Method for positioning mold line sample plate with positioning hole in repairing process

A die line template and positioning hole technology, which is applied to welding equipment, laser welding equipment, metal processing equipment, etc., can solve the problems of low production efficiency, waste of materials, scrap die line templates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

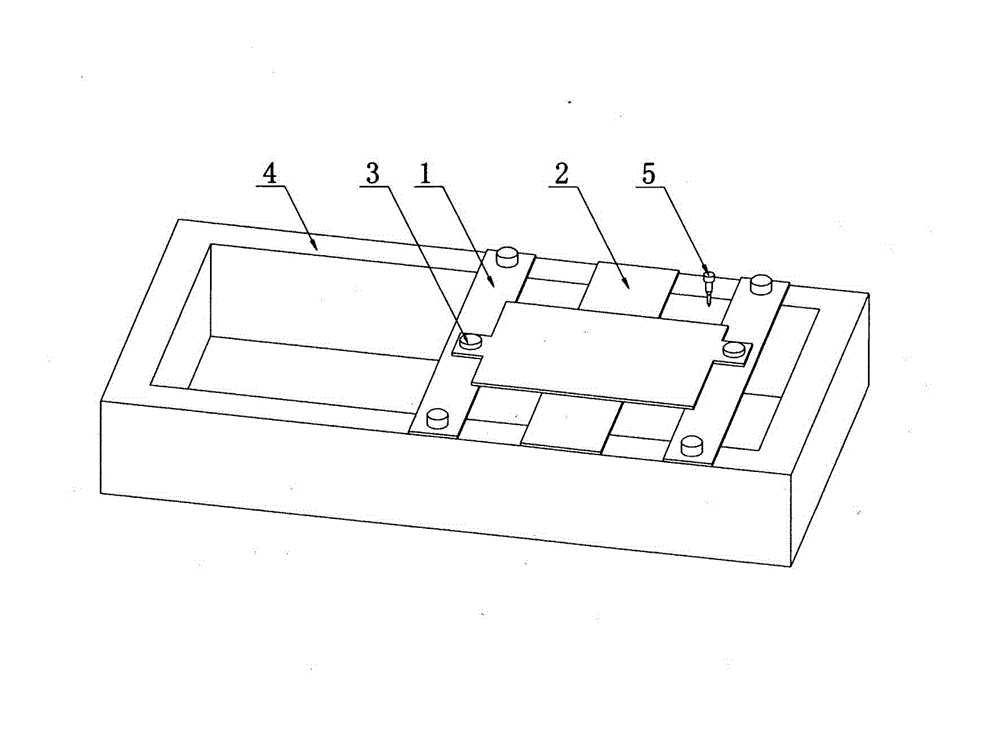

[0014] Such as figure 1 As shown, a method for positioning mold line templates with positioning holes in the repair process includes the following steps:

[0015] 1) Level the mold line template 2 and inspect it according to the polyester film to ensure that the positioning holes and outer edges of the mold line template are accurate;

[0016] 2) Compile the laser cutting program A with only the outer edge of the mold line template and the positioning hole, and ensure that the positioning hole is cut first, and then the outer edge is cut;

[0017] 3) Prepare the laser cutting program B that only has the outer edge of the mold line template and the repaired and modified parts, and ensure that the repaired and modified parts are cut first, and then the outer edge is cut;

[0018] 4) Increase the height of the laser head 5 of the laser cutting machine, and run the program A of the laser cutting machine. When the laser head is in the first positioning hole, press to stop the lase...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com