Automatic stacking and packing all-in-one machine

An all-in-one machine and stacking net technology, applied in the field of balers, can solve the problems of high labor intensity and low production efficiency, and achieve the effects of low labor intensity, high production efficiency and good folding effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

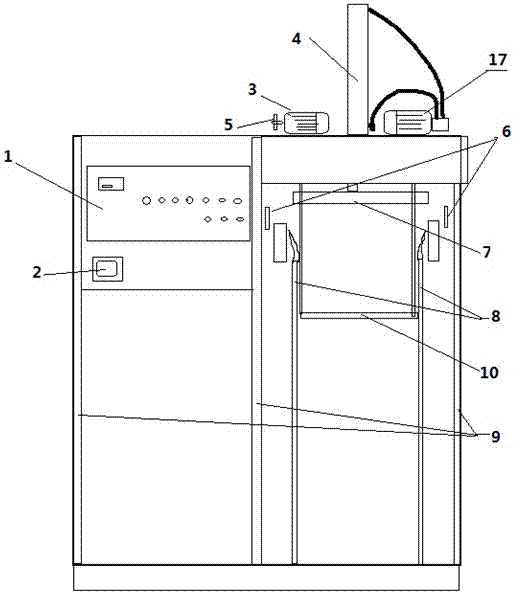

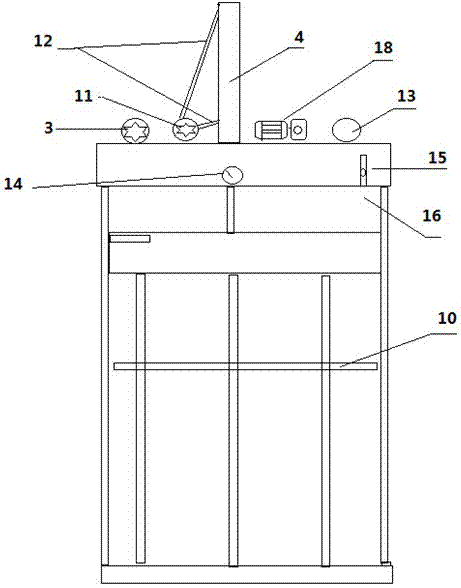

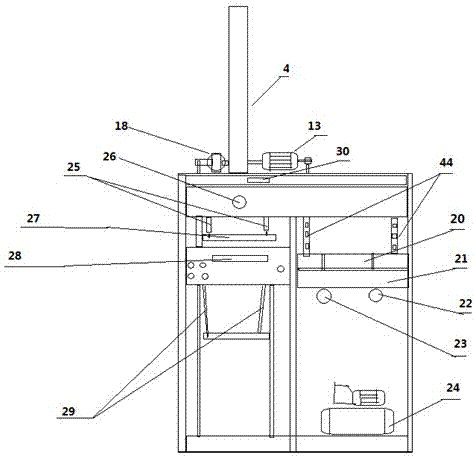

[0033] The technical solution of the present invention is further described below in conjunction with the accompanying drawings, but the accompanying drawings do not constitute a limitation to the technical solution, and any improvement on the basis of the technical solution of the present invention belongs to the protection scope of the present invention.

[0034] like Figure 1-11 As shown, the automatic stacking and packing all-in-one machine is composed of a rod insertion mechanism, a No. Composition; the frame is in two halves, one side of which is equipped with the rod insertion mechanism, the No. 1 rod pulling mechanism, the No. The pull-out mechanism is located at the other end, and the rod-feeding mechanism is installed horizontally on the rack between the No. 1 pull-out mechanism and the No. 2 pull-out mechanism; On the frame, the net bearing mechanism is installed on the frame below the pull rod mechanism, the net pressure mechanism is installed on the frame above ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com