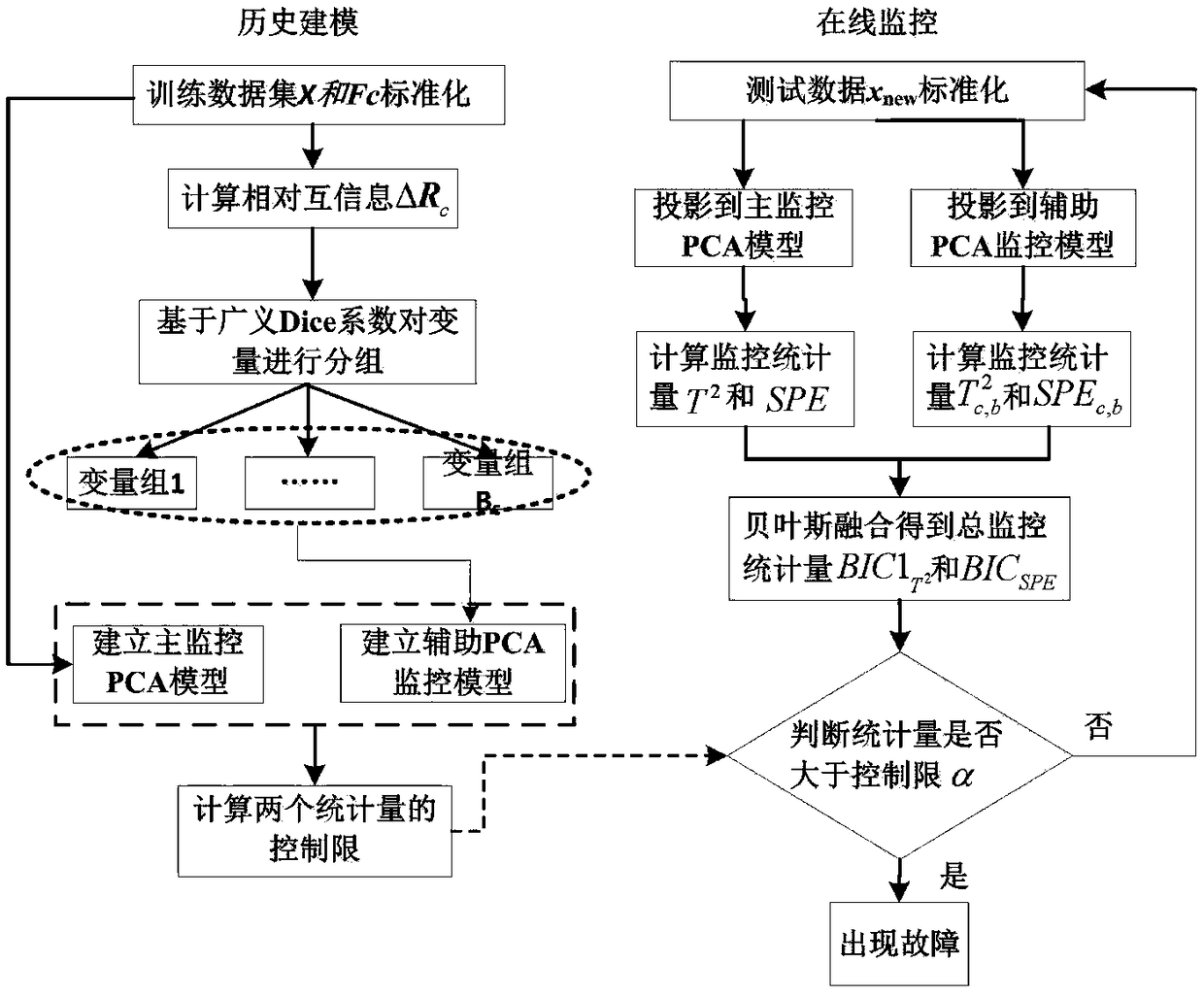

Multi-variable industrial process fault detection method based on primary assisted PCA model

An industrial process, fault detection technology, applied in program control, electrical testing/monitoring, testing/monitoring control systems, etc., to solve problems such as low fault detection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

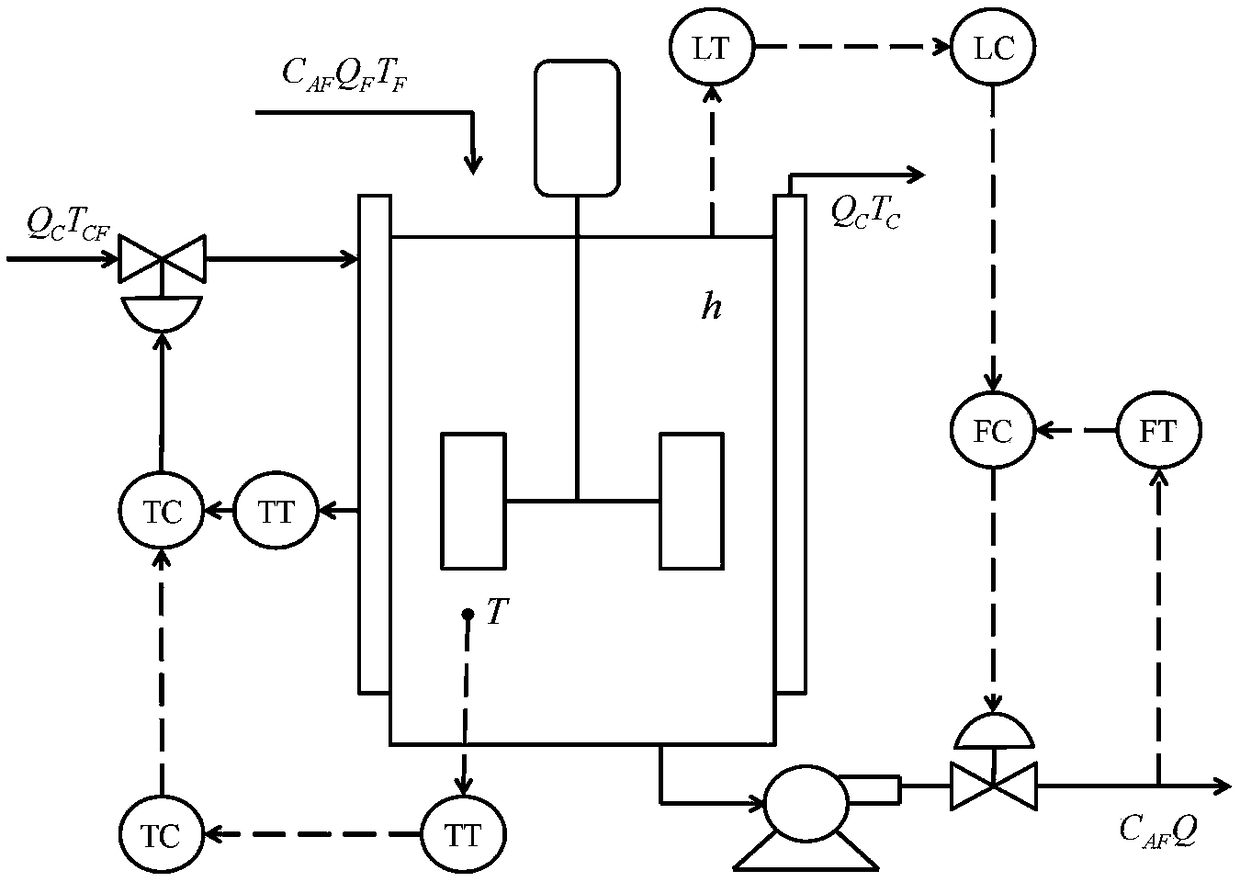

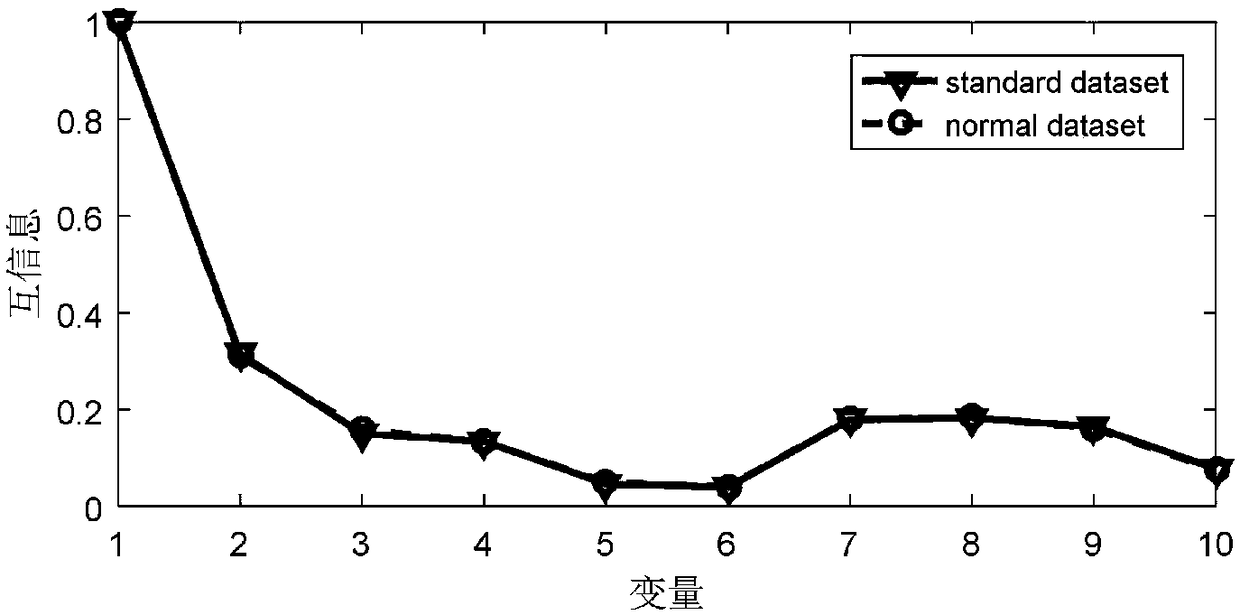

[0133] Example: Continuous Stirring Reactor (abbreviation: CSTR) control system, as a type of chemical reactor, has the advantages of low cost, strong heat exchange capacity and stable product quality, and is widely used in industrial process reactions. During the reaction, reactant A undergoes a first-order irreversible exothermic reaction in the reactor, and simultaneously produces substance B. 10 variables are measured in the CSTR control system, including 4 state variables and 6 input variables. See Table 1 for details of the variables.

[0134] Table 1

[0135] variable

illustrate

C a

The concentration of reactant A when it flows out of the reactor

T

Reactor temperature

T c

The temperature of the coolant at the outlet of the jacket

h

Reactor liquid level height

Q

The concentration of the effluent from the reactor

Q c

The flow rate of coolant in the jacket

Q f

Feed A flow rate

C a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com