Mainboard repairing method

A motherboard and repair technology, applied in manufacturing tools, electrical solid devices, laser welding equipment, etc., can solve problems such as low alignment accuracy, damage, abnormal pressure, etc., to achieve high repair efficiency, good adaptability, and small thermal impact. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described in detail with reference to the accompanying drawings.

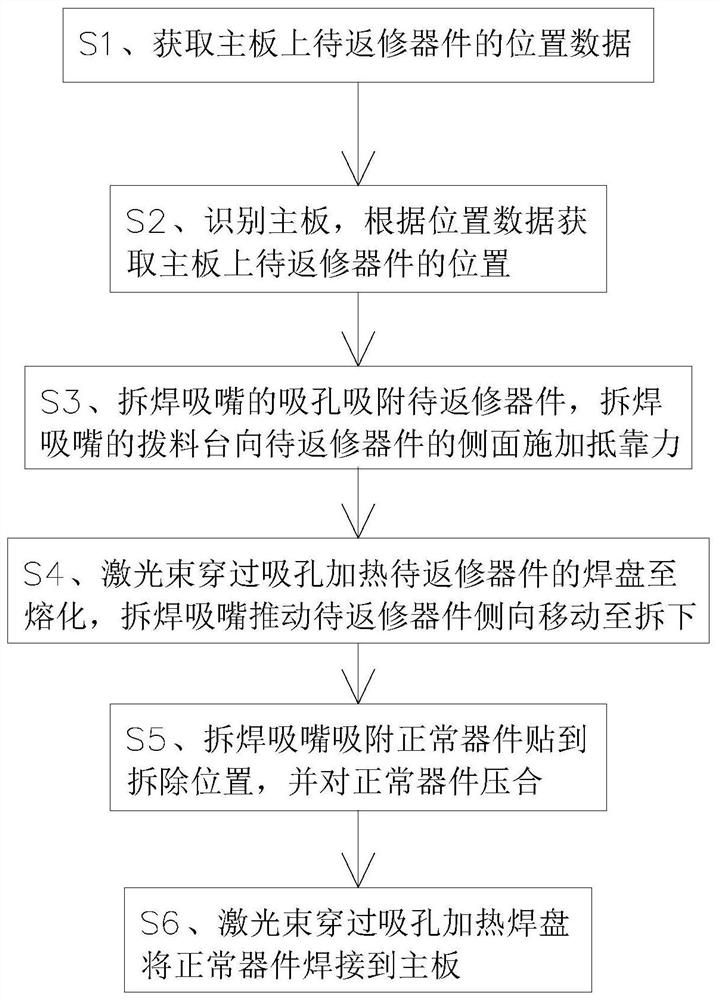

[0029] Such as figure 1 , figure 2 As shown, the motherboard repairing method in a preferred embodiment of the present invention comprises the following steps:

[0030] S1. Obtain the position data of the device 2 to be repaired on the main board 1;

[0031] S2. Identify the main board 1, and obtain the position of the device 2 to be repaired on the main board 1 according to the position data;

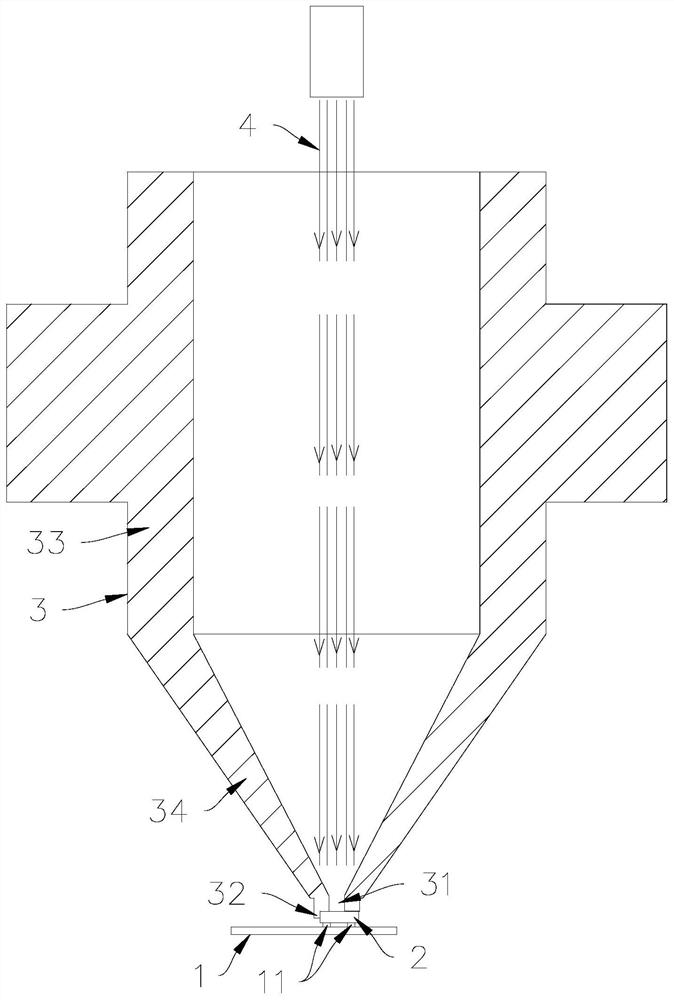

[0032] S3. The light-transmitting hole 31 of the desoldering nozzle 3 absorbs the device 2 to be repaired, and the material pushing table 32 of the desoldering nozzle 3 applies an abutting force to the side of the device 2 to be repaired;

[0033] S4. The laser beam 4 passes through the light transmission hole 31 to heat the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com