Patents

Literature

251 results about "Labor operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

The Service Merchandising application uses Labor Operation Codes (labor op codes) to bill out labor on an RO. These codes are defined during system installation. Labor Operation Codes can also be added while creating an RO.

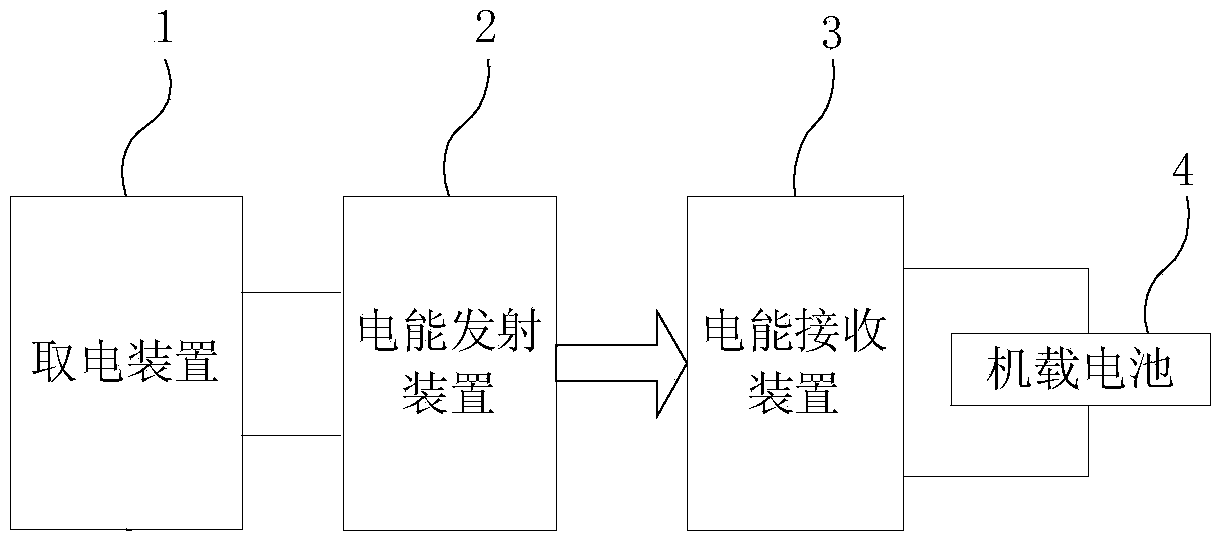

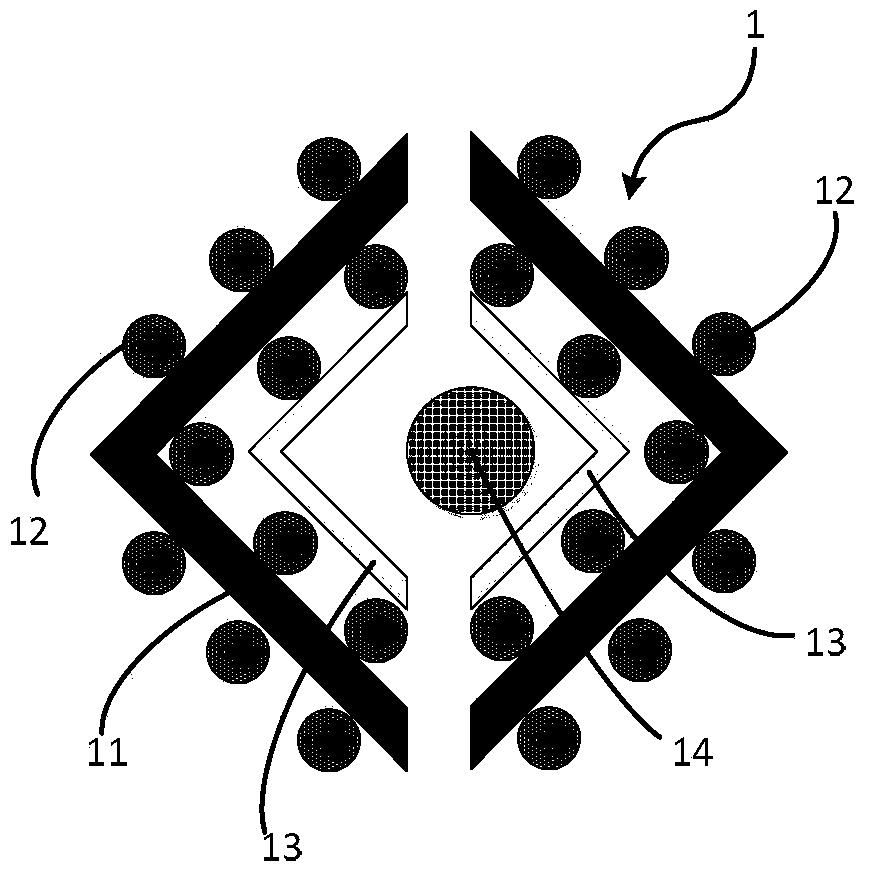

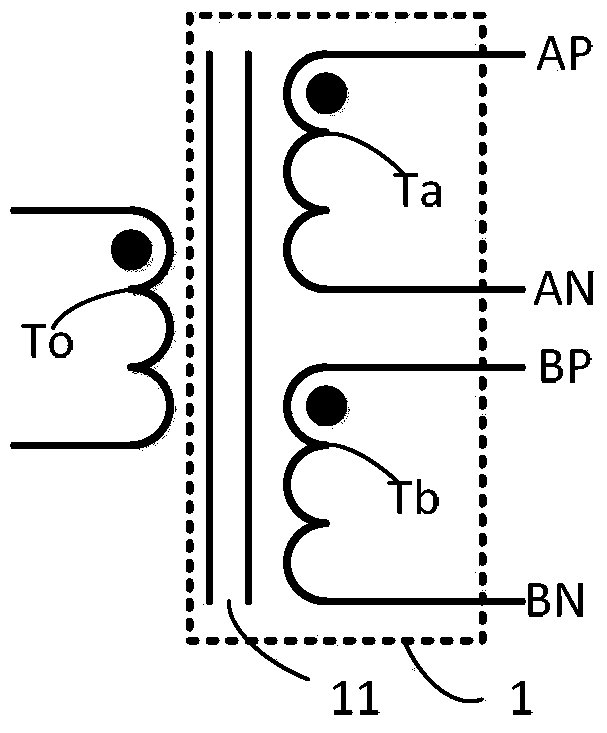

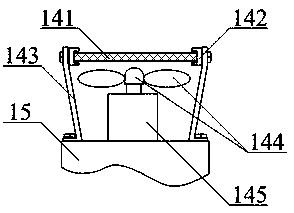

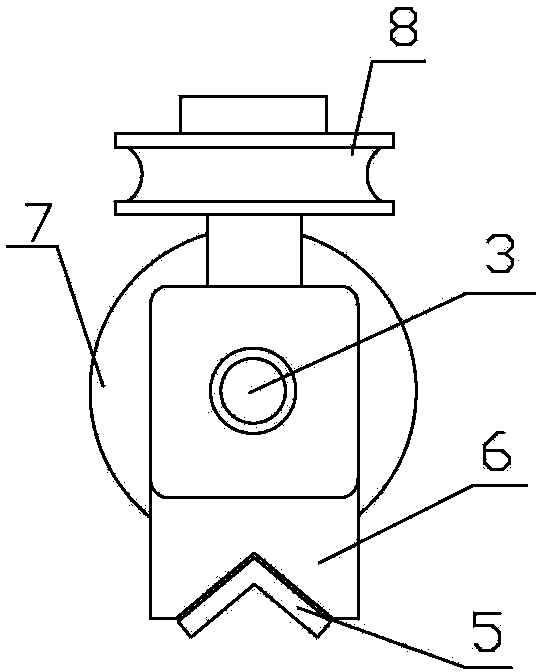

Charging system for unmanned aircraft

ActiveCN103872795AGuaranteed one-way flowEliminate low harmonic injectionElectromagnetic wave systemCircuit arrangementsElectric power transmissionEngineering

The invention discloses a charging system for an unmanned aircraft. The charging system is characterized by comprising a power-taking device, an electric energy transmitting device, an electric energy receiving device and an aircraft-mounted battery, wherein an overhead transmission line is arranged on the power-taking device; the electric energy transmitting device is for converting power frequency alternating current into high-frequency alternating current; the electric energy receiving device is arranged on the unmanned aircraft; electric energy transmission is realized in a wireless manner between the electric energy receiving device and the electric energy transmitting device; the aircraft-mounted battery is arranged on the unmanned aircraft, is used for supplying power to the unmanned aircraft, and is connected in series to a current loop of the electric energy receiving device. Compared with the prior art, an electric unmanned aircraft charging system based on an alternating-current power transmission overhead line provided by the invention has the advantages that a full-autonomous and safe charging way is realized for the unmanned aircraft, and the distance per charge of the unmanned aircraft is prolonged. Meanwhile, a high-frequency inductive constant-current charging circuit based on an unstable alternating-current power supply is provided, so that unmanned charging operation is fully realized, the dependence of the unmanned aircraft on a ground base or a mobile base station is reduced, labor operation is reduced, and labor cost is reduced.

Owner:王洋 +3

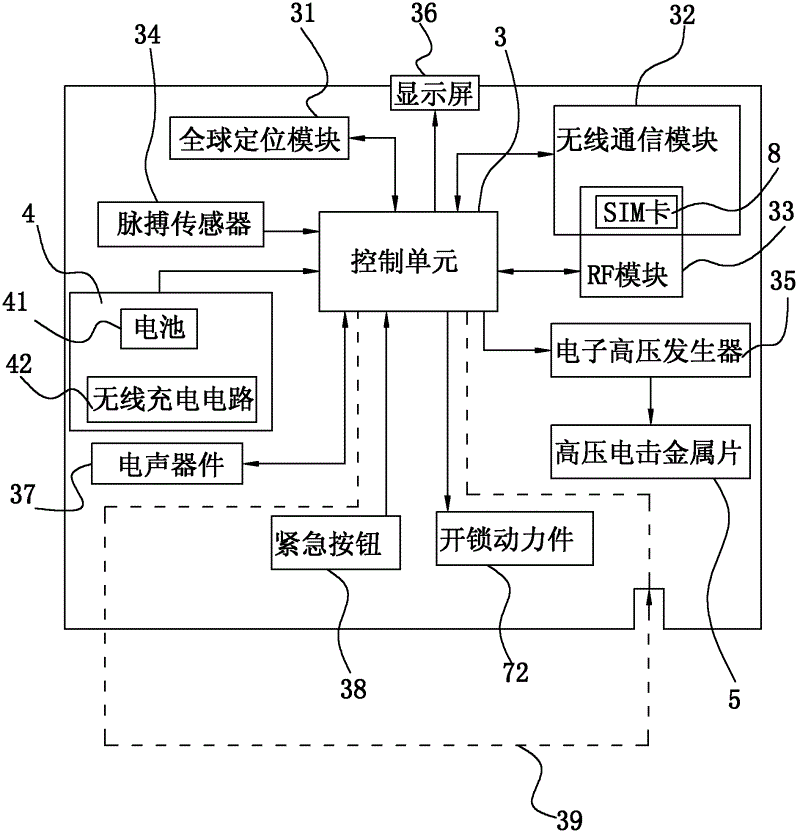

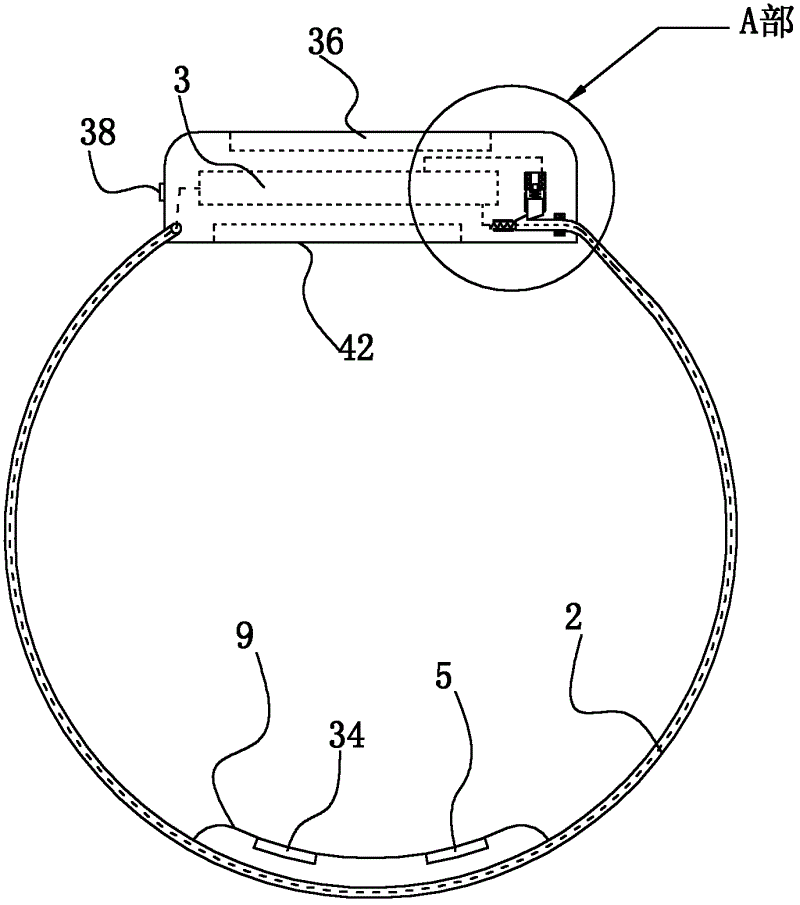

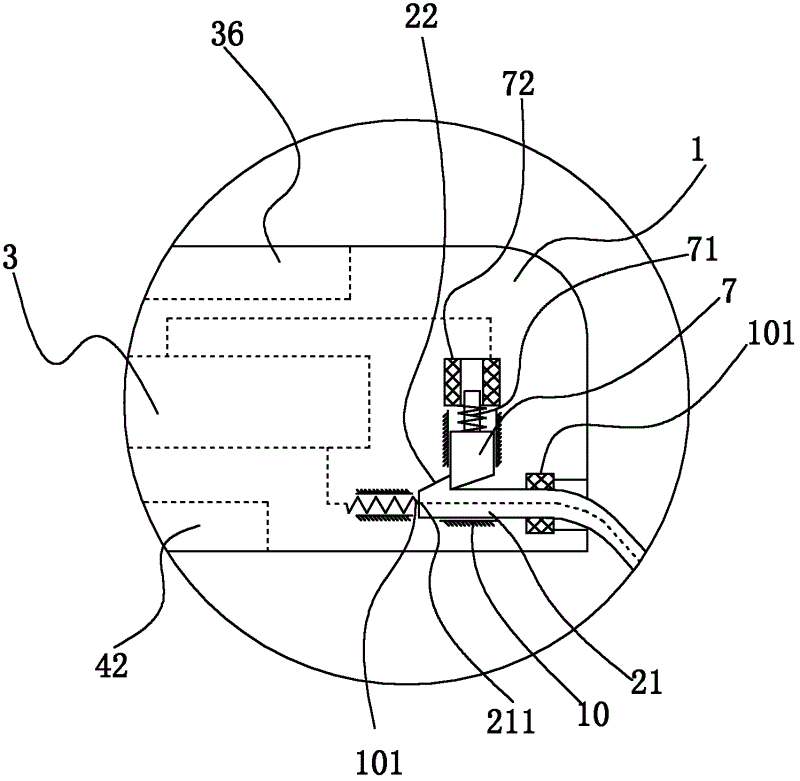

GPS (global positioning system) type electronic handcuff

InactiveCN102619414AConvenient labor operationConvenience of parole for medical treatmentHandcuffsWireless communicationLow voltageComputer module

The invention discloses a GPS (global positioning system) type electronic handcuff. The GPS type electronic handcuff comprises a main housing, a linking body linked with the main housing through a hinge, a control unit arranged in the main housing, a global positioning module and a wireless communication module which are connected with the control unit, as well as an RF (radio frequency) module and pulse sensors which are connected with the control unit, wherein the number of the pulse sensors is 1-3, and the pulse sensors are arranged on the inner side of the main housing and / or the inner side of the linking body; and the control unit comprises a micro-controller, as well as a memory and an output and input port which are connected with the micro-controller. The GPS type electronic handcuff disclosed by the invention can realize omnibearing waterproof protection, the RF module is used for opening and closing a machine and opening the handcuff, and battery low voltage and pulse information are reported to a server through the wireless communication module. The GPS type electronic handcuff only needs to be worn on the single wrist for facilitating labor operation or release for medical treatment and recuperation of a prisoner, and can provide convenience for labor of the prisoner, improve labor efficiency and facilitate the monitoring of criminal situations. Positioning signals of the global positioning module can report positioning information to a monitoring center in real time through the wireless communication module, and even the prisoner escapes, the prisoner can be pursued and captured back fast.

Owner:SHENZHEN CHINO E COMM CO LTD

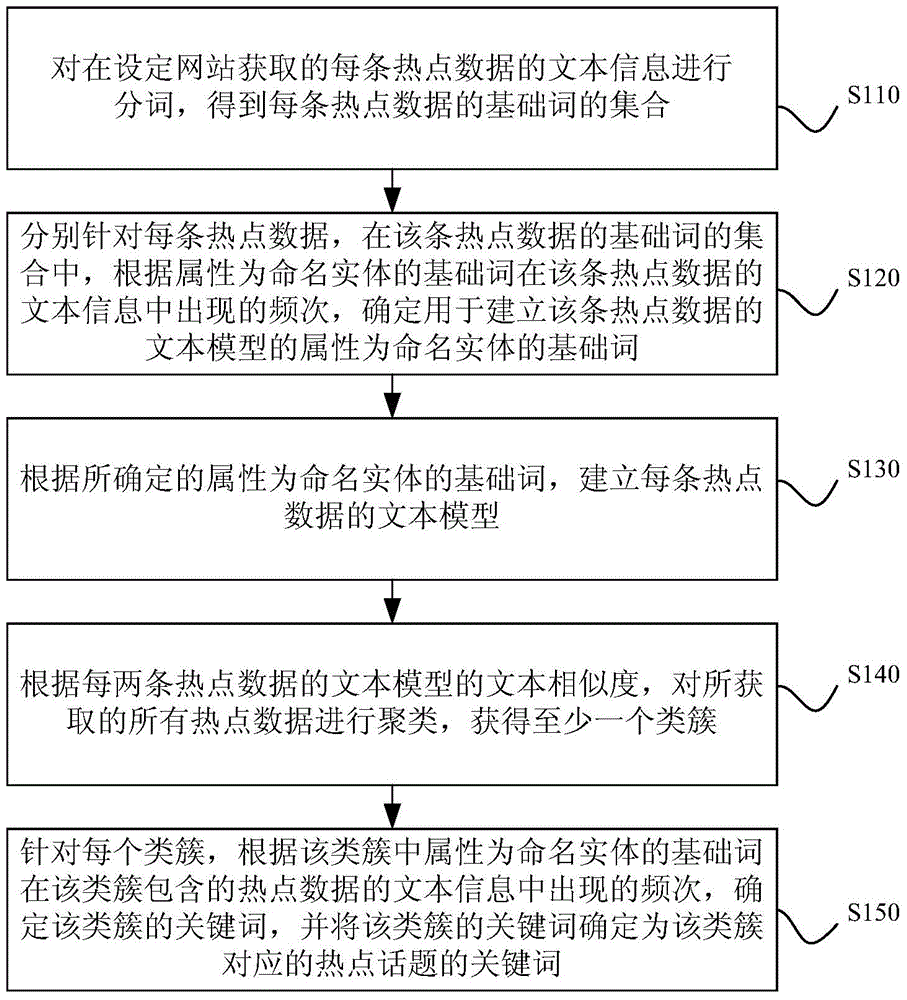

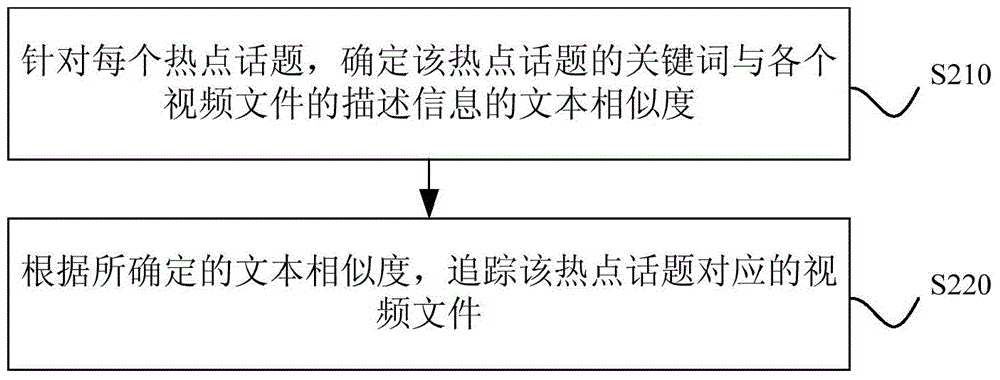

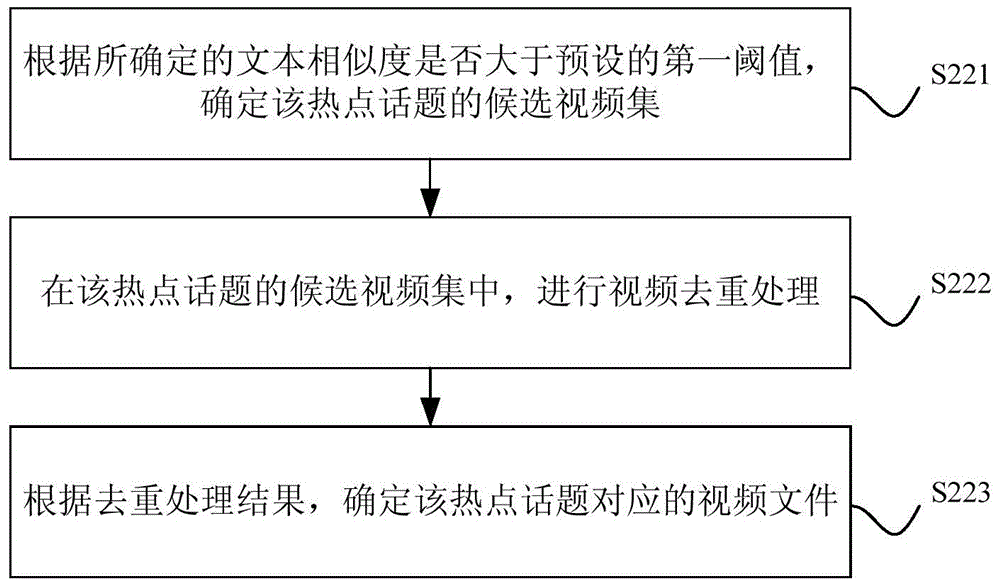

Method and device for tracing hot topics and confirming keywords

ActiveCN104915447AResolve lagReduce labor operating costsData processing applicationsWeb data indexingOperational costsComputer science

The present invention discloses a method for tracing hot topics and confirming keywords. The method comprises that hot data is obtained through a set website, and the hot data is classified and clustered so as to confirm the keywords of the hot topics in time. According to the method for tracing hot topics, a video file corresponding to each hot topic can be obtained through the text similarity of the keywords of the hot topics and the description of the video file. When the technical scheme adopted by the method provided by the embodiment of the invention is applied, the confirmation of the keywords of each hot topic and the tracing of the hot topics are automatically completed by a server, so that the delay caused by confirming the hot topics through manpower is effectively avoided; even though some hot topic can be composed of a plurality of phased events, the server can repeatedly implement the technical scheme so as to periodically update the video file corresponding to each hot topic, so that the labor operation cost is reduced.

Owner:BEIJING QIYI CENTURY SCI & TECH CO LTD

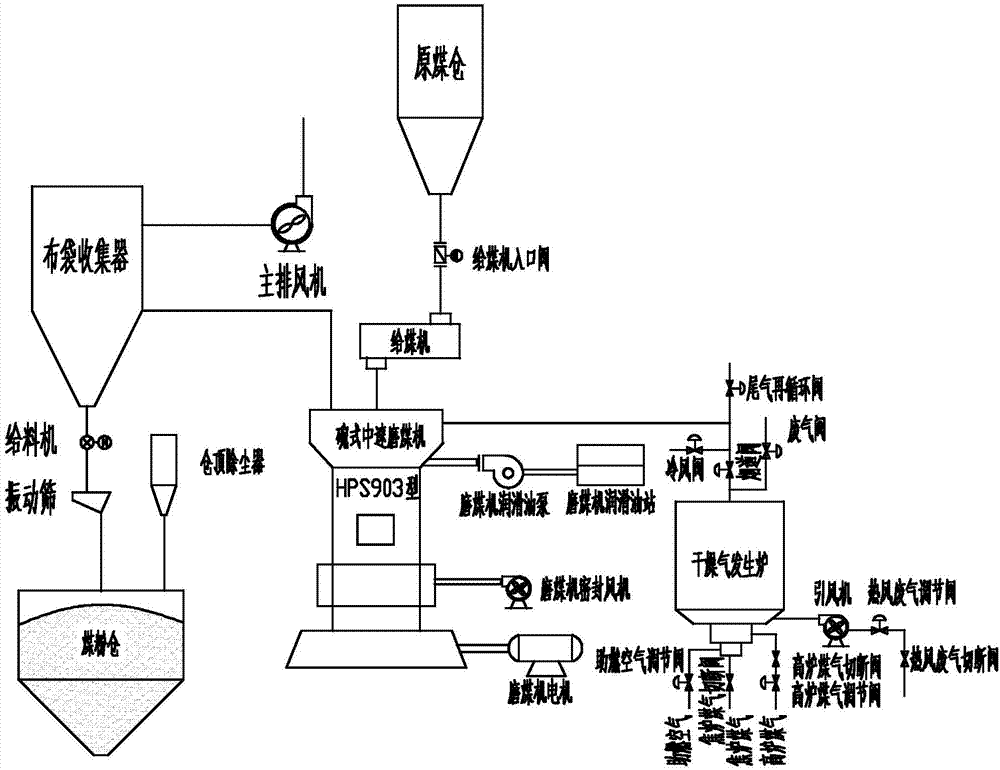

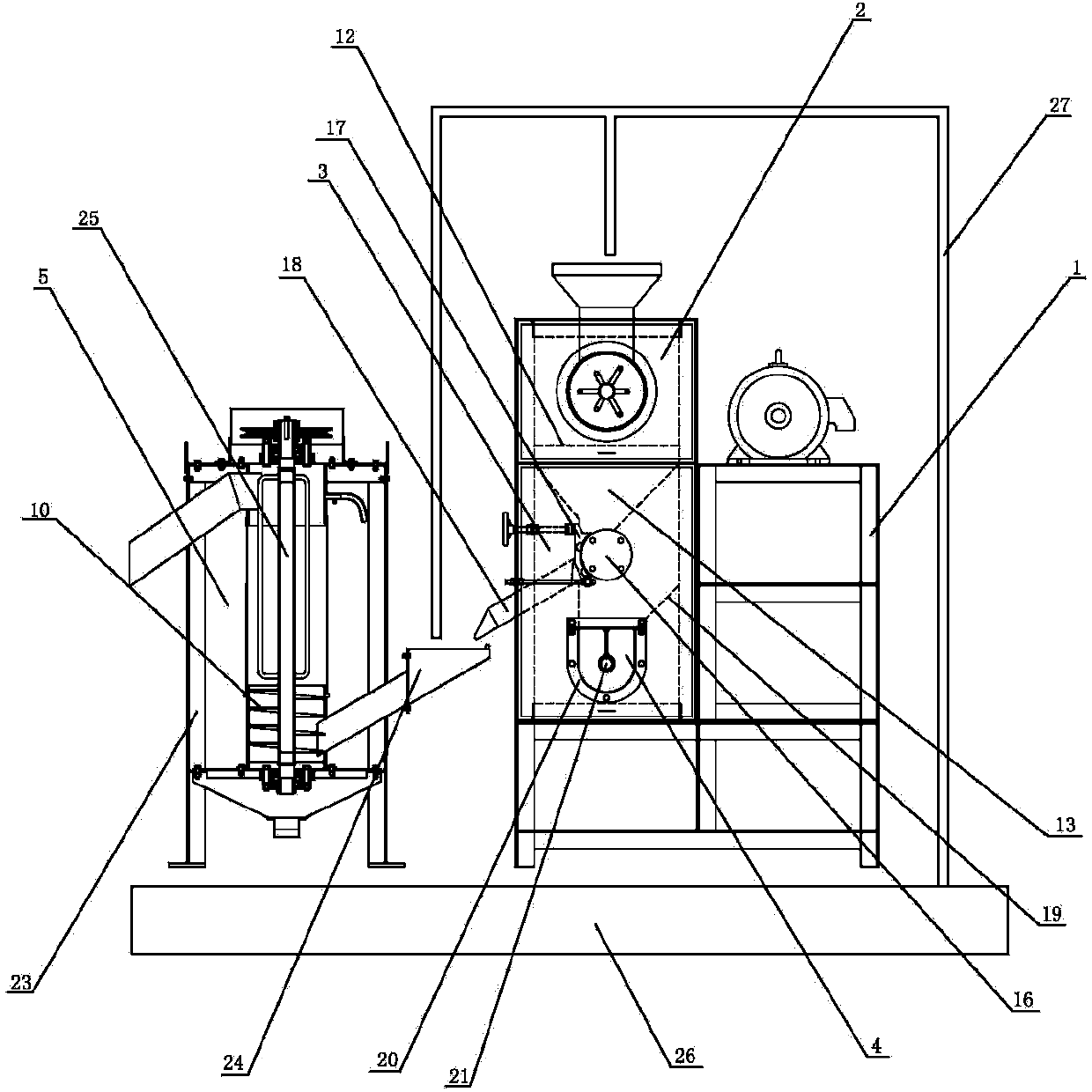

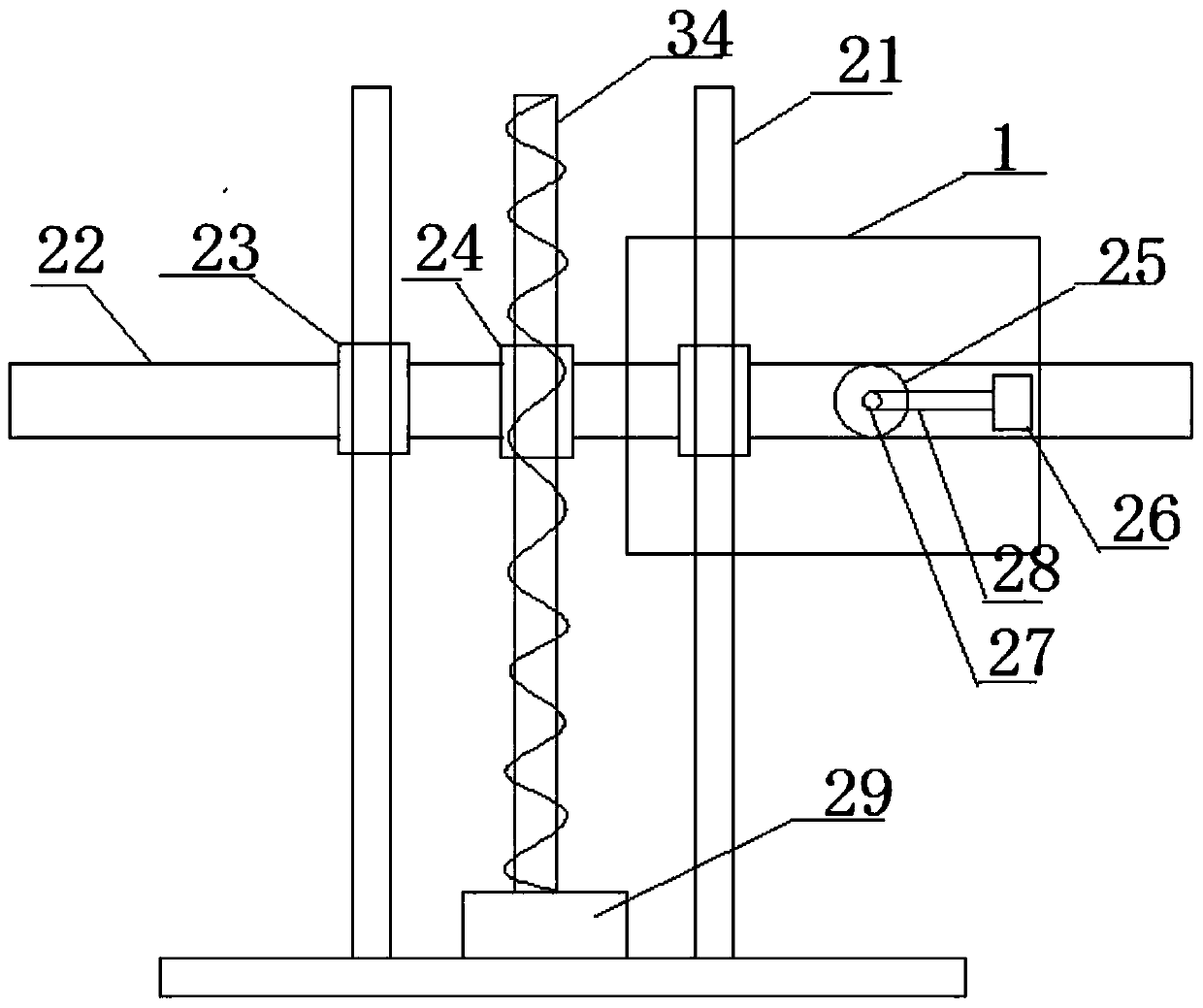

Full automatic control method and system for blast furnace pulverizing systems

ActiveCN103495488AReduce labor intensityReduce mental tensionBlast furnace componentsBlast furnace detailsAutomatic controlBunker

The invention discloses a full automatic control method and system for blast furnace pulverizing systems. Each blast furnace is provided with at least two pulverizing systems. All the pulverizing systems share the same pulverized coal bunker. The method comprises the following steps: preparing and starting, wherein starting judgments and starting control are included; operation adjustments; halt control. The method can realize uniform operation through program control, adjusts the number of started pulverizing systems according to actual conditions, and realizes full automatic control operation of the blast furnace pulverizing systems. The method greatly reduces labor intensity and thought tension degree of workers and improves working efficiency so as to eradicate manual operation errors and solve the problems that the equipment operation rate is high, running fluctuation is large, and index stability is poor when a manual operation system is used. Moreover, the method enables one person to monitor a plurality of pulverizing systems, improves the running efficiency of the systems, reduces operation cost, enables the systems to have more time to be maintained and repaired, and enables the whole pulverizing system to be in a virtuous circle.

Owner:JIANGSU JINHENG INFORMATION TECH CO LTD

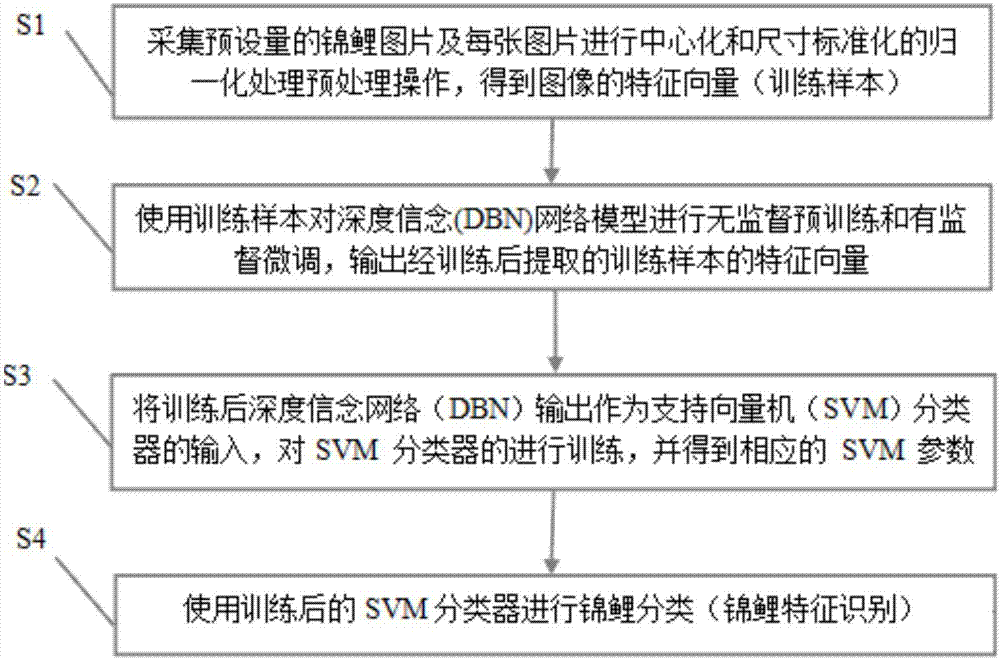

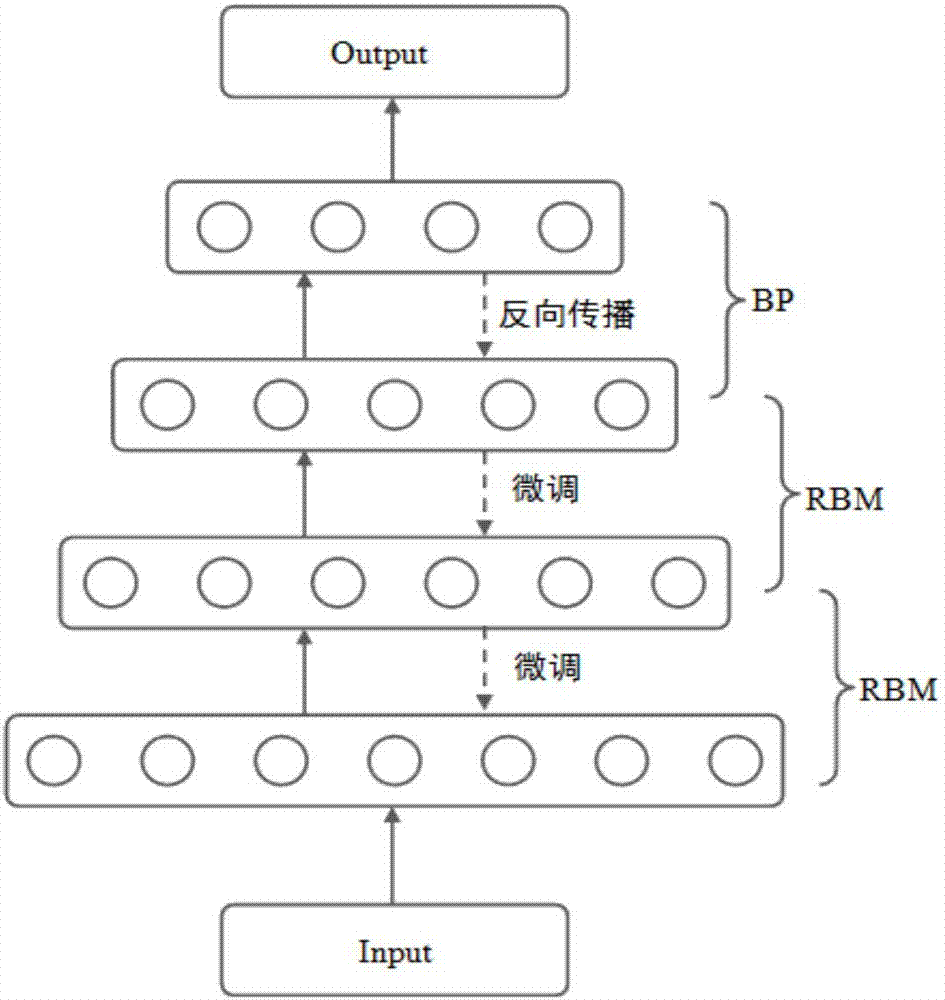

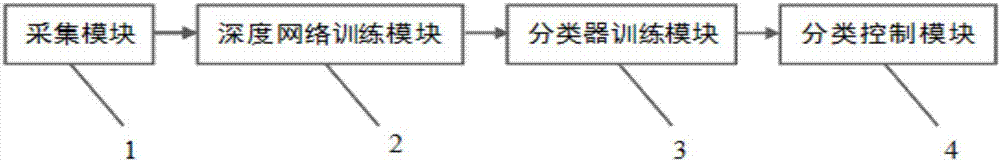

Deep learning-based fancy carp screening method and device

ActiveCN106980873AFully extractedRealize classification recognition outputCharacter and pattern recognitionDeep belief networkFeature vector

The present invention discloses a deep learning-based fancy carp screening method and a device. The method comprises the steps of collecting fancy carp images of a preset number, and subjecting each image to the centralized, size-standardized and normalized pre-treatment so as to obtain the feature vectors of the image; subjecting a deep belief network model to unsupervised pre-training and supervised fine tuning by utilizing a training sample, and outputting the extracted feature vectors of the training sample after being trained; adopting the output of the trained deep belief network as the input of a support vector machine classifier, and training the classifier so as to obtain corresponding parameters; and classifying the fancy carp by utilizing the trained classifier. According to the technical scheme of the invention, the deep belief network model for training a large amount of fancy carp image data is adopted and applied to the screening process for the high-quality seedlings of the fancy carp. Therefore, the dependence of the labor operation and breeding enterprises on the professional technical personnel is greatly reduced. The screening precision and the screening efficiency are improved.

Owner:NANJING UNIV OF SCI & TECH

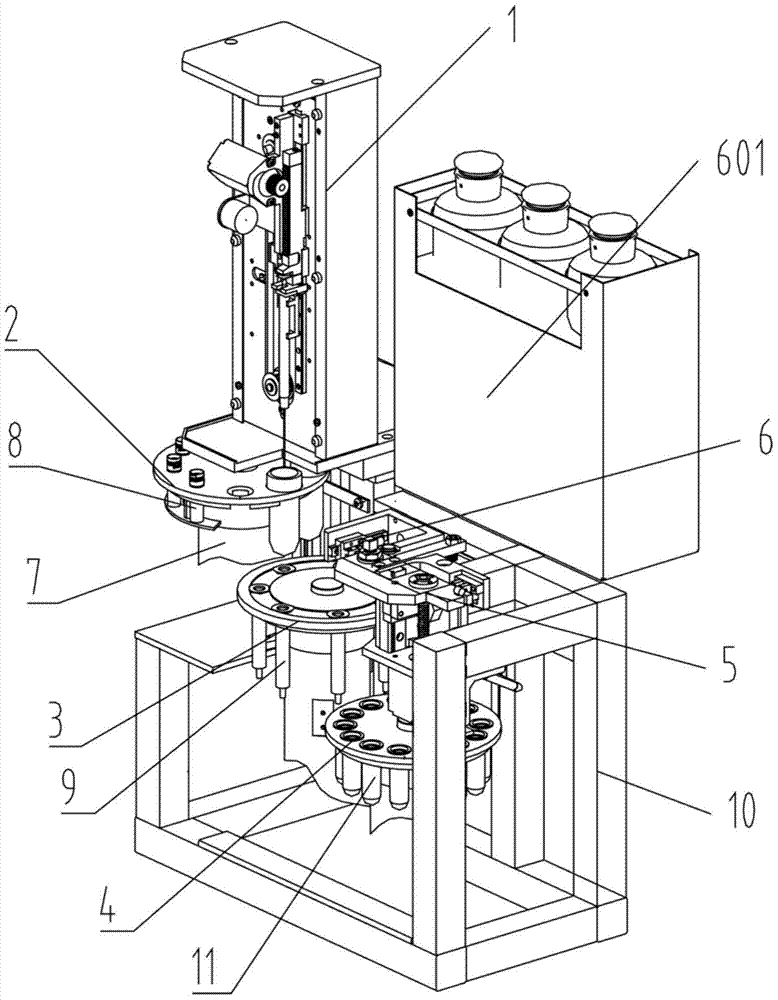

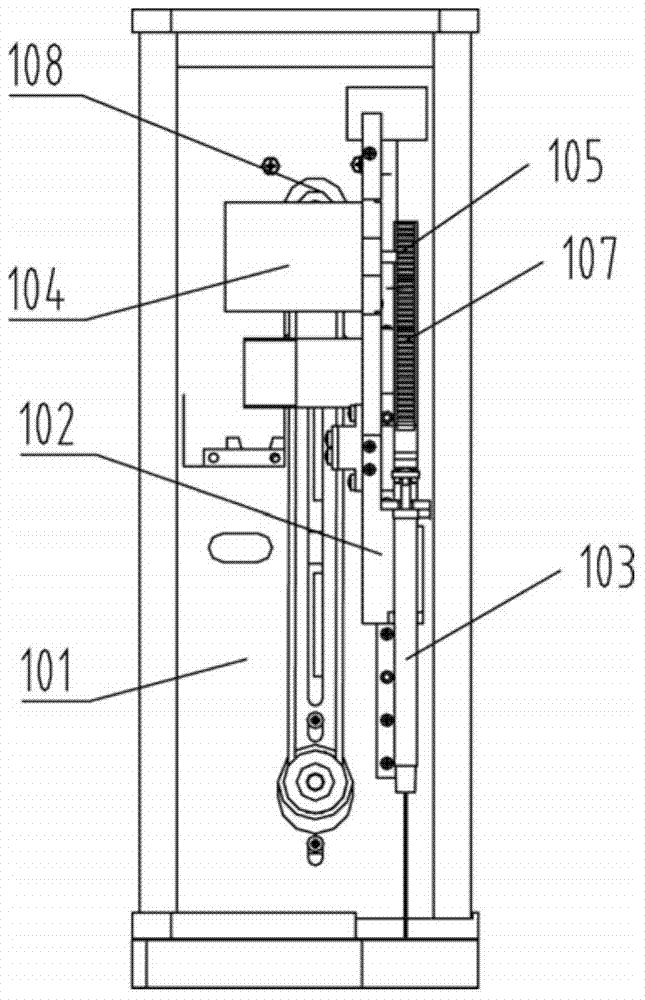

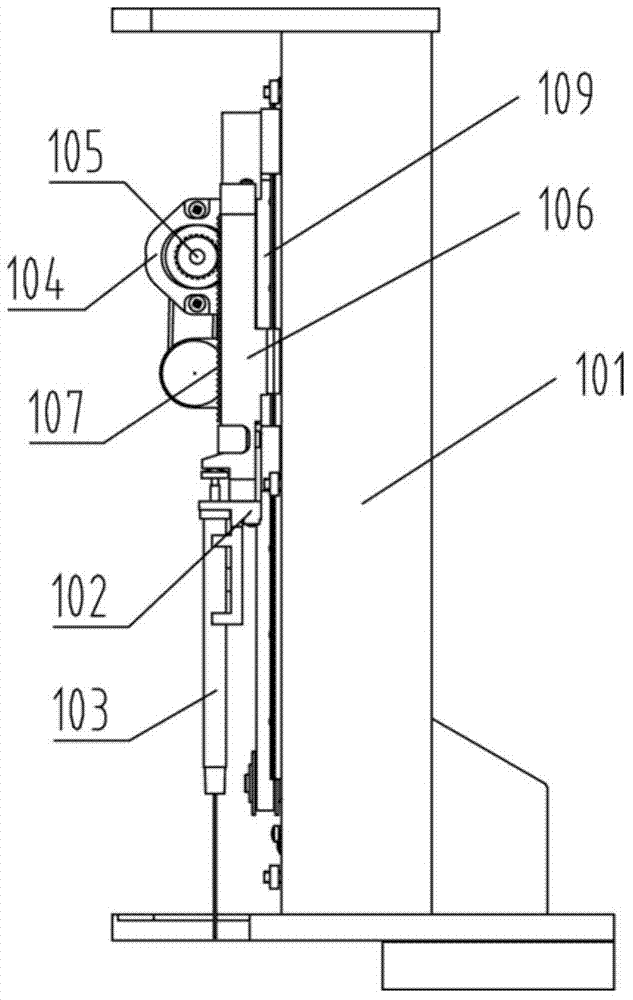

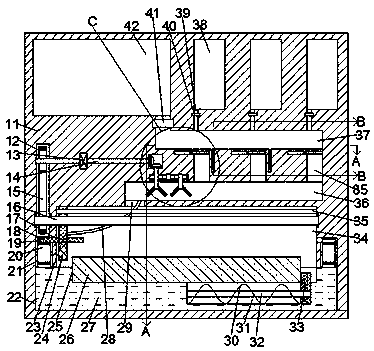

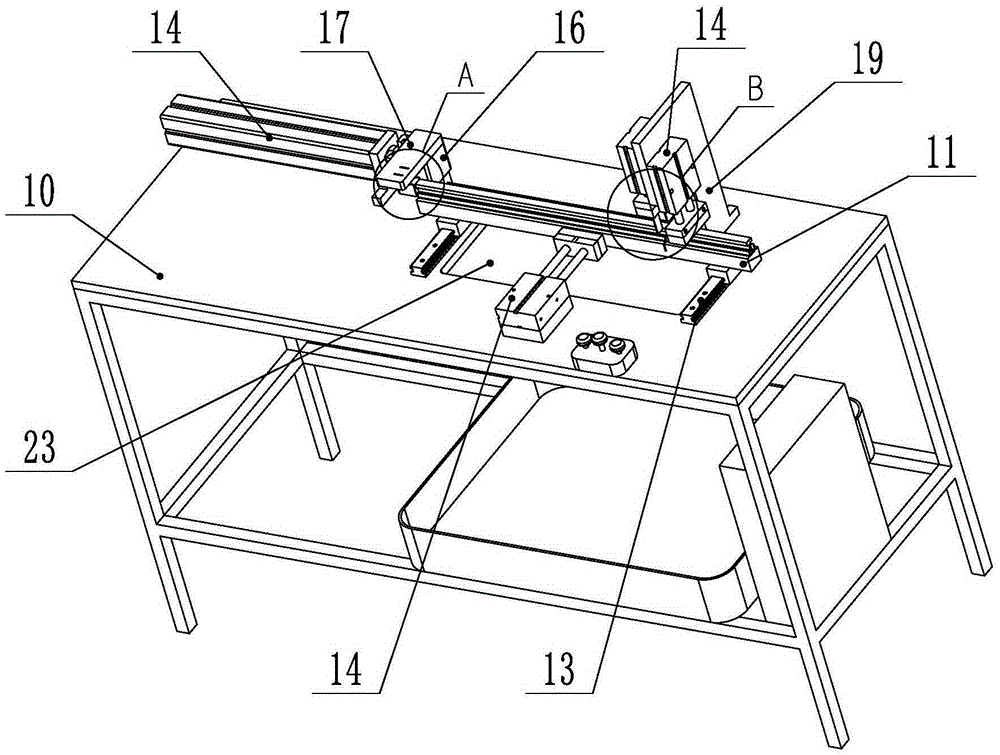

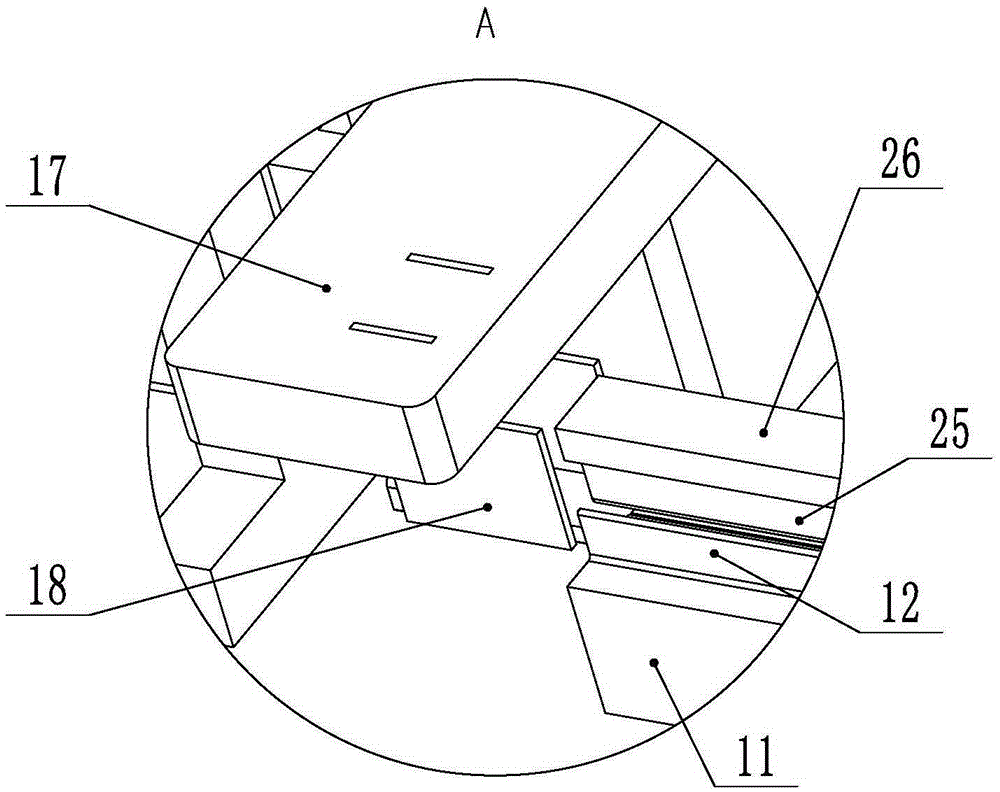

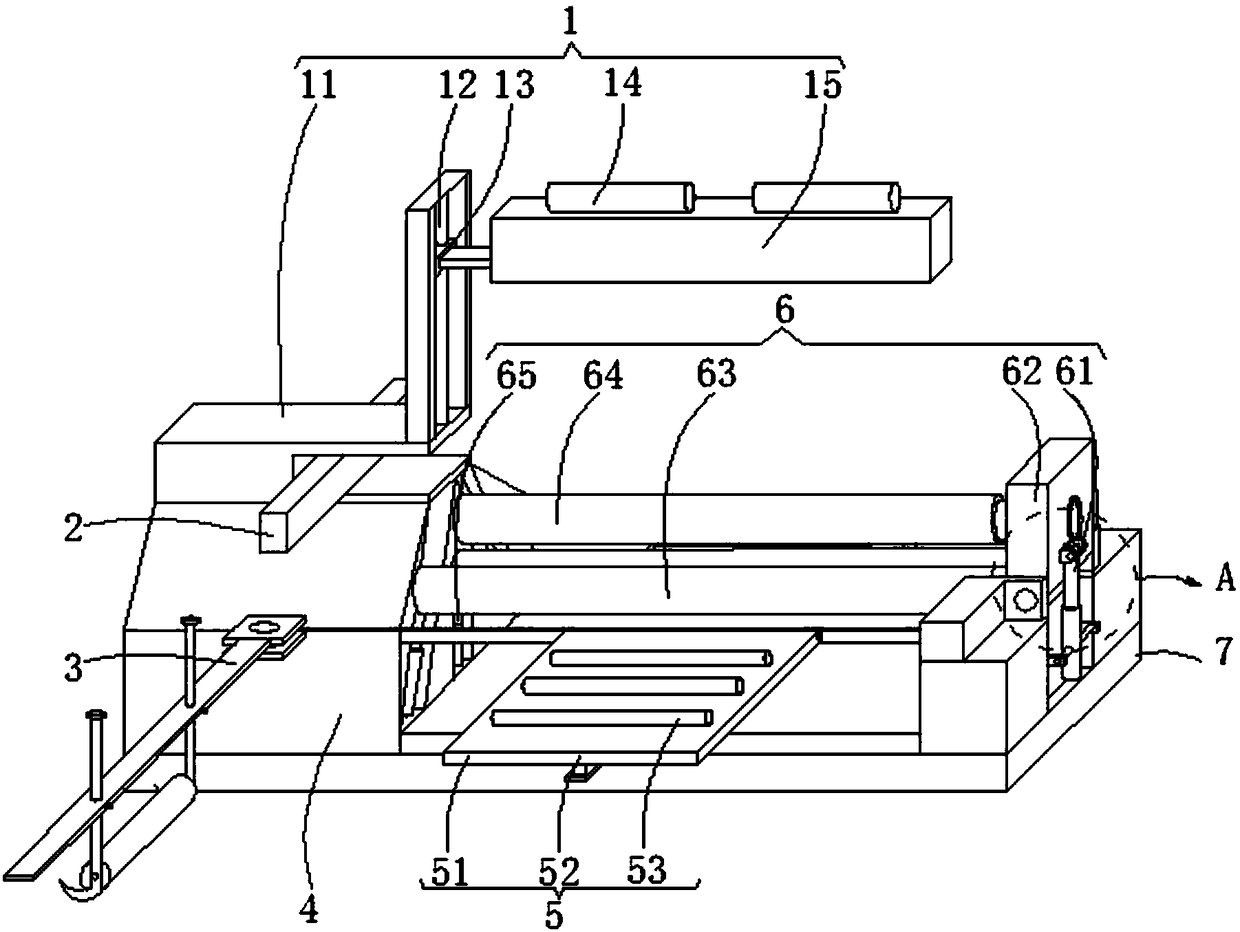

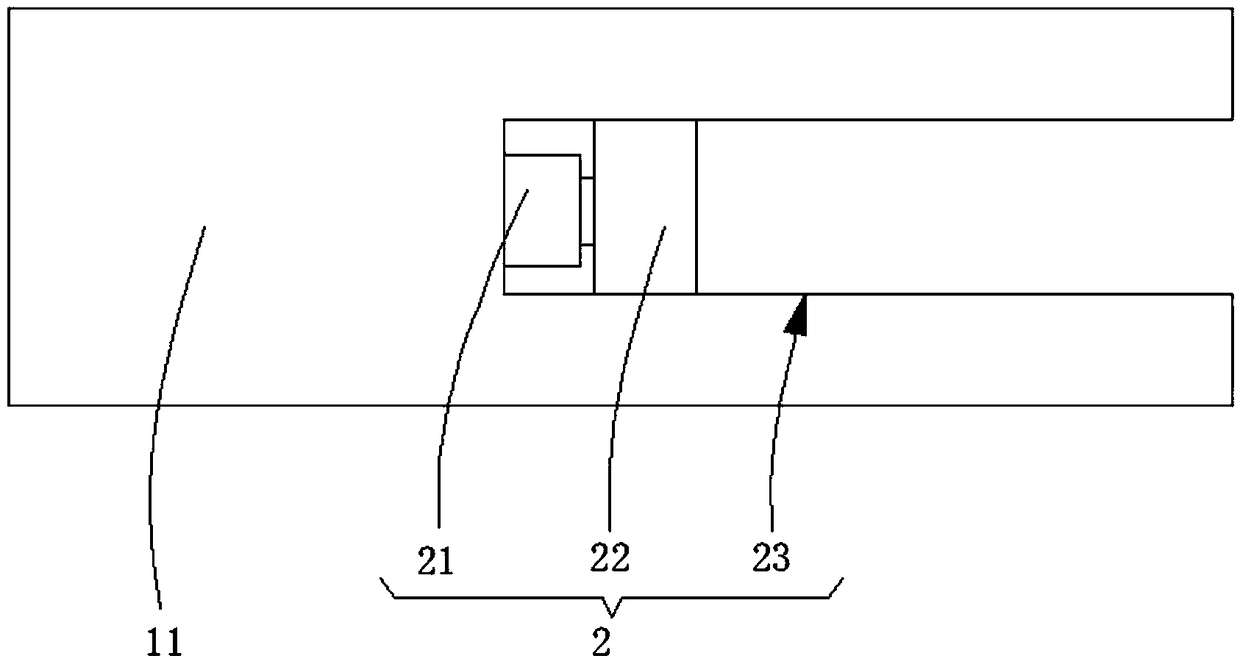

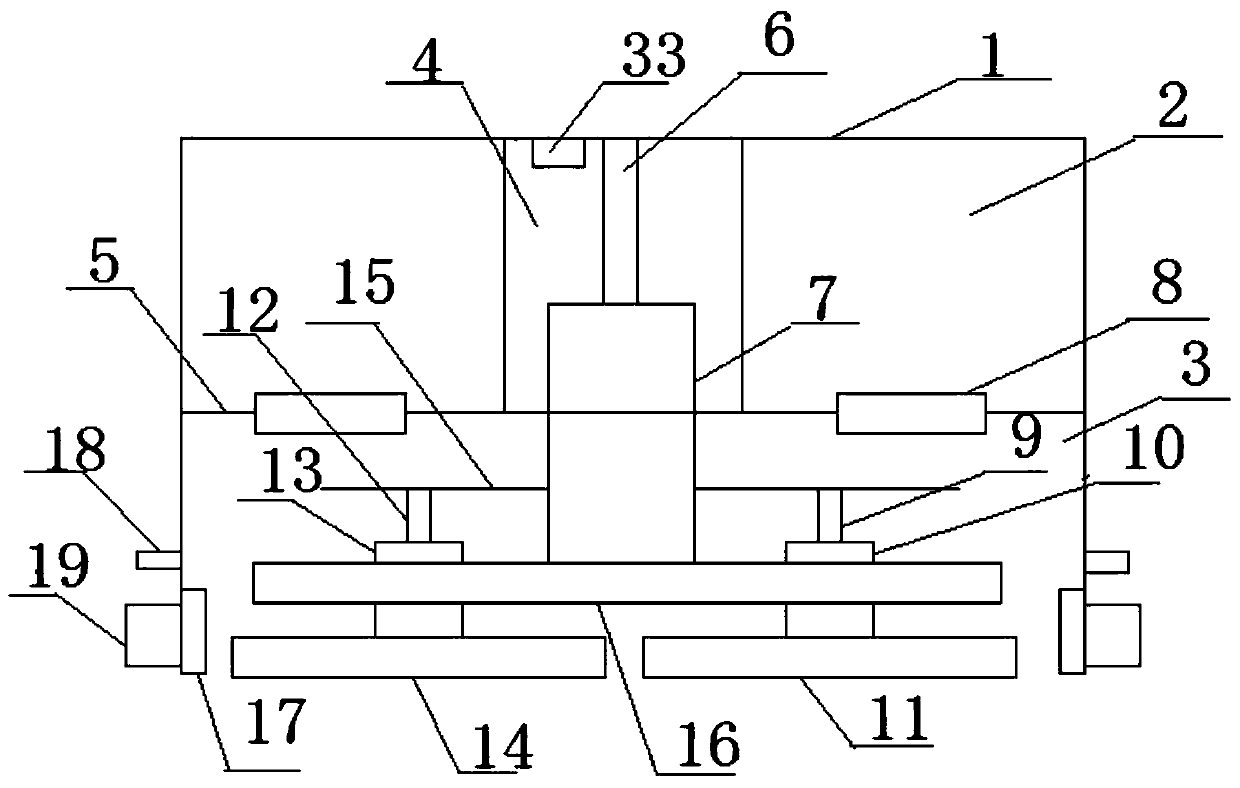

Automatic solid phase extraction equipment

ActiveCN103933754AReduce exposureAccurate measurementComponent separationSolid sorbent liquid separationEngineeringSolid phase extraction

The invention belongs to the field of extraction equipment for pretreatment of samples, and discloses automatic solid phase extraction equipment. The automatic solid phase extraction equipment comprises a stand, a sample injection device, a sample turntable, an extraction column turntable, a liquid feeding device, a pressure device, an extraction liquid turntable and a control device, wherein the sample turntable, the extraction column turntable and the extraction liquid turntable are successively mounted on the stand from high to low in a horizontal rotation manner; multiple extraction column support holes are formed in the circumference of the outer edge of the extraction column turntable; multiple sample support holes and one liquid injection through holes are formed in the circumference of the outer edge of the sample turntable; multiple extraction liquid pipe support holes are formed in the circumference of the outer edge of the extraction liquid turntable; the sample injection device is used for extracting samples from a sample tube and injecting samples into the solid phase extraction column through a liquid injection through hole; the pressure device is used for feeding solvent into the solid phase extraction column; the control device is used for controlling operation of the whole extraction equipment. By adopting the equipment, the difficulty of labor operation can be lowered, and the testing effect can be improved.

Owner:BEIJING CHUXIANGFEI TECH DEV

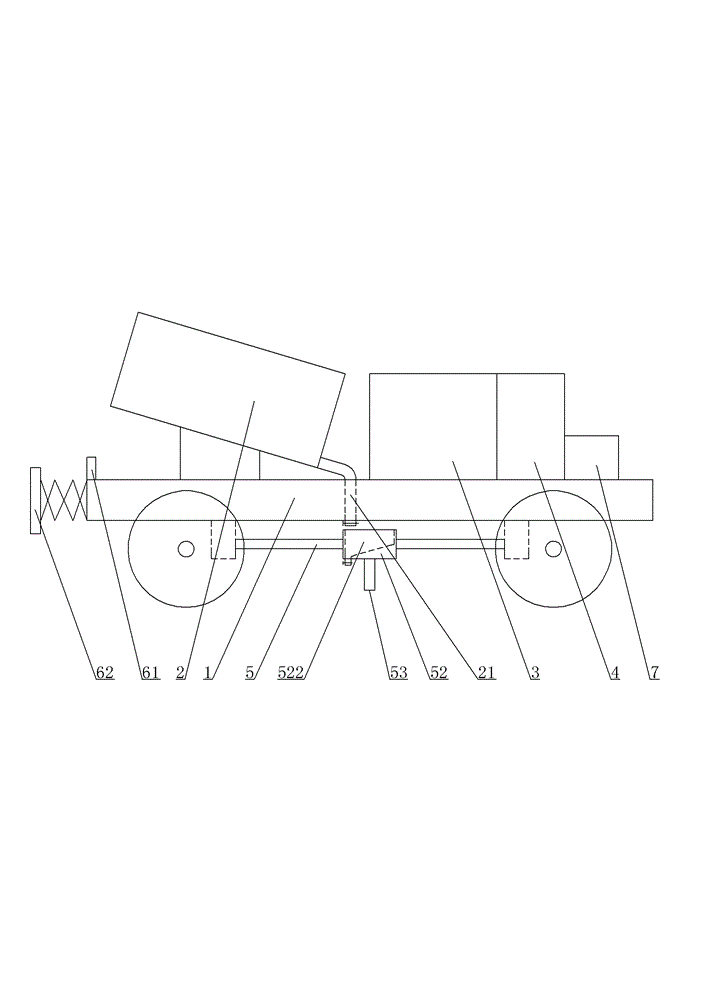

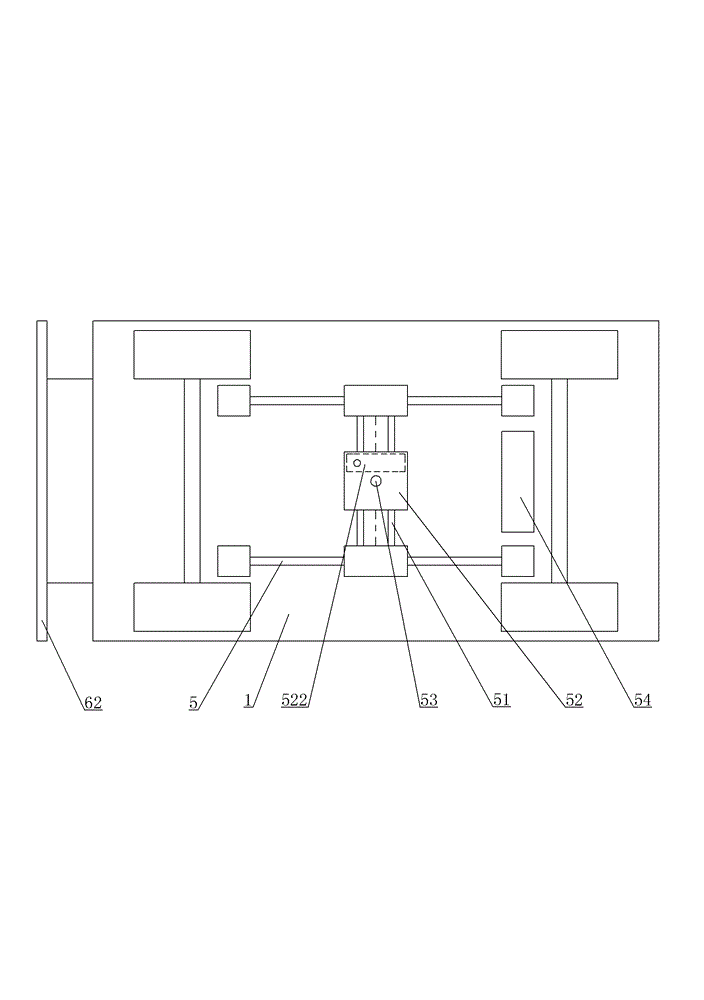

Intelligent repairing vehicle for asphalt roads with inspection wellheads

InactiveCN102877402ASolve the real problemRoad cleaningRoads maintainenceRoad surfaceLabor operations

The invention relates to repairing equipment for asphalt roads, and aims to provide an intelligent repairing vehicle for asphalt roads with inspection wellheads. The intelligent repairing vehicle is used for solving the problem of high labor consumption required for repairing asphalt roads on peripheries of wellheads in the prior art. The intelligent repairing vehicle comprises a road vehicle, a road excavating system, a measuring system, a supplying system and a tamping system, wherein the road excavating system, the measuring system, the supplying system and the tamping system are arranged on the road vehicle, the road excavating system comprises a processing center table used for excavating pits on the asphalt roads, and the processing center table is provided with cutting heads for excavating the roads. According to the scheme, the intelligent repairing vehicle has the advantages that a large quantity of labor operation is replaced by mechanical devices, and accordingly work efficiency is integrally improved.

Owner:CHINA MERCHANTS CHONGQING COMM RES & DESIGN INST

Efficient pipeline anti-corrosion treatment device

InactiveCN107617522AFacilitate subsequent anti-corrosion treatmentReduce labor operation intensityHollow article cleaningSpraying apparatusBristleCoupling

The invention provides an efficient pipeline anti-corrosion treatment device comprising a rotating motor, a supporting frame, a base, a hollow shaft, a sleeve coupler, an anti-corrosion liquid spray pipe structure, a sliding clamping block structure, a rotating disc, a regular bearing, a rapid rod-rotating structure, a sliding end plate structure, a height adjusting auxiliary wheel structure, an inner wall cleaning-brushing structure, a rapid blow-drying machine structure, a fastening sleeve pipe and a pipe body. A connecting rod, a brushing rod, a fixing sleeve and an adjusting bolt are arranged to be advantageously matched with steel-made bristles to conduct cleaning-brushing work of the inner wall of the pipe body, subsequent anti-corrosion treatment work is facilitated, the labor operation strength can be relived, and the efficient pipeline anti-corrosion treatment device can be suitable for cleaning work of the pipe bodies of different pipe types; through arrangement of a sponge block, protection for the interior of the pipe body is facilitated, and the pipe body is prevented from being scratched; and through arrangement of a stainless steel filtering net, a U-shaped block, aconnecting plate, fan blades and a blowing motor, blowing-away work on dust of the interior of the cleaned and brushed pipe body is facilitated, and subsequent anti-corrosion liquid spraying work canbe ensured.

Owner:邵宝军 +1

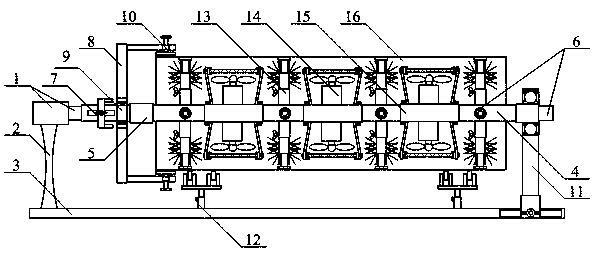

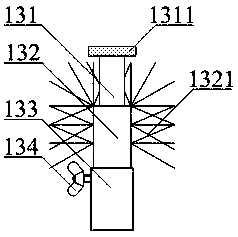

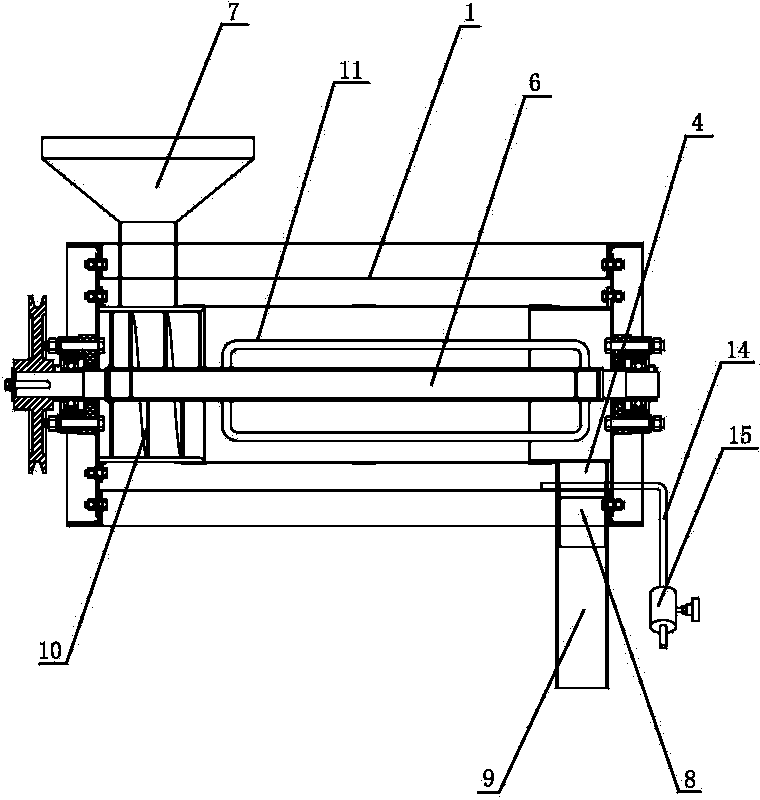

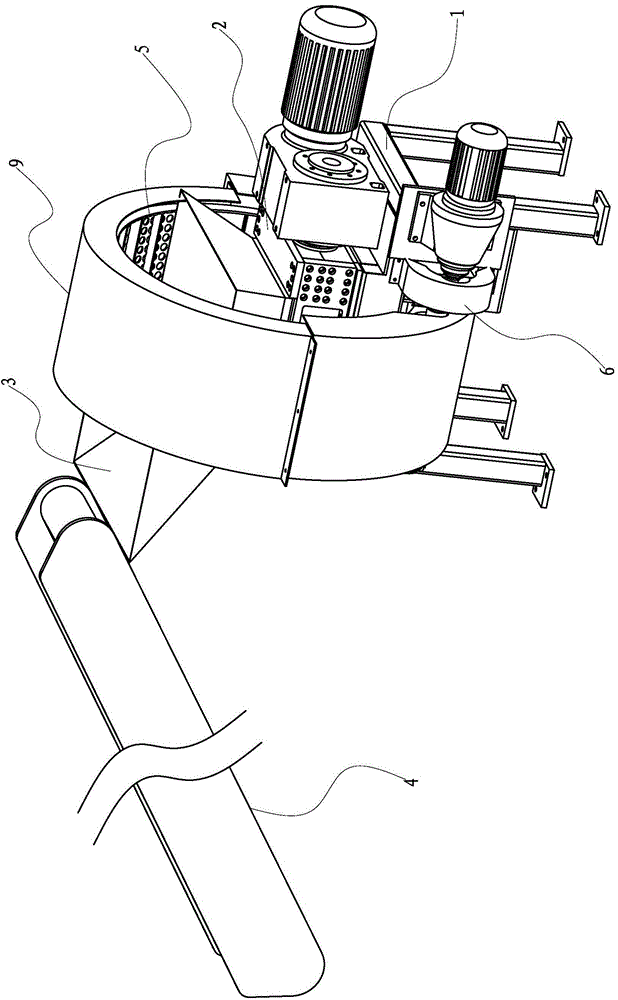

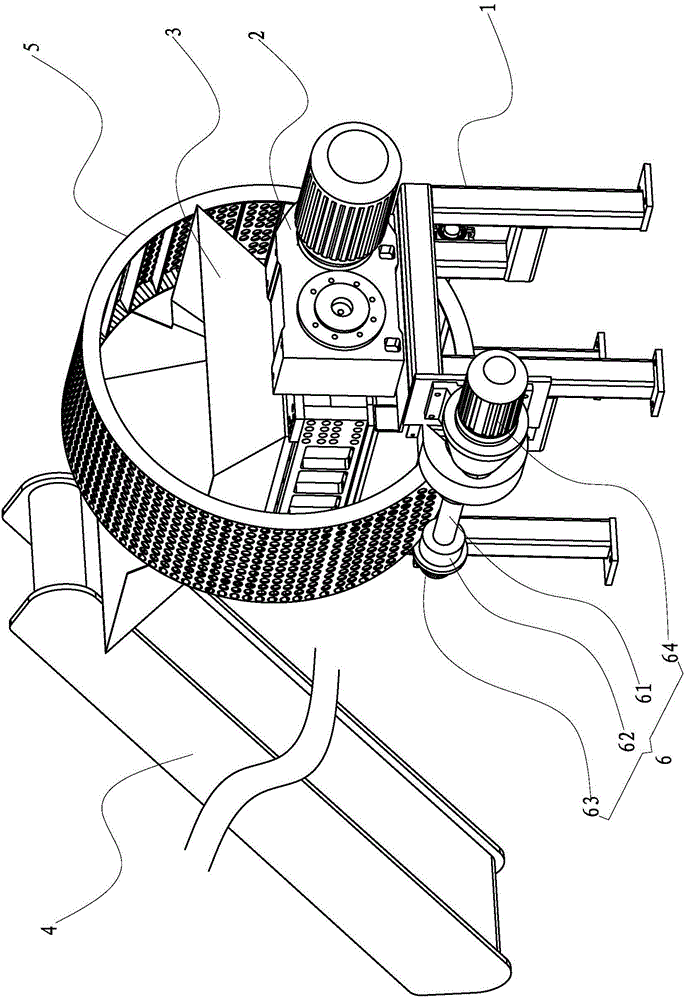

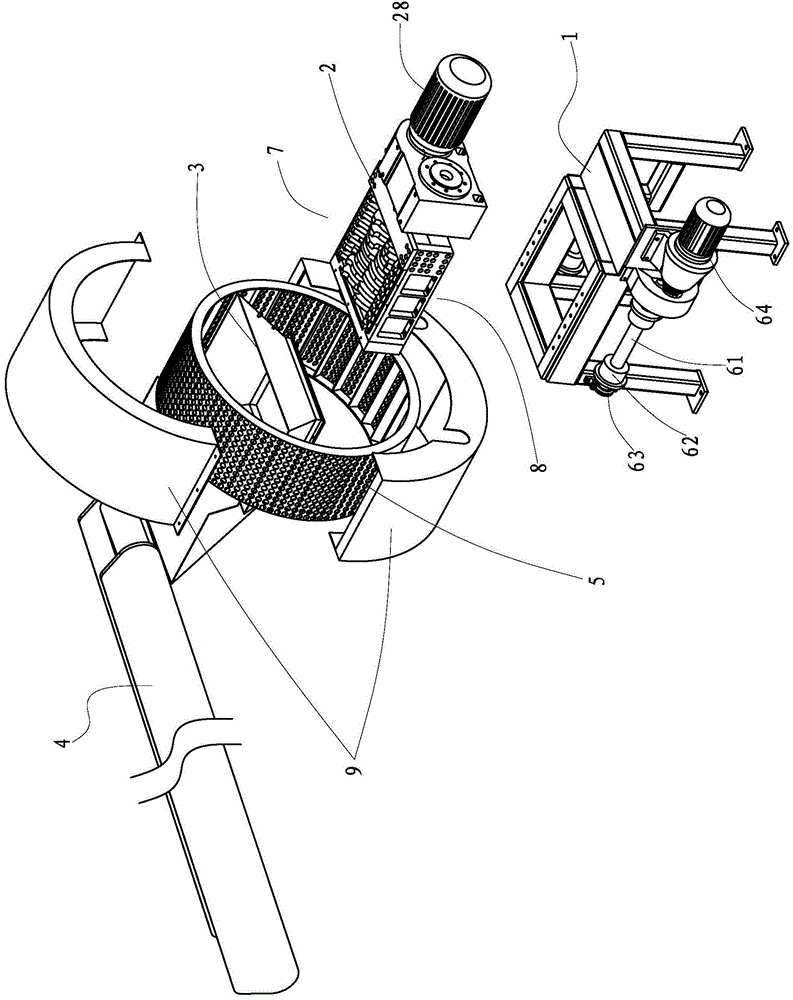

Coffee bean separating and rinsing device

ActiveCN103750513ASave waterSimple structureVegetable peelingFood treatmentWater circulationCoffee processing

The invention relates to a coffee processing device, in particular to a coffee bean separating and rinsing device integrating rapid sorting of unripe and ripe coffee cherries, separating of coffee beans and coffee peels and rinsing. The coffee bean separating and rinsing device is characterized by comprising a frame, an unripe and ripe coffee cheery separating device, a peel separating device, a drainage device, a degumming device and a cleaning water circulation device, wherein the unripe and ripe coffee cherry separating device, the peel separating device and the drainage device are arranged at the upper portion, in the middle and at the lower portion of the frame from top to bottom, the degumming device is arranged beside the frame and connected with the peel separating device, and the cleaning water circulation device is arranged at the bottom of the frame and connected with the drainage device and the unripe and ripe coffee cherry separating device. The coffee bean separating and rinsing device is simple in structure, reasonable in design, convenient to use and capable of saving resources, finishing procedures including unripe and ripe coffee cheery separating, peel removing, degumming and the like automatically, quickly and conveniently, reducing labor operation and increasing work efficiency.

Owner:YUNNAN PROV AGRI MACHINERY INST

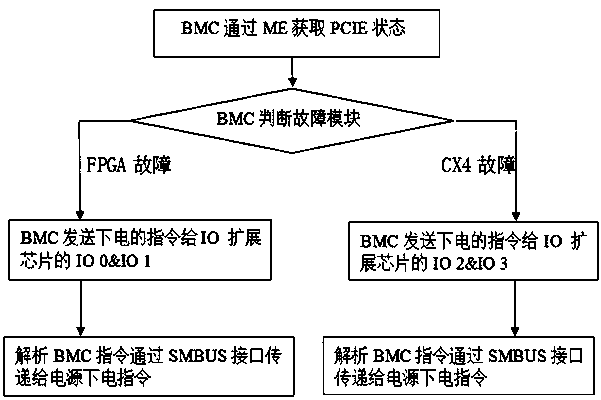

System and method for realizing power-on and power-off functions of intelligent network card

InactiveCN109634397APower on and offRealize the function of power on and offDetecting faulty computer hardwarePower supply for data processingIntelligent NetworkElectricity

The invention provides a system and a method for realizing power-on and power-off functions of an intelligent network card. The system comprises a host side and a remote server side, and BMC communication connection of the host side and the remote server side is achieved; wherein the host side comprises a main board, and an intelligent network card and an IO expansion chip are arranged on the mainboard. The intelligent network card is connected with the main board through the PCIE interface. The system further comprises a power supply, and the power supply is used for supplying power to the host end. The BMC of the remote server end is used for obtaining the state of the PCIE and judging the obtained state information, and if the intelligent network card has a PCIE fault, the BMC of the remote server end controls the intelligent network card to be powered on and powered off through the IO expansion chip. The method can be operated remotely through the BMC, machine room operation is not needed, and the labor operation and maintenance cost is saved.

Owner:ZHENGZHOU YUNHAI INFORMATION TECH CO LTD

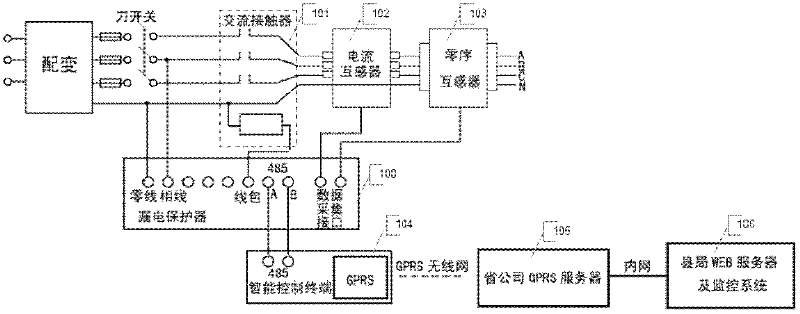

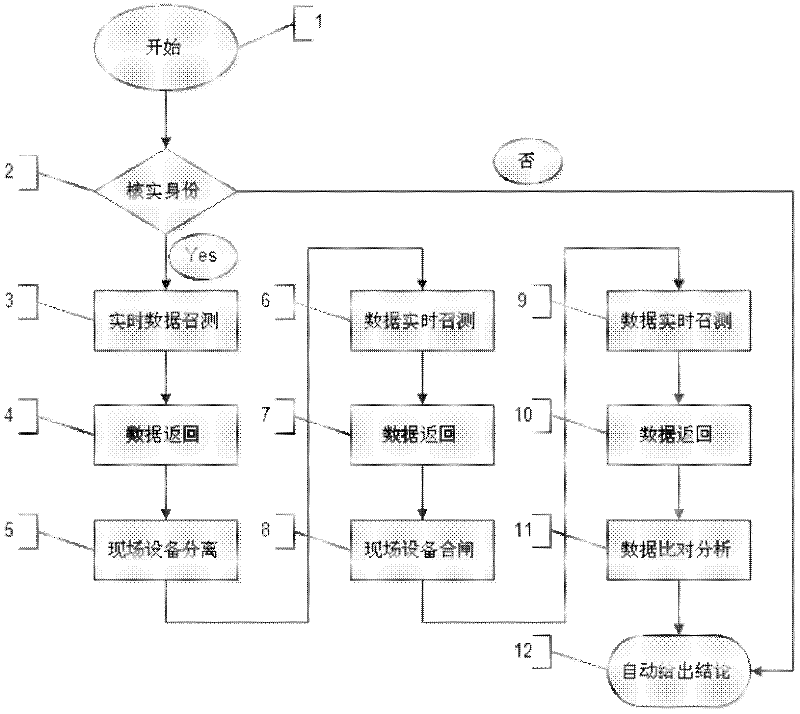

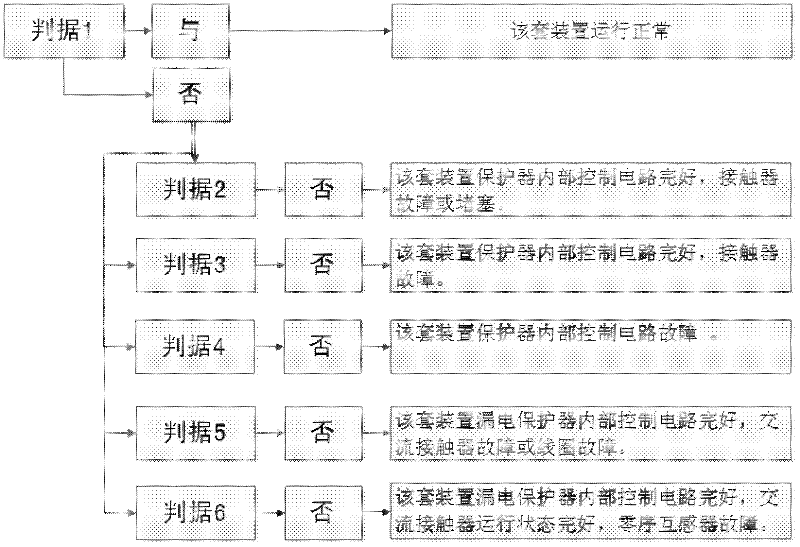

Device for judging fault of remote leakage protector and blockage or fault of alternating current contactor, and analysis method thereof

ActiveCN102636705AElectrical testingEmergency protective arrangements for automatic disconnectionLow voltageMonitoring system

The invention discloses a device for judging fault of a remote leakage protector and blockage or fault of an alternating current contactor, and an analysis method thereof. The analysis method comprises the following step of: judging whether a field protector device and a contactor successfully switch off and on by a method of reading a low-voltage outgoing line zero sequence current value, a three-phase current value and on / off state data of a protector through a remote monitoring system. Therefore, through adoption of the device and the analysis method thereof, disclosed by the invention, whether an inner control circuit of the protector has the fault or not and whether the contactor has faults of forced blockage and self-contact adhesion or not can be judged by utilizing an indirect electric measurement method, and an effect that remote trial jump and the field protector button trial jump detection are same is also guaranteed, thus a large amount of labor operation time is saved.

Owner:STATE GRID ZHEJIANG DEQING COUNTY POWER SUPPLY CO LTD +1

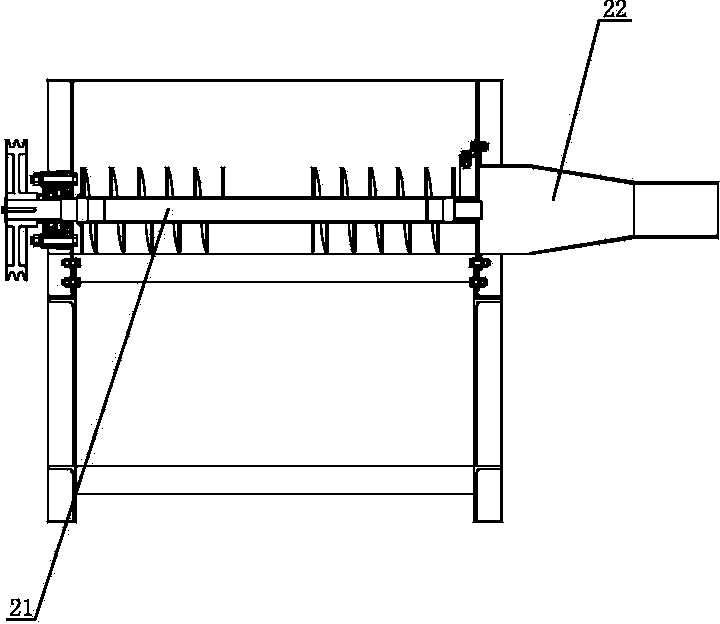

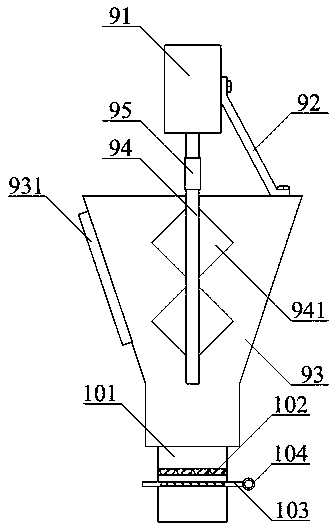

High-efficiency crushing machine

ActiveCN104624320AUniform finenessMeet the process requirementsGrain treatmentsCrusherLabor operations

The invention discloses a high-efficiency crushing machine. A crushing device is arranged on a rack; a crushing feeding hole and a crushing discharge hole are respectively formed in the upper part and the lower part of the crushing device; a rolling screen which can rotate relative to the rack and is of a cylindrical structure, and a rolling screen driving device for driving the rolling screen to rotate are arranged on the rack; the crushing discharge hole is positioned in the inner side of the rolling screen; crushed garbage falls on the continuously rotating rolling screen through the garbage discharge hole; when the fineness of the crushed garbage meets provided requirements, the garbage can be screened off from the rolling screen, the garbage which does not meet the fineness requirements rotates along with the rolling screen, falls into the crushing feeding hole when rotating to a highest point, and is further crushed. Therefore, the uniform fineness of the garbage screened off from the rolling screen is effectively ensured, the process requirements can be met, and garbage which does not meet the fineness requirements can be automatically crushed for the second time or multiple times, so that the labor operation cost can be lowered, and the crushing efficiency can be improved.

Owner:OMS MASCH CO LTD

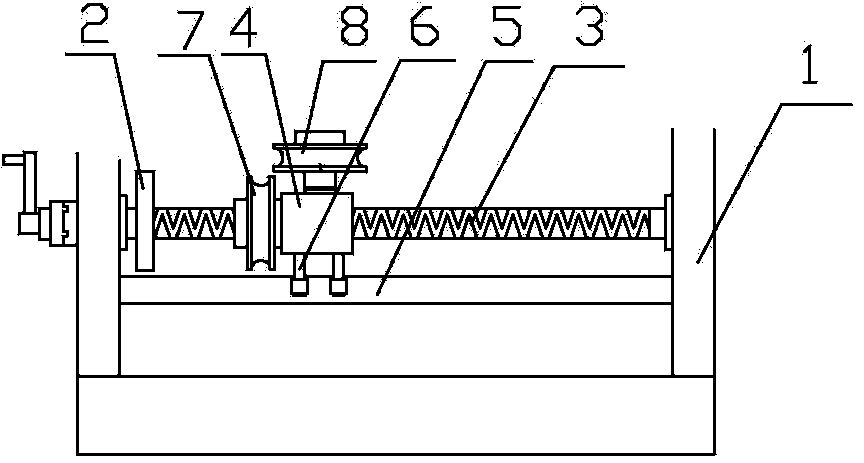

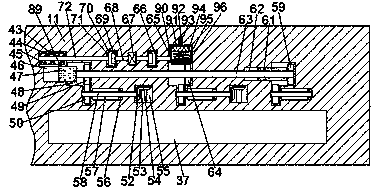

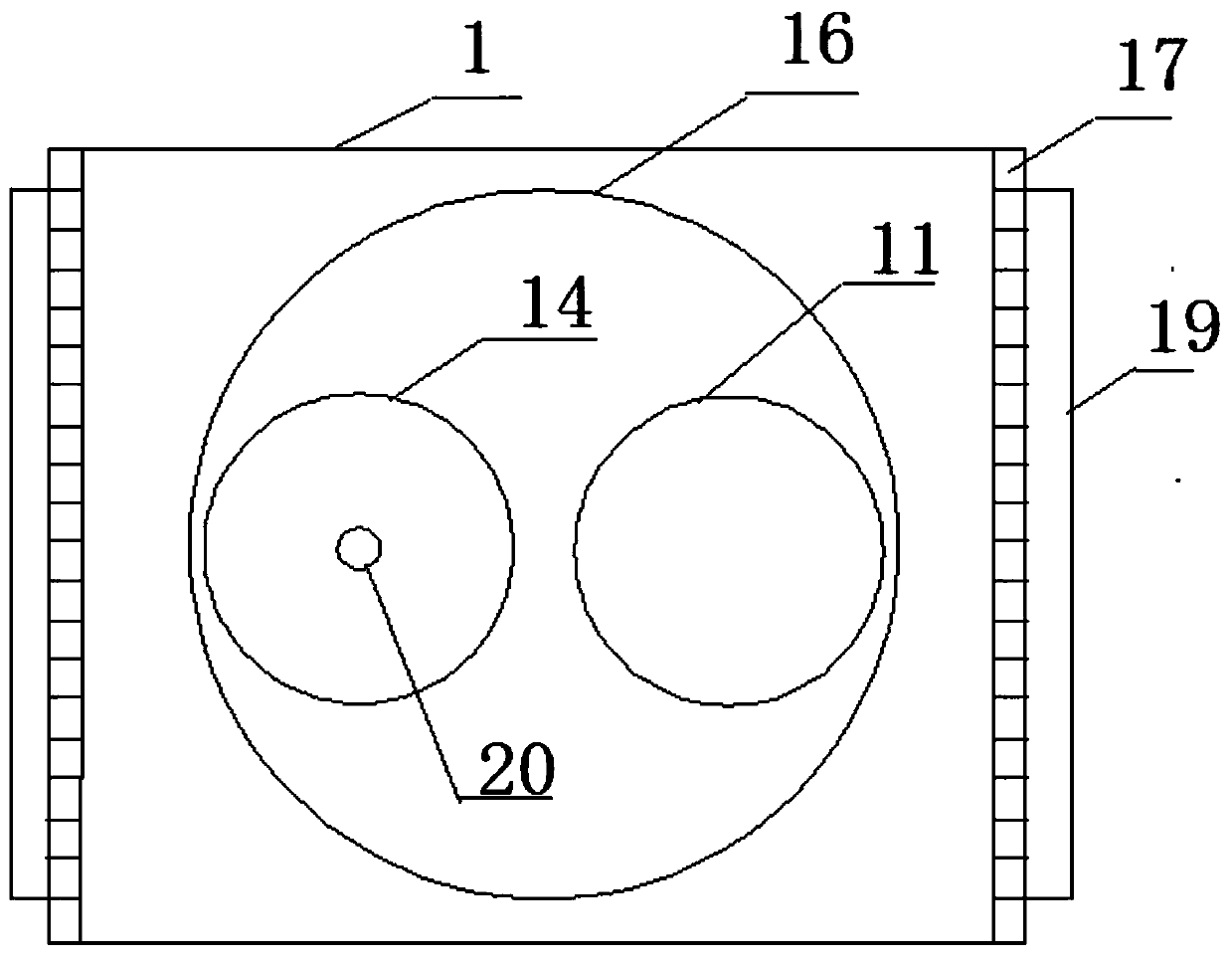

Guiding wiring arrangement apparatus for electric power cable take-up machine

InactiveCN103647246AWind evenlyImprove work efficiencyArrangements using take-up reel/drumElectric power equipmentPower equipment

The invention relates to electric power equipment and specifically to a guiding wiring arrangement apparatus for an electric power cable take-up machine. The apparatus comprises a support and a bidirectional leading screw installed on the support through a bearing. One end of the bidirectional leading screw is provided with a sprocket wheel and is in transmission connection with a power device through the sprocket wheel, the a wire arrangement tackle is installed on the bidirectional leading screw in a sleeved manner, a slide rail is fixedly installed on the support, the slide rail and the bidirectional leading screw are in parallel arrangement, a support bar installed in the slide rail is fixedly connected with the wire arrangement tackle, the wire arrangement tackle is provided with a wire arrangement pulley, and the wire arrangement pulley and the bidirectional leading screw are coaxially arranged. The guiding wiring arrangement apparatus can employ a power machine such as a tractor and the like as a driving mechanism to replace labor operation, and the operation efficiency is high. A wiring arrangement mechanism can uniformly wind cables on a take-up reel, the coiling quality is high, and the effects are good. The wire arrangement pulley and a head pulley can guide the cables from different directions, the user is convenient, and the adaptability is high.

Owner:郯城县明珠发展有限公司

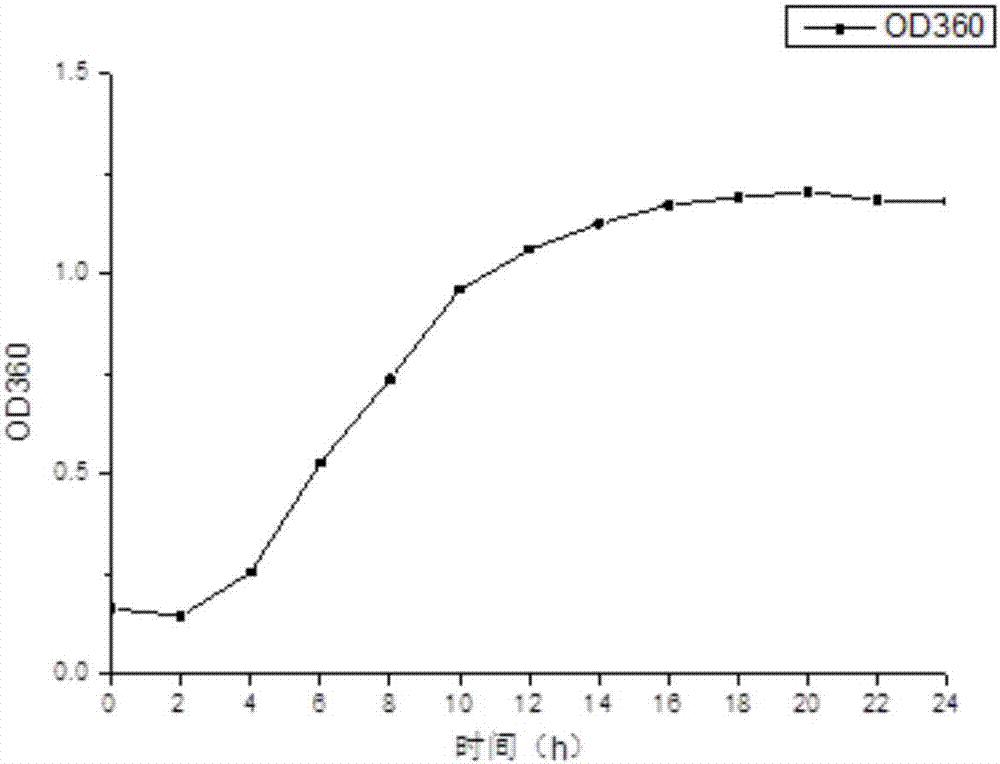

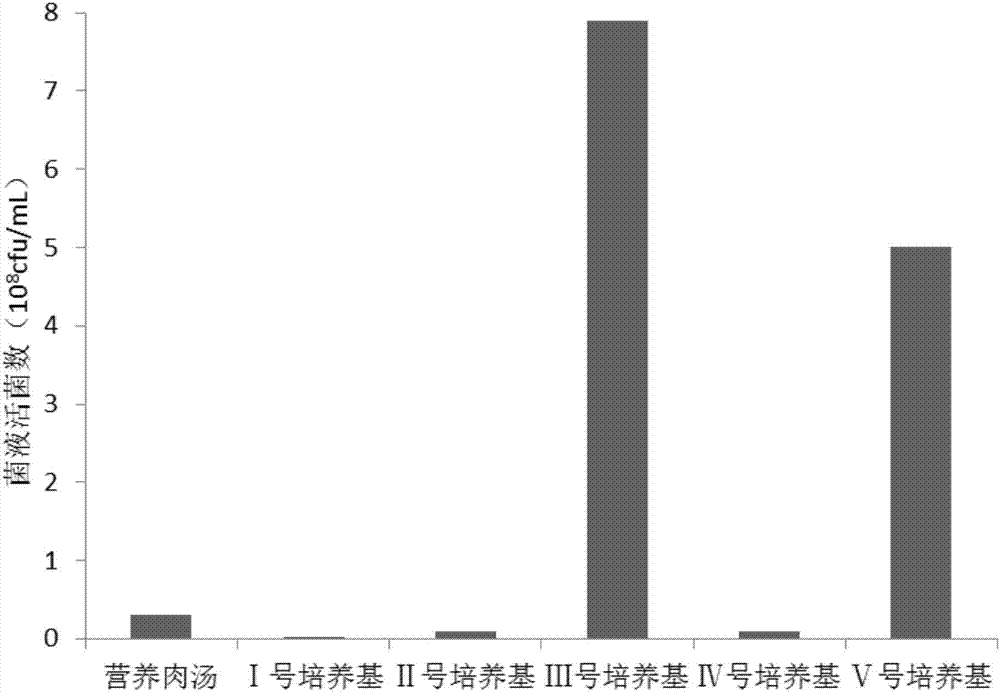

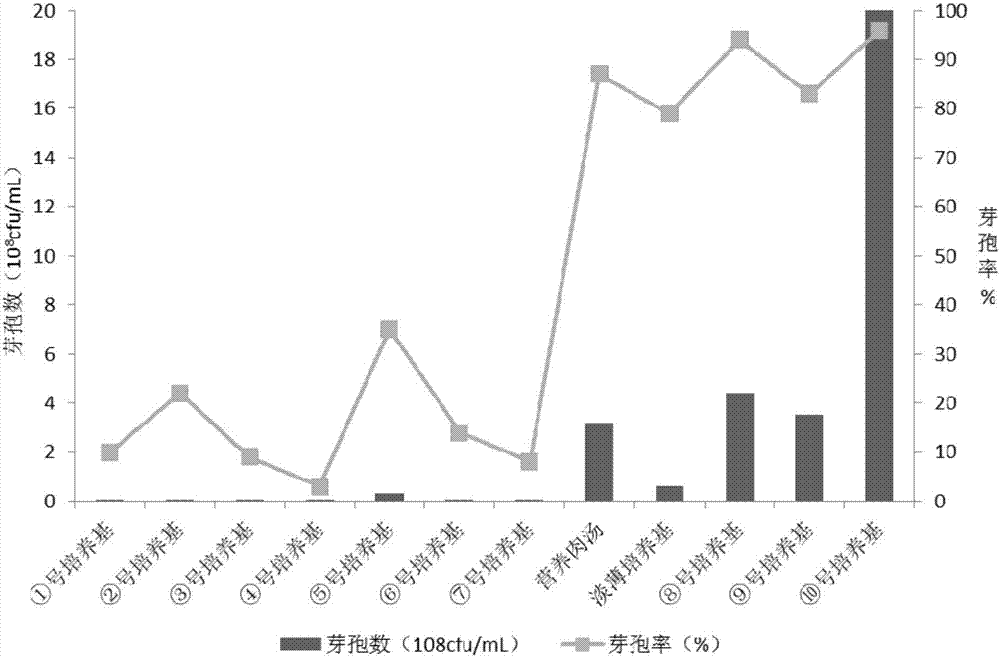

Method for obtaining geobacillus stearothermophilus spores

ActiveCN107475172AImprove cultivation efficiencyImprove induction efficiencyBacteriaMicroorganism based processesSporeGeobacillus stearothermophilus

The invention relates to a method for obtaining geobacillus stearothermophilus spores. The method comprises the following steps of inoculating the geobacillus stearothermophilus into a liquid seed culture medium; performing culture to obtain seed liquid; inoculating the seed liquid into a liquid spore producing inducing culture medium to be subjected to induced culture; performing induction to produce the spores. The method has the advantages that the culture of the seed cells and the induction of the spores are both performed in the liquid culture; the culture and induction efficiency are greatly improved; the time is shortened; the labor operation is reduced; the high spore number and the high spore yield can be obtained in 36 to 48 hours.

Owner:湖北省微工生物技术研究有限公司

Method for carrying out painting through automatically configuring painting devices by utilizing timber coloring agents

InactiveCN109127266AUniform textureAvoid cross-colorLiquid surface applicatorsRotary stirring mixersLabor operationsWood stain

The invention discloses a method for carrying out painting through automatically configuring painting devices by utilizing timber coloring agents. A device used in the method comprises a device main body, a coloring device, a painting device and a stirring device, wherein the coloring device, the painting device and the stirring device are arranged in the device main body; a pass-out pipeline is arranged between the coloring device and the stirring device in a communication manner; and multiple switch structures are arranged in the coloring device and control multiple connection channels whichare communicated with the pass-out pipelines. The device is capable of automatically driving a coloring agent to be automatically matched and driving a timber to be painted; during the painting; a brush uniformly moves to drive the timber to uniformly move, so that the painting effect is uniform; during the painting, the coloring agent is stirred to ensure that the coloring gent is uniform in character; meanwhile, the device can work for a long time, so that the efficiency is improved and the labor operation time is saved; and after automatic coloring, mixtures pass through respective different channels so as to avoid color crossing.

Owner:王文齿

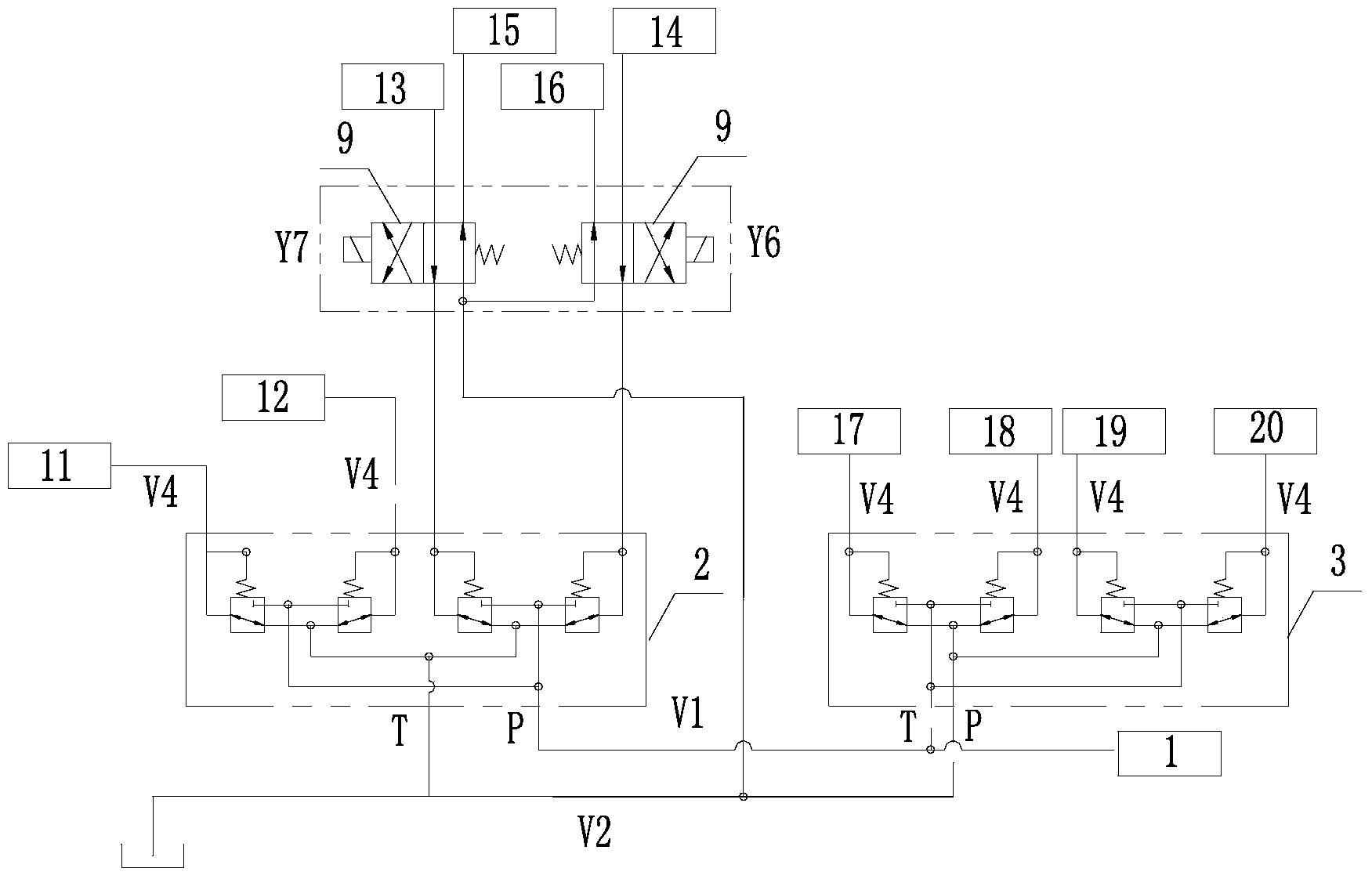

Hydraulic control handle system

ActiveCN103640975AImplement mobile controlLabor-free operationLoad-engaging elementsElectricityHuman–machine interface

The invention discloses a hydraulic control handle system. The hydraulic control handle system comprises a pressure oil source (1), a hydraulic control handle and an operating control loop, which are successively connected through an oil way, wherein the operating control loop realizes the operating control through the operation of the hydraulic control handle; the hydraulic control handle system also comprises a proportion pressure reducing valve (10) and a controller for controlling the proportion pressure reducing valve, the proportion pressure reducing valve is arranged on a handle oil inlet oil way (V1) arranged between the pressure oil source and an oil inlet (P) of the hydraulic control handle, and a controller is electrically connected with the proportion pressure reducing valve so as to control the pressure of the hydraulic oil which flows through the proportion pressure reducing valve. Therefore, the opening of the proportion pressure reducing valve is controlled and set through the controller such as computer software, a condition that a human-computer interface control manner can enhance control or replace a manual operation hydraulic control handle manner, the labor operation of the manual operation is avoided, the operation control is accurate, and in addition, the electronic control manner is combined with the proportion pressure reducing valve to realize the movable control and the like.

Owner:ZOOMLION HEAVY IND CO LTD

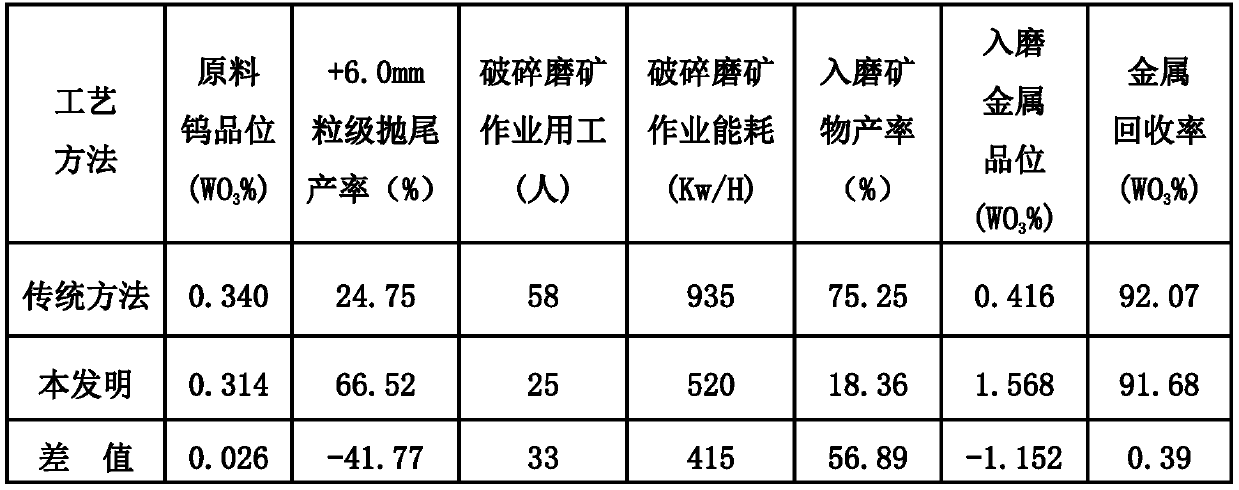

Wolframite tailing discarding and refining beneficiation method

ActiveCN109894268AReduce energy consumptionReduce the burden onMagnetic separationWet separationX-rayHigh pressure

The invention discloses a wolframite tailing discarding and refining beneficiation method. The method aims to solve the technical problems that an existing wolframite beneficiation method is high in manpower cost and low in labor operation efficiency. The method comprises the steps that single-stage crushing grading operation is adopted to meet the fraction requirement of subsequent-stage tailingdiscarding operation; then an X-ray intelligent concentrating machine is adopted to perform sorting operation, metallic minerals and non-metallic minerals are separated, and large-yield direct tailingdiscarding of 6-50mm large-fraction minerals is realized; next, a high-pressure roller mill is adopted to make the granularity of broken minerals below 6.0mm; and then a coarse-particle ultrahigh-field-intensity vertical-ring high-gradient magnetic separator is used to perform one-roughening-one-sweeping sorting operation, and by use of super-strong magnetic force of the ultrahigh-field-intensityvertical-ring high-gradient magnetic separator, weakly-magnetic wolframite is effectively recovered, and meanwhile direct tailing discarding of coarse-particle minerals is further realized. Through the method, the large-fraction minerals can be subject to direct tailing discarding, the burden on subsequent operation can be greatly relieved, therefore, the beneficiation cost of wolframite is substantially lowered, and low-energy-consumption high-efficiency recovery of wolframite is realized.

Owner:赣州金环磁选科技装备股份有限公司

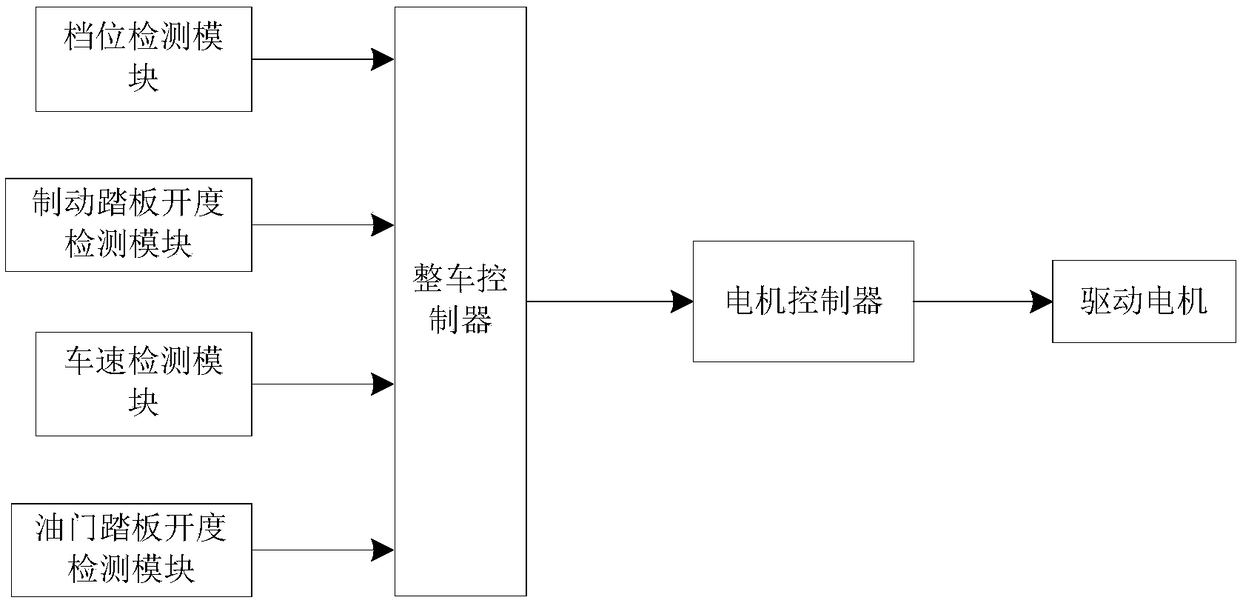

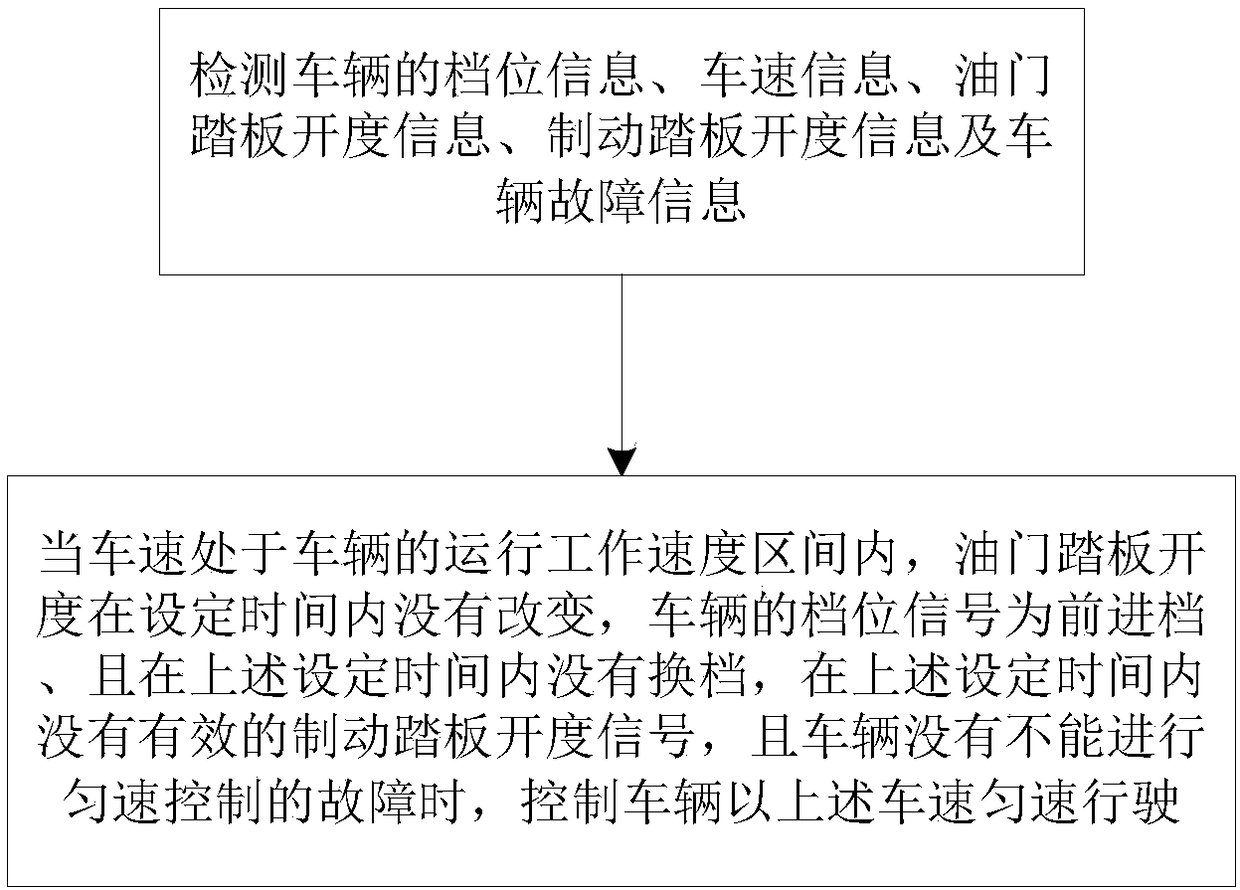

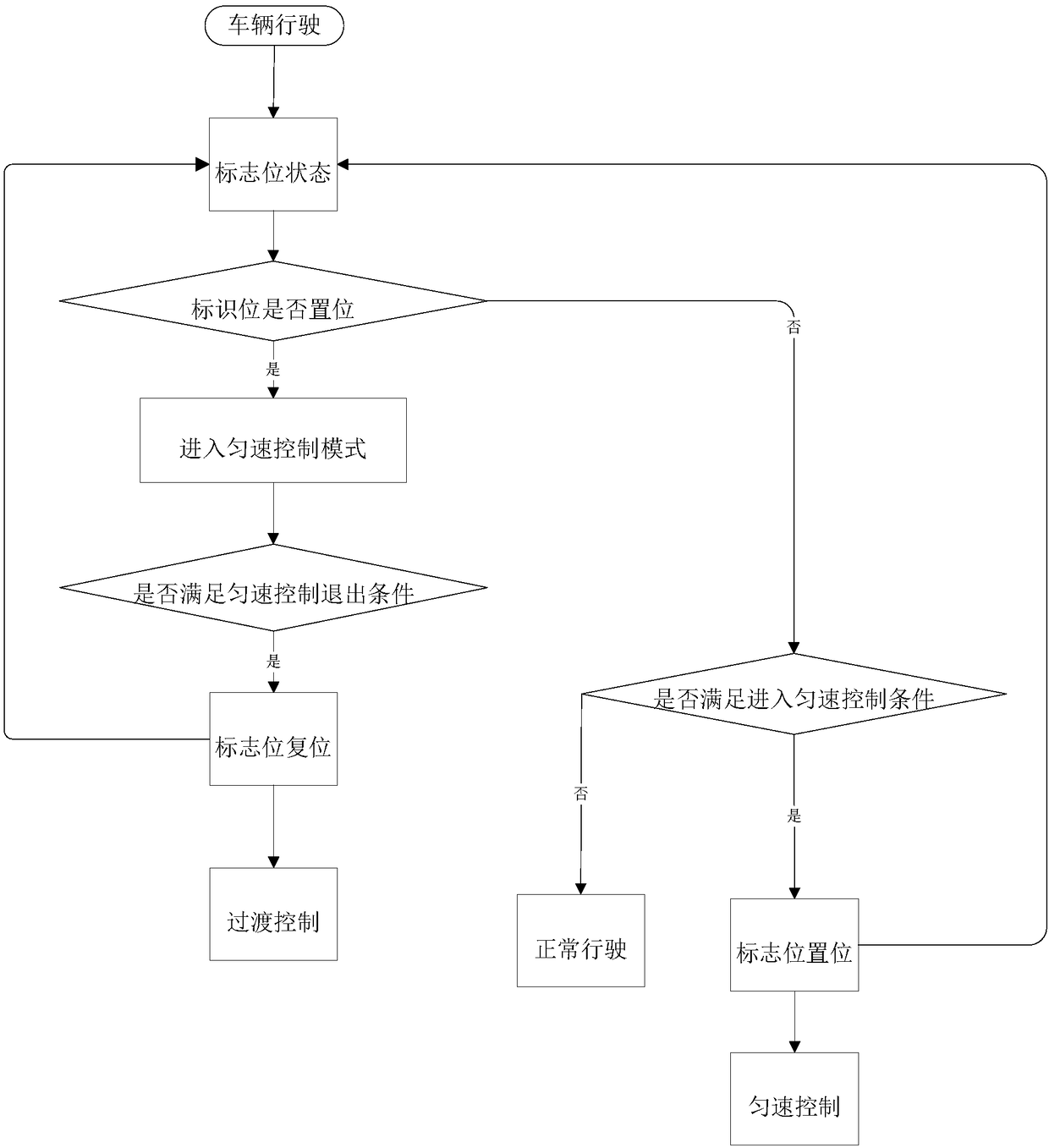

Pure-electric environmental sanitation vehicle constant-speed control method and device

The invention relates to a pure-electric environmental sanitation vehicle constant-speed control method and device. The method includes the steps that firstly, gear information, vehicle speed information, accelerator pedal opening degree information, brake pedal opening degree information and vehicle fault information of a vehicle are detected; and then, when the vehicle speed is in the operationworking speed interval of the vehicle, the accelerator pedal opening degree is not changed within set time, a gear signal of the vehicle indicates a forward gear and the gear is not shifted within theset time, no effective brake pedal opening degree signal is sent out within the set time, and when the vehicle has no fault forbidding constant-speed control, the vehicle is controlled to travel at the current constant speed. Through control of the constant-speed control method, the pure-electric environmental sanitation vehicle can be in a constant-speed traveling state and also a low-stable-speed driving state, a driver does not operate an accelerator pedal for a long time and does not accurately control the accelerator pedal, and the driver control burden and labor operation intensity arereduced.

Owner:ZHENGZHOU YUTONG BUS CO LTD

Sealing rubber strip edge cutting machine

ActiveCN105397848AReduce labor intensityReduce labor pressureMetal working apparatusEngineeringUltimate tensile strength

The invention relates to the technical field of processing equipment for sealing rubber strips, and particularly relates to a sealing rubber strip edge cutting machine. The sealing rubber strip edge cutting machine comprises a machine frame, wherein a fixing seat used for fixing a sealing rubber strip is arranged on the machine frame, two guiding plates parallel to each other are arranged on the fixing seat in the axial direction, a sliding rail is arranged on the machine frame and on one side of the fixing seat, a sliding seat driven by a power device is arranged on the sliding rail in a sliding manner, a mounting frame is arranged on the sliding seat, two longitudinal cutters parallel to each other and arranged at an interval are mounted on the mounting frame, and the power device drives the sliding seat to slide on the sliding rail so as to drive the two longitudinal cutters to be close to the outer side walls of corresponding guiding plates to move in the axial direction. The sealing rubber strip edge cutting machine provided by the invention has the advantages as follows: the entire edge cutting process is completely automated, manual scribing for edge cutting is not required, the labor intensity and the labor pressure of workers can be alleviated, manual work requirements can be reduced greatly, skilled labor operation is not required, and the work efficiency is improved greatly.

Owner:ZHEJIANG XIANTONG RUBBER & PLASTIC CO LTD

Method for preparing titanium oxysulfate solution by flotation of titanium concentrate

ActiveCN102515266AReduce splatterReduce volume expansion heightTitanium dioxideAcid hydrolysisTitanium

The invention discloses a method for preparing a titanium oxysulfate solution by flotation of titanium concentrate, and belongs to the field of chemical engineering, wherein the method has characteristics of reduction of material spitting degree during the mineral acid reaction and avoidance of material spitting out of the acid hydrolysis pot during the mineral acid reaction. The method comprises the following steps: a, uniformly mixing titanium concentrate powder and concentrated sulfuric acid; b, placing the resulting mixture in an acid hydrolysis pot, adding an initiation liquid to initiate a mineral acid reaction, and blowing high pressure gas to the acid hydrolysis pot during the mineral acid reaction; c, carrying out ripening on the mixture after the mineral acid reaction, adding a leaching liquid to the acid hydrolysis pot to carry out leaching, and filtering to obtain the titanium oxysulfate solution. With the method of the present invention, the phenomenon of the material spitting out of the acid hydrolysis pot is avoided, the safety of the operator during the production process is ensured, the environmental sanitation is improved, and the labor operation intensity is reduced, such that the popular application of the titanium concentrate flotation in the titanium pigment production by the sulfuric acid method is promoted.

Owner:PANZHIHUA DONGFANG TITANIUM IND

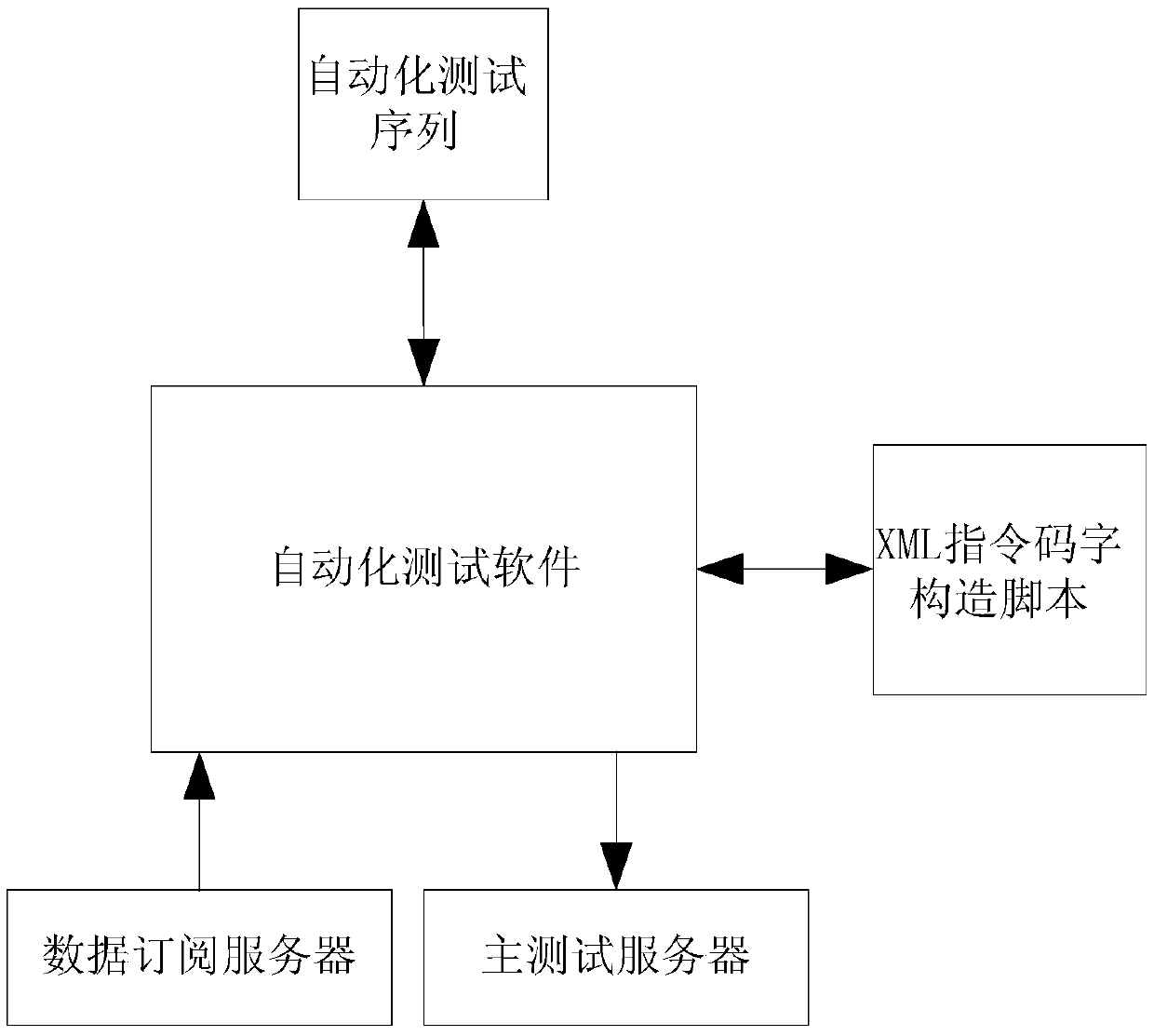

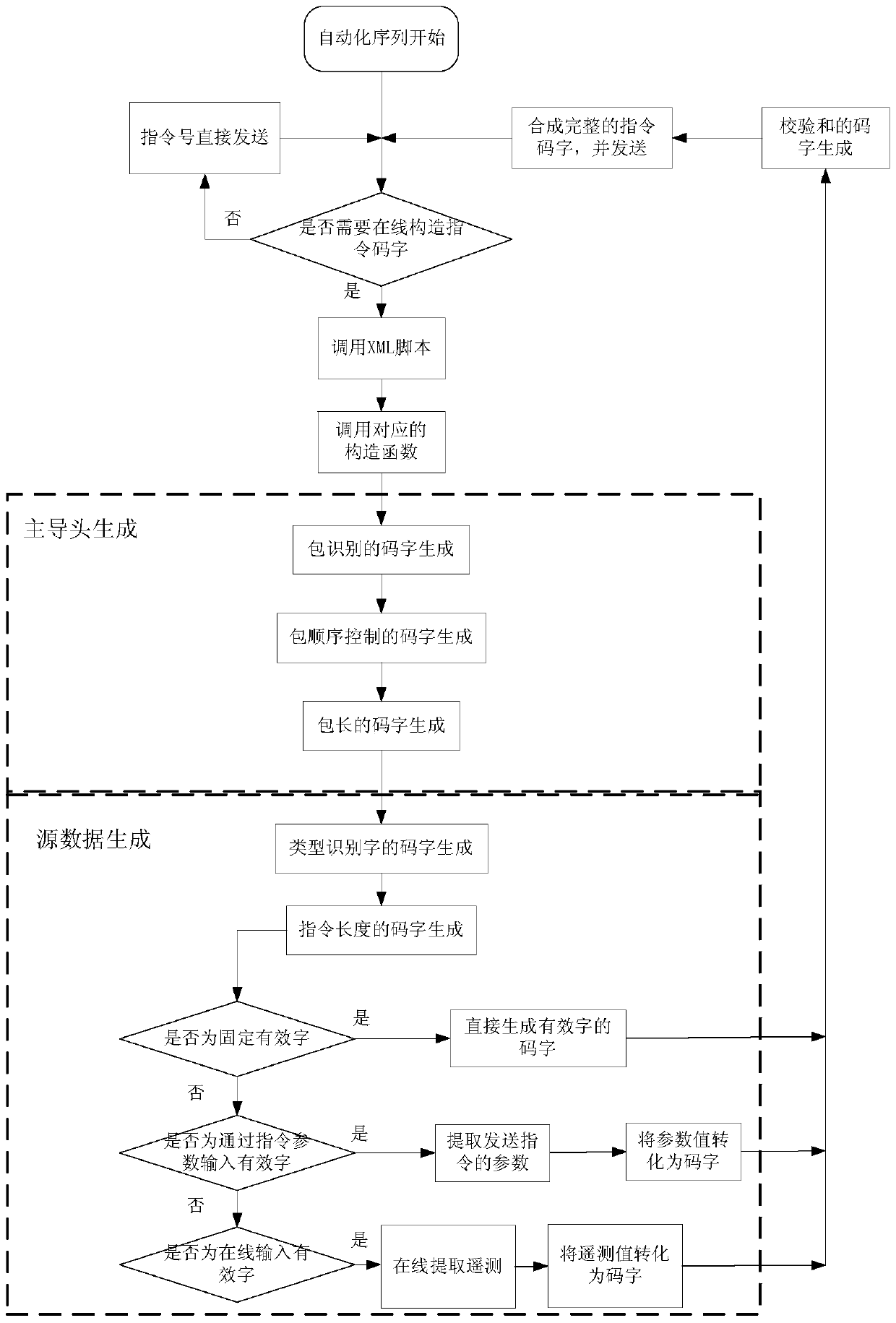

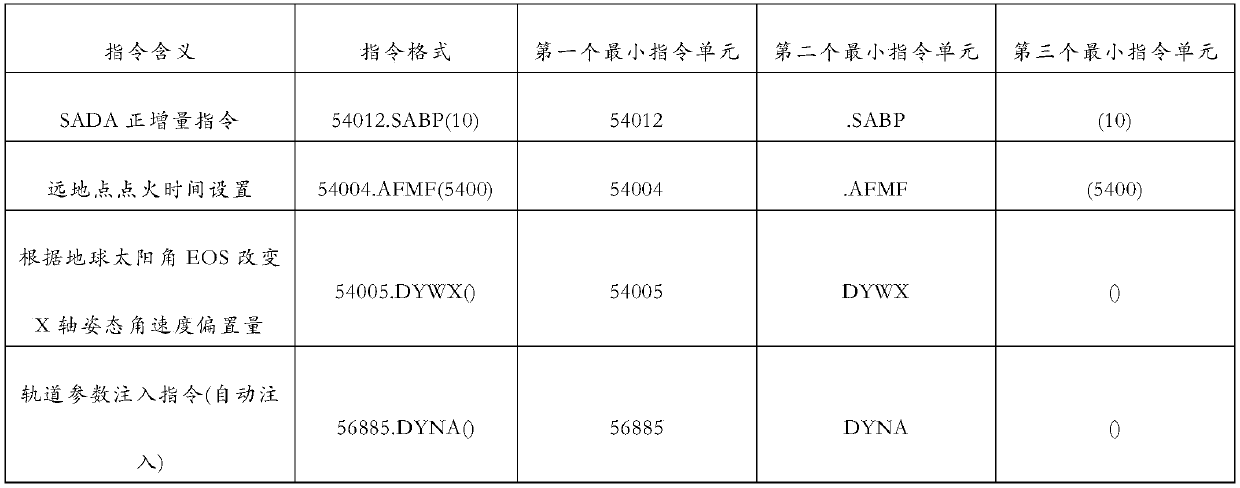

Satellite test efficiency improving method based on satellite order code word intelligent construction

ActiveCN105512030AEnsure refinementEnsure full coverageSoftware testing/debuggingState parameterTest order

The invention relates to a satellite test efficiency improving method based on satellite order code word intelligent construction; the method comprises the following steps: defining a remote control order and a parameter format according to a satellite remote control order function and complexity; in an XML coder code word construction script, combining XML language with Lua language to automatically carry out code word generation for satellite remote control order dominant head, source data and checksum, and integrating the code words into a complete order code word. The Lua function can read satellite remote measurement parameters online, and can calculate and process parameters, cannot be directly formed by XML, so as to the order code word; the Lua function can form a test order sequence according to satellite single machine test demand, can remotely control the satellite single machine state, and can compare satellite remote measurement parameters with order valid word preset state parameters, thus completing satellite single machine performance test. The method can reduce labor operation, can improve satellite remote control order generation efficiency and order readability, can reduce error rate, can reduce satellite test time, thus enhancing satellite test intelligent degree and actionability.

Owner:CHINA ACADEMY OF SPACE TECHNOLOGY

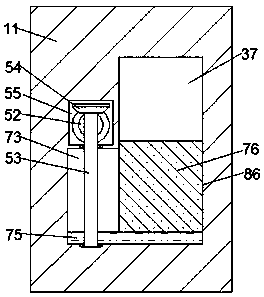

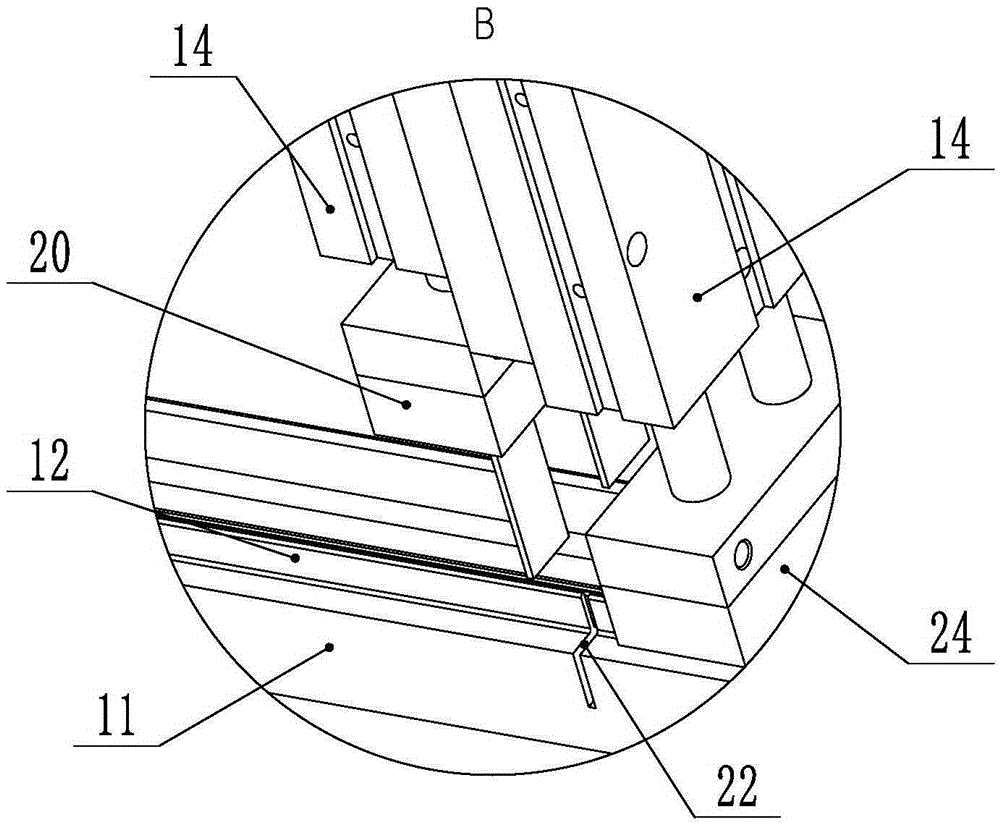

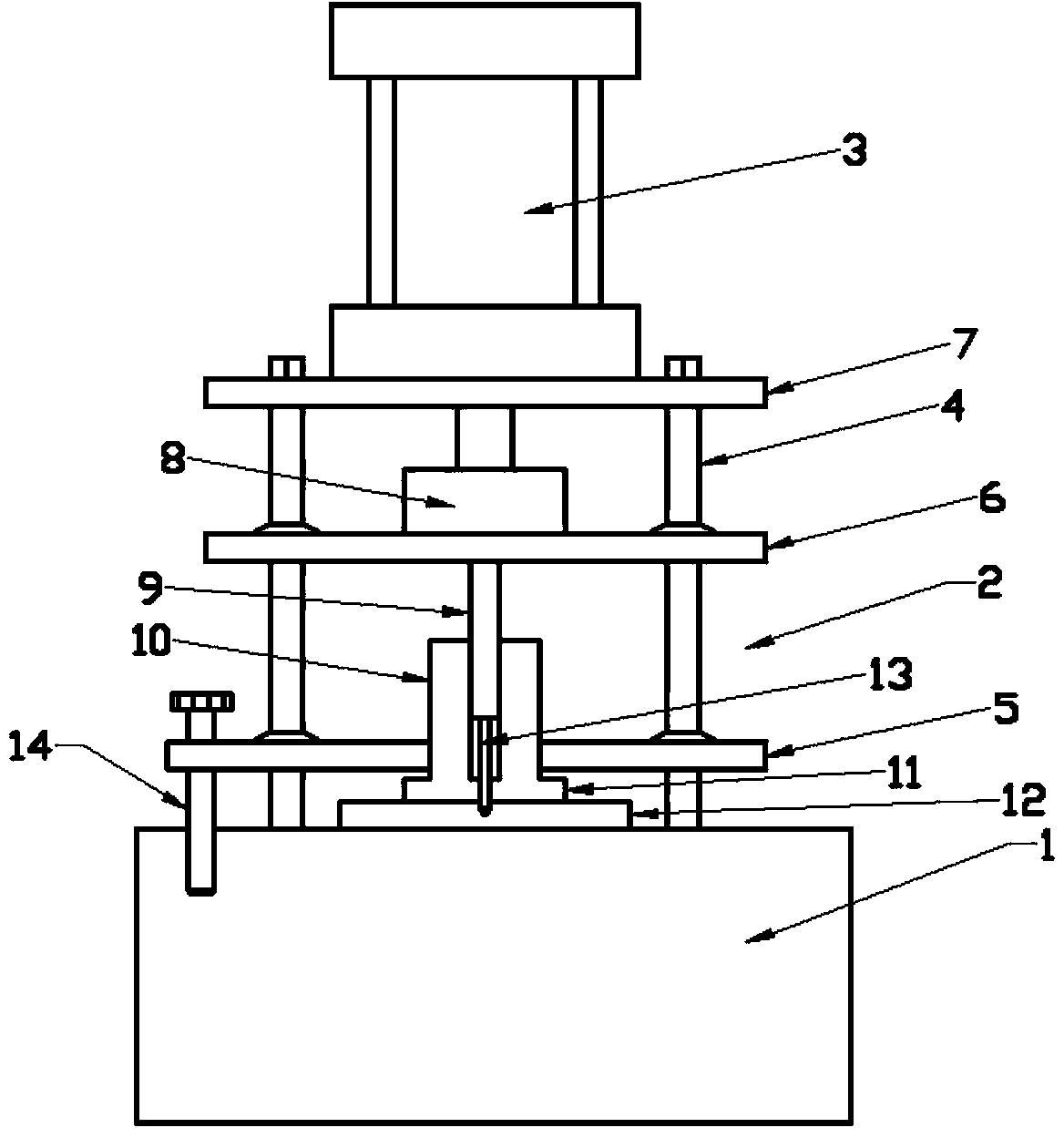

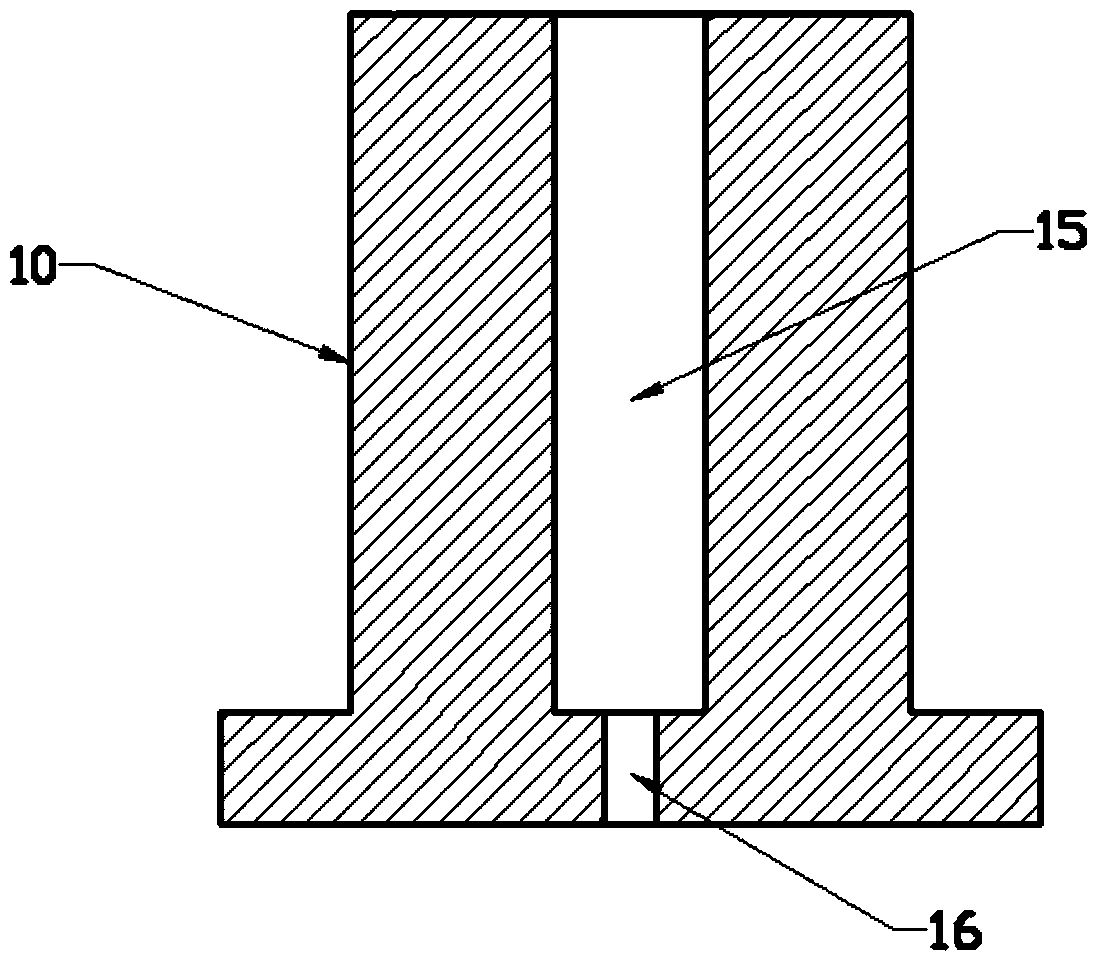

Locating pin press fitting device

InactiveCN104289899APrecise positioningAvoid misalignmentMetal working apparatusPunch pressEngineering

The invention relates to a locating pin press fitting device. The locating pin press fitting device comprises a base, a rack, a downwards pressing air cylinder and a fastening bolt; the rack comprises a guide rod, a clamping board, a sliding board and a fixed board; the guide rod is vertically fixed to the base; the guide rod penetrates through the fixed board, the sliding board and the clamping board in sequence from top to bottom; the fixed board is fixed to the top end of the guide rod; the sliding board, the clamping board and the guide rod are in sliding connection; the downwards pressing air cylinder with a piston rod downwards arranged is fixed to the upper surface of the fixed board; a balancing weight is fixed to the lower end of the piston rod of the downwards pressing air cylinder; a vertical pushing rod is fixed to the center of the lower surface of the sliding board. The downwards pressing air cylinder serves as pressure, the sliding board and the clamping board can only vertically move, it is avoided that due to pressure deviation, a locating pin is not accurate and staggered or the like in the press fitting process, tedious labor operations are reduced, labor intensity of workers is relieved, the press fitting speed is high, and the production efficiency and product percent of pass are improved.

Owner:NINGBO XUSHENG AUTO TECH CO LTD

Three-roller linkage adjustable numerical control four-roller plate winding machine

ActiveCN108580606ALabor savingIncrease productivityMetal-working feeding devicesPositioning devicesWinding machineNumerical control

The invention relates to the field of plate machining, in particular to a three-roller linkage adjustable numerical control four-roller plate winding machine which comprises an arranging mechanism, adischarging mechanism, a pressing mechanism, a working table, a conveying mechanism, a plate winding mechanism and a base. The arranging mechanism is used for arranging a machined plate to enable theplate to tend to form the needed radian. The discharging mechanism facilitates pushing out of the machined plate. The pressing mechanism can press the input plate to prevent the plate from warping upand waggling. The conveying mechanism can input the plate. The base has good damping performance. According to the machine, rotatable conveying plates are installed on the two sides of the plate winding mechanism, the input and output plate can be carried, received and conveyed, meanwhile, in the plate winding forming process, the two sides of the wound plate can be arranged to enable the plate totend to form the needed radian, labor operation is reduced, the machining efficiency is improved, safety performance is improved, the situation that in the feeding process, the plate waggles can be effectively avoided, the machining efficiency is improved, and the quality of the wound plate is improved.

Owner:南通威锋重工机械有限公司

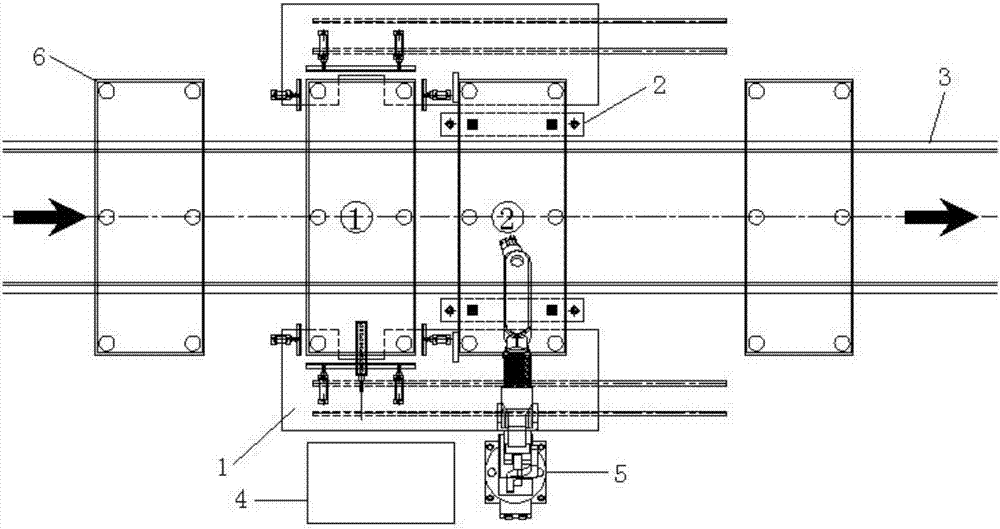

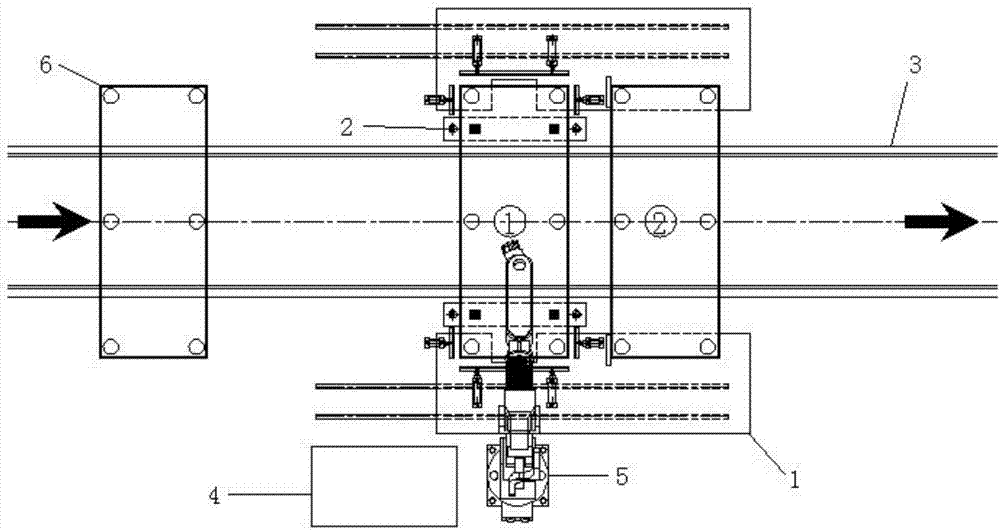

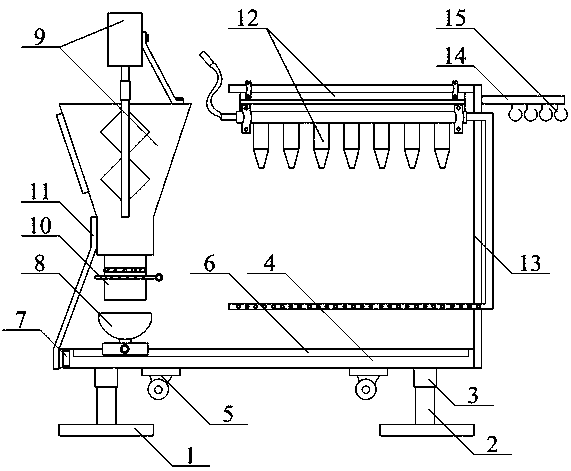

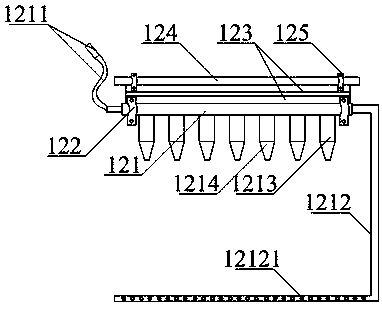

Gluing device and method for inner container of refrigerator body

ActiveCN107225071AImprove consistencyIncrease productivityLiquid surface applicatorsCoatingsEngineeringRobot control

The invention discloses a gluing device and method for an inner container of a refrigerator body, and relates to the field of refrigerator body inner container pre-assembly. The gluing device for the inner container of the refrigerator body comprises a conveying line. The conveying line is used for placing workpieces. The two sides of the conveying line are provided with lifting pallets. The two sides of each lifting pallet are provided with feeding and positioning devices. One side of each feeding and positioning device is provided with a gluing machine. A gluing gun of each gluing machine is connected with a robot. One side of the conveying line is provided with a two-dimensional code scanner. The two-dimensional code scanner and the robots are in signal connection. After the workpieces are conveyed by the conveying line and pass through the two-dimensional code scanner to be scanned, the robots control the gluing machines to glue for the workpieces. According to the gluing device for the inner container of the refrigerator body, machine automated production of a working procedure of filling a gap of the combination position of the refrigerator inner container and a refrigerator outer shell is achieved, and a technology of filling the gap of the combination position of the refrigerator inner container and the refrigerator outer shell by existing manual labor sponge bar pasting is replaced; and the product consistency is improved, the operation process is accurate, the glue amount can be control precisely and is less than the glue amount used by manual labor, the cost is saved, the potential safety hazard of manual labor operation is removed, and the production efficiency is improved.

Owner:盐城恒华智造科技有限公司

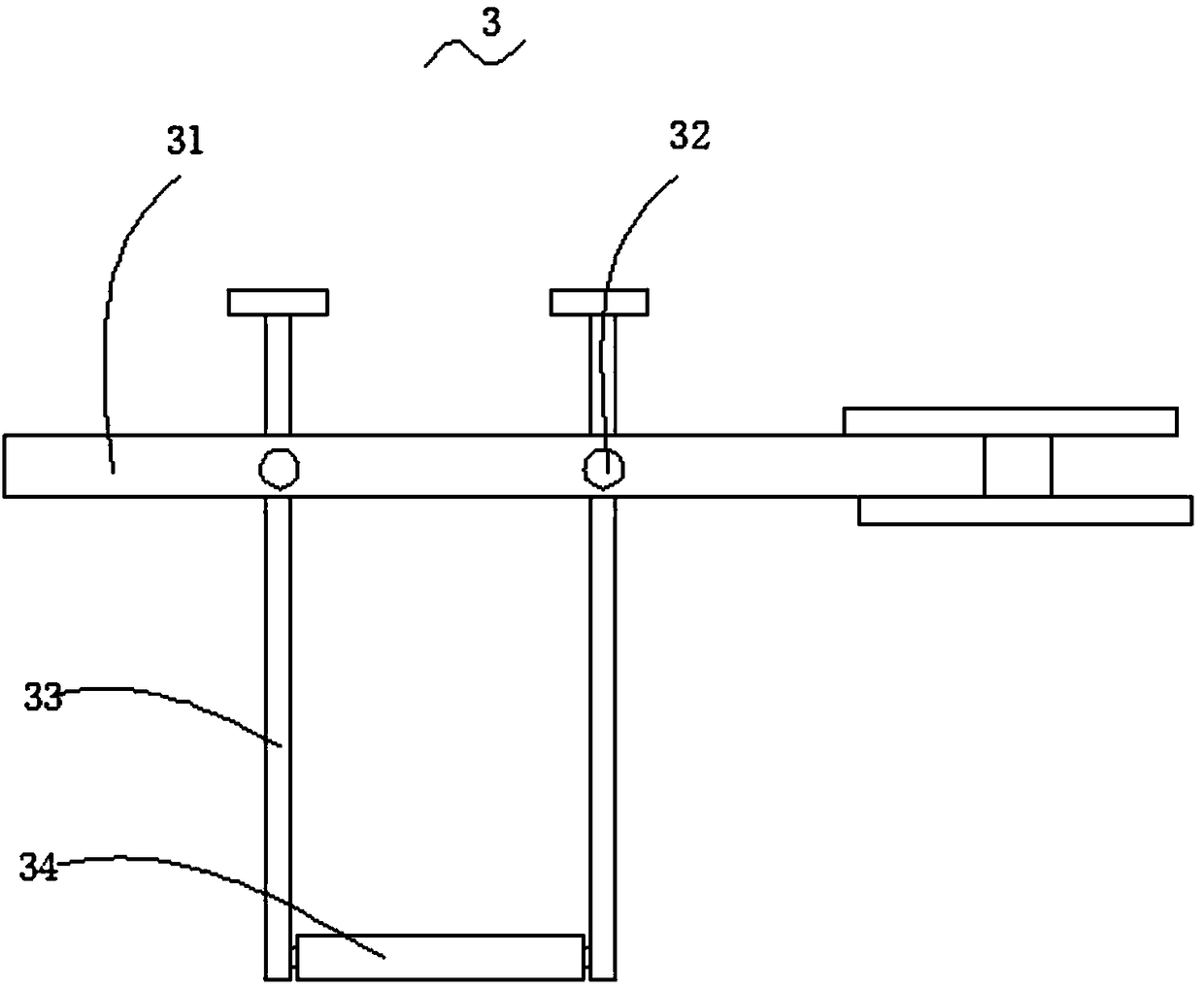

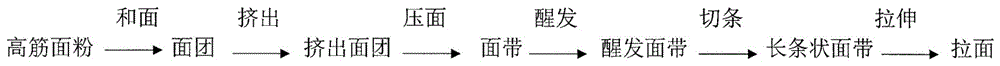

Method for making stretched noodles industrially

PendingCN105707694ASuitable for industrial productionSoft and smooth tasteFood scienceEngineeringFermentation

The invention discloses a method for making stretched noodles industrially. The method comprises the following steps of dough kneading, extrusion, dough pressing, fermentation, cutting to strips and stretching. Most labor operation is replaced with machine equipment, so that time and labor are saved, efficiency is high, and the method is applicable to industrial batch production of stretched noodles. By combining extrusion and dough pressing, a traditional stretched noodle making technology is restored to the high degree, gluten is sufficiently formed, and the stretched noodles are smooth and soft in mouthfeel and rich in elasticity. One-time fermentation is adopted, and therefore stretched noodle making time is greatly shortened.

Owner:HENAN UNIVERSITY OF TECHNOLOGY

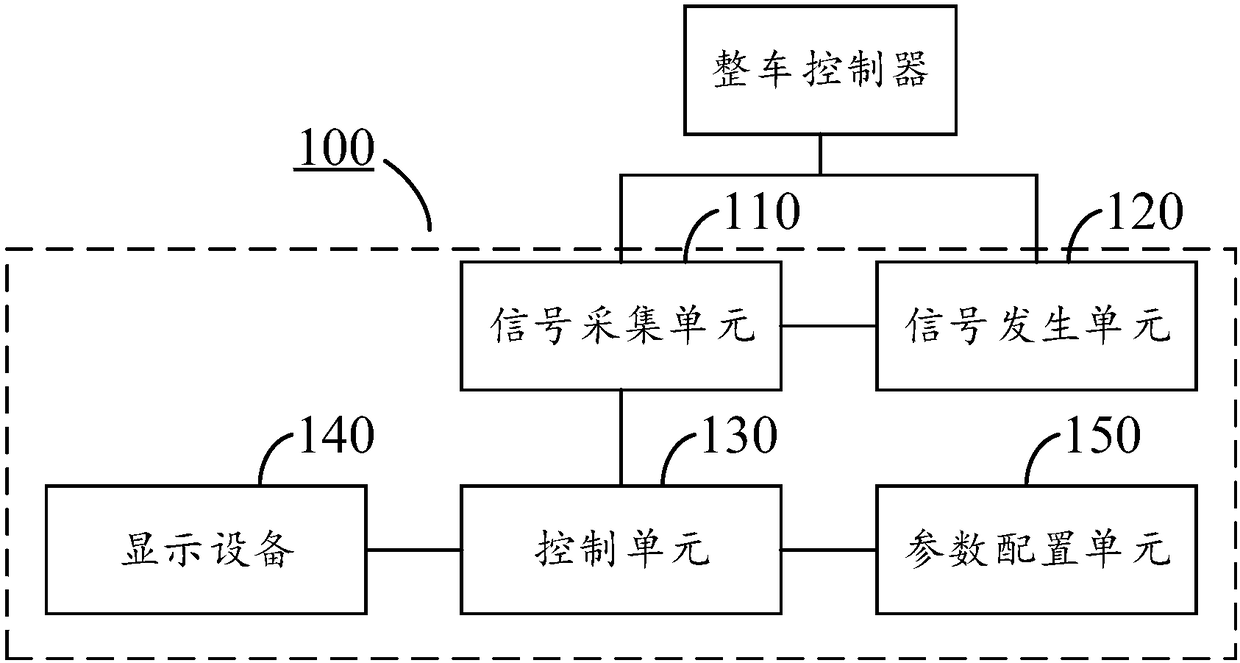

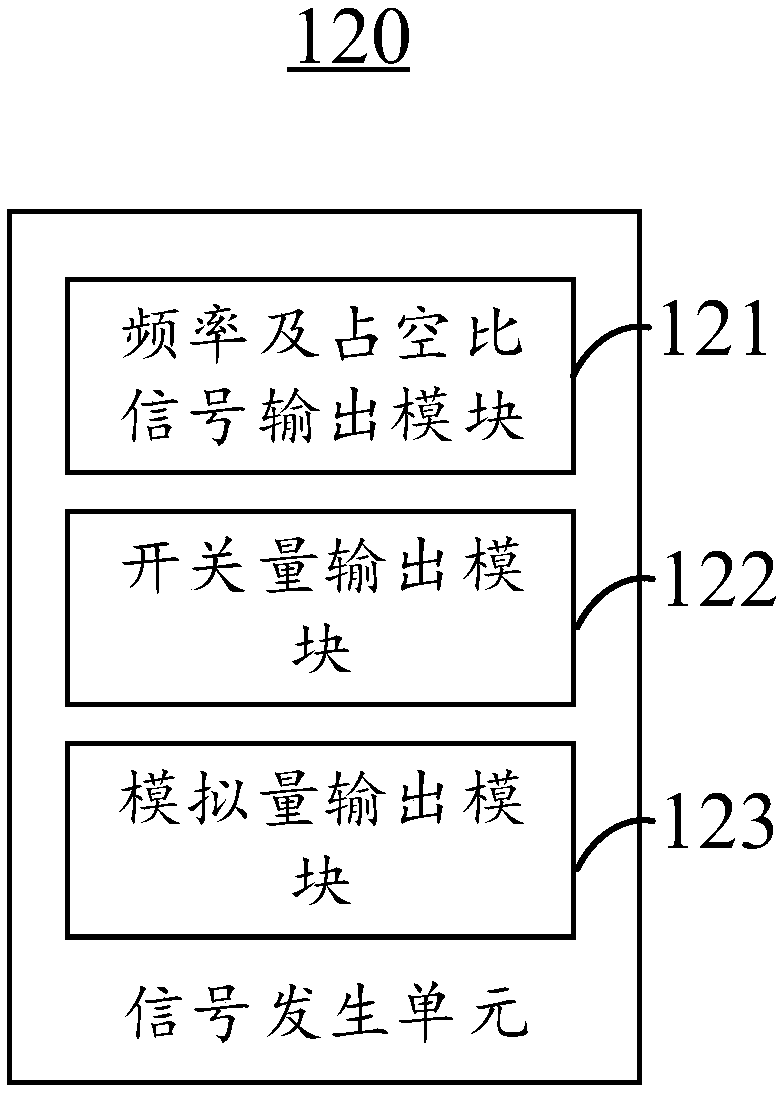

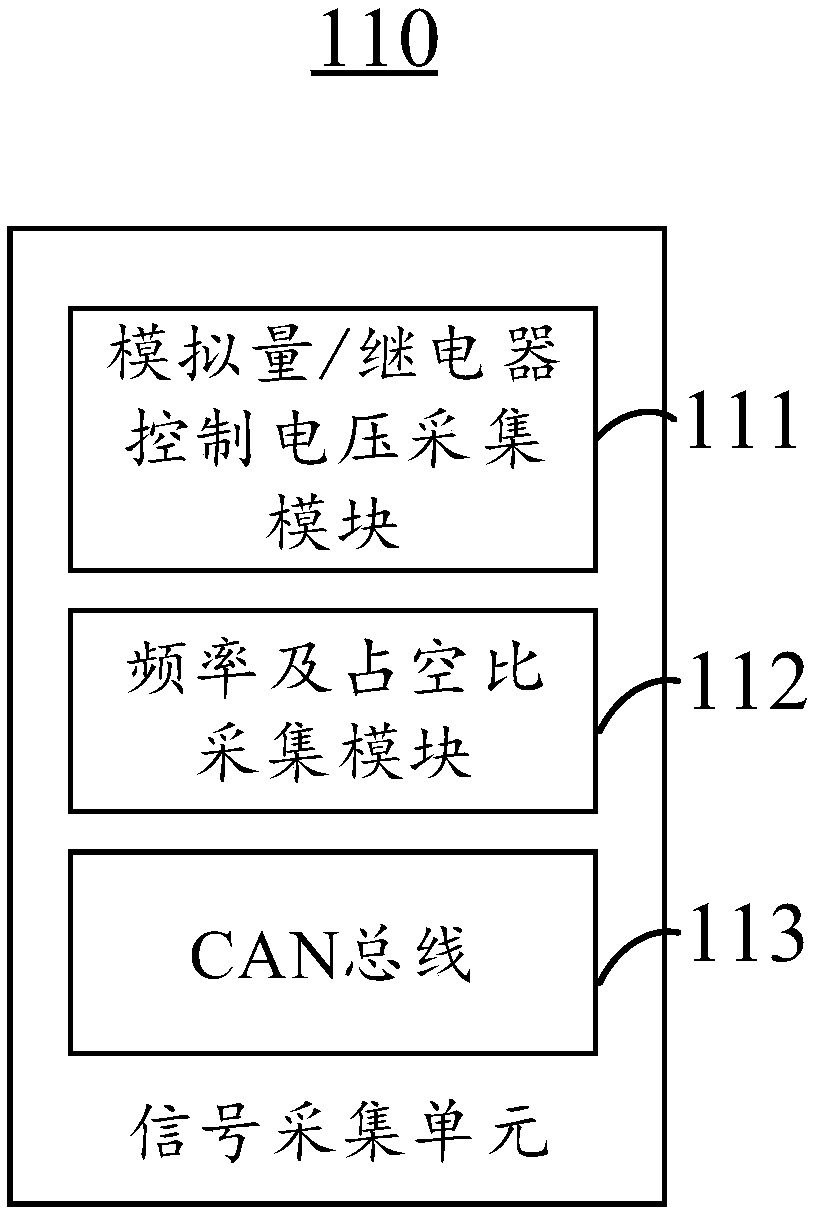

Automatic tester and automatic method for vehicle controller

PendingCN108594796ARealize automatic test functionTest accurateElectric testing/monitoringTotal factory controlTest efficiencyProduction line

The invention provides an automatic tester and an automatic method for a vehicle controller. The automatic tester for the vehicle controller is connected with the vehicle controller to test the vehicle controller, and comprises a signal collection unit, a signal generation unit, a control unit and a parameter configuration unit. The signal generation unit is used for generating test signals underthe control of the control unit and sending the test signals to the vehicle controller to do tests. The signal collection unit is used for collecting output signals, which are output by the vehicle controller to respond the test signals, and sending the output signals to the control unit. The control unit is used for judging whether the vehicle controller has operation faults or not according to the collected output signals. The automatic tester for the vehicle controller has the advantages that automatic testing can be realized, comprehensive and accurate testing is guaranteed, testing efficiency is improved greatly, testing reliability is improved, artificial influences are avoided, labor operation is reduced, testing content and parameters can be adjusted, and support is provided to production line visualization.

Owner:武汉菱电汽车电控系统股份有限公司

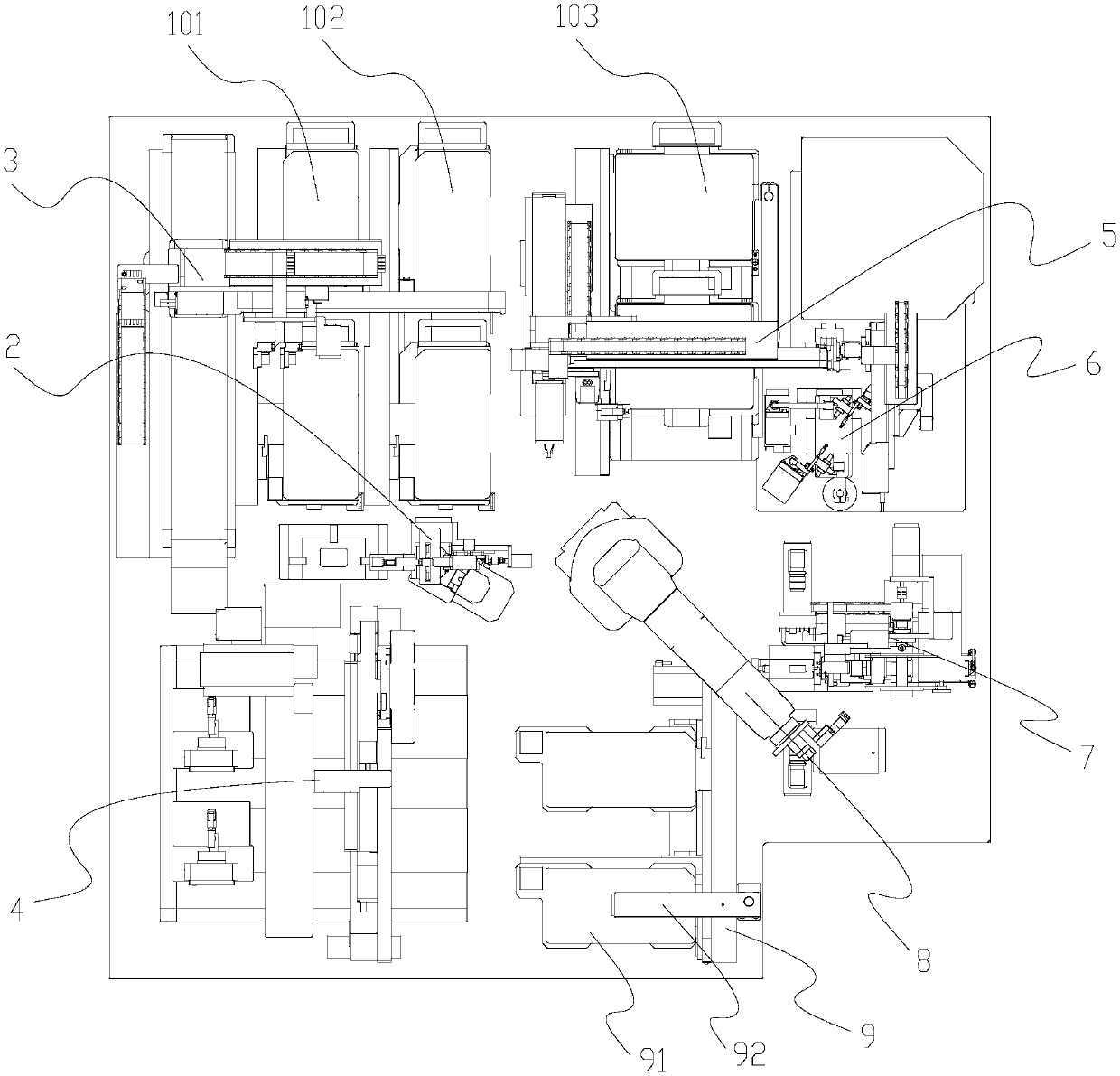

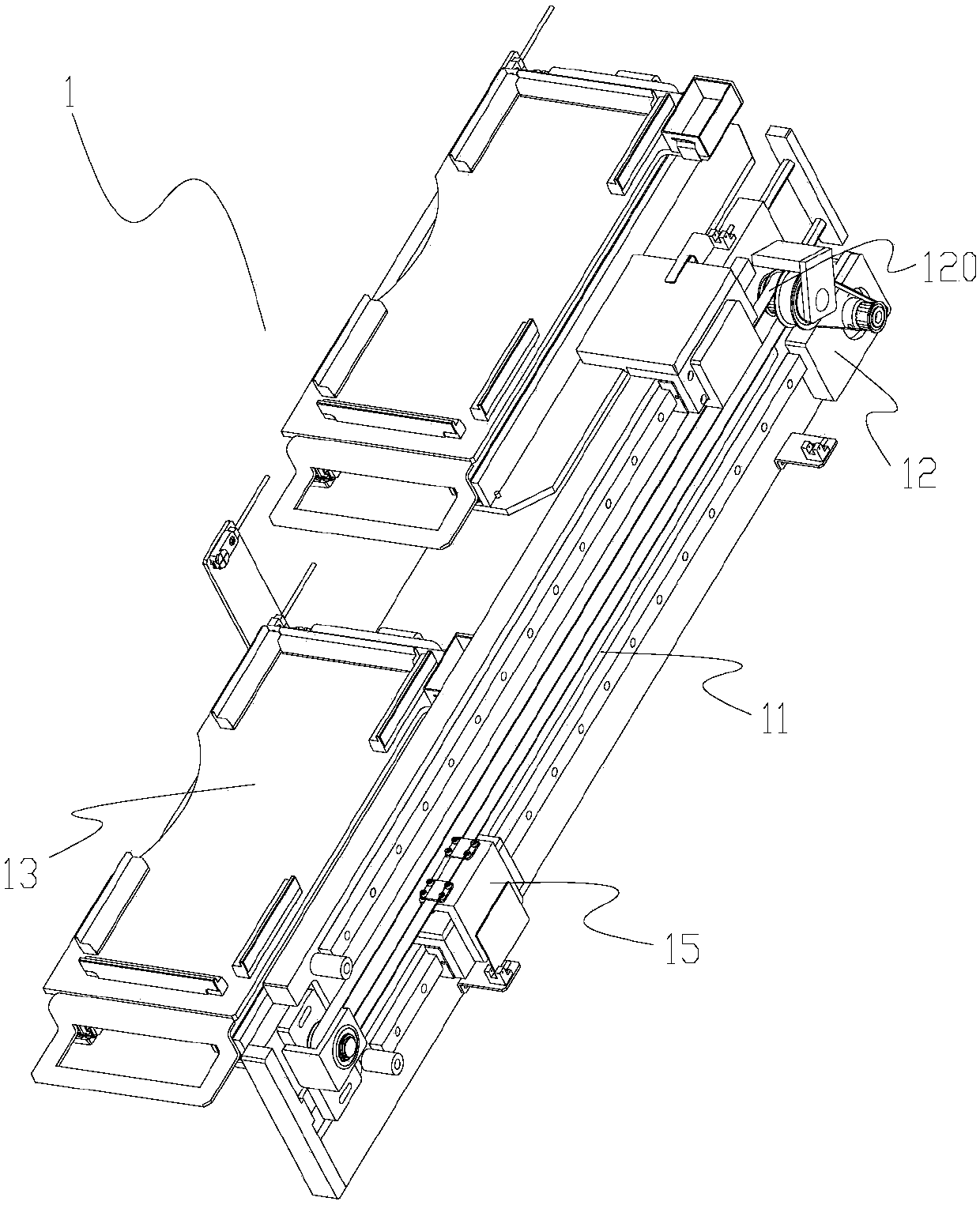

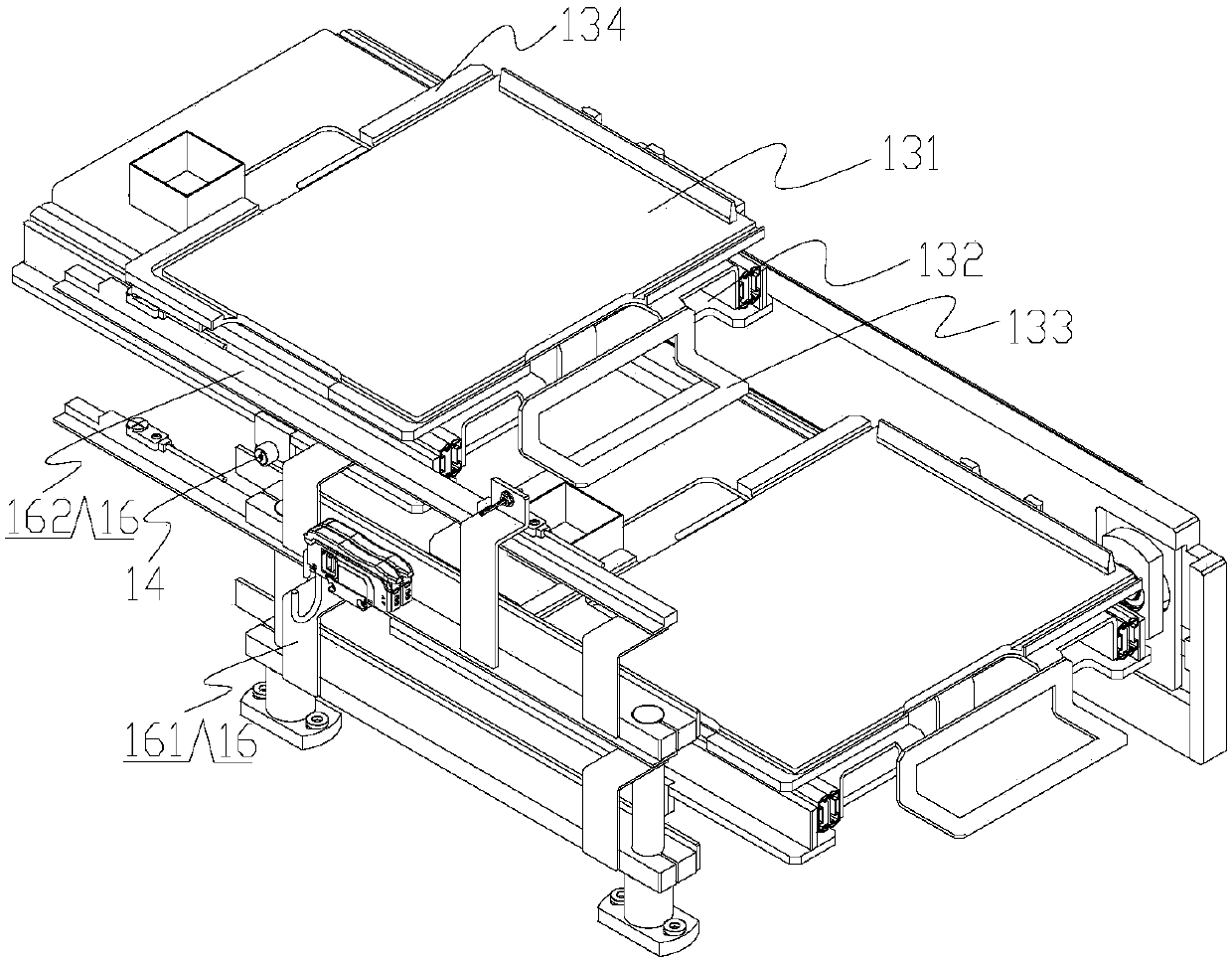

Electroacoustic device assembling equipment

ActiveCN107613448AQuick assemblyReduce manual operationsElectrical transducersLabor operationsComputer engineering

The invention provides electroacoustic device assembling equipment. The electroacoustic device assembling equipment comprises a loading device, a substrate positioning device, a substrate connector pre-assembling device, a substrate connector welding device, a top plate conveyer, a rubber part top plate assembling device, a mesh stripping positioning device and a total assembling device. The electroacoustic device assembling equipment provided by the invention has one purpose of implementing operations of automatic loading, automatic assembling and the like of each constituent part of an electroacoustic device, labor operation can be greatly reduced, and production efficiency is improved.

Owner:GEER TECH CO LTD

Multifunctional combined feeding device for animal husbandry

InactiveCN107581084AEasy to operateReduce labor operation intensityAnimal watering devicesAnimal feeding devicesWater storageSprayer

The invention provides a multifunctional combined feeding device for the animal husbandry. The feeding device comprises a landing base, an inserted link, an insert tube, a base, universal wheels, slide rails, a switch, a sliding rotation feeding plate structure, a stirrer, a component plate structure, a supporting plate, a water spraying raft structure, a longitudinal supporting beam, a cross beamand a hanging hook. According to the feeding device, the position of a water storage raft can be adjusted through a spring hinge due to the arrangement of a water storage raft, a primary hoop, the spring hinge, a hanging rod and a secondary hoop, the operation is facilitated, and the labor operation intensity is reduced; an external tap water pipe can be connected through a metal hose due to thearrangement of a metal hose, a U-shaped water feeding pipe, a sprayer and a rubber plug, water spraying operation can be carried out through the sprayer, so that breeding of the animal husbandry can be favored, and the using function of the device can be added.

Owner:领投企业管理集团(西安)有限公司

Automatic dust-free equipment for grinding and polishing stone wall surface

PendingCN109955126AImprove the finishShorten the timeGrinding machine componentsPlane surface grinding machinesStone wallEngineering

The invention relates to automatic dust-free equipment for grinding and polishing a stone wall surface. The automatic dust-free equipment for grinding and polishing the stone wall surface comprises ashell and a bracket, the shell is divided into an airtight dust chamber and a polishing chamber with an open lower end by a partition plate arranged in the middle, a first motor is arranged in a mounting chamber, and the top of the first motor is connected with the top of the shell through a first electric telescopic rod. The bottom of the first motor penetrates through the partition plate and isconnected with a rotary disc in a driving mode, a grinding motor penetrating through the rotary disc is arranged at the top center of a grinding disc, and the top of the polishing motor is connected with the mounting plate arranged above the rotary disc through a second electric telescopic rod. A polishing motor penetrating through the rotary disc is arranged at the top center of a polishing disc,the top of the polishing motor is connected with a mounting plate arranged above the rotary disc through a third electric telescopic rod, the top of the shell is connected with the bracket, the shellcan move up and down and left and right along the bracket, and a controller is arranged on the shell. According to the automatic dust-free equipment for grinding and polishing the stone wall surface,labor operation is not required, and the wall surface can be automatically ground and polished.

Owner:德仁天下(北京)环保科技有限公司

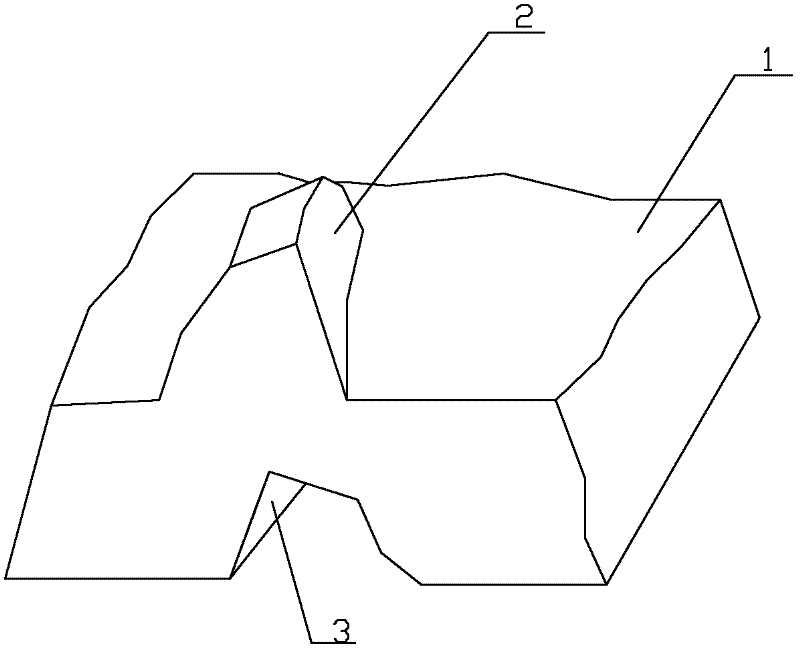

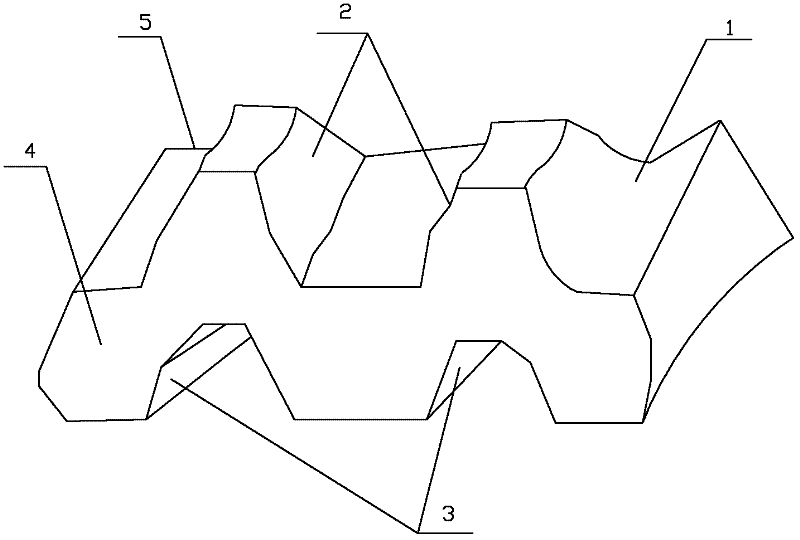

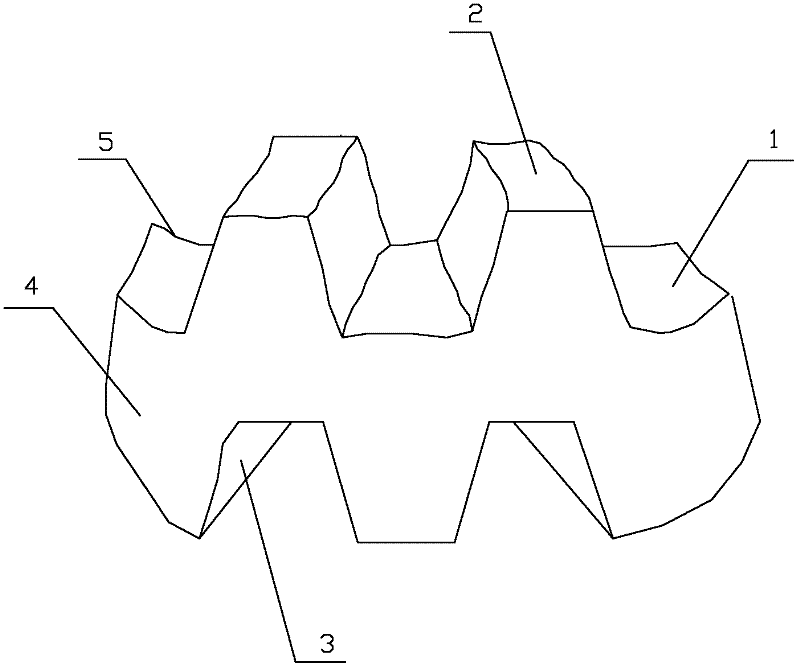

Irregular micro electrolysis iron carbon filling material

ActiveCN102336456AEasy to handleIncrease contact reaction areaWater/sewage treatmentElectrolysisFilling materials

The invention relates to an irregular micro electrolysis iron carbon filling material, which is in a blocky shape. At least one irregular bulge and at least one irregular groove are respectively distributed and arranged on the two opposite end surfaces of the filling material, the irregular bulge and the irregular groove are correspondingly distributed and arranged at top and bottom on the two opposite end surfaces of the filling material, the irregular bulge and the irregular groove are approximately in a gear shape, and the whole of the filling material is inclined and / or has the radian. The technology solves the technical problems of the traditional filling material that the production cost is high, the contact reaction area is small, the reverse flushing is not easy, in addition, the effect is poor, the service life is short, and the like. The irregular micro electrolysis iron carbon filling material has the advantages that the large contact reaction area is realized, the sewage treatment effect is good, the reverse flushing is easy, in addition, the effect is good, the labor operation quantity is reduced, and the production cost and the use cost are reduced.

Owner:常州海龙环保设备厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com