Gluing device and method for inner container of refrigerator body

A gluing device and box technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of difficult control of production quality, low efficiency of manual operation, and potential safety hazards, so as to improve product consistency, The effect of eliminating safety hazards and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

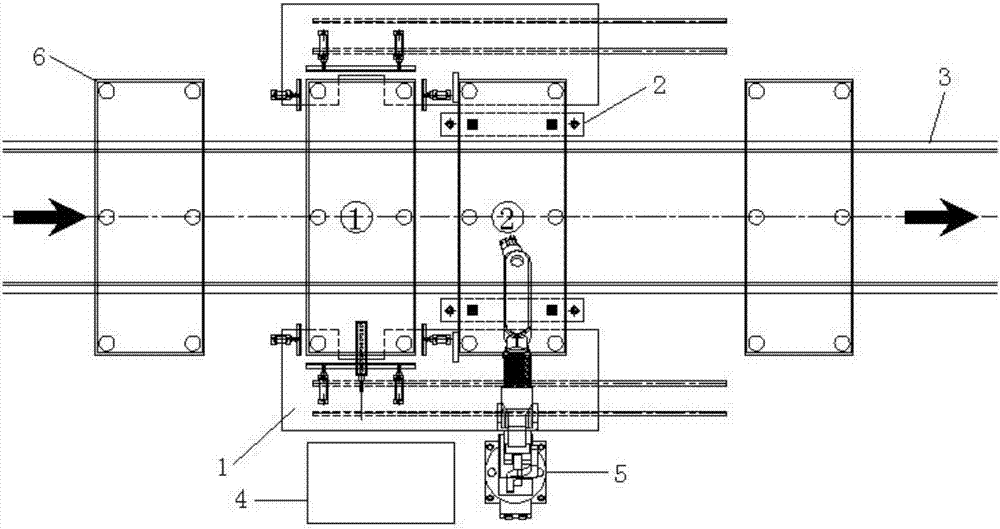

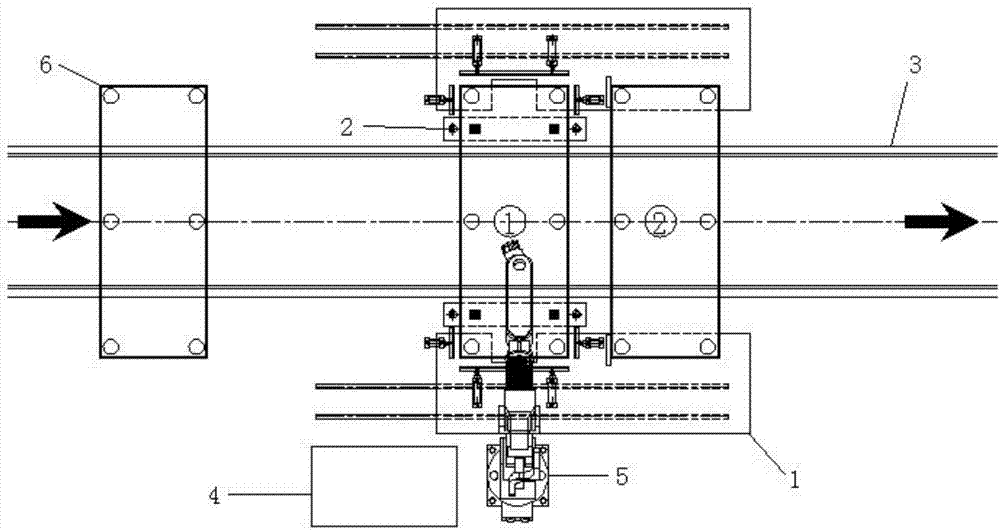

[0034] Such as figure 1 , 2 As shown, the present invention provides a device for gluing the inner liner of a refrigerator box, comprising a conveying line 3 on which a workpiece 6 is placed, two sides of the conveying line 3 are provided with elevating pallets 2, and the elevating pallets 2 are two There is a feeding positioning device 1 on one side of the feeding positioning device 1. A glue machine 4 is installed on one side of the feeding positioning device 1. The glue gun of the glue machine 4 is connected to a robot 5. A two-dimensional code scanner is installed on one side of the conveying line 3. Two-dimensional The code scanner is connected to the robot 5 with a signal, and the workpiece 6 is conveyed through the conveying line 3 and scanned by the two-dimensional code scanner, and the robot 5 controls the gluing machine 4 to glue the workpiece.

[0035] In order to position the workpiece 6 on the feeding positioning device 1, a first air cylinder and a first positio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com