Intelligent spinning packaging production line fault detection system

A technology for fault detection and intelligent spinning, applied in the field of fault detection systems for intelligent spinning and packaging production lines, can solve problems such as difficulty in fault detection, affecting the overall operation of packaging production lines, and being easily affected, so as to reduce the impact of product quality and improve failures. The detection rate and the effect of ensuring the quality of packaging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

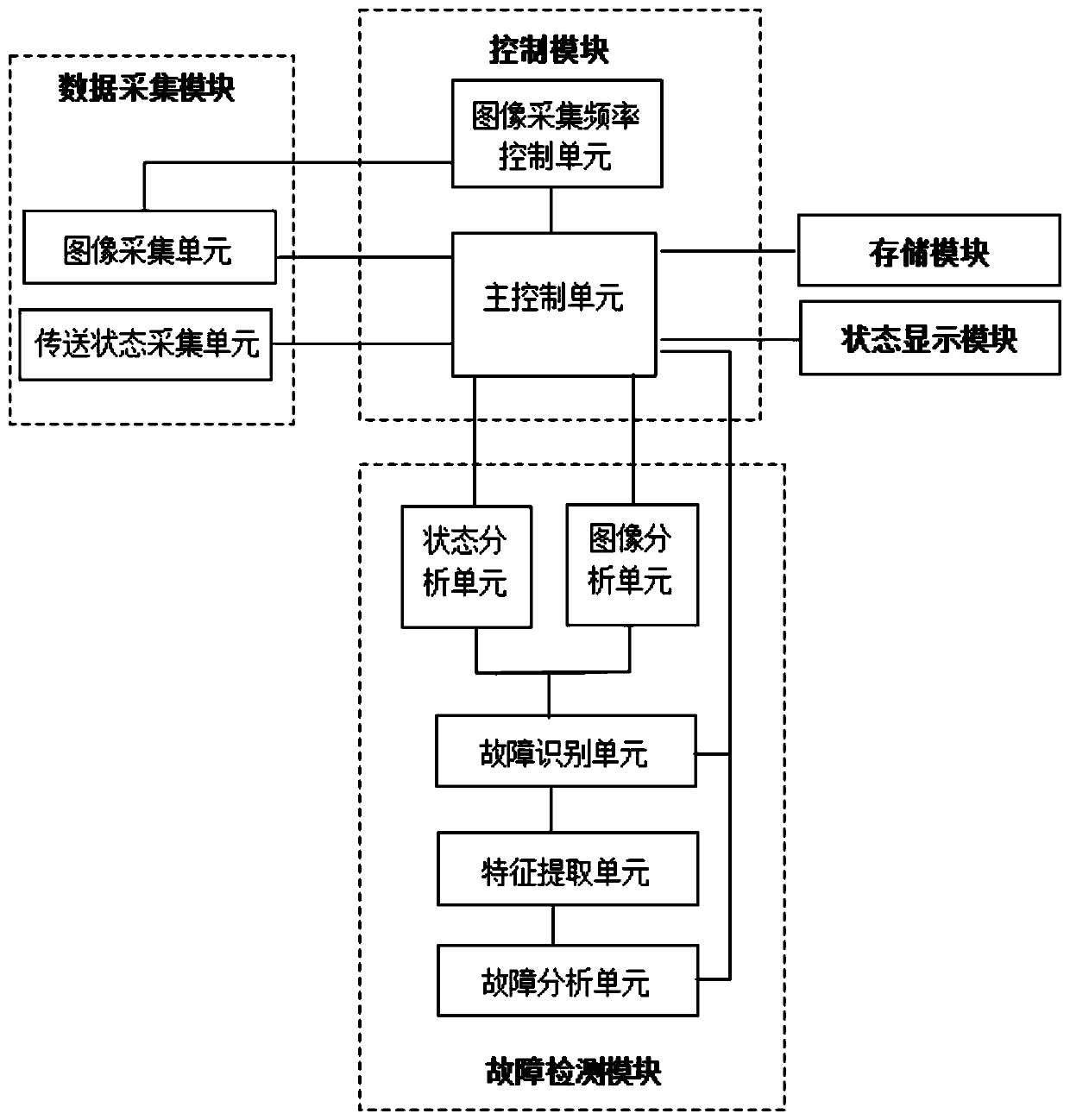

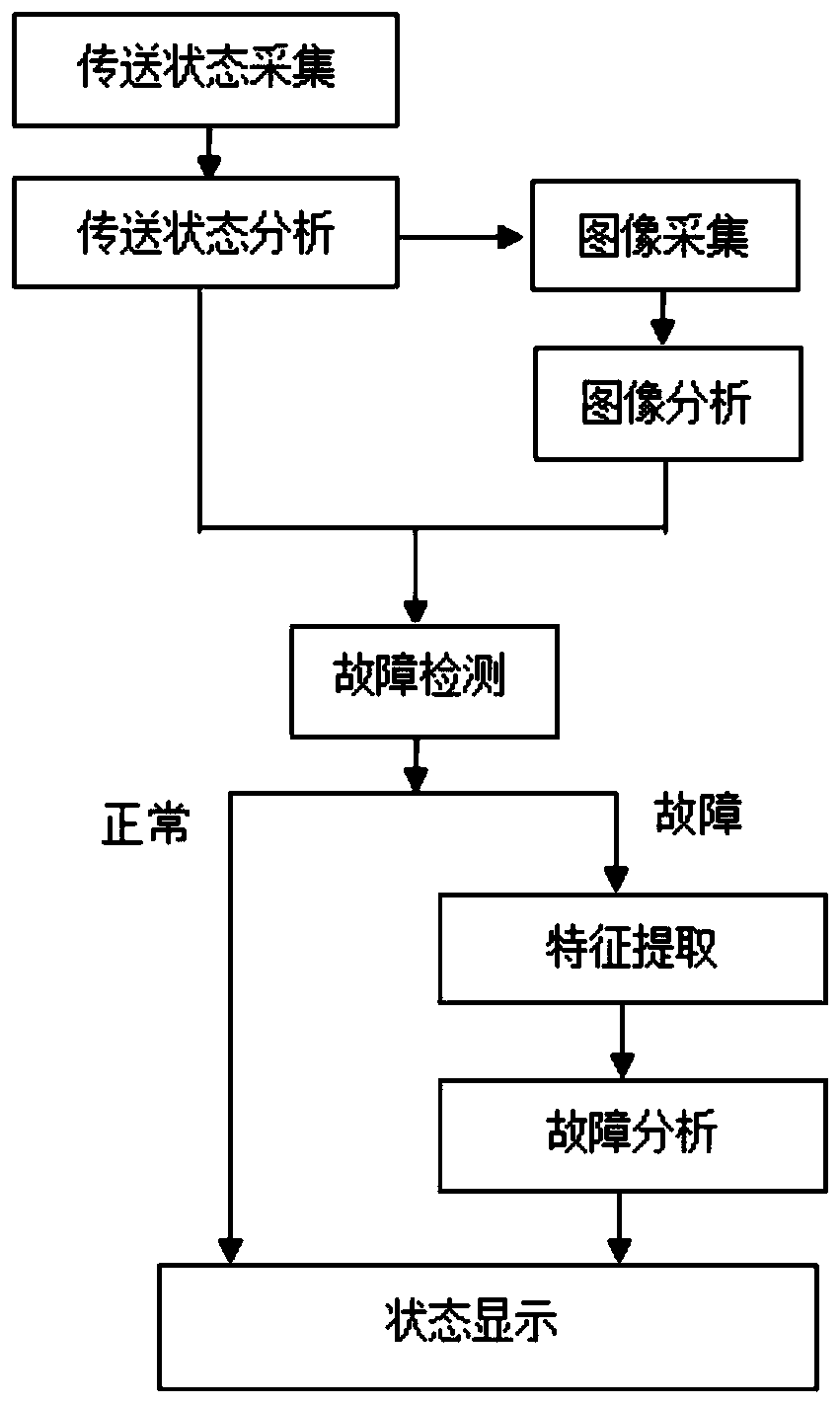

[0025] see figure 1 , this embodiment provides a fault detection system for an intelligent spinning and packaging production line, including a data acquisition module, a control module, a fault detection module, a storage module, a status display module, and an information transmission module, and the control module passes through the information transmission module Connect with the data collection module, the fault detection module, the storage module and the status display module respectively; the data collection module includes a transmission status collection unit and an image collection unit, which are respectively used to collect the transmission status of each bobbin in real time and carry out a single Images before and after yarn packaging; the fault detection module is used to analyze the information collected by the data acquisition module, detect whether a fault occurs and analyze the cause of the fault; the storage module is used to store historical data and each mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com