Chemical process fault detection method based on sparse filtering and logic regression

A logistic regression, chemical process technology, applied in electrical testing/monitoring and other directions, can solve problems such as poor generalization ability, complex modeling, and difficult industrial processes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

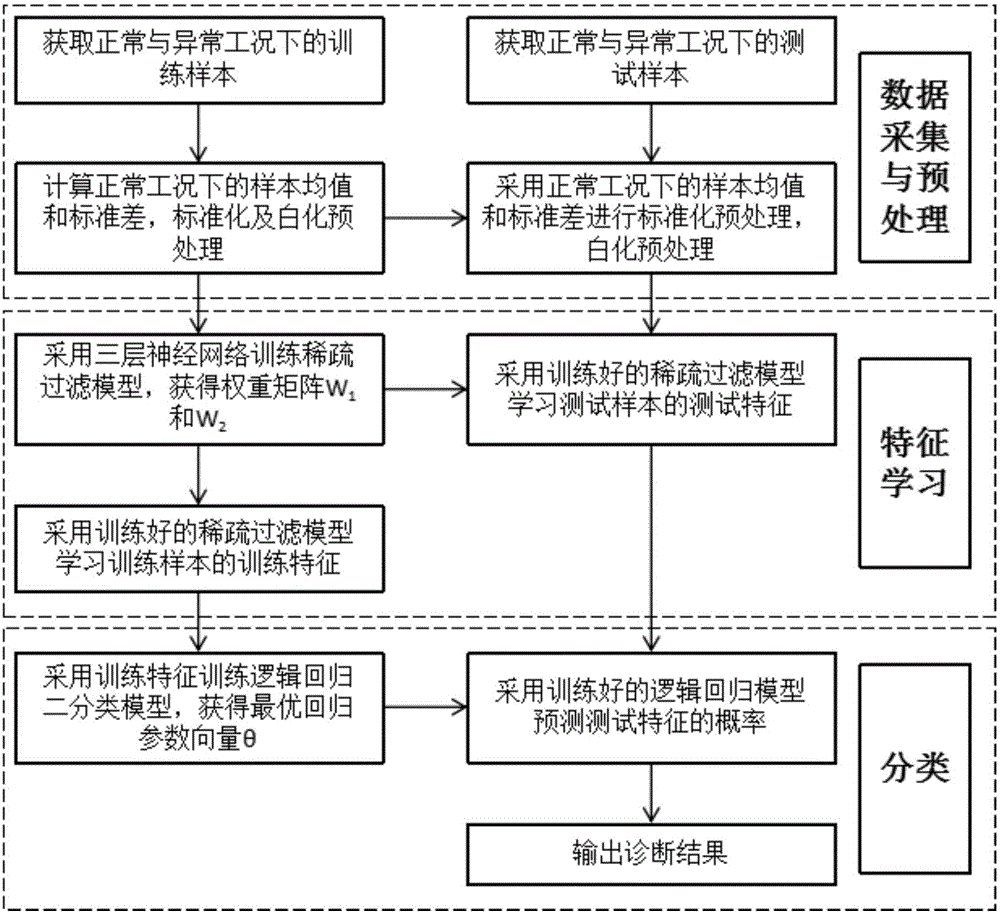

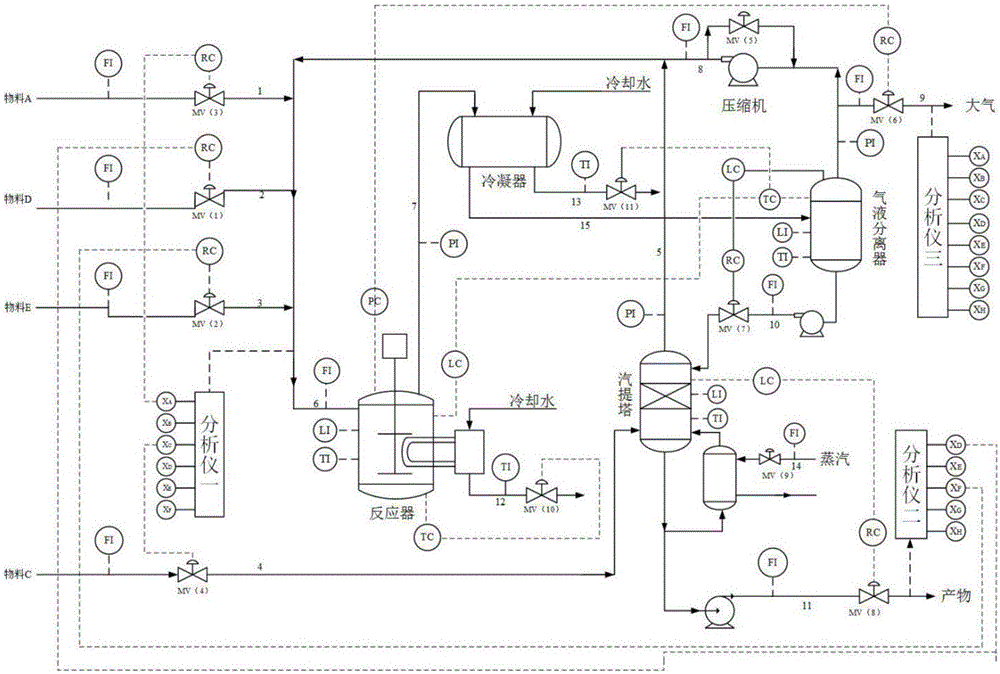

[0073] This embodiment provides a chemical process fault detection method based on sparse filtering and logistic regression, the flow chart of the method is as follows figure 1 As shown, the method proposed in this embodiment is applied to the Tennessee-Eastman (TE) chemical process to further illustrate the method of this embodiment, and the TE process was published in 1993 by Downs and Vogel of Eastman Chemical Company in the United States The computer simulation of the actual chemical process of Eastman Company, which was later mainly developed to evaluate the performance of process control technology and process monitoring methods, the process flow chart of the process is as follows figure 2 shown. The TE process mainly includes five operating units, namely: reactor, condenser, vapor-liquid separator, cycle compressor, and stripper. In the simulated data, a total of 41 observed variables were monitored, including 22 continuous process variables and 19 component variables...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com