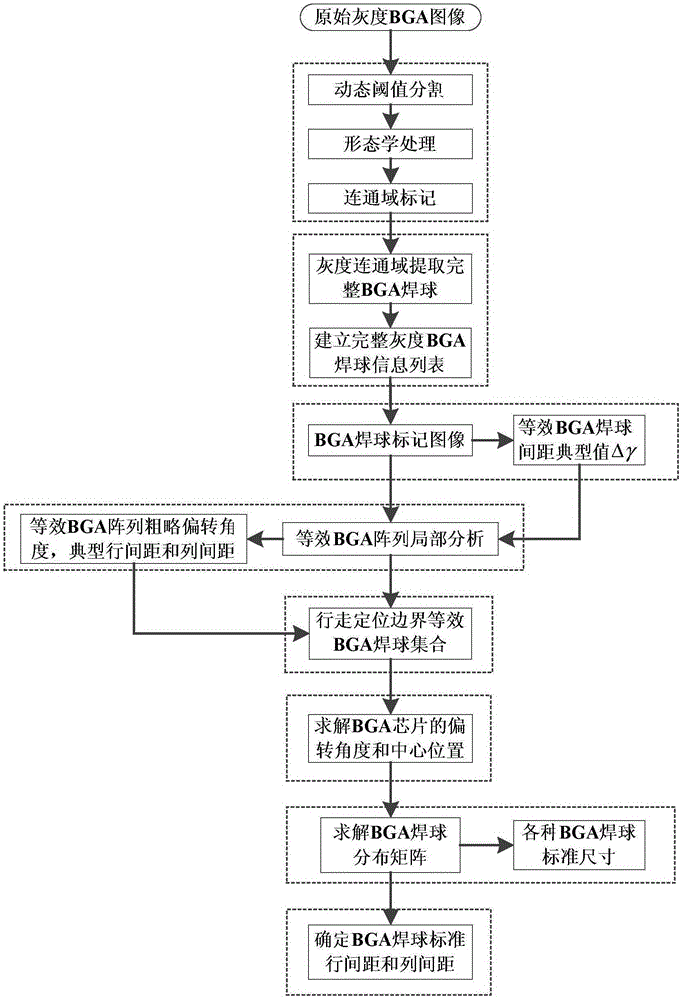

[0048] Specific implementation manner 1: The implementation process of the solder ball positioning and parameter identification method for the ball grid array pin chip described in this embodiment is:

[0049] Step 1: Perform dynamic threshold segmentation on the gray-scale BGA chip image collected by the camera, which is the original image, to obtain a binary solder ball image, and perform morphological opening and closing operations on the binary solder ball image. Each connected domain obtained on the binary solder ball image is recorded as a binary BGA solder ball, and then the connected domain is marked for each binary BGA solder ball;

[0050] Step 2: Perform gray-scale connected domain extraction for each binarized BGA solder ball after the connected domain mark obtained in Step 1 in the corresponding neighborhood on the original image to obtain a complete gray-scale BGA solder ball, and establish a complete gray Degree BGA solder ball information list;

[0051] Among them, t...

specific Embodiment approach 2

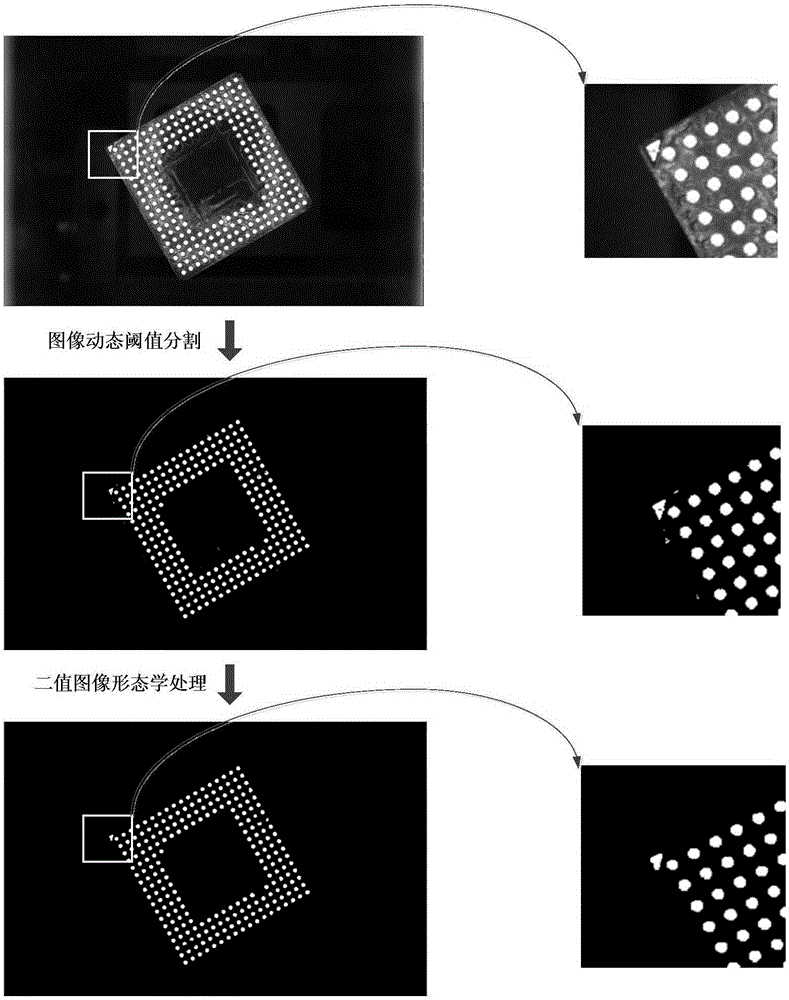

[0059] Specific implementation manner 2: the following combination figure 2 To illustrate this specific embodiment, this embodiment is a further description of specific embodiment 1. In the steps, the gray-scale BGA chip image collected by a pair of cameras is the original image, and the binary solder ball image is obtained by dynamic threshold segmentation. These operations The specific expression is as follows:

[0060] Among them, the gray-scale BGA chip image undergoes dynamic threshold segmentation to obtain the binary solder ball image I(x,y), which is represented by the following mathematical expression:

[0061] I ( x , y ) = 1 f ( x , y ) ≥ g ( x , y ) + C 0 f ( x , y ) g ( x , y ) + C

[0062] Among them, f(x, y) gray-scale BGA image is the original image; g(x, y) is the image after f(x, y) is average filtered. C is considered to be a constant.

[0063] Compared ...

specific Embodiment approach 3

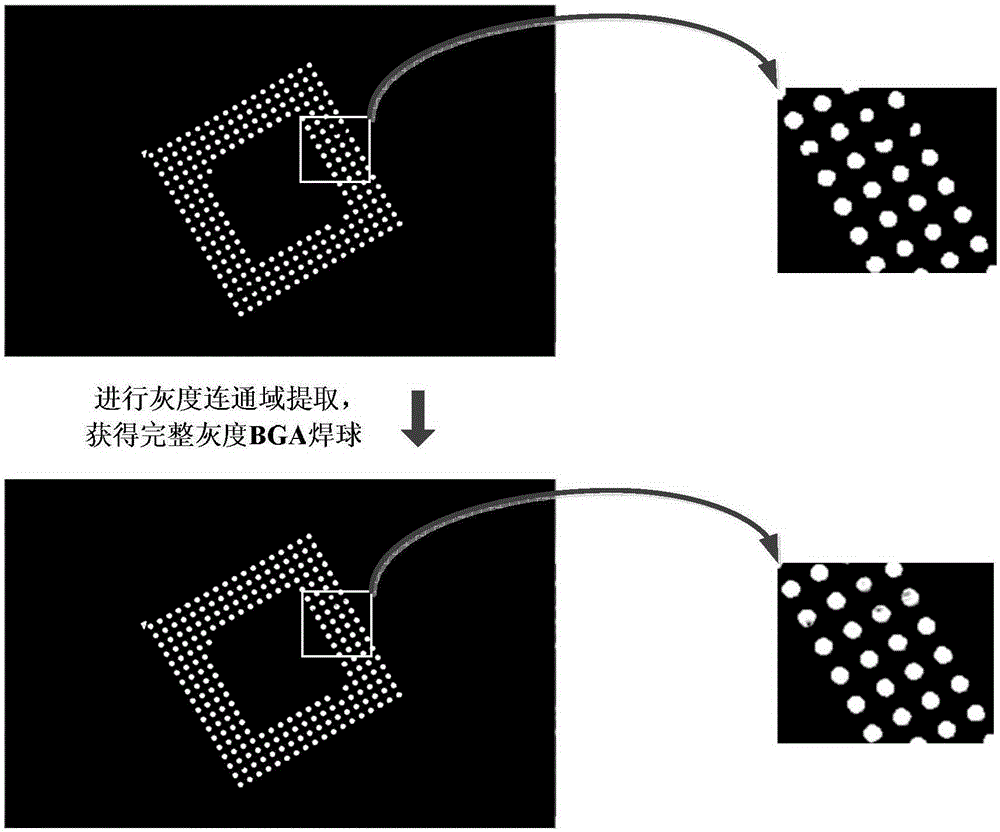

[0064] Specific implementation manner three: the following combination image 3 This specific embodiment is described. This embodiment is a further description of specific embodiment 1. In step 2, each binarized BGA solder ball obtained in step 1 after being marked with connected domains is within the corresponding neighborhood on the original image Perform gray-scale connected domain extraction to obtain complete gray-scale BGA solder balls, and establish a complete gray-scale BGA solder ball information list, and establish a complete gray-scale BGA solder ball information list. The content includes: the gray contained in each complete gray-scale BGA solder ball Degree pixels, and the center point coordinates of each complete gray-scale BGA solder ball calculated from gray-scale pixels, the smallest outer circle diameter corresponding to each complete gray-scale BGA solder ball, the circumference of each complete gray-scale BGA solder ball, and Roundness; among them, the pixel ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com