Switching power supply with testability function and testing method thereof

A switching power supply and function technology, applied in the field of power supply, can solve the problems of switching power supply not being testable, complicated manual test process, difficult maintenance and support, etc., to achieve the effect of improving the failure detection rate, reducing the difficulty of testing, and improving the life cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

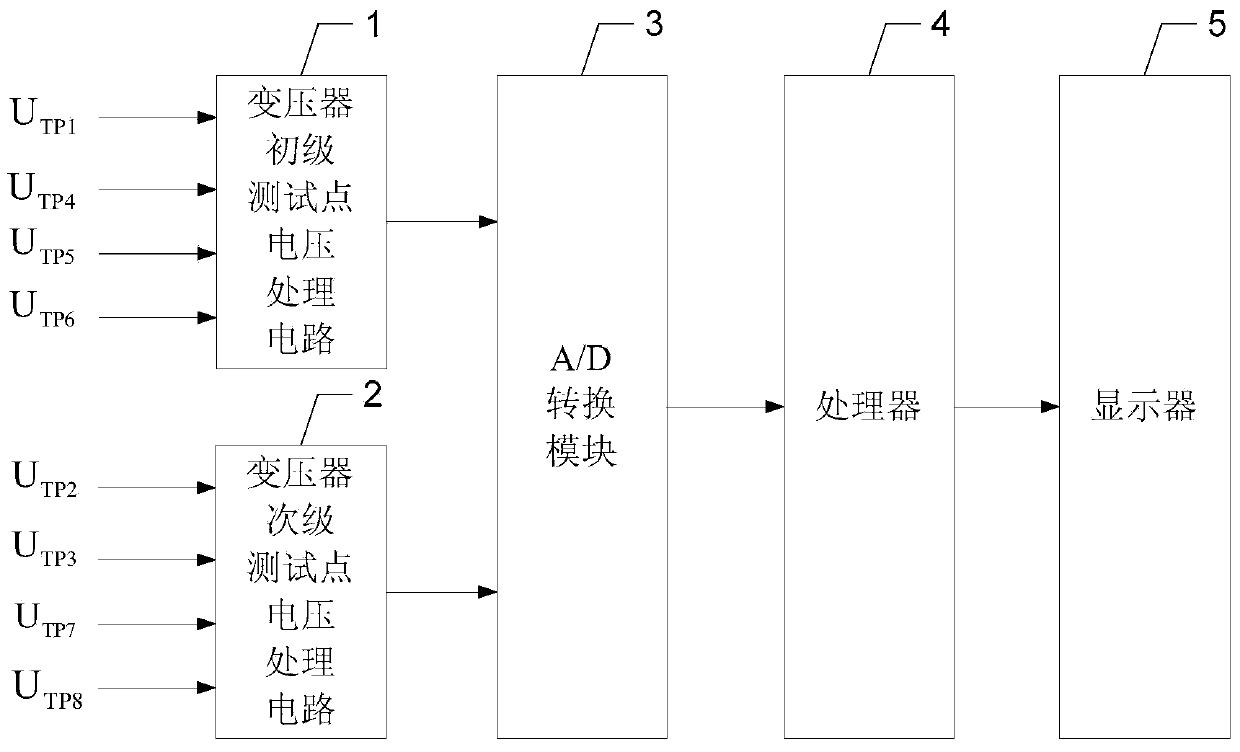

[0097] Specific implementation mode one: the following combination figure 1 , Figure 4 to Figure 7 Describe this embodiment, the switching power supply with testability function described in this embodiment, it includes auxiliary power supply, main power supply and test point voltage monitoring part, select test points TP1, TP2 and TP3 from the auxiliary power supply, from the main power supply Select the test points TP3, TP4, TP5, TP6, TP7 and TP8, the auxiliary power supply and the main power supply both include the transformer, where the test points TP1, TP4, TP5 and TP6 are taken from the primary side of the transformer, and TP2, TP3, TP7 and TP8 are taken from the The secondary side of the transformer; the voltage values of the eight voltage monitoring points are U TP1 , U TP2 , U TP3 , U TP4 , U TP5 , U TP6 , U TP7 and U TP8 ; and is collected and processed by the voltage monitoring department of the test point;

[0098] The test point voltage monitoring part...

specific Embodiment approach 2

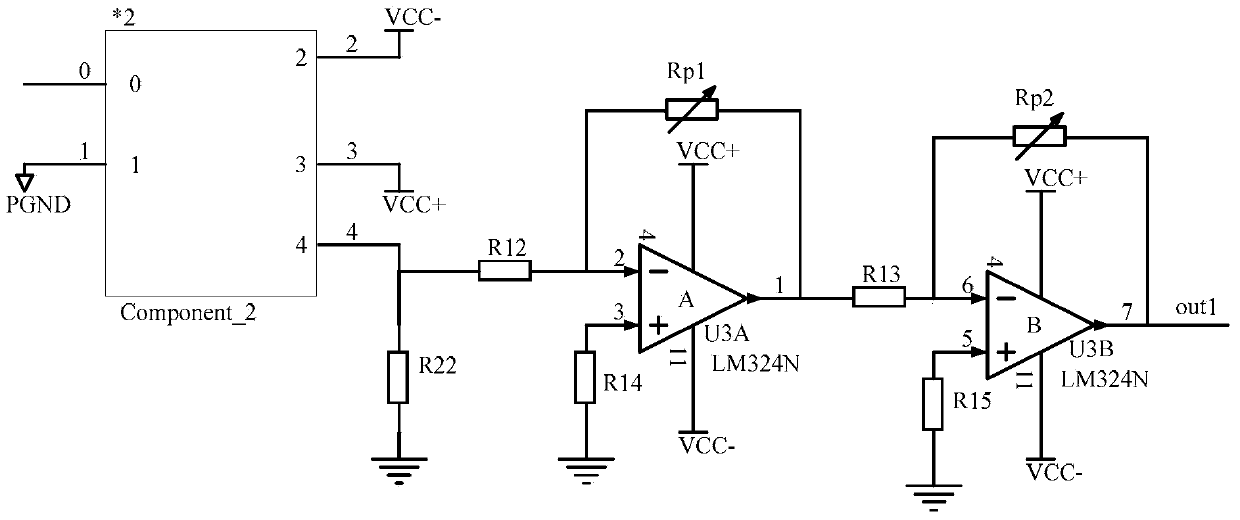

[0140] Specific implementation mode two: the following combination figure 2 Describe this embodiment, this embodiment will further explain the first embodiment, the transformer primary test point voltage processing circuit 1 includes a Hall sensor, a comparator A, a comparator B, a resistor R12, a resistor R13, a resistor R14, a resistor R15, and a resistor R22 , sliding rheostat Rp1 and sliding rheostat Rp2;

[0141] The input pin of the Hall sensor is connected to the voltage signal U of the test point TP1, TP4, TP5 or TP6 TP1 , U TP4 , U TP5 or U TP6 ;

[0142] The output pin of the Hall sensor is grounded through the resistor R22;

[0143] The output pin of the Hall sensor is also connected to the inverting input terminal of the comparator A through the resistor R12; the non-inverting input terminal of the comparator A is grounded through the resistor R14; the sliding rheostat Rp1 is connected in series between the inverting input terminal and the output terminal of ...

specific Embodiment approach 3

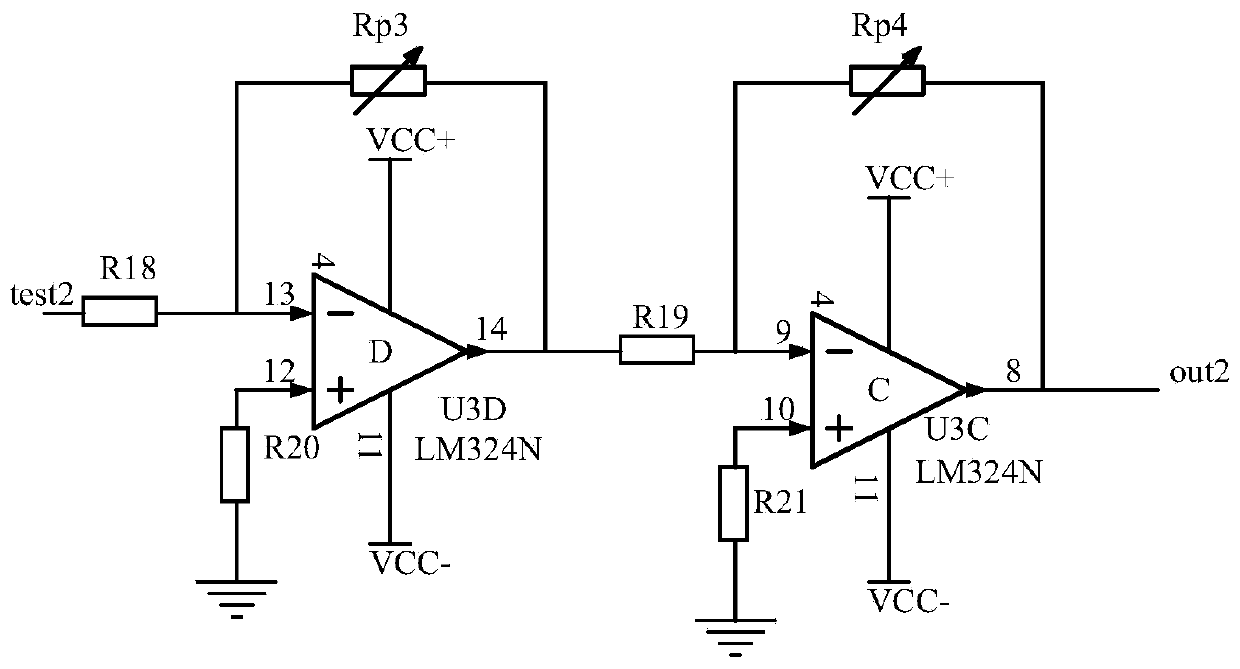

[0146] Specific implementation mode three: the following combination image 3 Describe this embodiment, this embodiment will further illustrate the first embodiment, the transformer secondary test point voltage processing circuit 2 includes a comparator C, a comparator D, a resistor R18, a resistor R19, a resistor R20, a resistor R21, a sliding rheostat Rp3 and a sliding Rheostat Rp4;

[0147] Voltage signal U of TP2, TP3, TP7 or TP8 TP2 , U TP3 , U TP7 or U TP8 The inverting input terminal of comparator D is connected through resistor R18; the non-inverting input terminal of comparator D is grounded through resistor R20, and the sliding rheostat Rp3 is connected in series between the output terminal of comparator D and the inverting input terminal; the output terminal of comparator D is passed through Resistor R19 is connected to the inverting input terminal of comparator C;

[0148] The non-inverting input terminal of comparator C is grounded through resistor R21, the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com