Patents

Literature

87results about How to "Avoid cross-color" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

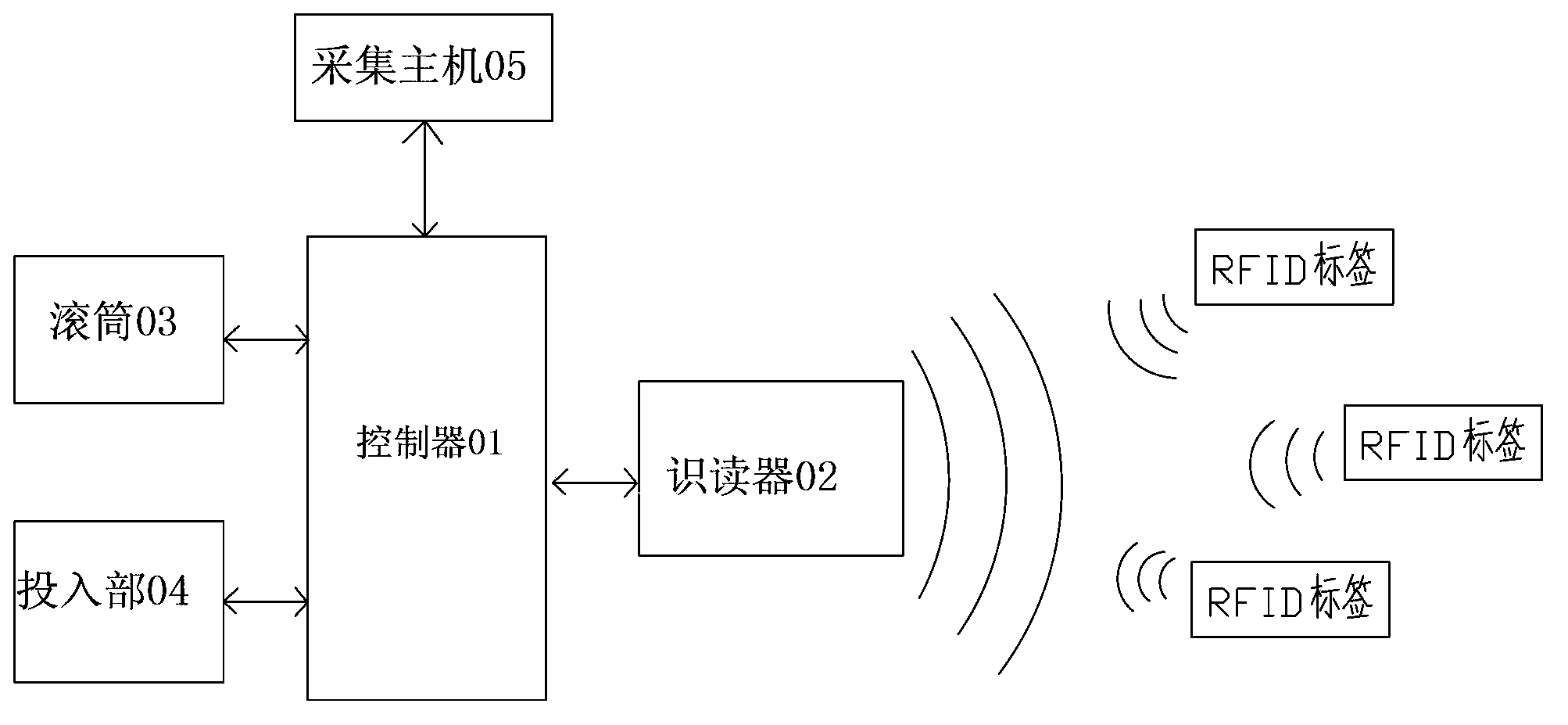

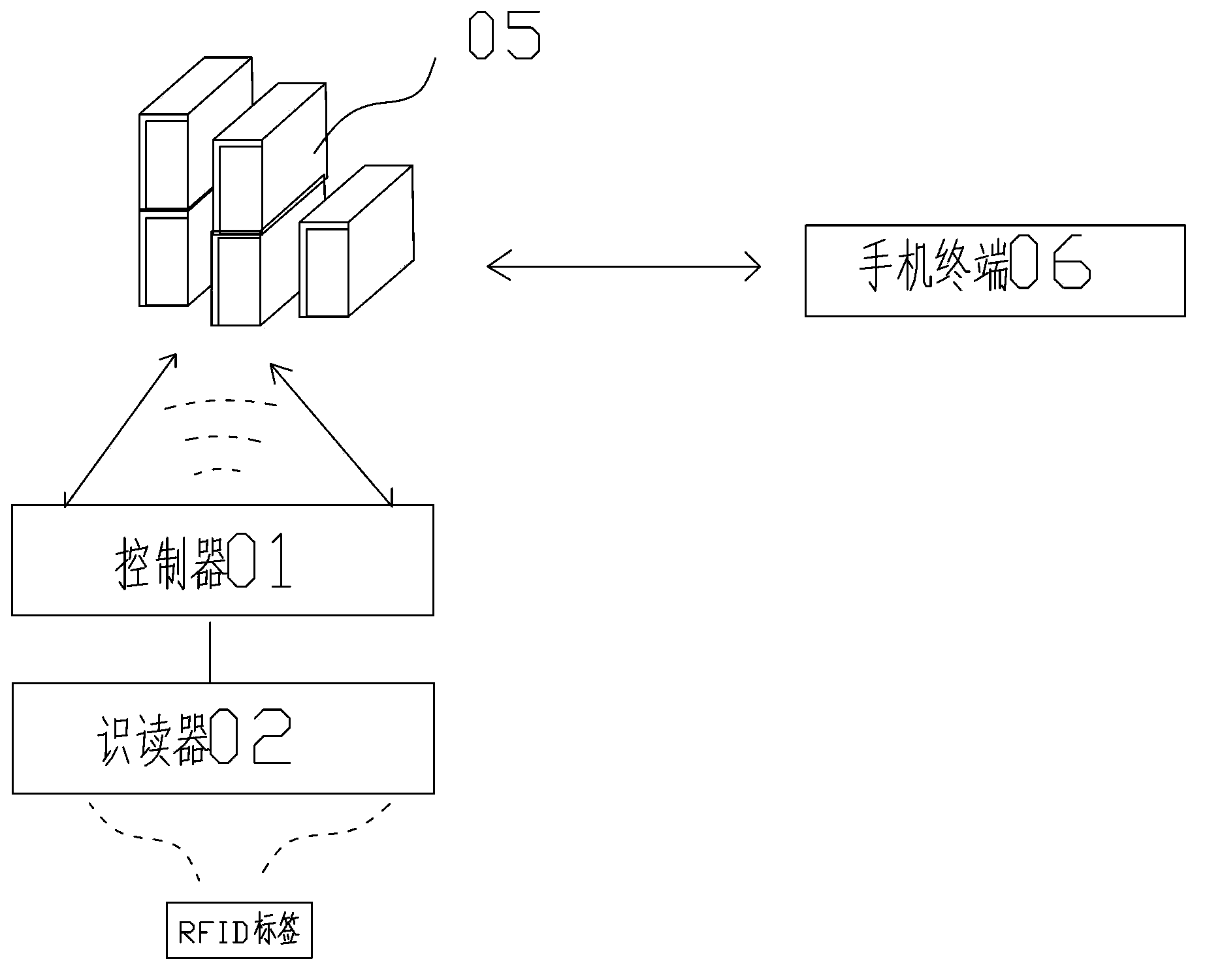

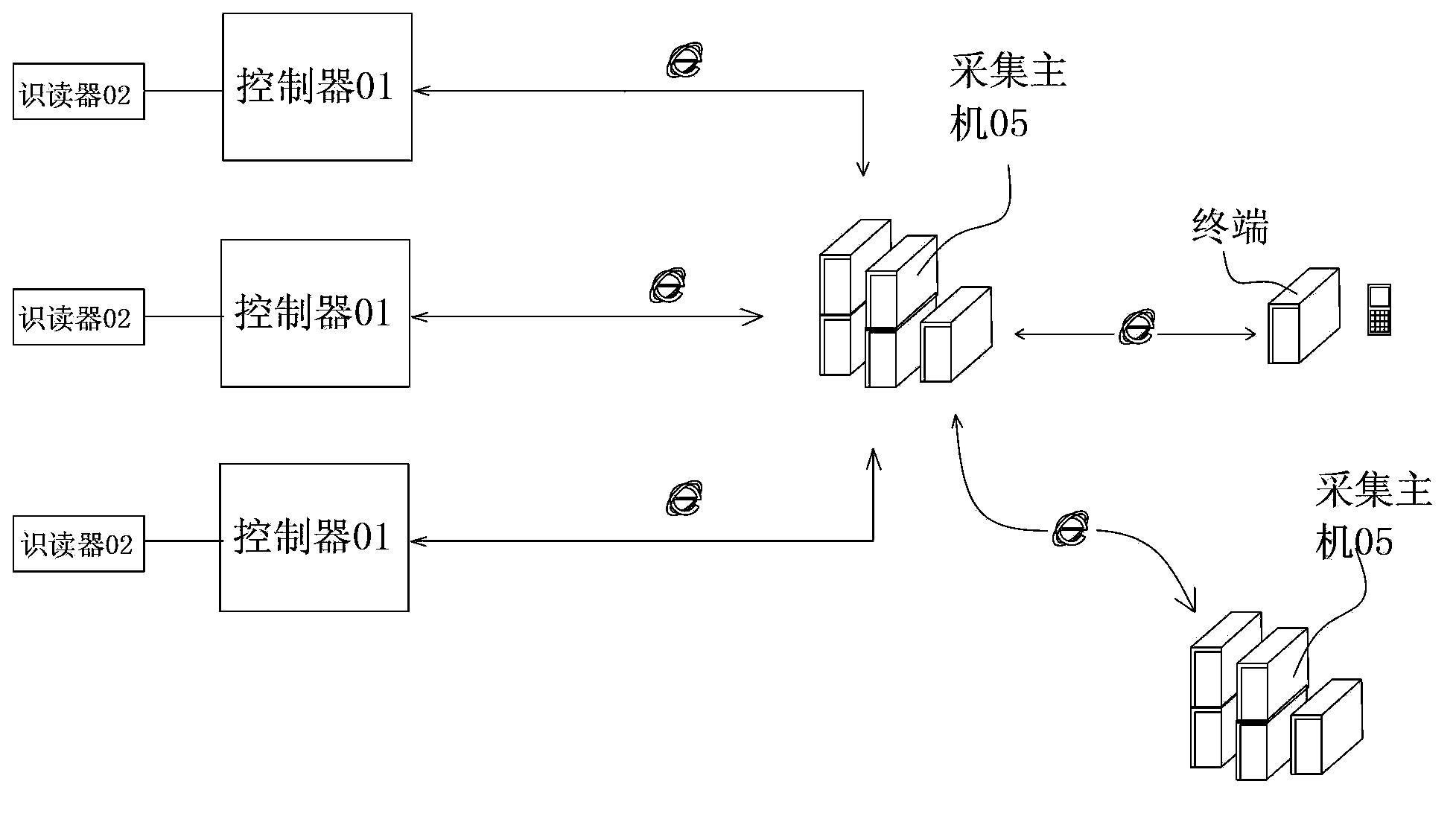

Washing machine based on RFID technology and clothes washing information collecting system

ActiveCN103726262AAvoid cross-colorAverage wearing frequencyControl devices for washing apparatusCo-operative working arrangementsRadio frequencyWork status

The invention discloses a washing machine based on the RFID technology and a clothes washing information collecting system. The washing machine comprises a recognizer and a controller. The recognizer is used for reading clothes information from an RFID tag of clothes, and the clothes information is stored in the RFID tag and comprises the unique code of the clothes. The controller is used for recording the clothes information read by the recognizer. The number of times of washing the clothes is recorded through a counting unit inside the controller, compensation is made for a control stroke according to the number of times of washing the clothes, and the controller is used for controlling the working states of driving parts through the compensated stroke. The clothes washing information collecting system based on the washing machine comprises a collecting main machine which is connected with the controller in a wired or wireless mode, the controller is used for sending the information of the number of times of washing the different clothes to the collecting main machine, and the collecting main machine is used for obtaining clothes using tendency data, personal clothes loving data and / or clothes matching data according to the number of times of washing the different clothes.

Owner:FOSHAN SHUNDE SINCERE HOME HOME APPLIANCE MFG +1

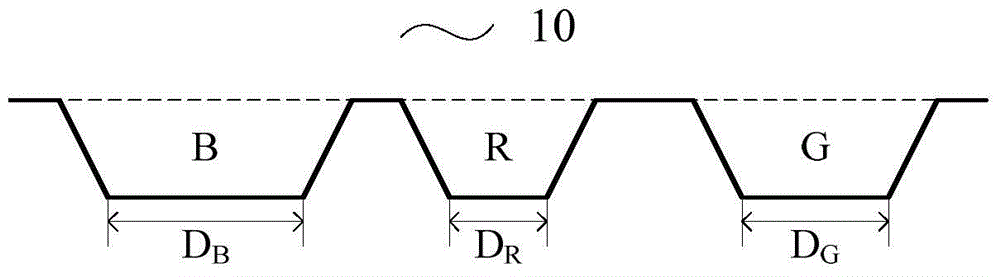

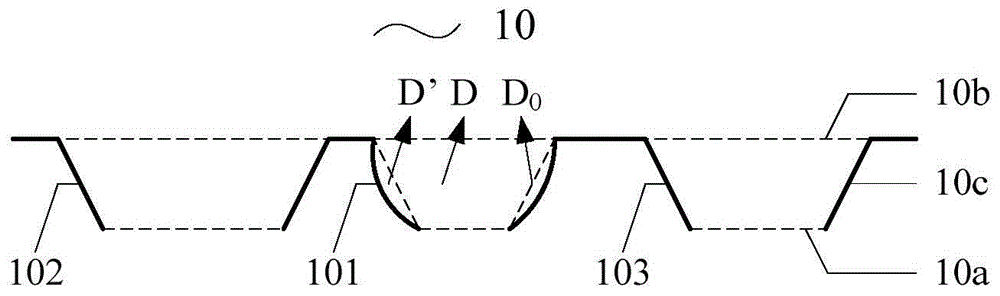

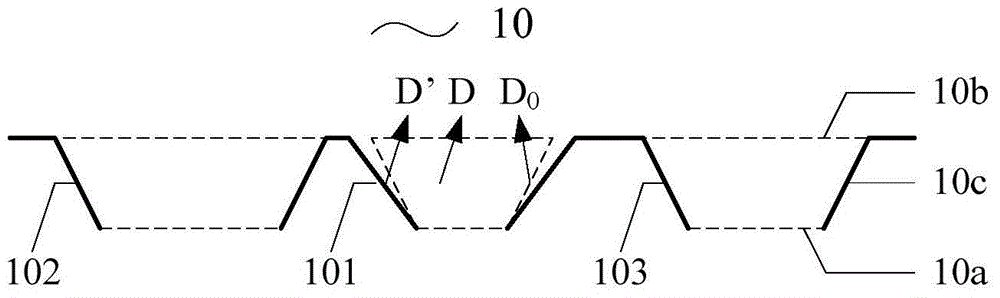

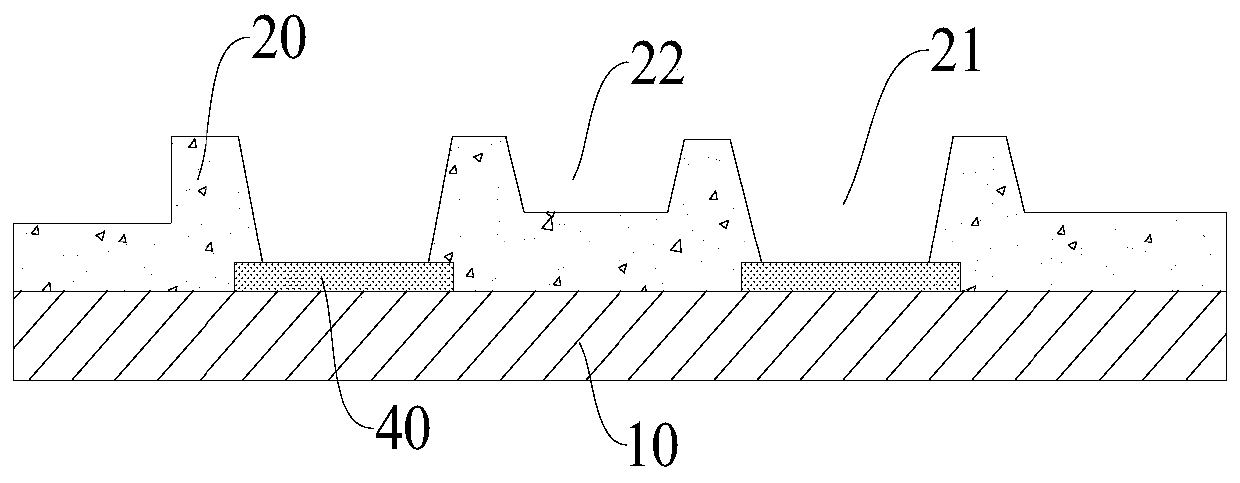

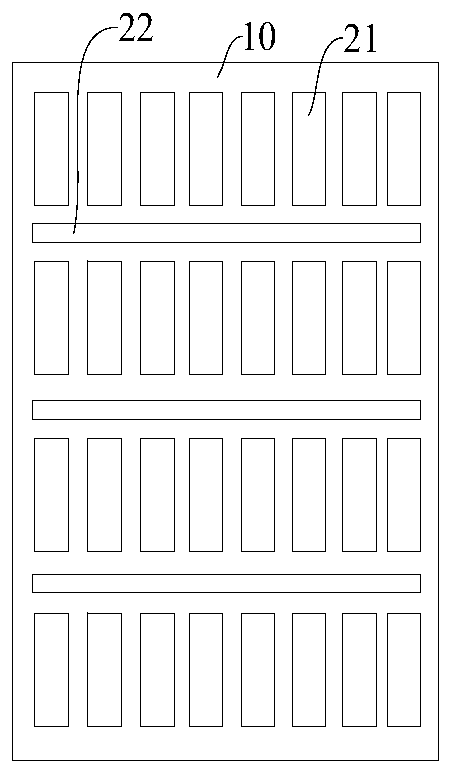

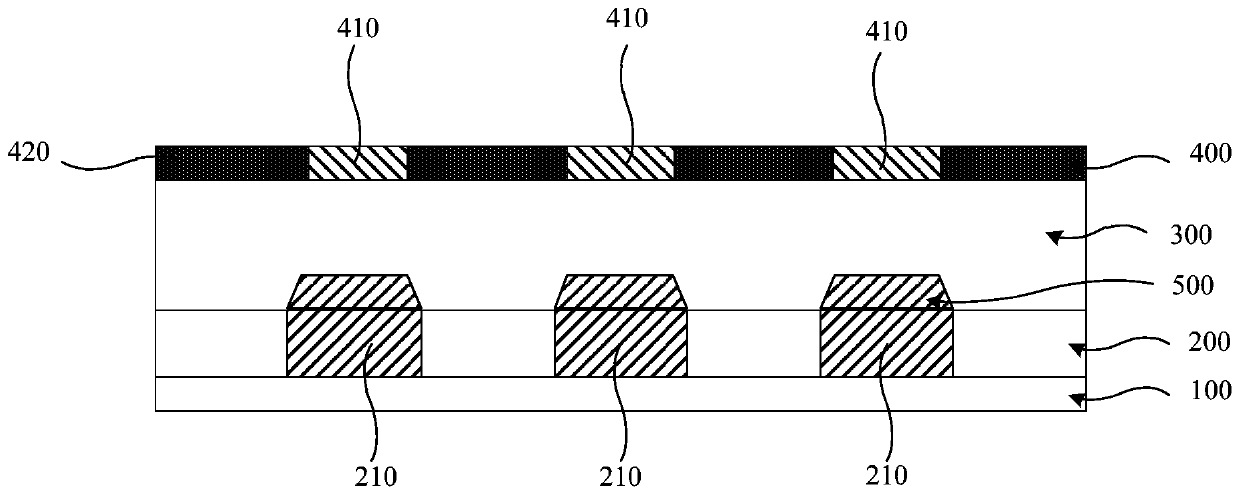

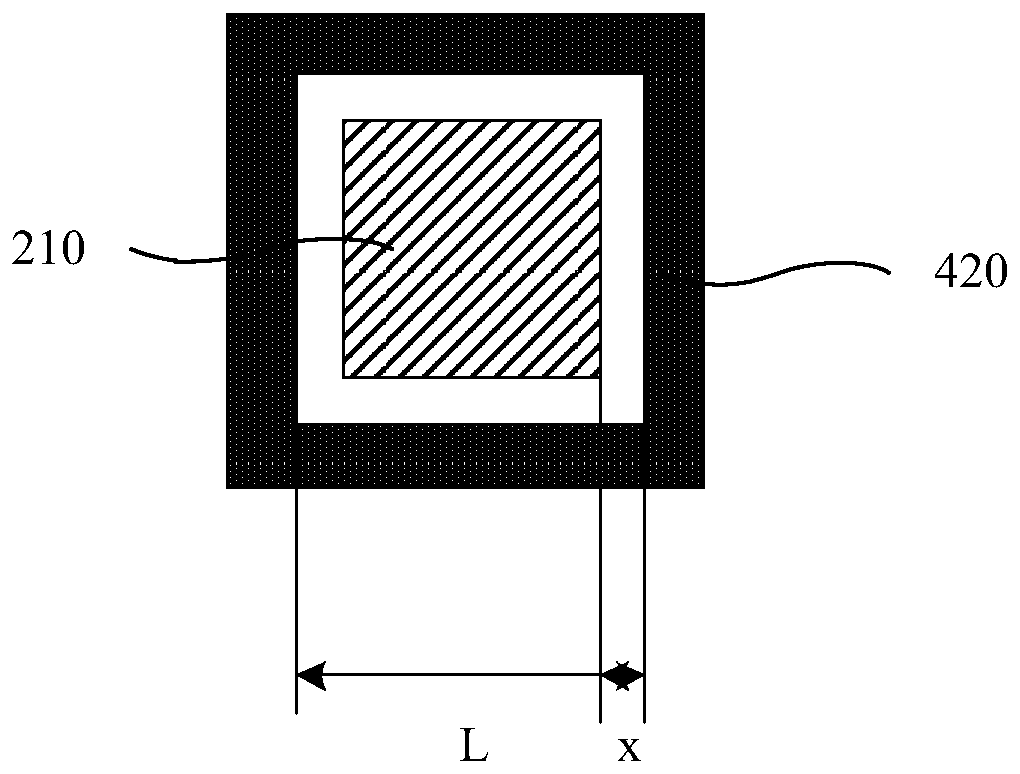

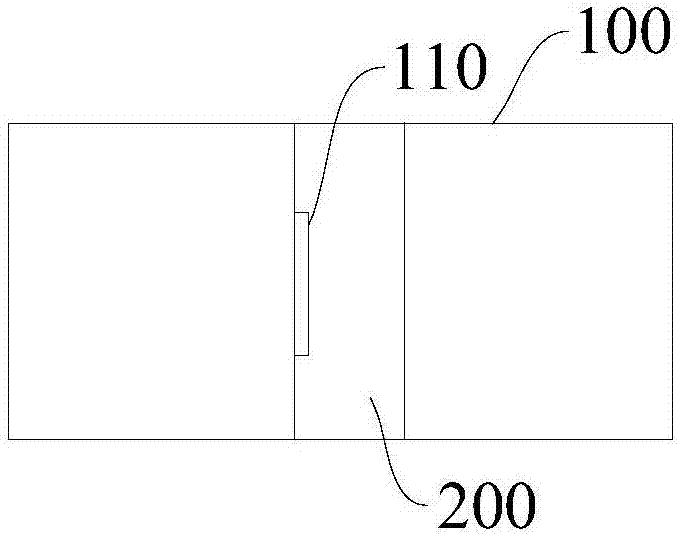

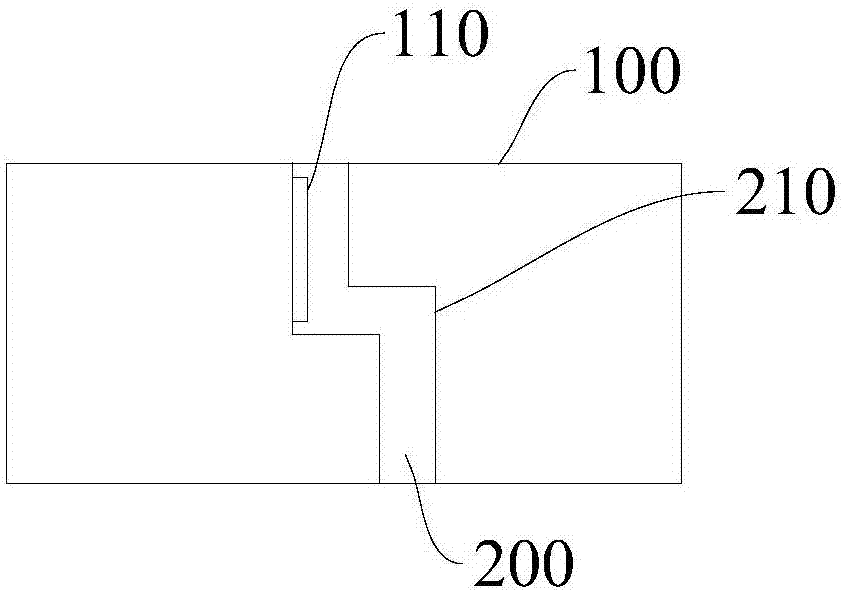

Pixel demarcation layer and OLED (organic light emitting diode) device

ActiveCN104638147AConsistent attenuation stateIncrease the internal volumeSolid-state devicesSemiconductor/solid-state device manufacturingUltrasound attenuationLight-emitting diode

The embodiment of the invention provides a pixel demarcation layer and an OLED (organic light emitting diode) device, and relates to the technical field of display. The attenuation state of luminous materials of each pixel unit can be identical, and in addition, the color staining caused by solution overflow can be avoided. The pixel demarcation layer comprises a plurality of openings, wherein each opening comprises a bottom surface opening, a top surface opening and a side wall, the openings at least comprise a first opening for limiting a first pixel unit and a second opening for limiting a second pixel unit, the first opening is filled with first pixel luminous materials, the second opening is filled with second pixel luminous materials, the attenuation speed of the first pixel luminous materials is lower than the attenuation speed of the second pixel luminous materials, the bottom surface opening area of the first opening is smaller than the bottom surface opening area of the second opening, the side wall of each opening is provided with a preset reference surface, the space limited by each opening comprises a main body space in the reference surface and an expansion space outside the reference surface; the expansion space size of the first opening is greater than the expansion space size of the second opening. The pixel demarcation layer is used for preparing the OLED device.

Owner:BOE TECH GRP CO LTD

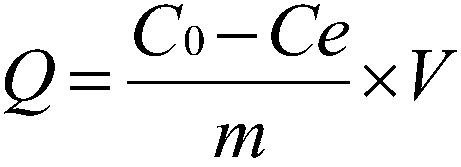

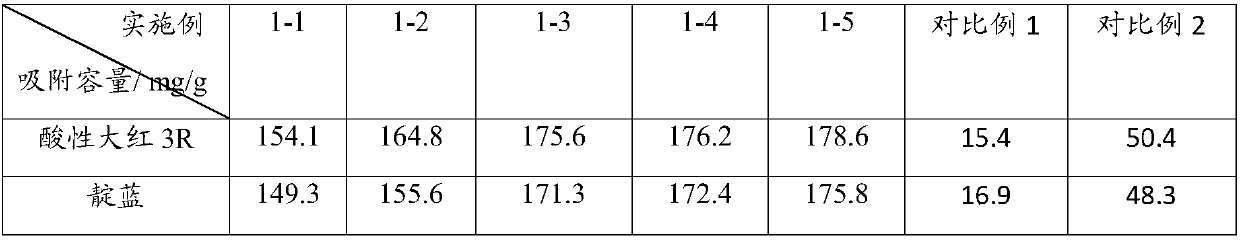

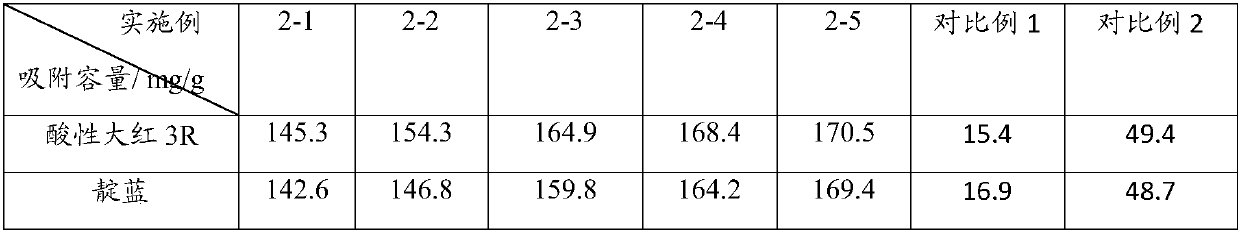

Nanoparticles containing organosilicon quaternary ammonium salt and preparation method and application of nanoparticles

The invention relates to a method for preparing nanoparticles containing organosilicon quaternary ammonium salt. The method includes: treating amorphous nano silica with halogenated alkyl trialkoxy silane to form an intermediate product; allowing the intermediate product to react with C14-C20 tertiary amine, and after reaction, performing separation, cleaning and drying to obtain the nanoparticlescontaining organosilicon quaternary ammonium salt, wherein halogenated alkyl trialkoxy silane is gamma-chloropropyl trimethoxysilane or gamma-chloropropyl triethoxysilane, and the molar ratio in feeding of amorphous silica to halogenated alkyl trialkyl silane is 1:1-5:4. The nanoparticles containing organosilicon quaternary ammonium salt have high adsorption effect on dyes, and color crossing offabric during washing can be prevented; in addition, the nanoparticles have high bactericide action and can effectively eliminate bacteria on the fabric.

Owner:INST OF IND TECH GUANGZHOU & CHINESE ACADEMY OF SCI

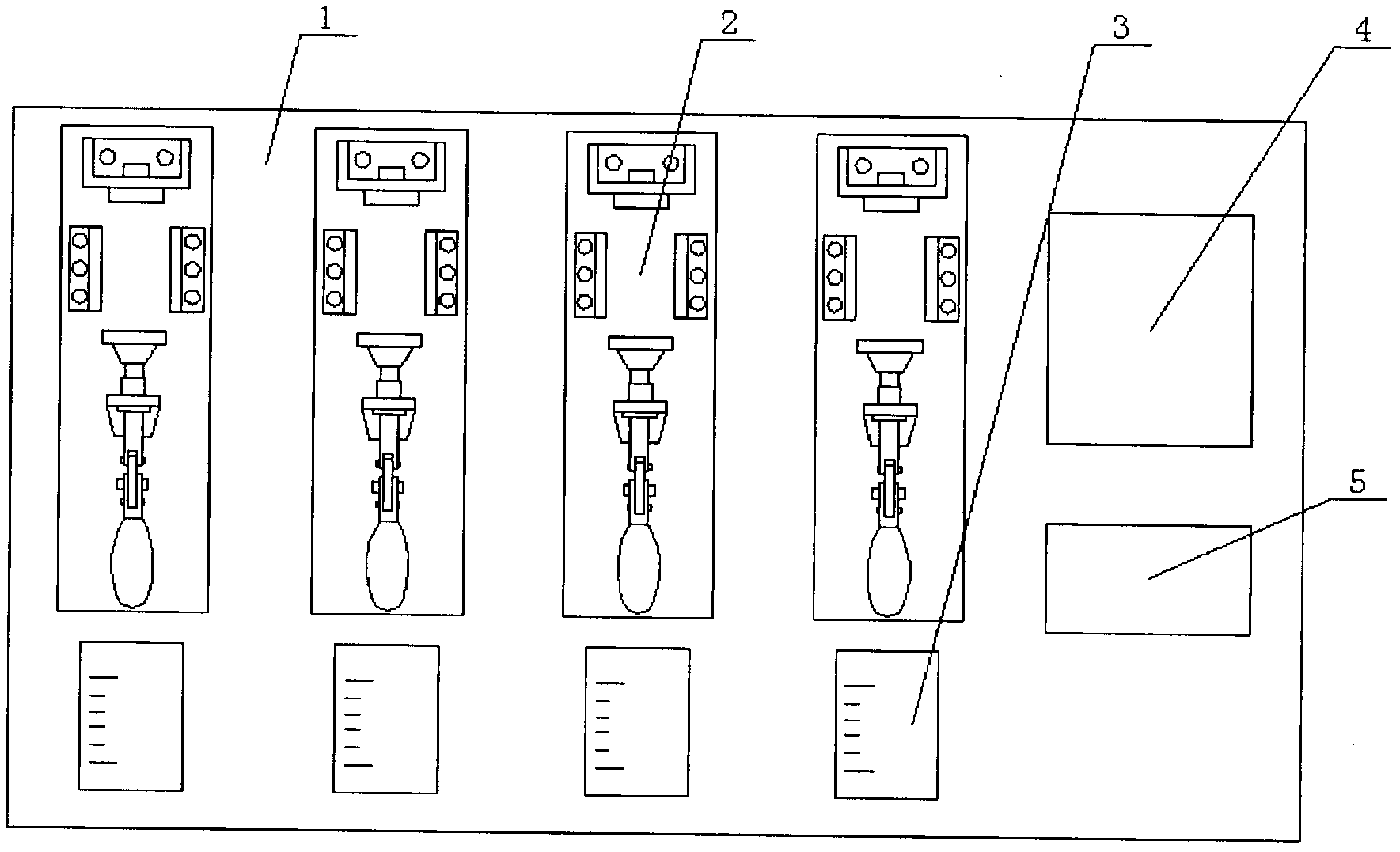

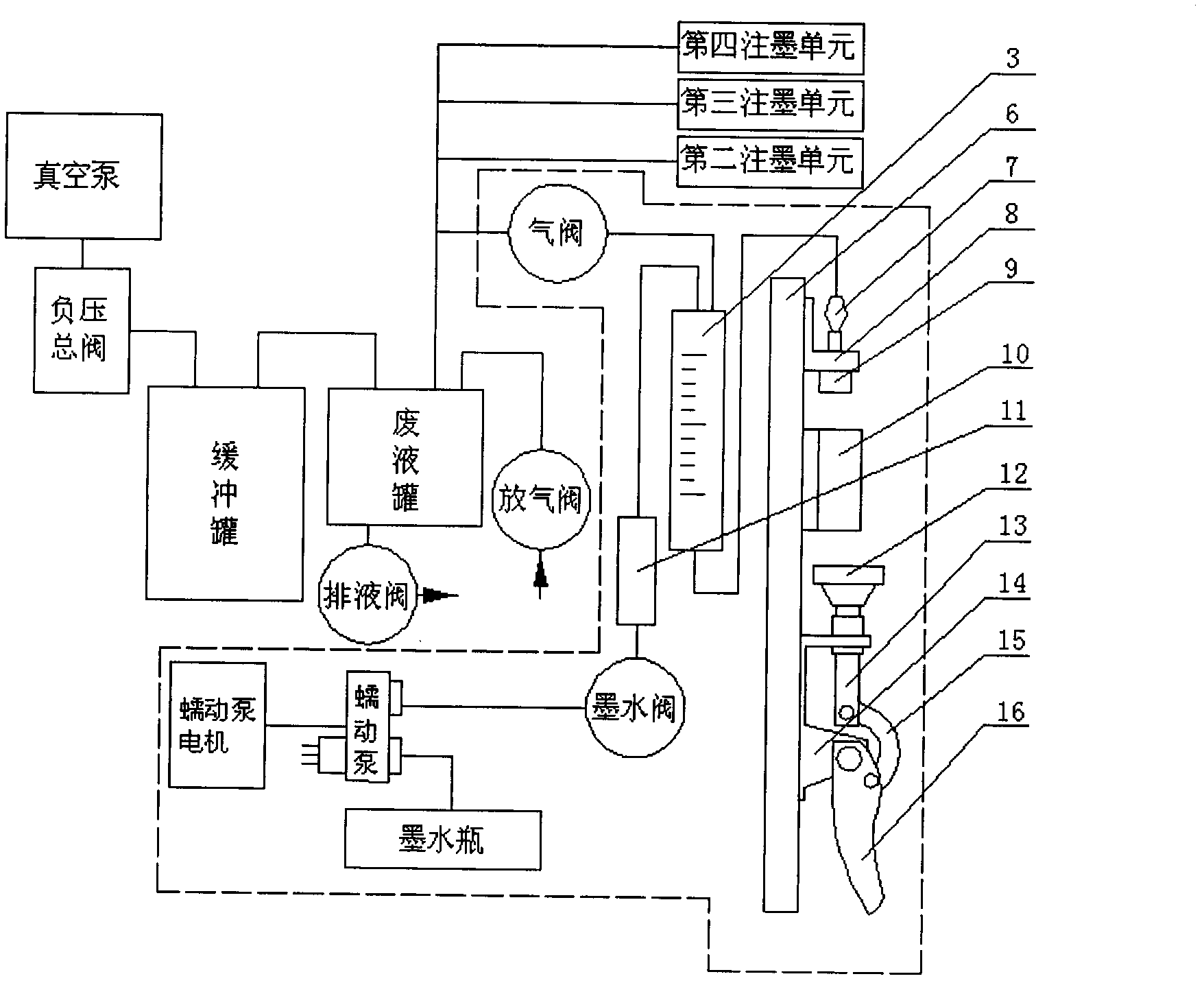

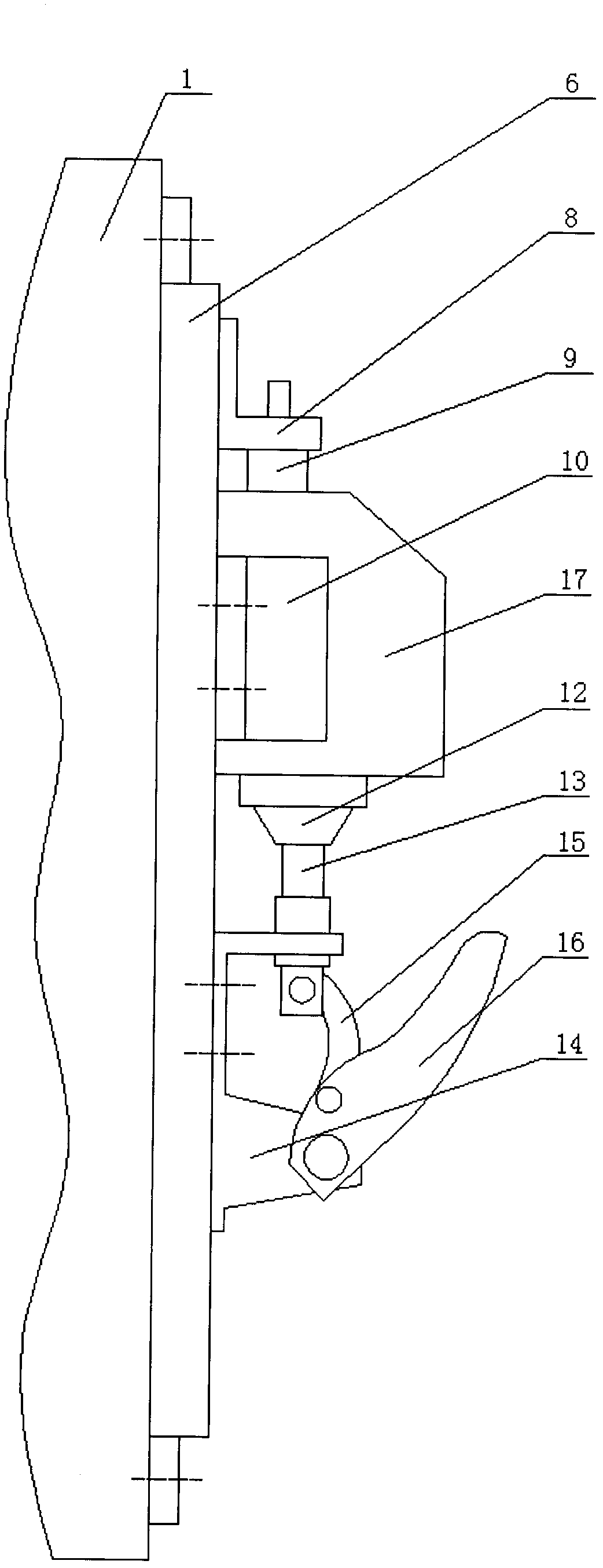

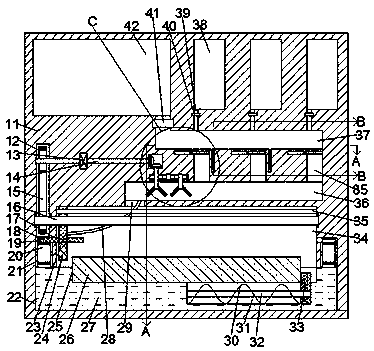

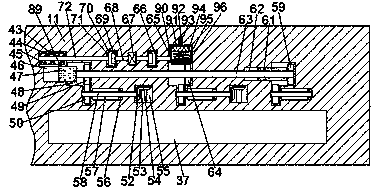

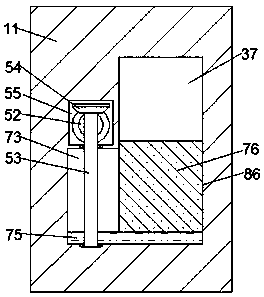

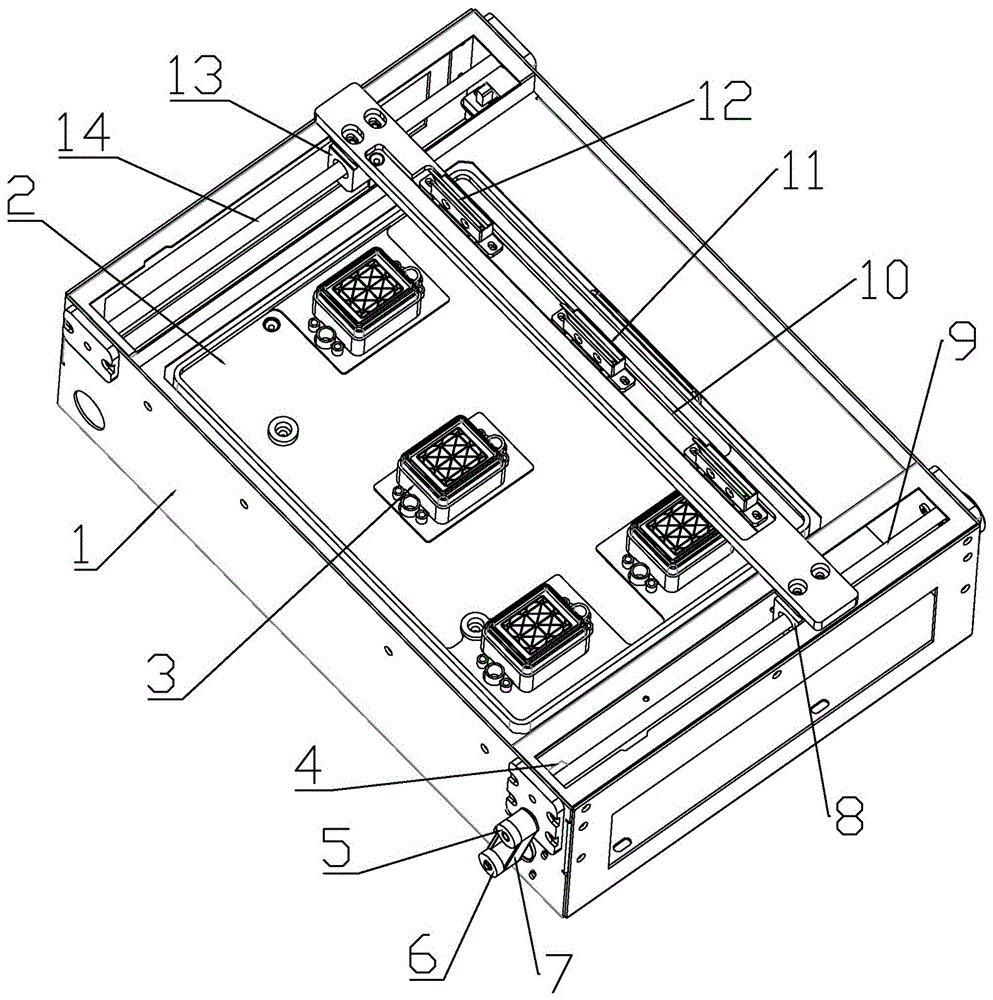

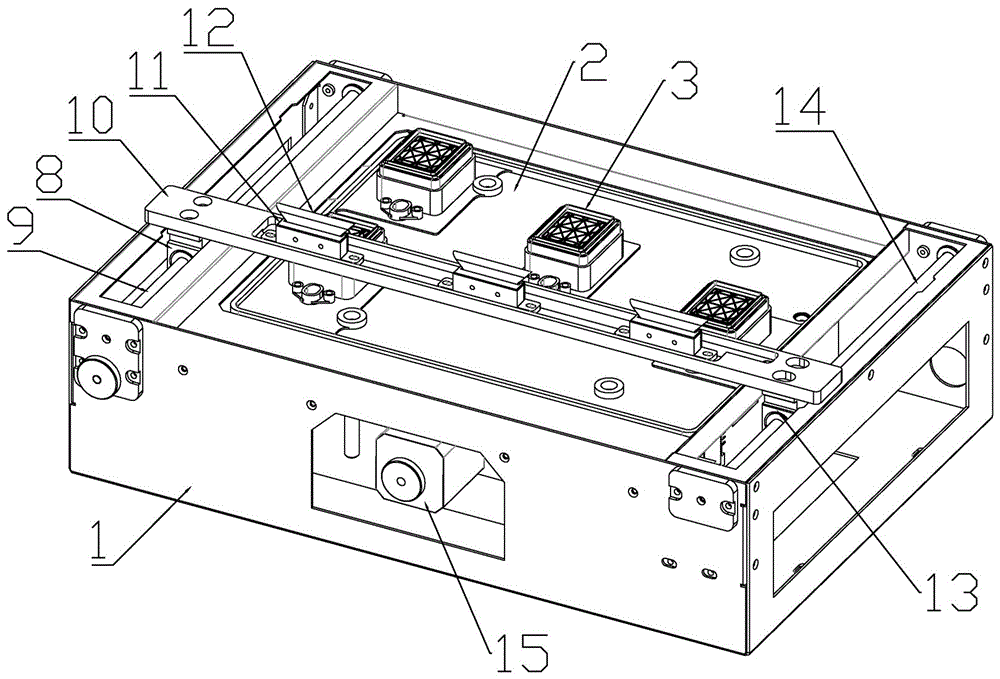

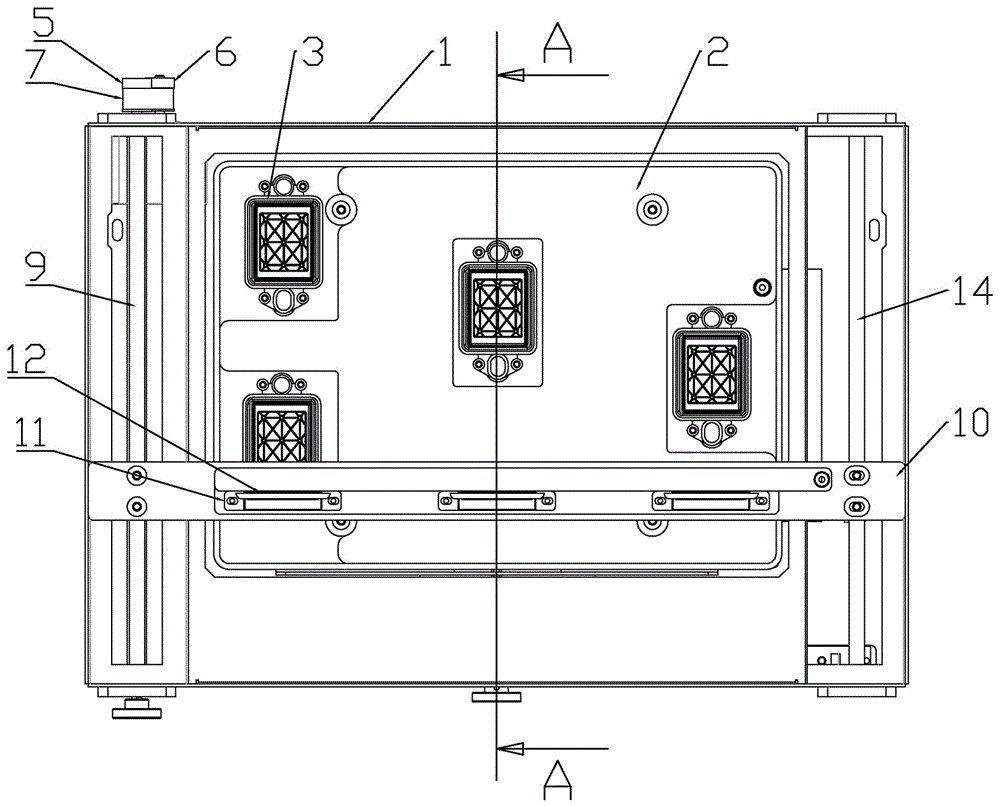

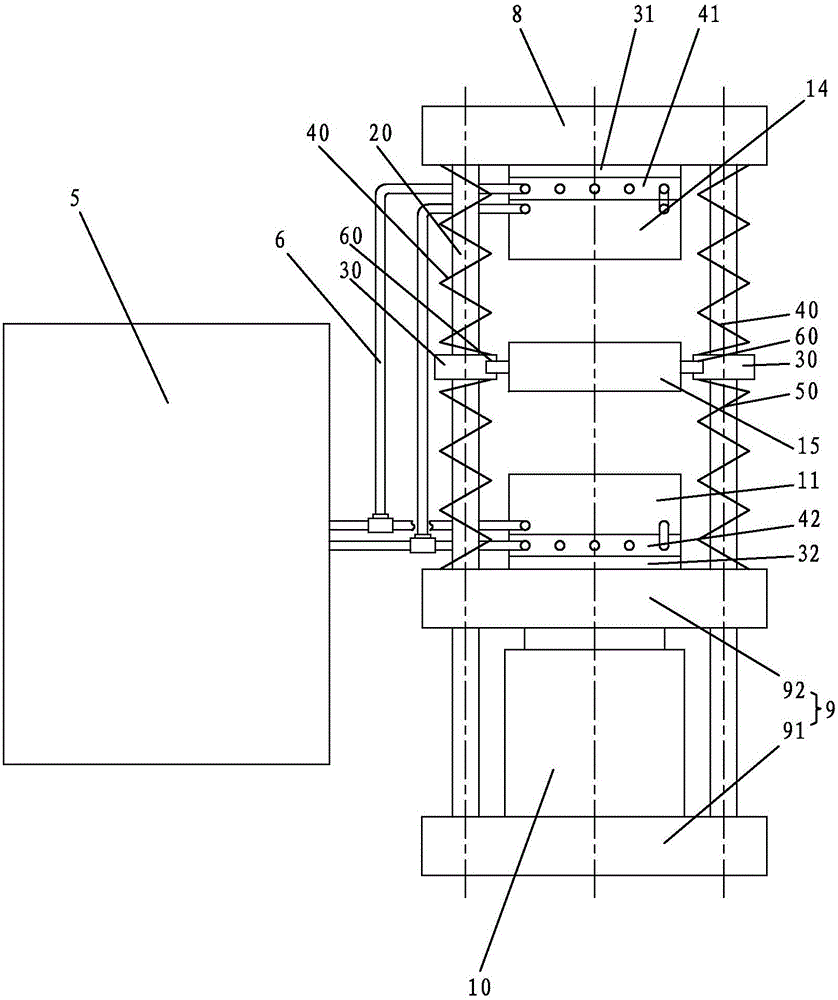

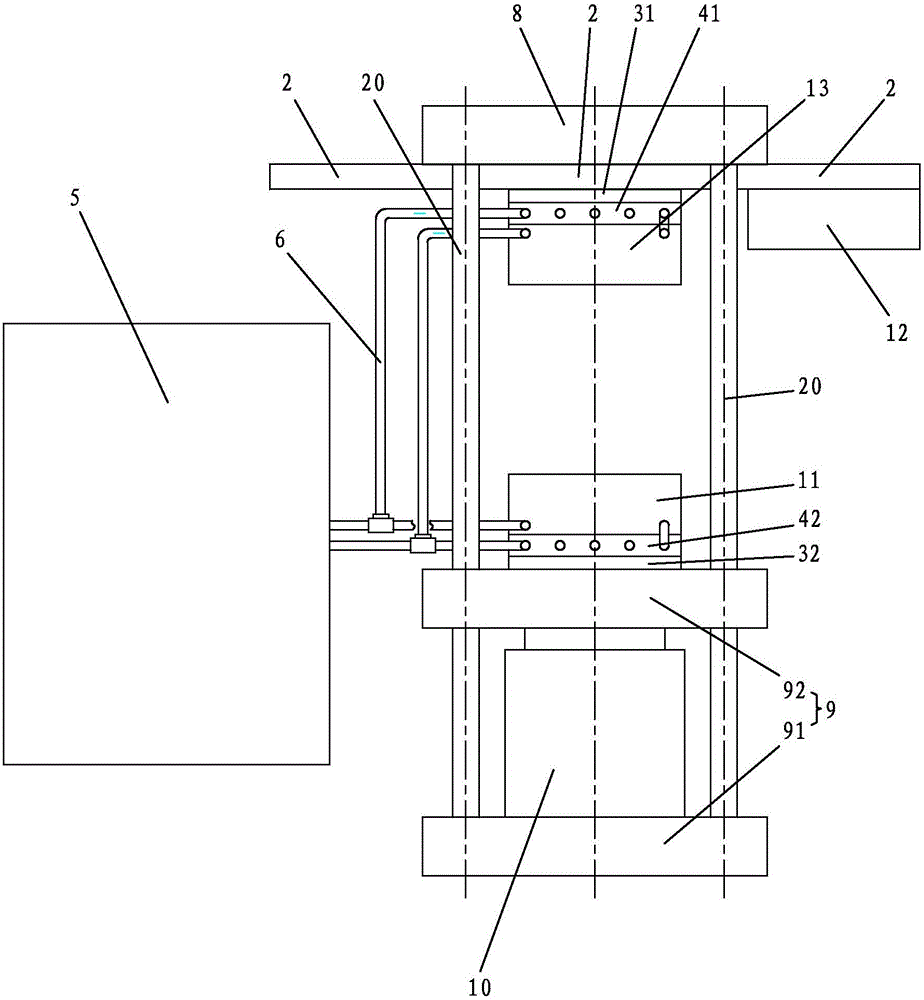

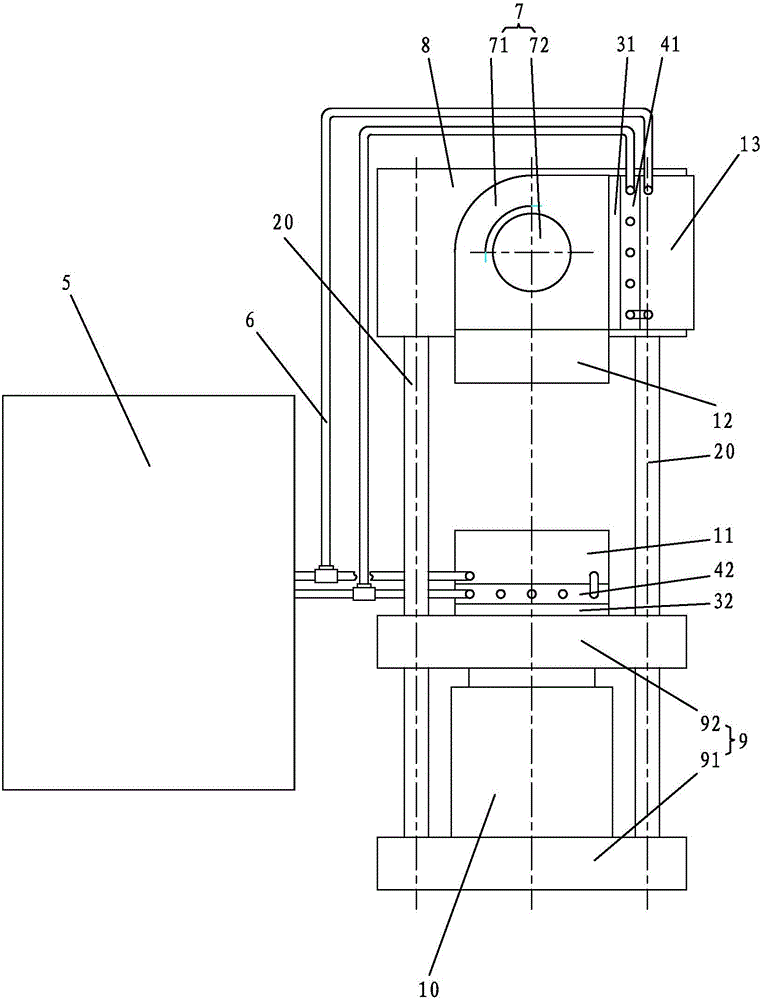

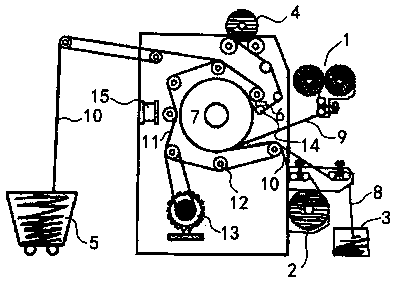

Accurately-metering automatic ink injection machine

The invention relates to an accurately-metering nondestructive automatic ink injection machine. The ink injection machine comprises a shell, a vacuum pump arranged in the shell, a negative pressure main valve, a waste liquid tank, a control module, and at least one set of ink injection units, wherein the vacuum pump is connected with the waste liquid tank through the negative pressure main valve; and the waste liquid tank is connected with each set of ink injection units. The automatic ink injection machine is suitable for injecting ink to various ink boxes with a structure such as an ink box and sprayer head integrated structure, an ink box and sprayer head separated structure, an in-box sponge structure, an in-box non-sponge structure, and the like, which means the automatic ink injection machine can inject ink to all most ink boxes on the market; thus, the automatic ink injection machine has a wide application range. When the ink is injected, the sponge structure is protected from being damaged and the sprayer heat from being worn, and the regeneration times of the ink box can be increased to a maximum extent to save the cost of a user. When the ink injection is finished, the ink can be fully filled to an ink spray nozzle, the automatic ink injection machine can be directly arranged on a printer for use and the ink does not need to be absorbed to the ink spray nozzle from the sprayer head with negative pressure.

Owner:陈换芳

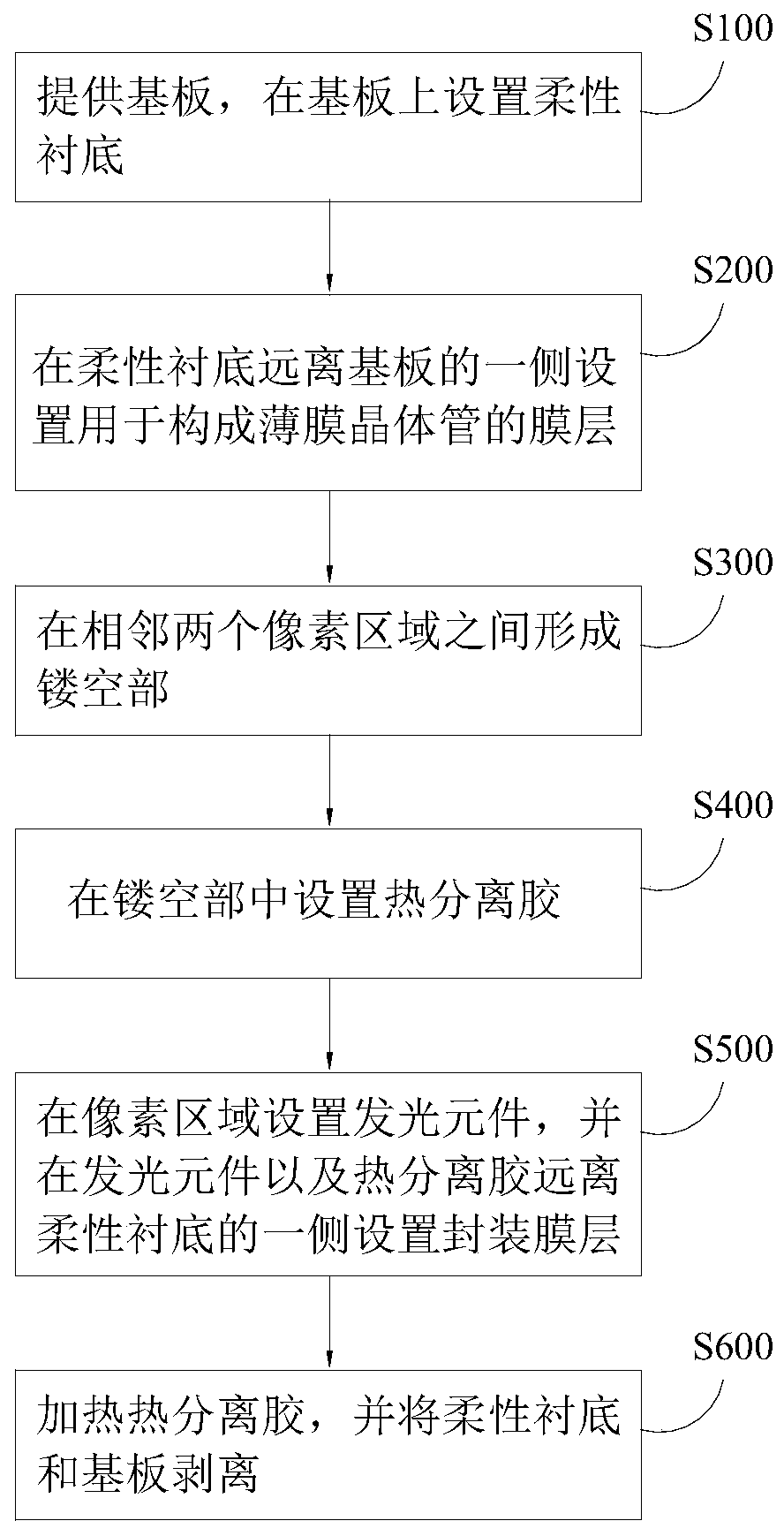

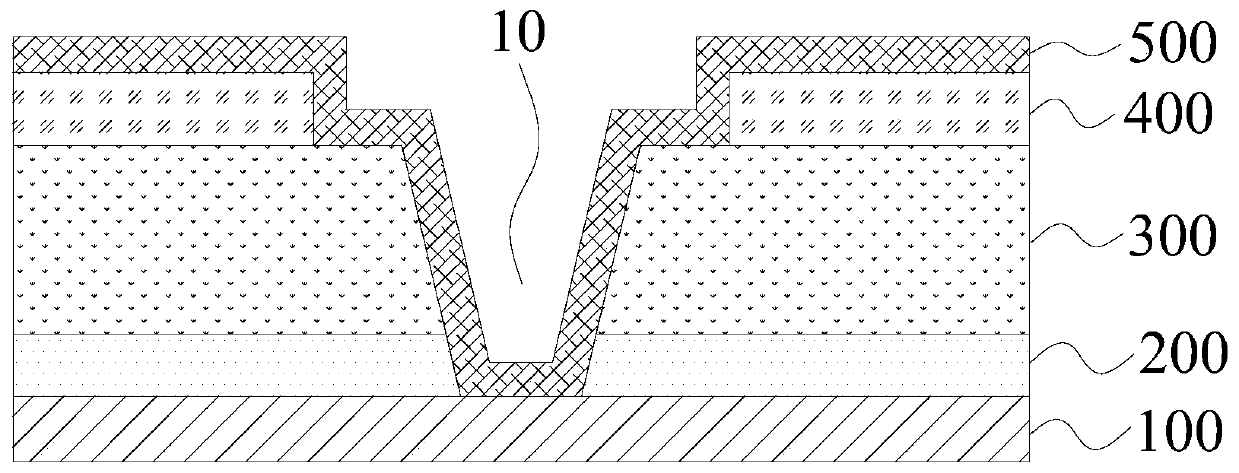

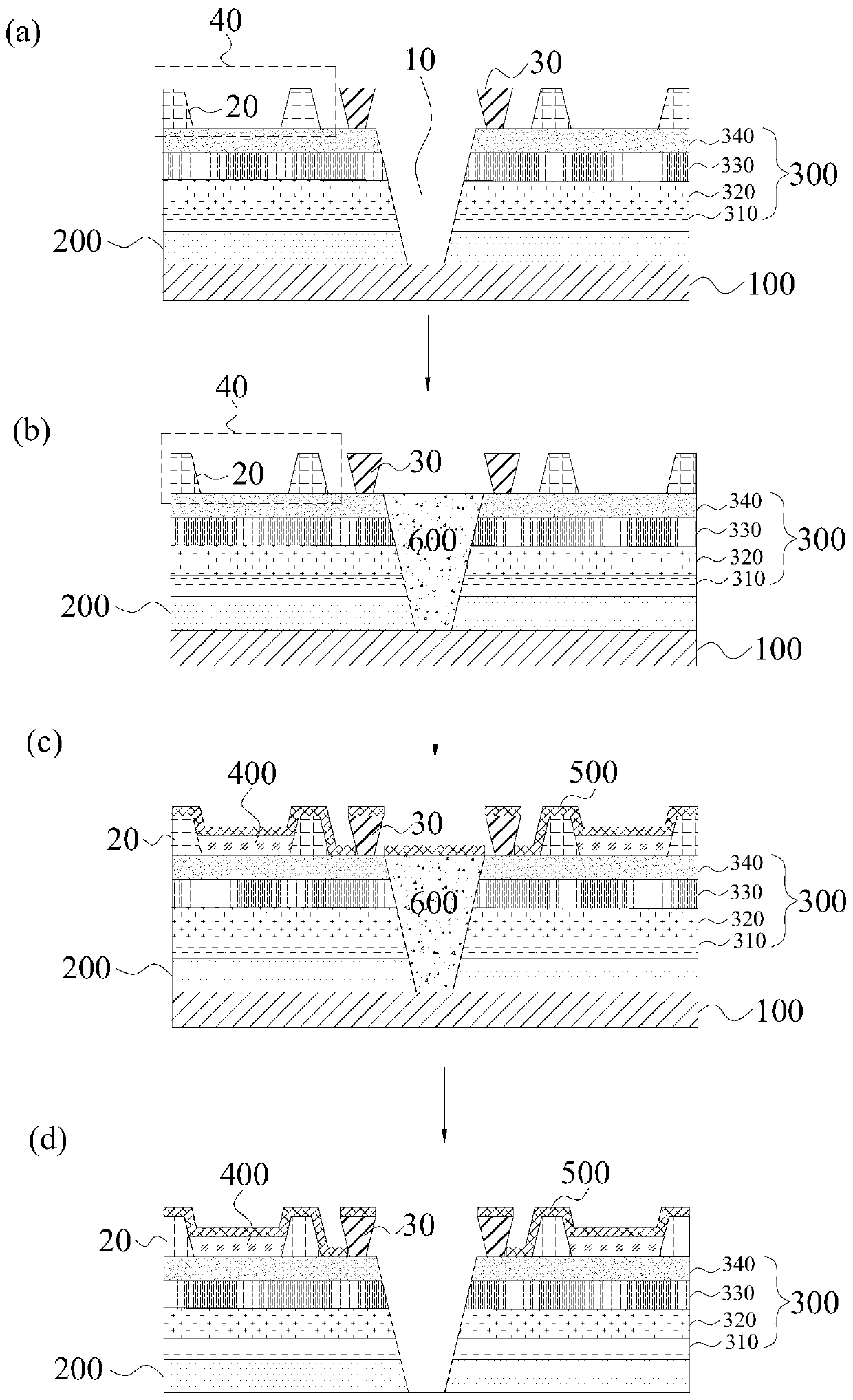

Tensile display device and preparation method

ActiveCN109786428AGood removal effectFacilitate strippingSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceTransistor

The invention discloses a tensile display device and a preparation method. The method comprises the steps of providing a base board, and arranging a flexible substrate on the base board; arranging a film layer used for forming a thin film transistor on one side, far away from the base board, of the flexible substrate, and defining a plurality of pixel areas on one side, far away from the flexiblesubstrate, of the film layer; forming a hollow part between the every two adjacent pixel areas, wherein the hollow parts run through the film layer and the flexible substrate; arranging thermal separation gel in the hollow parts; arranging light-emitting elements in the pixel areas, and arranging packaging film layers on one sides, away from the flexible substrate, of the light-emitting elements and the thermal separation gel; and heating the thermal separation gel, and stripping the flexible substrate and the base board. When the base board is stripped by using the method, the problem that the flexible substrate and the film layer used for forming the thin film transistor are damaged can be relieved, so that the production yield of the tensile display device is remarkably improved.

Owner:BOE TECH GRP CO LTD

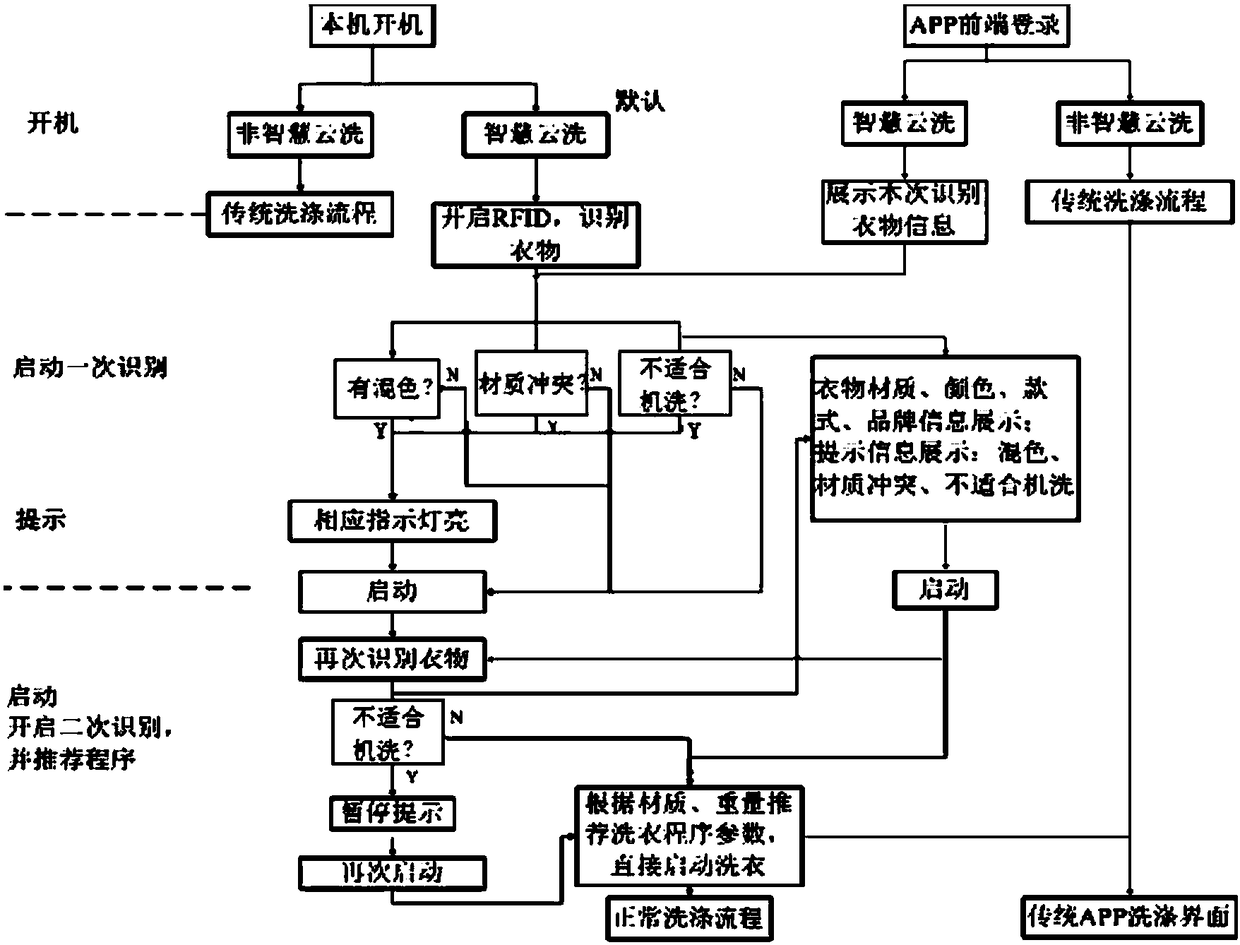

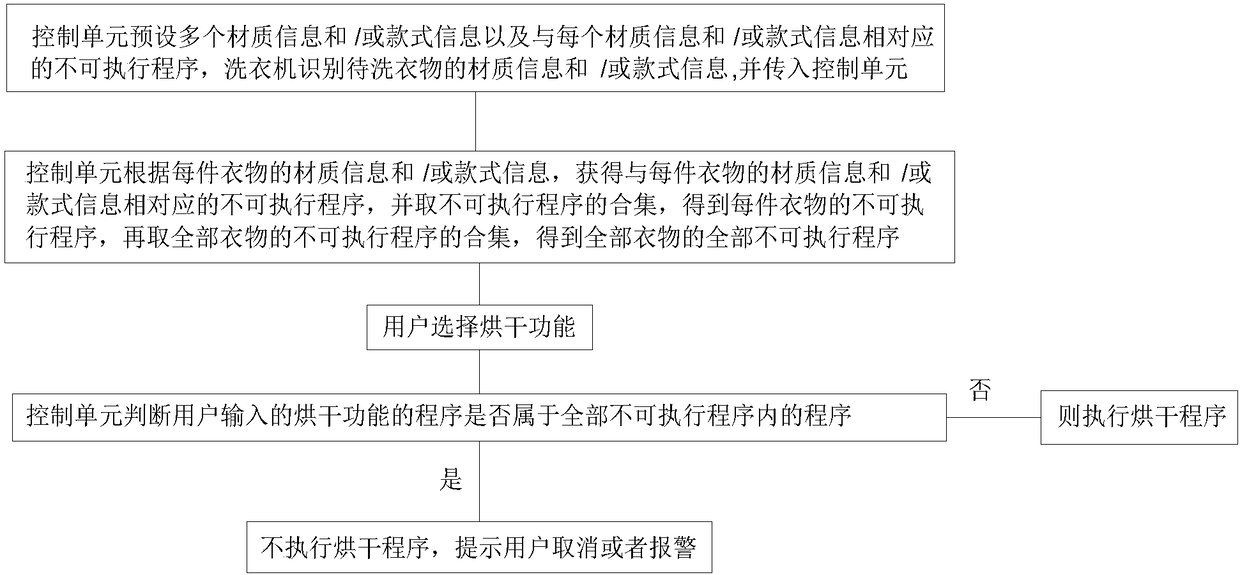

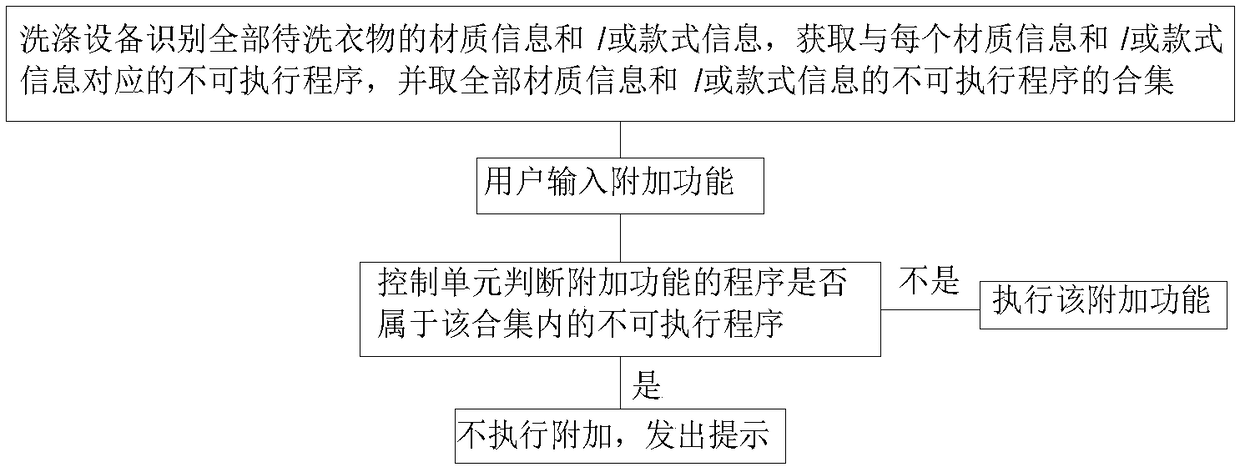

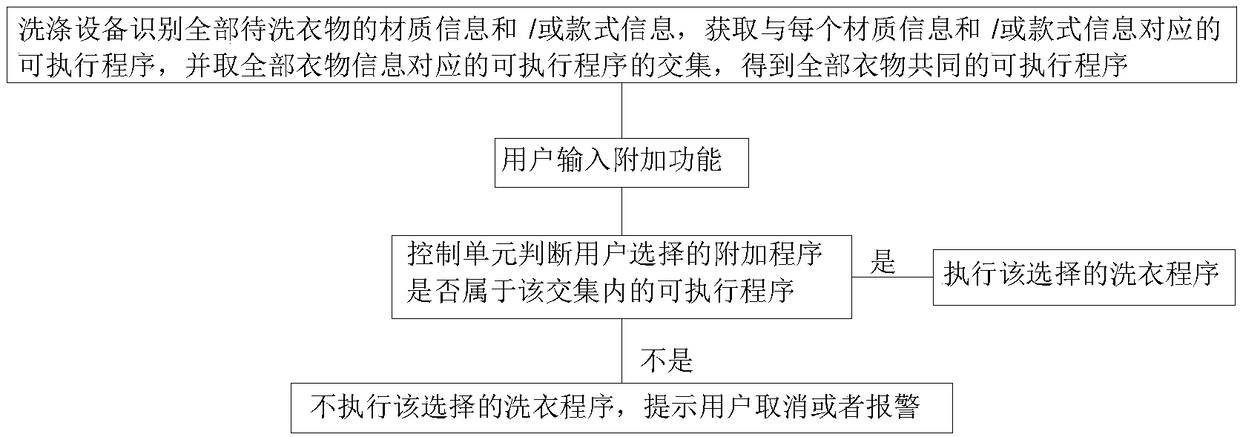

Washing equipment control method and washing equipment

ActiveCN108978111AReduce risk of damageImprove securityOther washing machinesControl devices for washing apparatusProcess engineeringColor mixing

The invention discloses a washing equipment control method and washing equipment. The method comprises the steps that after to-be-washed clothes is put into the washing equipment, whether or not the to-be-washed clothes is suitable for machine washing is judged by the washing equipment by recognizing clothes information of the to-be-washed clothes, if yes, a washing program is recommended and executed, and if not, the washing equipment is paused and a reminder is given. By means of the method, whether or not the to-be-washed clothes is suitable for machine washing is judged by recognizing theclothes information of the to-be-washed clothes to further judge whether there exits color conflict and material conflict and give corresponding reminders and an advised proper washing program so thatthe risk of damaging the clothes which is not suitable for machine washing can be greatly reduced, dyeing and color mixing can be prevented, a recommended clothes washing program can be automaticallymatched, the recommended program is conducted in a manner in which the clothes is prevented from being damaged as much as possible, and therefore the safety of washing is greatly improved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

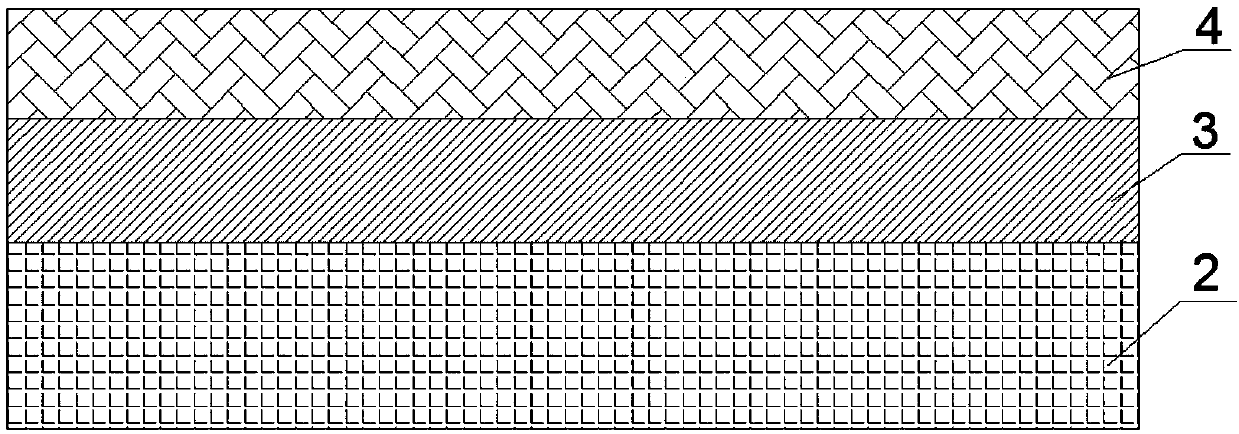

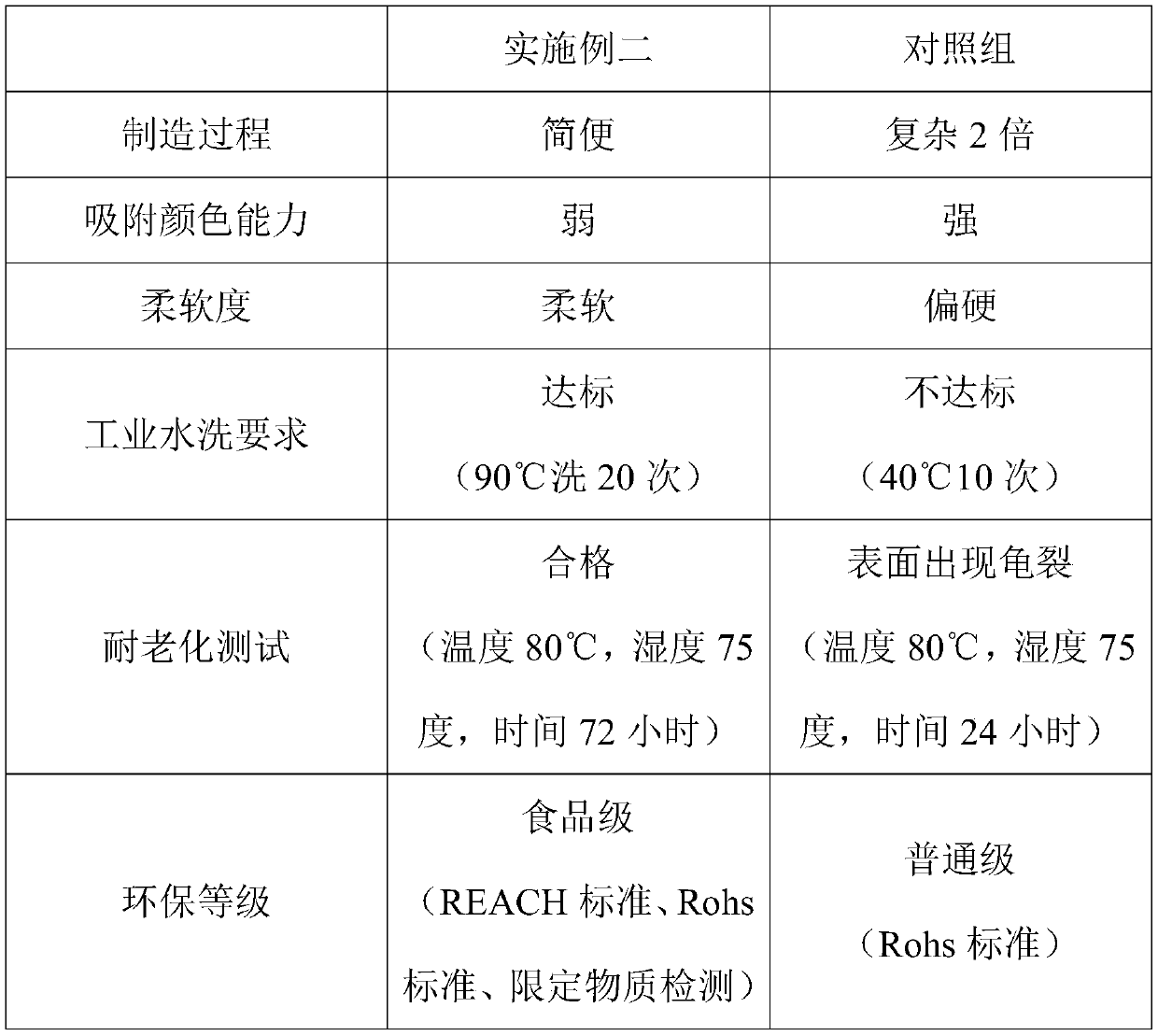

Anti-cross color dyeing laundry sheet, preparation method and use method thereof

InactiveCN107629895AAvoid stickingProduct surface is dryInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsColor effectPolymer science

The invention relates to an anti-cross color dyeing laundry sheet, a preparation method and a use method thereof. The laundry sheet is a compressed towel shaped product, and consists of a color adsorption layer and a laundry layer disposed on the inner side of the color adsorption layer, the color adsorption layer includes cation modified spunlaced nonwoven fabric, the fiber composition of the spunlaced nonwoven fabric is formed by mixing of viscose fiber and polypropylene fiber in certain proportion, the viscose fiber is cation modified fiber, and the viscose fiber and polypropylene fiber arein a mass ratio of 2-4:1. Through single side spraying of the laundry layer and stamping into a compressed towel shape, the product has relatively dry and clean surface and does not stick to hands, and while good laundry and anti-cross color effects are ensured, adhesion of the laundry sheet to outer packing is well avoided. The laundry sheet provided by the invention also has the advantages of strong adsorption capacity, good laundry effect, convenient carrying, cross color dyeing prevention and the like, also can meet users' demand for intelligent home appliances, provides convenience for laundry, and can improve people's quality of life.

Owner:周泽涵

Method for carrying out painting through automatically configuring painting devices by utilizing timber coloring agents

InactiveCN109127266AUniform textureAvoid cross-colorLiquid surface applicatorsRotary stirring mixersLabor operationsWood stain

The invention discloses a method for carrying out painting through automatically configuring painting devices by utilizing timber coloring agents. A device used in the method comprises a device main body, a coloring device, a painting device and a stirring device, wherein the coloring device, the painting device and the stirring device are arranged in the device main body; a pass-out pipeline is arranged between the coloring device and the stirring device in a communication manner; and multiple switch structures are arranged in the coloring device and control multiple connection channels whichare communicated with the pass-out pipelines. The device is capable of automatically driving a coloring agent to be automatically matched and driving a timber to be painted; during the painting; a brush uniformly moves to drive the timber to uniformly move, so that the painting effect is uniform; during the painting, the coloring agent is stirred to ensure that the coloring gent is uniform in character; meanwhile, the device can work for a long time, so that the efficiency is improved and the labor operation time is saved; and after automatic coloring, mixtures pass through respective different channels so as to avoid color crossing.

Owner:王文齿

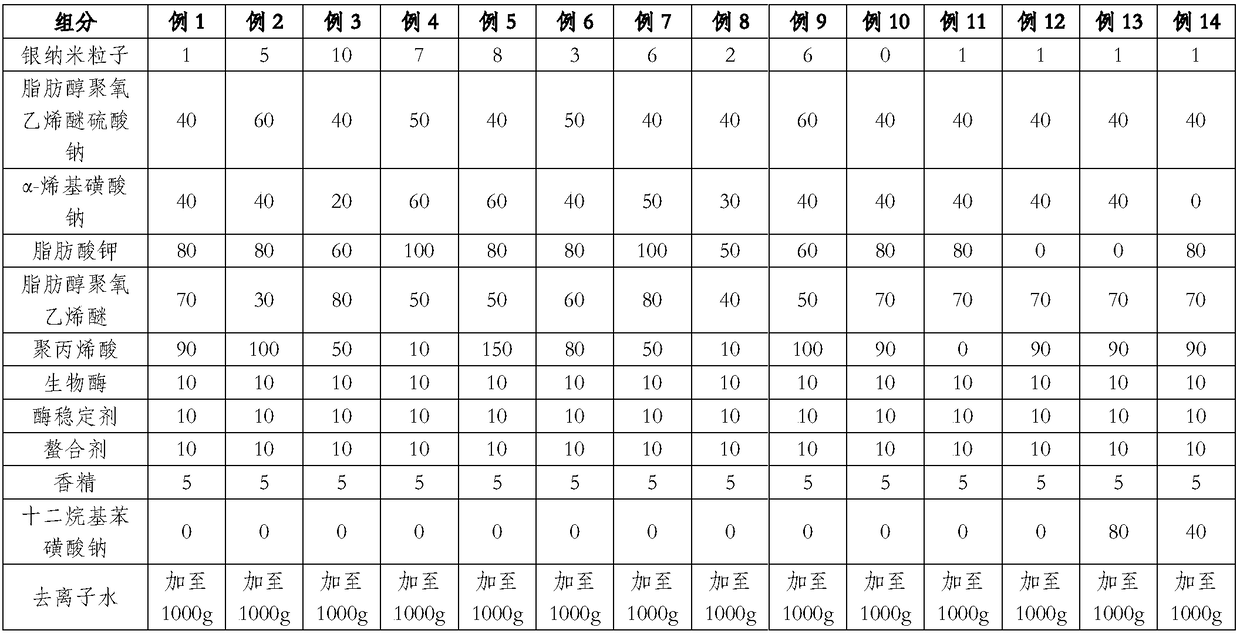

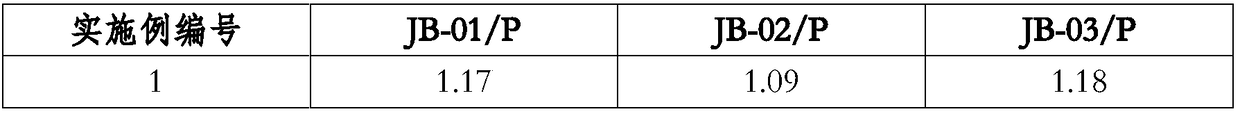

Antibacterial laundry detergent and application thereof

ActiveCN109370799AImprove decontamination abilityHave suppleInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsSulfonatePotassium

The invention relates to an antibacterial laundry detergent and application thereof. The antibacterial laundry detergent is composed of, by weight percentage, 0.1-1.0% of silver nanoparticles and 13.0-30.0% of surfactant, wherein the surfactant is a mixture of anionic surfactant and nonionic surfactant, the anionic surfactant is composed of fatty alcohol-polyoxythylene ether sodium sulfate, alpha-sodium alkenyl sulfonate and potassium aliphatate, and the nonionic surfactant is fatty alcohol-polyoythylene ether. The antibacterial laundry detergent also comprises acrylic polymers and other auxiliaries such as bio-enzymes, enzyme stabilizer, chelating agent and fragrance. The antibacterial laundry detergent has the advantages of being clean in washing, easy to rinse, antibacterial, anti-static, soft, good in color preservation and environmentally friendly.

Owner:ZHONGSHAN LANJU DAILY CHEM IND CO LTD

Transverse ink scrapping ink stack for improving printing quality

Owner:NEW CENTURY DIGITAL PRINT TECH

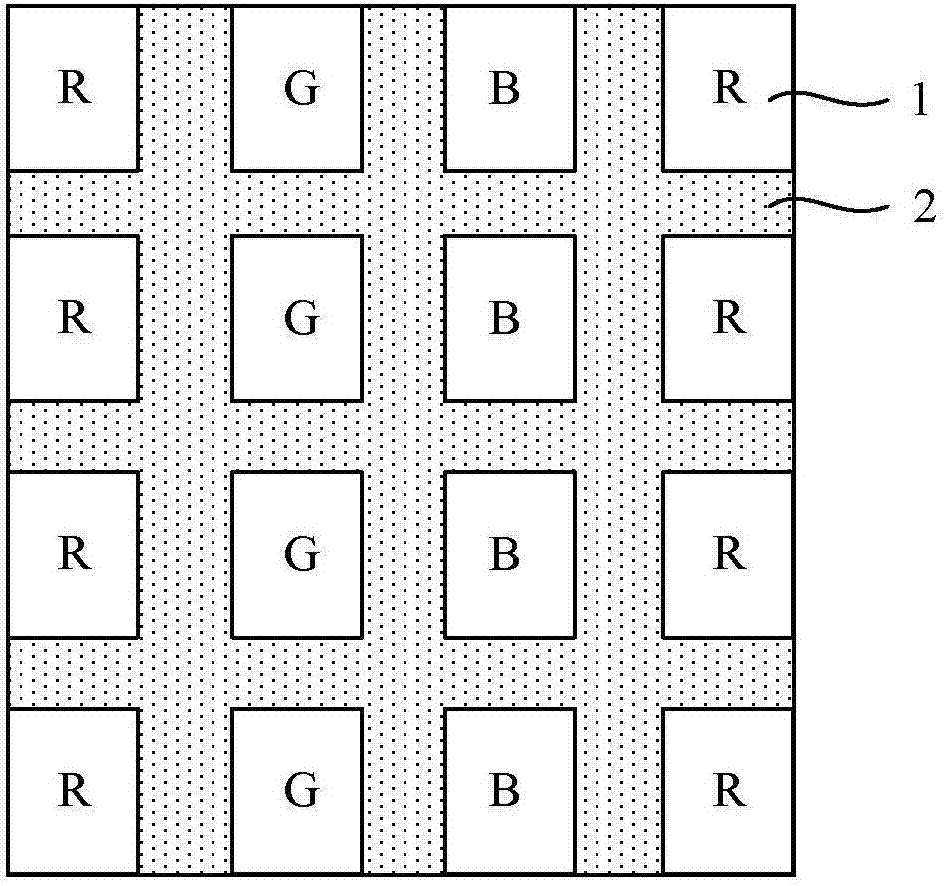

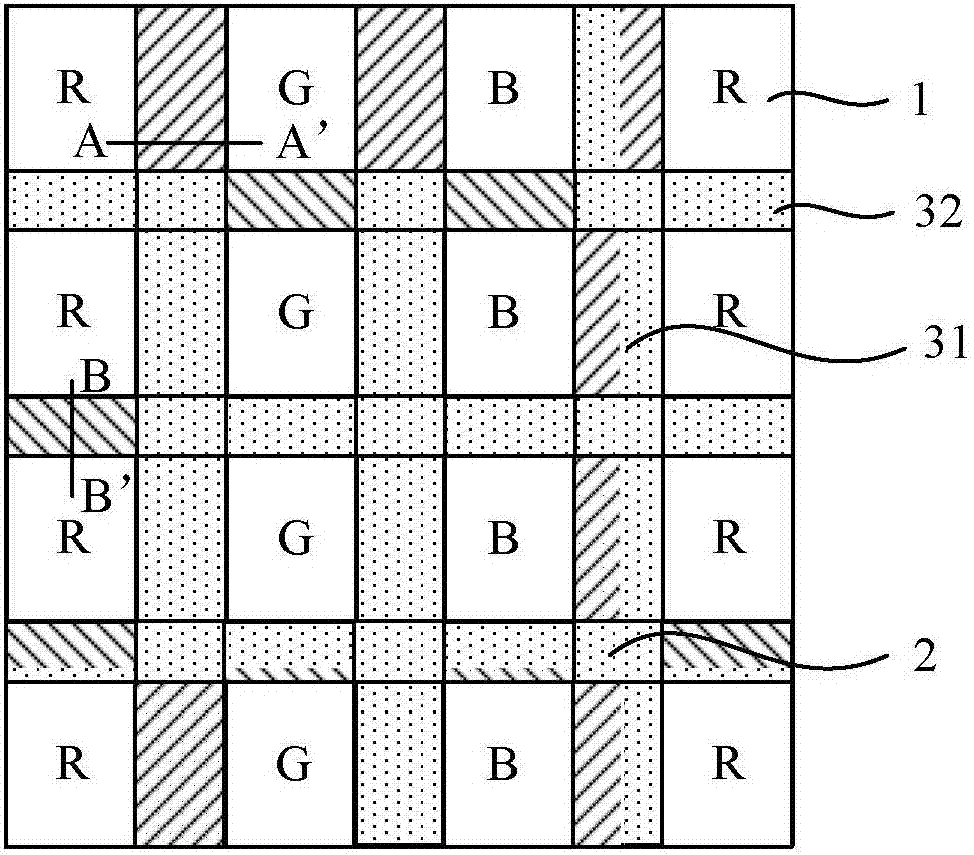

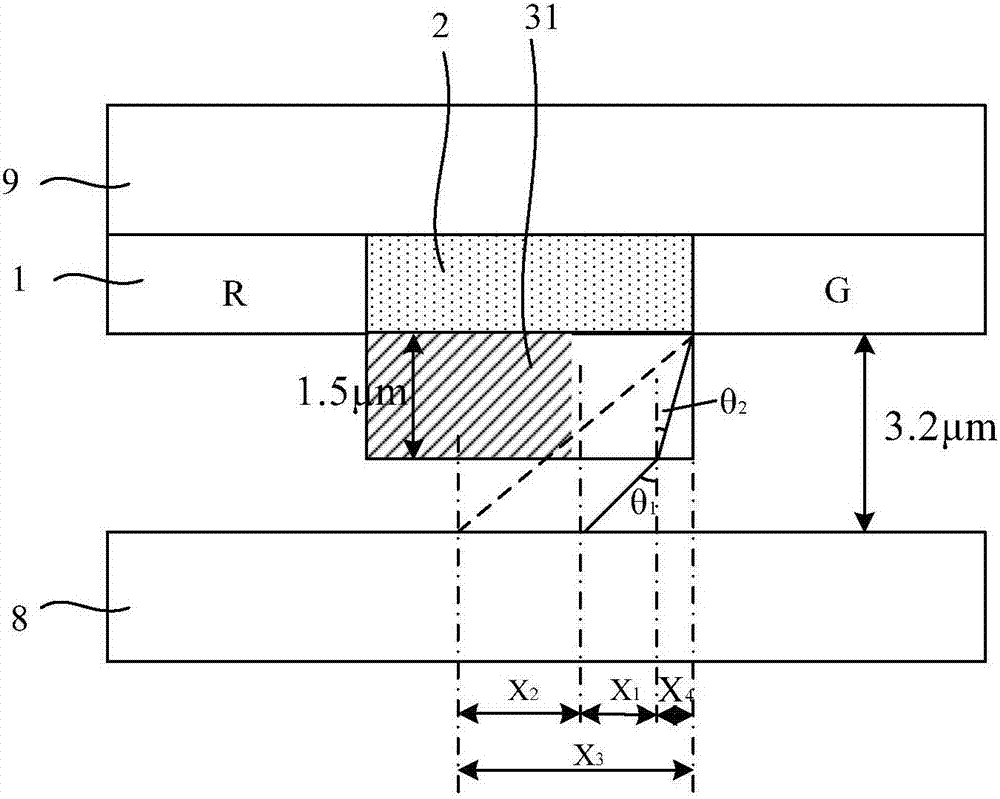

Color film substrate and display panel

The invention provides a color film substrate and a display panel and belongs to the technical field of color film substrates. The problems that an existing color film substrate cannot meet the requirements of avoiding color crossing avoidance and increasing penetration rate simultaneously can be at least partially solved. The color film substrate comprises a base, wherein a plurality of interval color filtering films are arranged on the base, black matrixes are arranged between adjacent color filtering films, and a high refraction transparent layer is arranged on one side, away from the base, of each black matrix which is arranged between the color filtering films of different colors; the refraction index of the high refraction transparent layers is higher than that of the black matrixes, and intermediate mediums are mediums, wherein a display panel which is composed of the color film substrate and a box substrate is filled with the mediums.

Owner:BOE TECH GRP CO LTD +1

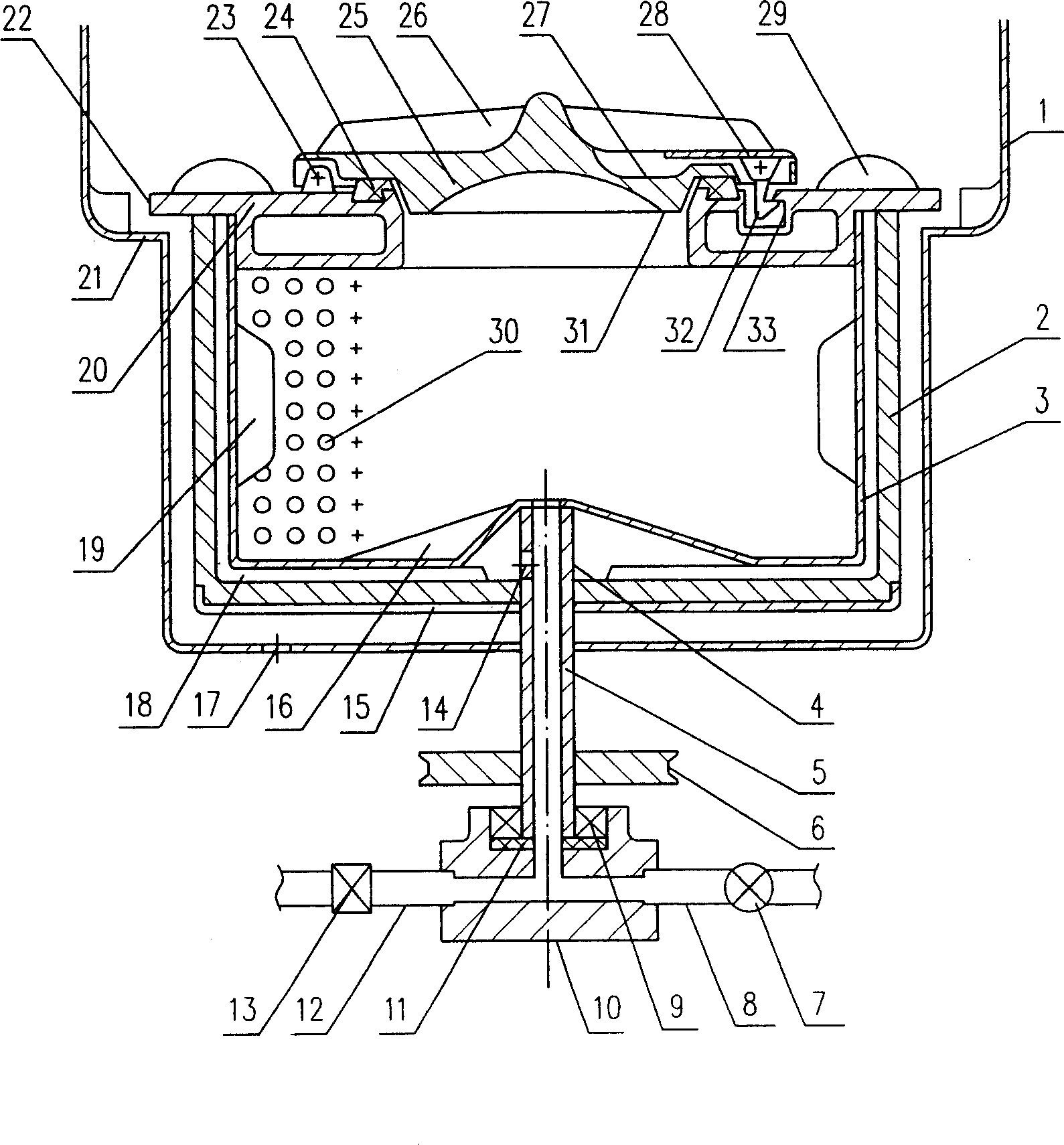

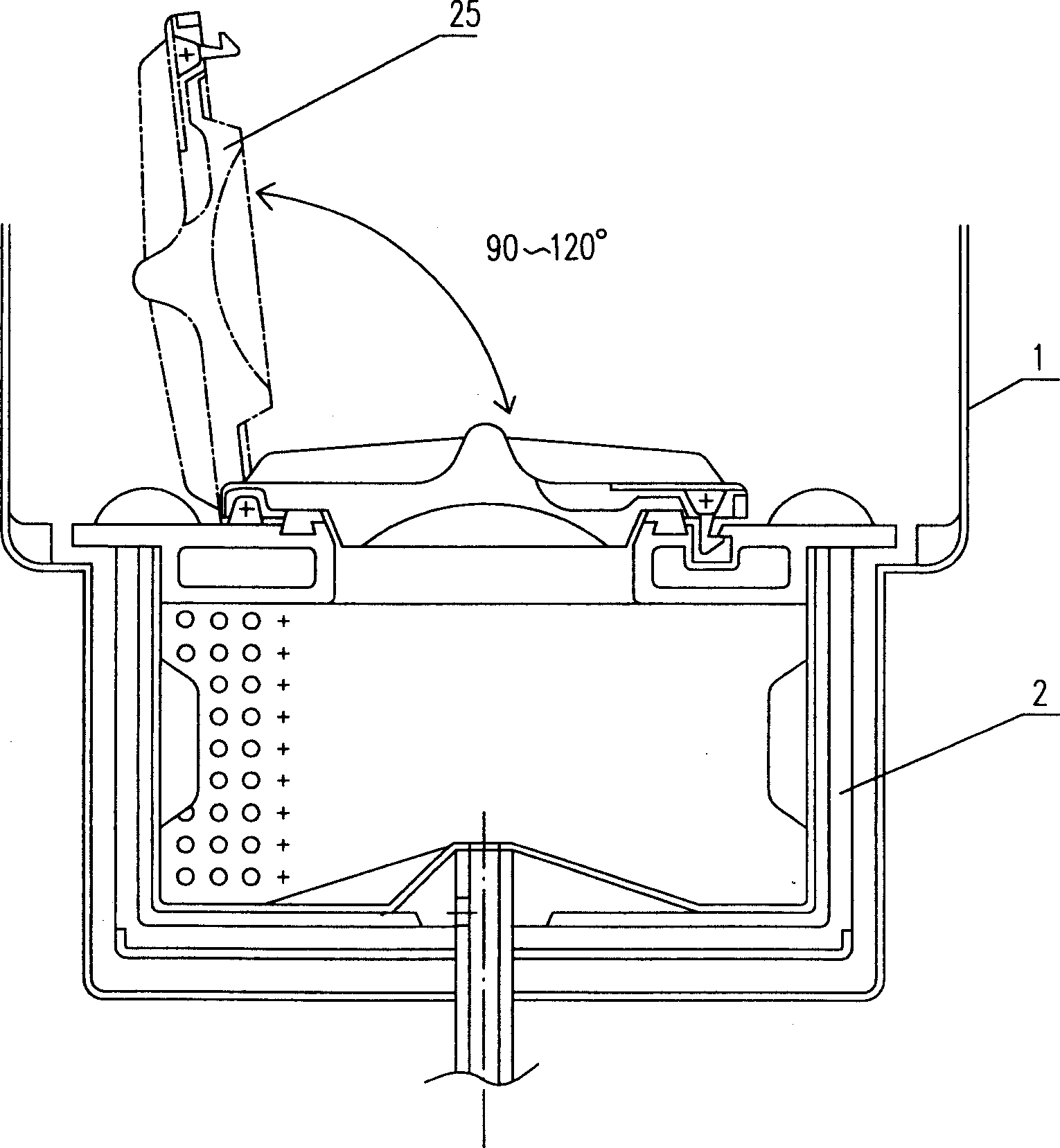

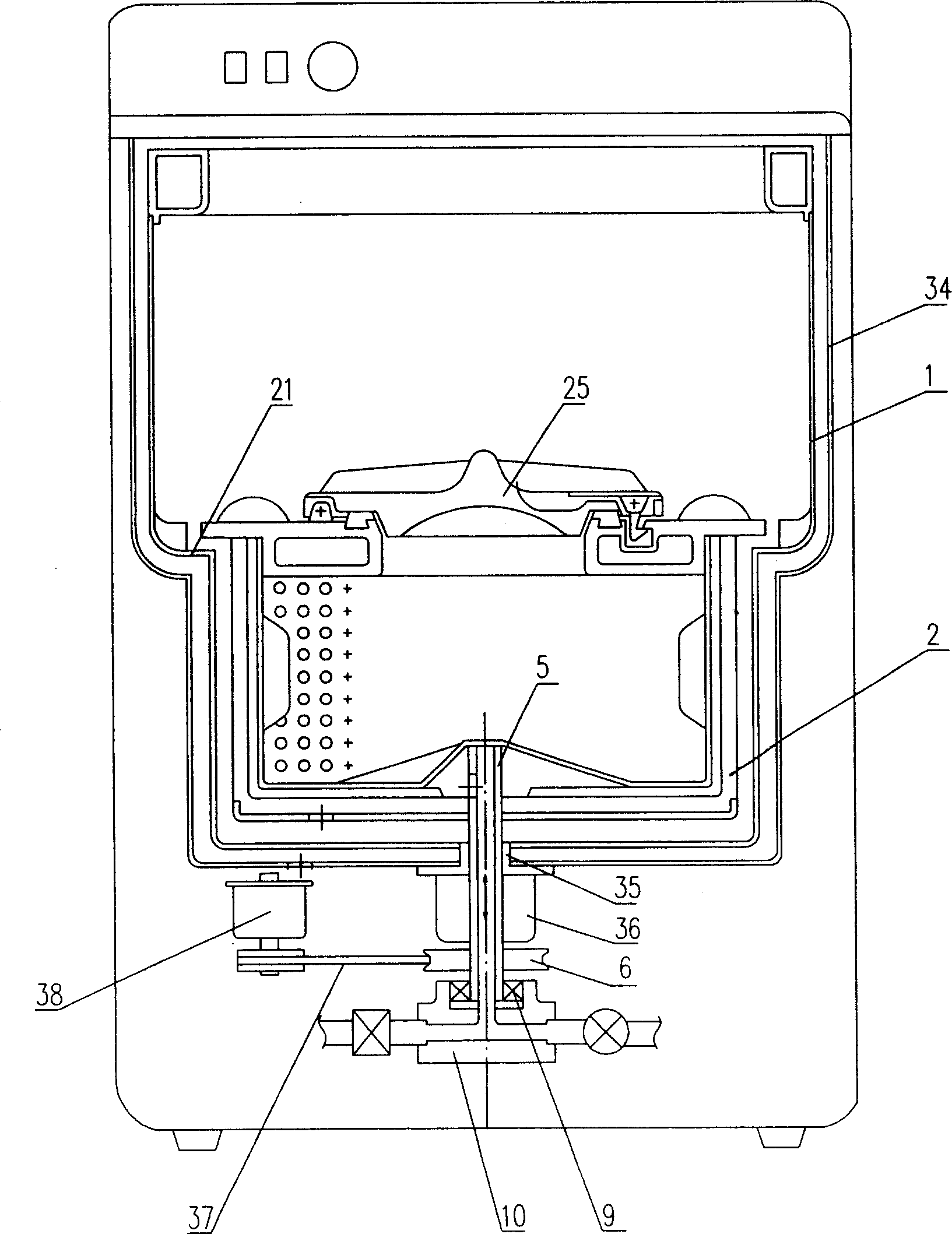

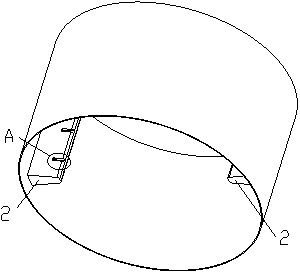

Washing machine for classified washing

InactiveCN1876931AAvoid cross-colorAvoid ContaminationWashing machine with receptaclesTextiles and paperEngineeringMechanical engineering

A washer of sort washing, comprising inner barrel and agitator, the characters lie in: the agitator is a agitator with cover that the bosom set airtight scouring / dehydration cavity and agitation protuberance, the top set unseal able airproof coping and agitator with cover of agitation protuberance, the actuating shaft connected with the mentioned agitator is the quill water leading shaft perforating with the scouring / dehydration cavity inside the cover owning agitator, and the latter end axis body below the actuating shaft meet a hollow water leading setting communicated with inner cavity by bearing and water guiding trepanning; the mentioned the scouring / dehydration cavity inside the cover owning agitator is joined with the actuating shaft, water guiding setting, supply pipe and exhaust water pipe to actualize water supply and drainage. When washing, different kinds of things to be washed can be partly put in inner barrel washing cavity, scouring / dehydration cavity of cover owning agitator and be washed by the running of cover owning agitator.

Owner:宁小静

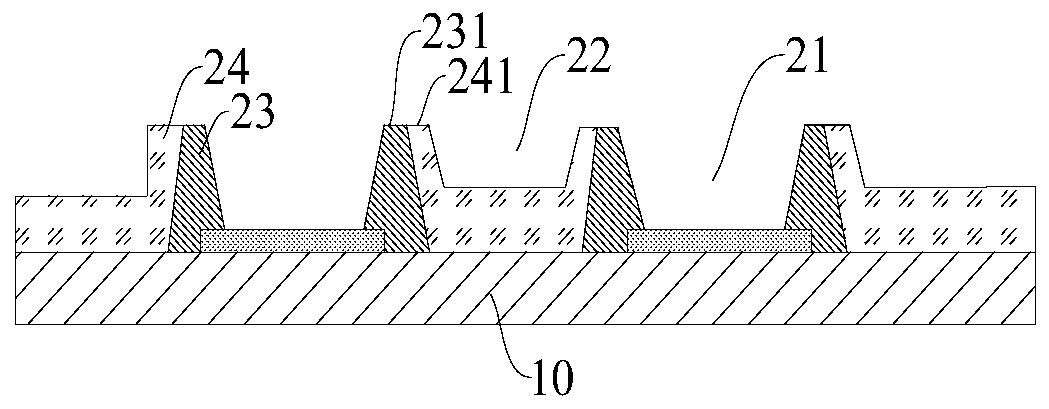

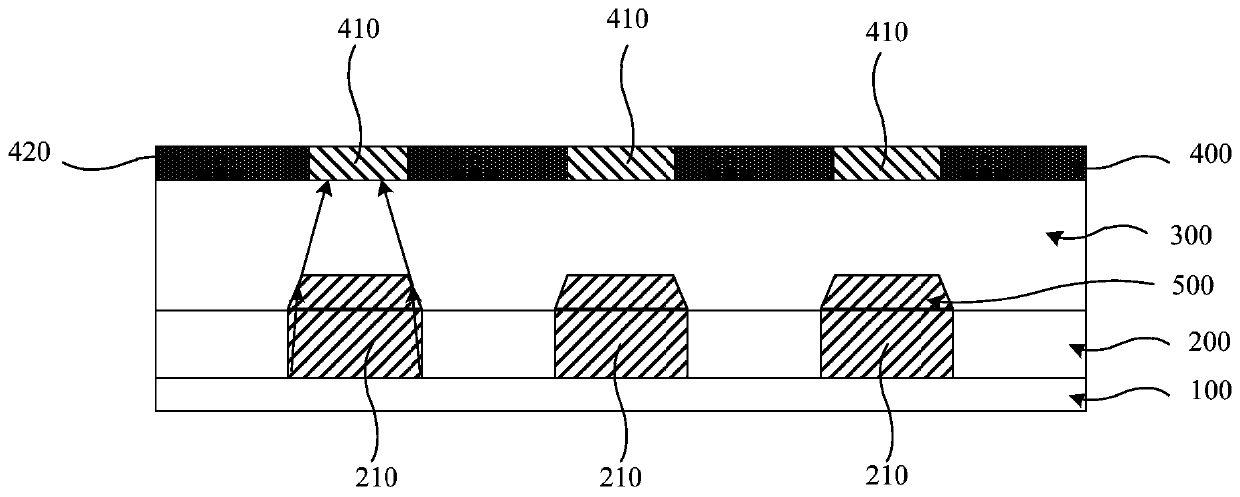

Display back plate and preparation method thereof, and display device

ActiveCN110112203APrevent overflowImprove display qualitySolid-state devicesSemiconductor/solid-state device manufacturingImage resolutionDisplay device

The invention provides a display back plate and a preparation method thereof, and a display device. The display back plate comprises a substrate and a pixel defining layer arranged on the substrate, wherein the pixel defining layer defines a plurality of sub-pixel openings; and the surface, far away from the substrate, of the pixel defining layer is provided with overflow grooves which are locatedbetween the adjacent sub-pixel openings. Therefore, when a light emitting layer is formed through ink-jet printing, the ink overflowing from the sub-pixel openings can flow into the overflow groovesso as to effectively avoid color mixing between adjacent sub-pixels, obviously improve the process defect and improve the processing yield, and the distance between each two adjacent sub-pixel openings is decreased so as to improve the resolution and display quality.

Owner:BOE TECH GRP CO LTD

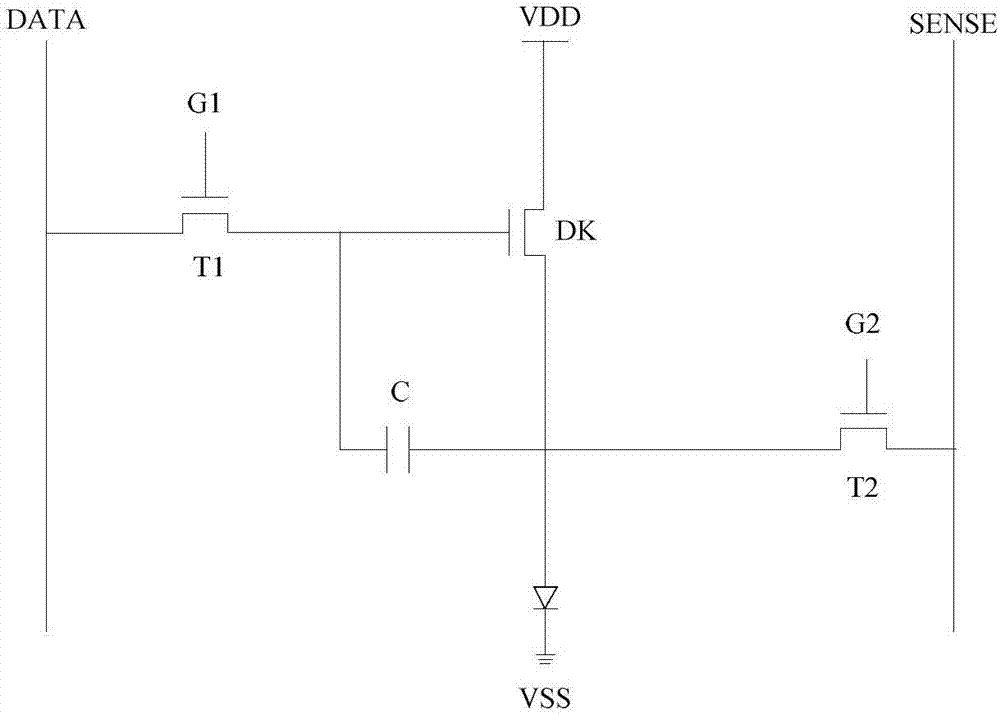

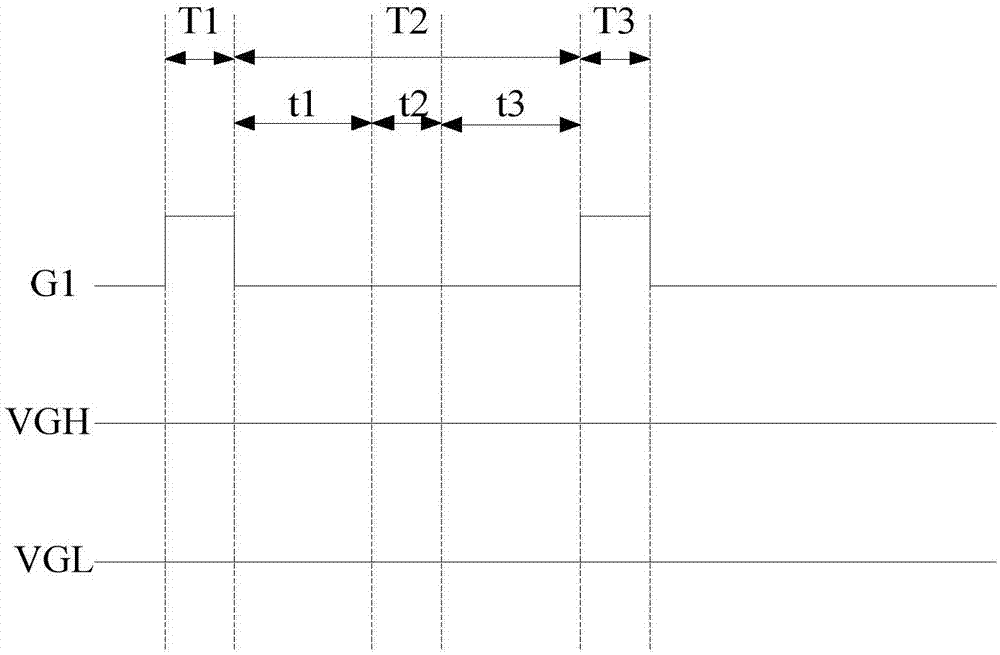

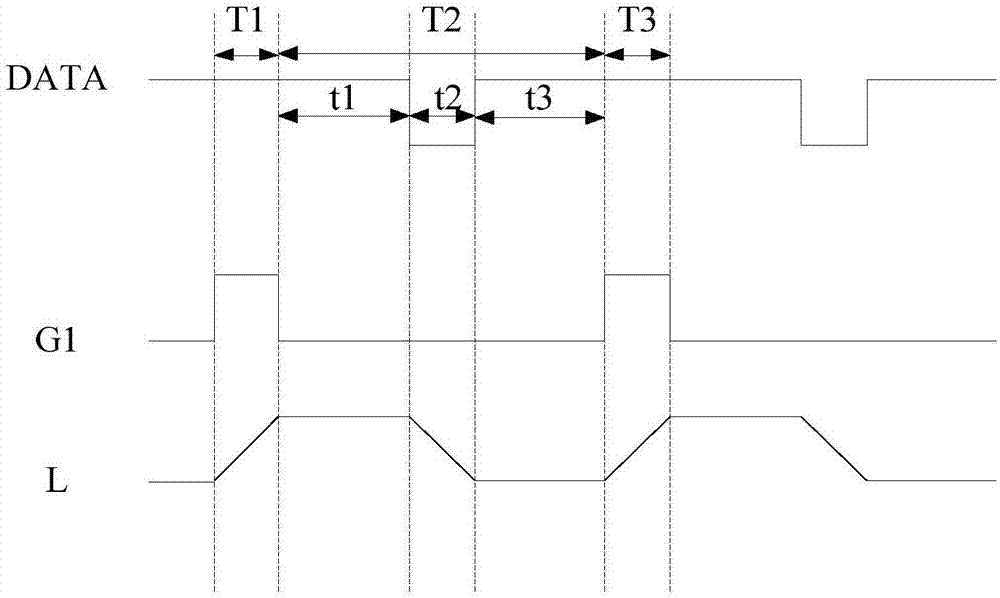

Scanning signal generation method and device, and display device

ActiveCN107507565APrevent leakageConsistent display brightnessStatic indicating devicesCapacitanceElectricity

The present invention provides a scanning signal generation method and device, and a display device, and applied to the display technology field. The method comprises: providing conduction signals; providing turn-off signals, wherein the turn-off signals are controlled to jump to a preset voltage according to the type of a switching transistor in the black insertion phase of a pixel driving circuit; and generating scanning signals according to the conduction signals and the turn-off signals. In the black insertion phase, the turn-off signals are jumped to the preset voltage in a preset mode according to the type of the switching transistor so that even if the threshold voltage of the switching transistor generates negative drifting, the turn-off signals after jumping can turn off the switching transistor after the threshold voltage generates negative drifting to prevent charges in a capacitor from electric leakage through the switching transistor, allow the display brightness of electroluminescent cells to be consistent and avoid generation of cross color and splash screen phenomenons.

Owner:BOE TECH GRP CO LTD +1

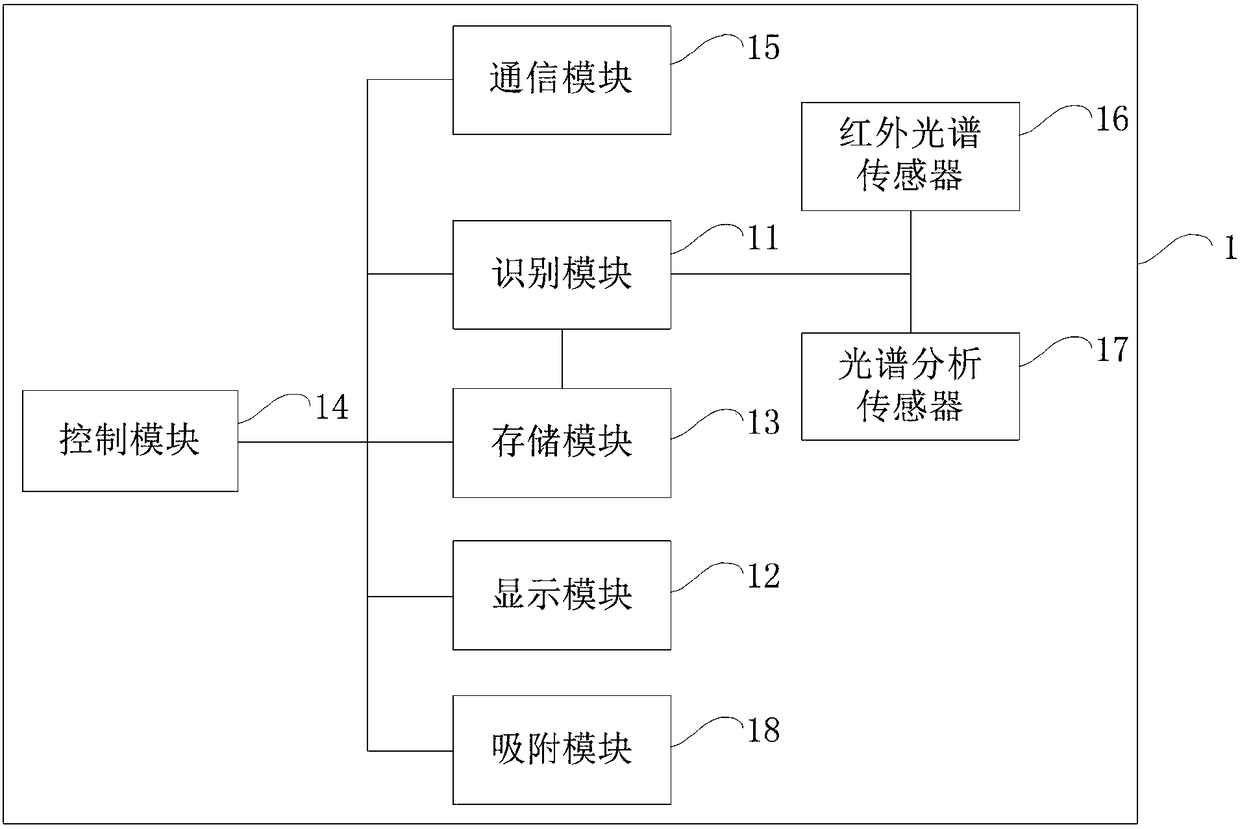

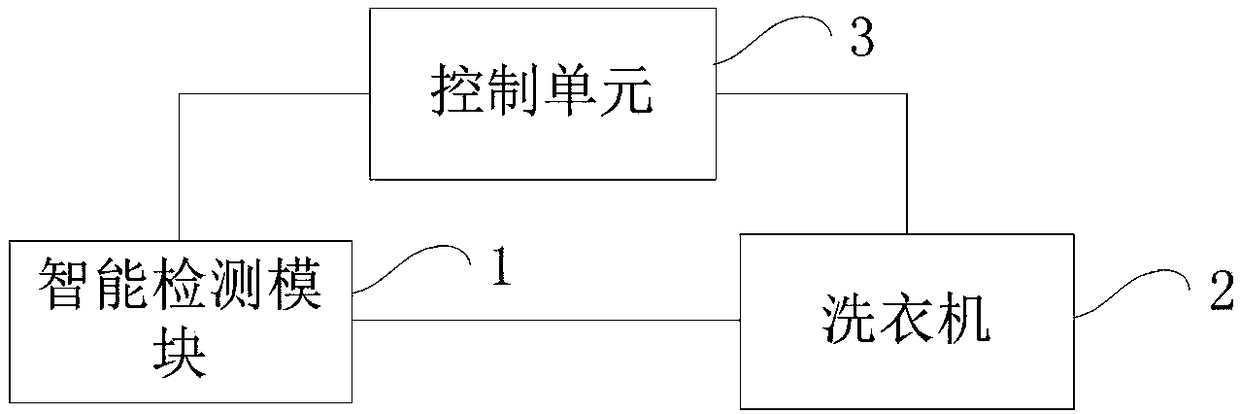

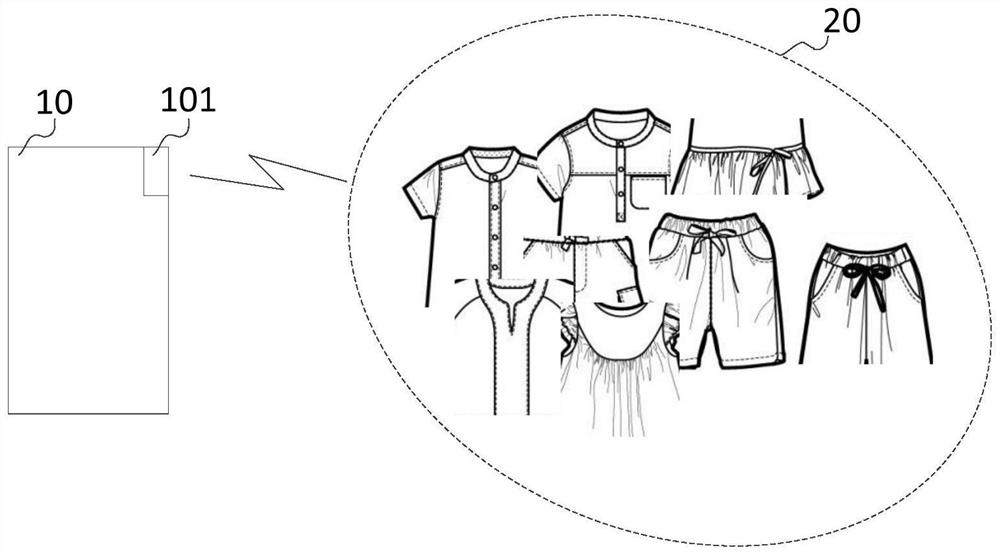

Intelligent detection module, washing machine and washing procedure recommendation method of washing machine

ActiveCN108950983AAvoid Unrecognized ProblemsFlexible identificationControl devices for washing apparatusTextiles and paperComputer vision

The invention relates to the technical field of washing machines and aims at solving the problem that existing washing machines cannot flexibly identify the materials and color of washed objects and cannot prevent color crossing of the washed objects. In order to solve the problem, the invention provides an intelligent detection module, a washing machine and a washing procedure recommendation method of the washing machine. The intelligent detection module is detachably connected with a washing machine body. The intelligent detection module includes an identification module which can identify the materials and / or color of the washed objects in the disassembly state and / or fixed state of the intelligent detection module. The washing machine includes the intelligent detection module. The recommendation method includes the following steps that the intelligent detection module is close to the washed objects or the washed objects are close to the intelligent detection module so as to identify the materials and / or color of the washed objects, and according to the identified material and / or color information, a washing procedure is recommended. The intelligent detection module can flexiblyidentify the materials and color of the washed objects, and prevent color crossing of the washed objects.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

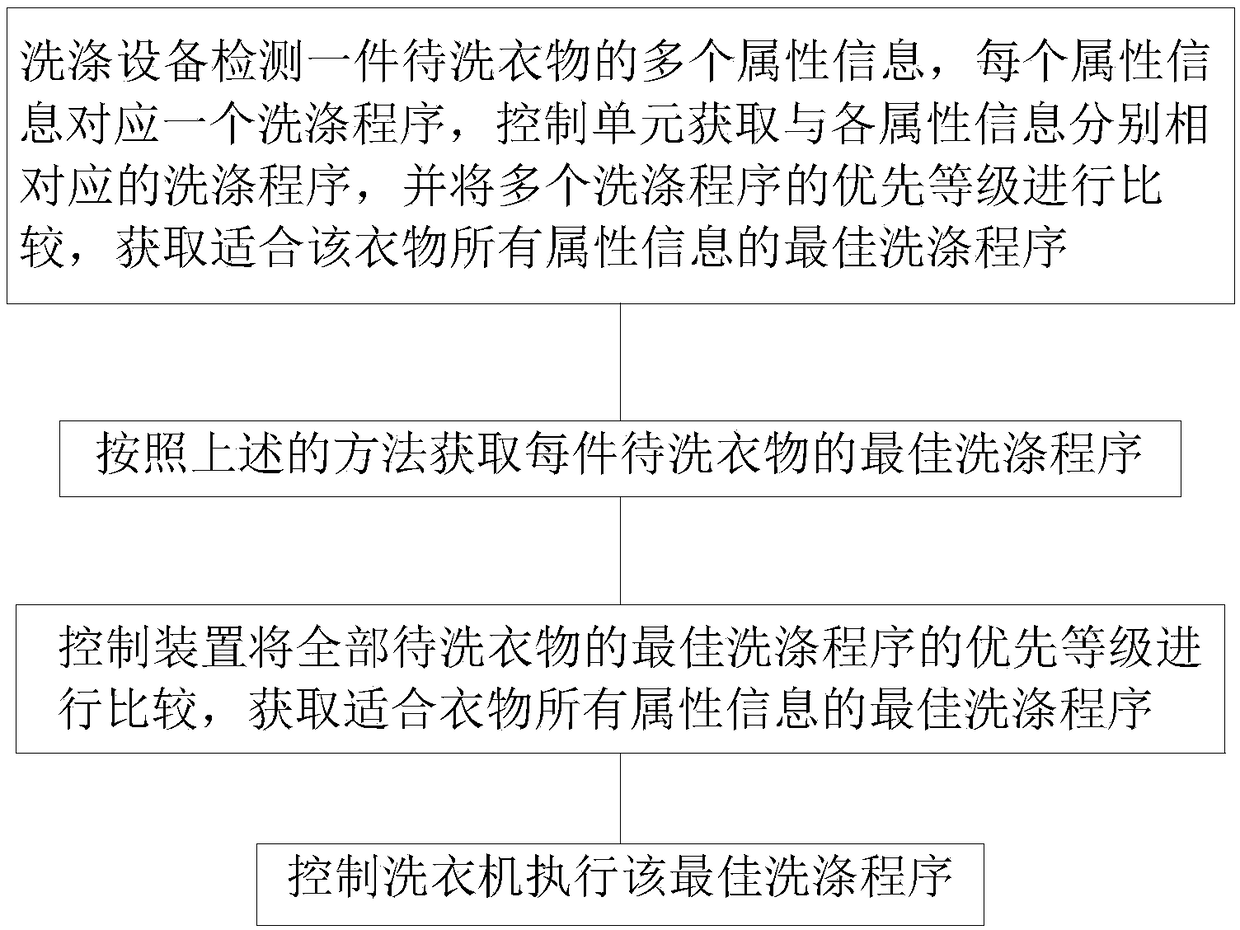

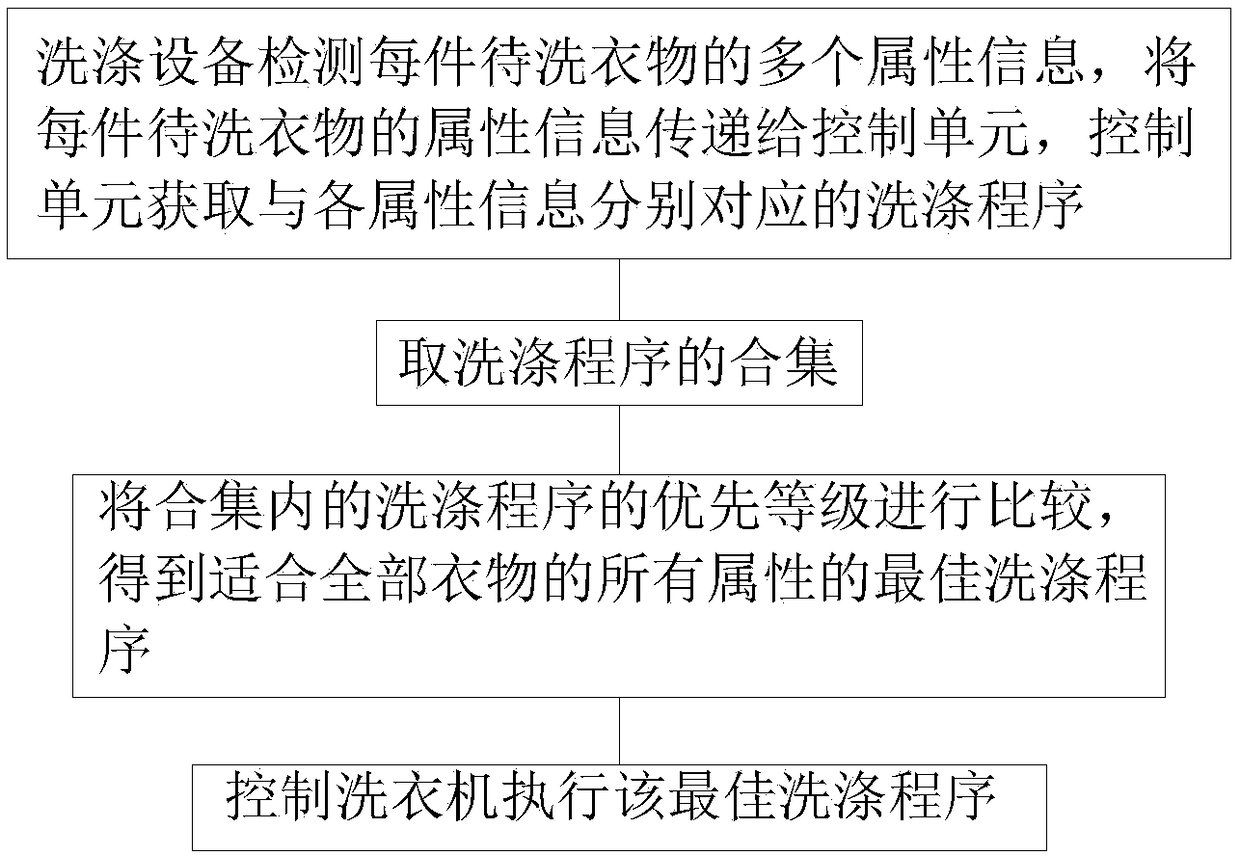

Washing equipment control method and washing equipment

ActiveCN108978109AReduce damage rateReduce risk of damageControl devices for washing apparatusTextiles and paperMultiple attributeComputer science

The invention belongs to the field of washing equipment, and particularly relates to a washing equipment control method and washing equipment. The method comprises the steps that multiple attribute information of to-be-washed clothes is recognized by the washing equipment and transmitted to a control unit, and corresponding washing programs of the attribute information are obtained by the controlunit respectively to perform logical judgement on the washing programs to select the optimal washing program which is suitable for all attribute information of the clothes. The method has the advantages that the corresponding washing programs are obtained through the attribute information of the to-be-washed clothes, the optimal washing program which is suitable for all attribute information of the clothes is selected, a user does not need to input or select the washing program, intelligent washing program selection is achieved, the probability of damage of the clothes caused by the wrong selection of the washing program is reduced, the selection of the washing program is related to multiple factors, the most important material information and type information are selected, and the optimalwashing program is selected; the method is simpler, and automatic washing is achieved.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

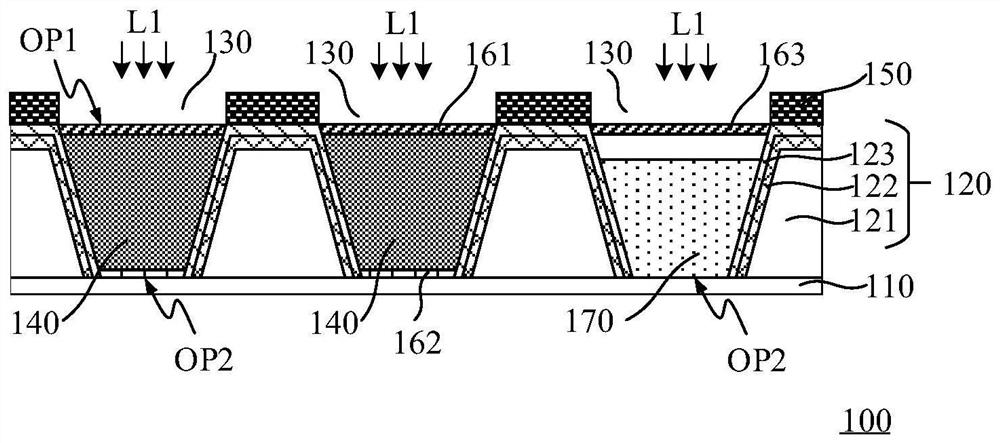

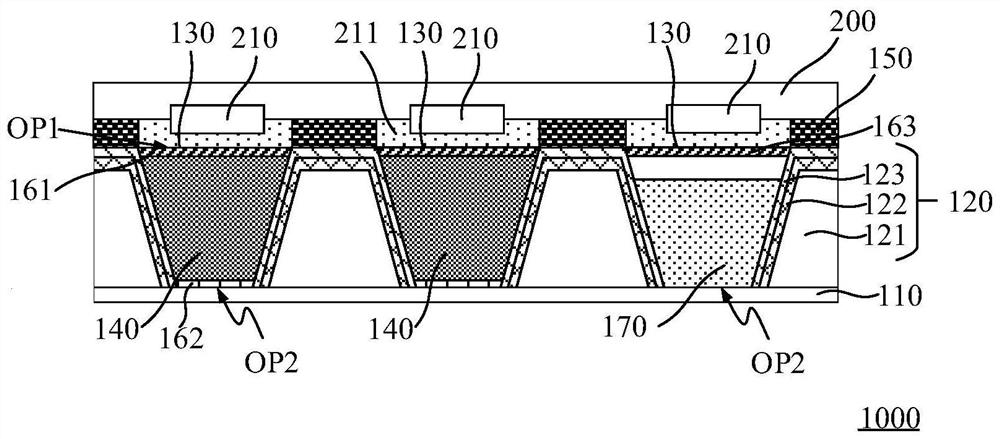

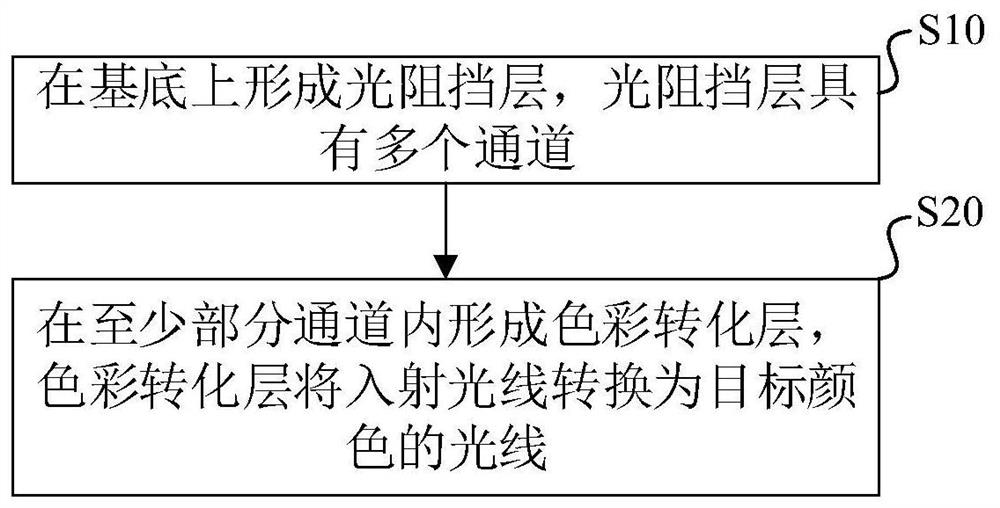

Color conversion assembly, manufacturing method thereof and display panel

InactiveCN112233567AIncrease heightIncreasing the thicknessSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringReflective layer

The invention discloses a color conversion assembly, a manufacturing method thereof and a display panel. The color conversion assembly includes: a substrate; a light blocking layer located on the substrate and having a plurality of channels; a color conversion layer located in at least part of the channel, wherein the color conversion layer converts the incident light into light of a target color,and the light blocking layer includes: a support layer, which is located on a substrate; a black matrix layer continuously extending on an upper surface and a side surface of the support layer, the upper surface of the support layer facing away from the substrate; and a reflective layer continuously extending on an upper surface and a side surface of the black matrix layer, wherein the upper surface of the black matrix layer faces away from the substrate. According to the color conversion assembly provided by the embodiment of the invention, the problem of color crossing between channels of adjacent sub-pixels can be reduced, and the light emitting efficiency is improved.

Owner:CHENGDU VISTAR OPTEOLECTRONICS CO LTD

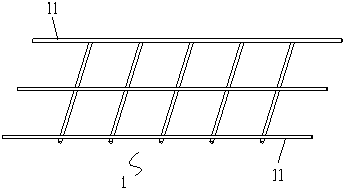

Clothes dryer barrier, clothes dryer and installation method of clothes dryer barrier

InactiveCN109750467AAvoid cross-colorIncrease floor area ratioTextiles and paperLaundry driersProcess engineering

The invention provides a clothes dryer barrier, a clothes dryer and an installation method of the clothes dryer barrier. The barrier is detachably fixed into a clothes dryer drum, two oppositely extending lifting ribs are arranged on the inner wall of the clothes dryer drum, and the barrier is of a mesh-shaped structure disposed between the two lifting ribs. The barrier is detachably fixed into the clothes dryer drum, so that different drying areas can be spaced within the clothes dryer for sorting and drying the clothes, the wrapping and coating and color crossing of the clothes are avoided,and the improvement of the drying speed and the volume ratio of the clothes dryer are facilitated; by fixing the barrier to the lifting ribs, the installation and fixing operation of the barrier and the firmness of the barrier after fixing are facilitated; and the barrier is of a mesh-shaped structure, the airflow in the drum can pass through the barrier, first, it is ensured that the arrangementof the barrier has less influence on the airflow orientation in the drum, and second, the drying speed of the clothes close to the barrier is ensured.

Owner:QINGDAO HAIER DRUM WASHING MACHINE

Display panel and display device

ActiveCN110246873AImprove the display effectHigh color puritySolid-state devicesSemiconductor/solid-state device manufacturingConvex structureRefractive index

The invention provides a display panel and a display device. The display panel comprises a substrate, a light emitting layer, an encapsulation layer, and a light shielding unit which are stacked, wherein the light emitting layer includes a plurality of light emitting units for emitting light of different colors; in the direction perpendicular to the substrate, the projection of a portion of the light shielding unit overlaps the projection of a portion of the light emitting unit; a convex structure or concave structure is disposed on the light-emitting path of the display panel, and has a refractive index greater than the refractive index of the encapsulation layer. The display effect of the display panel is further improved.

Owner:KUNSHAN NEW FLAT PANEL DISPLAY TECH CENT +1

Forming process of double-color watch belt

The invention relates to the technical field of watchband molding, in particular to a forming process of a double-color watch belt. The forming process of the double-color watch belt comprises the following steps that 1, materials are prepared; 2, a forming mold is prepared; 3, primary material placing is carried out; 4, primary oil pressure forming is carried out; 5, a middle plate is taken out;6, burrs are torn off; 7, secondary material placing is carried out; 8, secondary oil pressure forming is carried out; and 9, mold opening is carried out. According to the forming process of the double-color watch belt, the primary oil pressure forming is completed through a lower mold and the middle plate by the aid of the forming mold, then the middle plate is taken out, and then the secondary oil pressure forming is carried out through the lower mold and the upper mold to prepare the double-color watch belt, so that the pursuit of consumers on the appearance of a product is met, and the forming process has the advantages of being simple in process and low in production cost; and in addition, high-temperature solid silica gel is adopted for the materials of the two colors so that the cross color between the two colors caused by over-good material fluidity can be avoided, the bonding between the two colors is strong, and the layering cannot be generated in a using process.

Owner:DONGGUAN SINCO ELECTRONICS

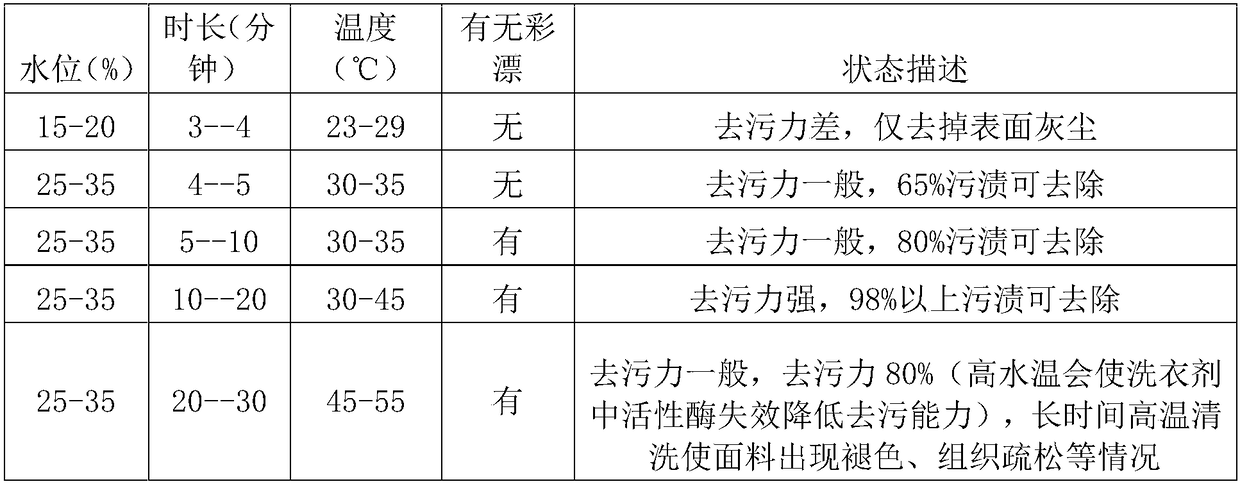

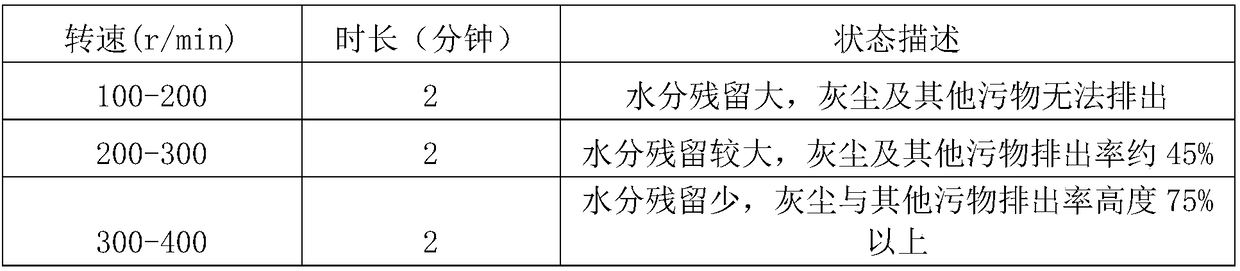

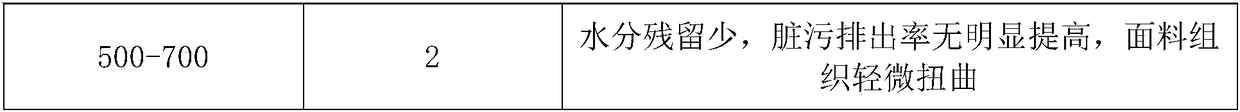

Method for cleaning pure polyester fabric curtain

InactiveCN108301193AMaintain vividnessWon't breakInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsPolyesterEngineering

The invention relates to a method for cleaning a curtain. The method for cleaning a pure polyester fabric curtain is characterized in that the drum capacity of a washing machine is 25-60 kg, and the method sequentially comprises the following steps: main washing, primary uniform distribution, primary dehydration, primary rinsing, secondary uniform distribution, secondary dehydration, secondary rinsing, tertiary uniform distribution, dehydration drying and dryer drying; and a laundry detergent and a finishing agent used in the method do not contain phosphorus or fluorescent agents. The method for cleaning the pure polyester fabric curtain has the advantage of good stain removal effect and no damages to the curtain.

Owner:浙江喜创联电子商务有限公司

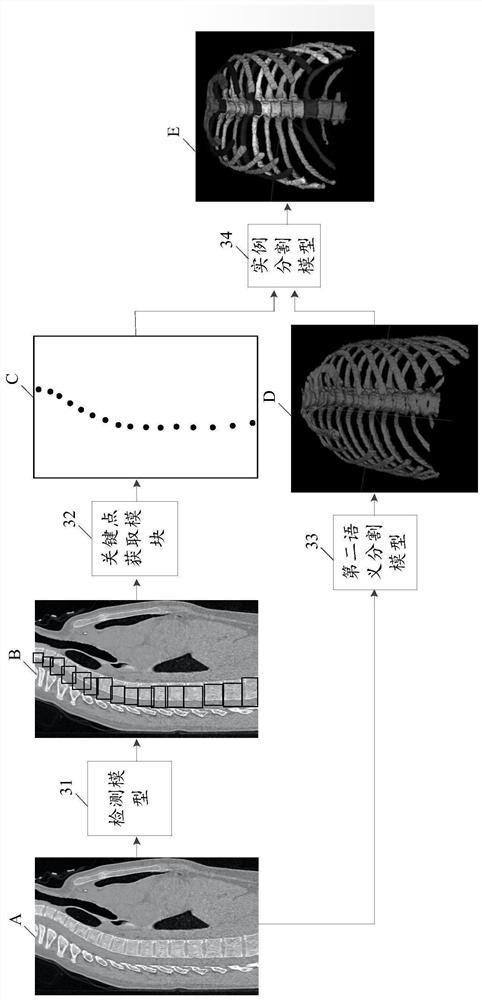

Image processing method and device, model training method and device, and electronic equipment

PendingCN113256672AAvoid undersegmentationAvoid over-segmentation etc.Image enhancementImage analysisImaging processingVertebral bone

The invention discloses an image processing method and device, a model training method and device and electronic equipment. The method comprises the steps of performing target detection on a current rib corresponding to a current second vertebral section on a vertebra rib mask image of a to-be-segmented image according to a key point corresponding to a current first vertebral section of the to-be-segmented image and an instance segmentation model, so as to determine the position of the current rib; and according to the position of the current rib, performing instance segmentation on the current rib to obtain the background of the to-be-segmented image and the instance segmentation result of the current rib, thereby not only avoiding the phenomena of under-segmentation, over-segmentation and the like when the ribs are segmented, but also avoiding color crossing between the ribs.

Owner:INFERVISION MEDICAL TECH CO LTD

Color protection device for washing machine, and washing machine

PendingCN106917233AAvoid cross-colorPrevent fadingOther washing machinesTextiles and paperPulp and paper industry

The invention discloses a color protection device for a washing machine, and a washing machine. The color protection device for a washing machine comprises a base and a color fixative disposed in the base. By adoption of the washing machine with the color protection device to wash clothes, fade of the clothes and color crossing among the clothes can be effectively prevented.

Owner:WUXI LITTLE SWAN ELECTRIC CO LTD

Instant cold and hot forming method and forming equipment for multi-color products

Owner:QUANZHOU THREE SICHUAN MACHINERY

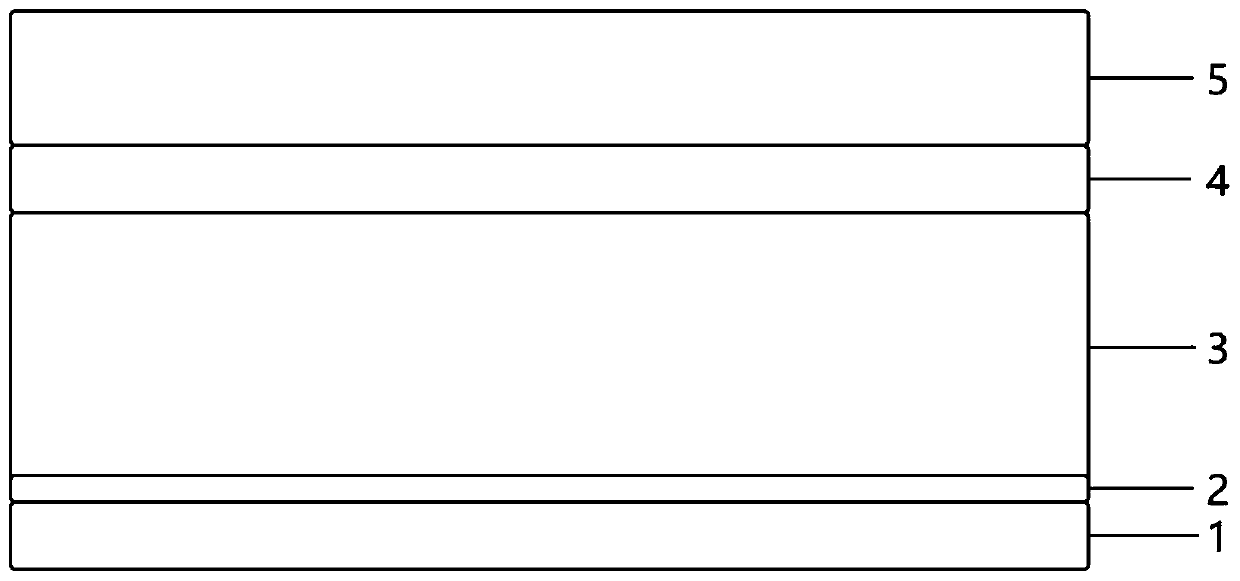

Reflective silica gel decoration sheet and preparation method thereof

InactiveCN110466227ASoft materialFeel goodLiquid surface applicatorsLamination ancillary operationsChemistryHot-melt adhesive

The invention relates to the technical field of decoration sheet manufacturing, and especially relates to a reflective silica gel decoration sheet and a preparation method thereof. The reflective silica gel decoration sheet sequentially includes a PET protective film, a reflective layer, a silica gel base layer, a silica gel bonding layer and a hot-melt adhesive film from bottom to top, and the reflective layer includes, by weight, 10-15 parts of reflective powder, 60-80 parts of silica gel and 3-5 parts of a diluent; the silica gel base layer includes, by weight, 4-6 parts of the silica gel and 3-5 parts of the diluent; and the silica gel bonding layer includes, by weight, 29-43 parts of the silica gel and 3-5 parts of the diluent. The reflective silica gel decoration sheet of the presentinvention is simple to make, and has the characteristics of cross color resistance, soft touch feeling, washing resistance, aging resistance and environmental protection.

Owner:张忠松

Preparation method of anti-microbial color absorption cloth for preventing color crossing during laundry

The invention relates to a preparation method of an anti-cross-color antibacterial laundry color-absorbing cloth. The method uses chitosan non-woven fabric and a color-fixing agent as main raw materials, and uses a color-fixing agent solution to dynamically treat chitosan non-woven fabrics at a certain temperature. The cloth is spun and dried to obtain an anti-cross-color antibacterial and color-absorbing cloth. The preparation method of the present invention is simple in process, and the process conditions are highly controllable. The present invention can absorb dyes dissolved in water to prevent it from polluting other fabrics of different colors, and has antibacterial and bactericidal effects on the washed fabrics, and can seal the dyes on the fabrics at the same time. The water-soluble groups of dye molecules fix the color of colored fabrics.

Owner:天津晖景隆科技有限公司

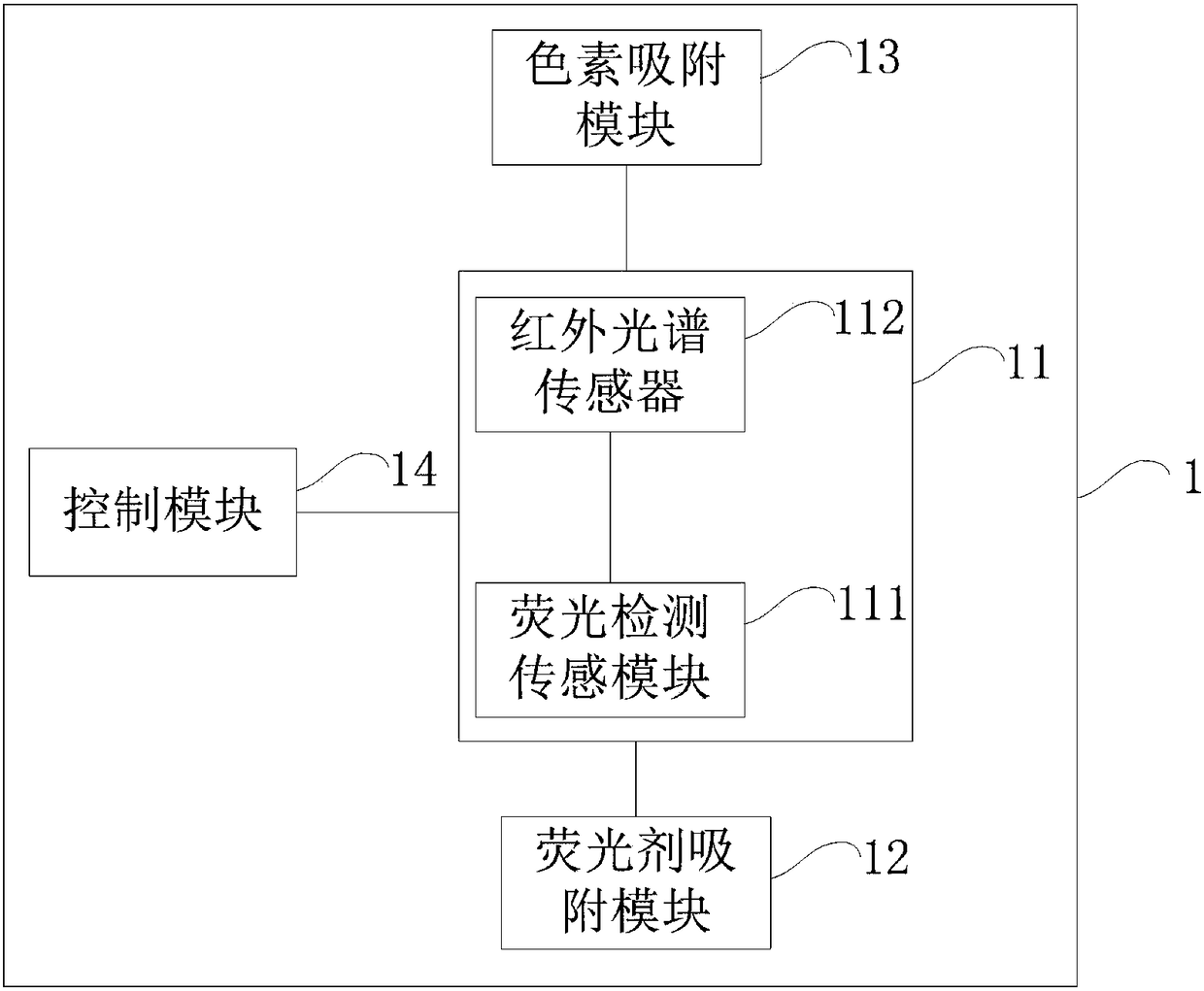

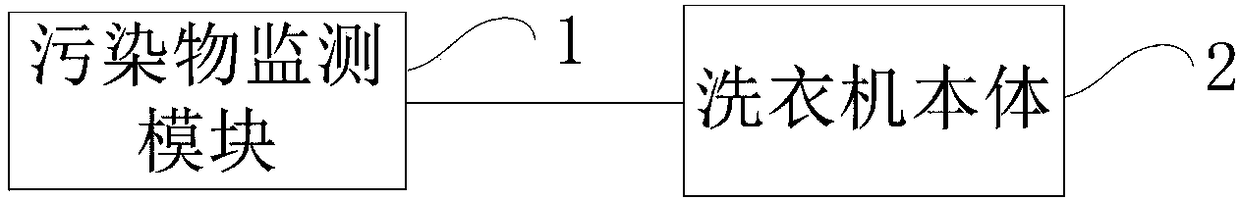

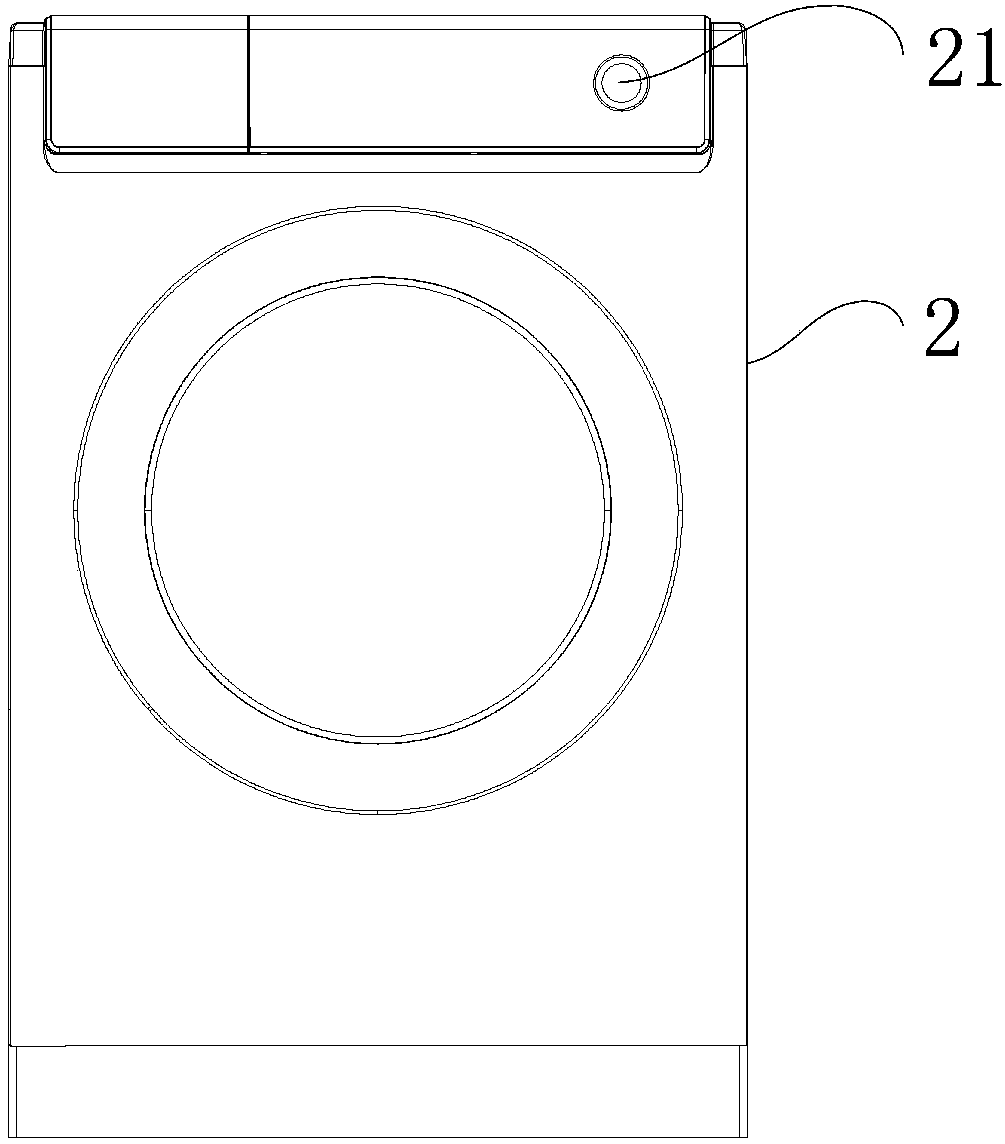

Pollutant monitoring module used for washing machine, washing machine, and control method thereof

ActiveCN108930138AFlexible identificationEasy to identifyOther washing machinesControl devices for washing apparatusEngineeringFluorescent light

The invention relates to the technical field of washing machines, and an objective is to solve problems that a fluorescent agent and / or pigments cannot be detected flexibly and conveniently, and accumulation of the fluorescent agent and / or pigments in a washing machine cannot be prevented. For this purpose, the invention provides a pollutant monitoring module used for a washing machine, a washingmachine, and a control method thereof. The pollutant monitoring module can be connected with a washing machine body in a detachable manner, and the pollutant monitoring module comprises an identification module. In a dismounted state and / or a connected state of the pollutant monitoring module, the identification module can identify pollutants in a detected object. The washing machine comprises thepollutant monitoring module. The control method comprises: making the pollutant monitoring module close to clothes or making clothes close to the pollutant monitoring module, to identify whether clothes pigments and / or the clothes have fluorescent agents; and according to information of the identified pigments and / or the fluorescent agents, recommending a washing program. The module can flexiblydetect the fluorescent agents and / or the pigments, and absorb the fluorescent agents and / or the pigments.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Duplex printing and automatic single-face film covering printing and dyeing device

InactiveCN107813593ASimple mechanical structureImprove mechanical stabilityTransfer printingStainingEngineering

A duplex printing and automatic single-face film covering printing and dyeing device comprises a rack, a transfer film conveying part, a transfer back plate conveying part, a fabric conveying part, afabric rolling part, a transfer back plate rolling part, a transfer back plate separation part and an embossing part. The mechanical structure of the printing and dyeing device is simple, and during transfer printing, machine operation is high in stability. According to a transfer printing process, a roller transfer method, namely cold transfer printing, at the natural environment temperature is adopted, and the situation that transfer patterns are dim during traditional transfer printing can be prevented. A pattern is printed and dyed to a fabric through a transfer film, a printing and dyeingback plate assists in the printing and dyeing processes, after embossing is completed, the back plate is stripped off, cyclic utilization is achieved, and the transfer film is not stripped off and isrolled and stored along with the fabric; due to the existence of the transfer film, the transfer film can protect the printed and dyed fabric; and the transfer film is located between the two layersof fabrics all the time when the transfer film is rolled along with the fabrics, the situation that the printed and dyed fabrics make direct contact is avoided, cross color and mutual staining of dyesare avoided, and the duplex printing and automatic single-face film covering printing and dyeing device has the beneficial effect of being high in production efficiency.

Owner:TONGXIANG YIZHIJIANNENG INFORMATION TECH

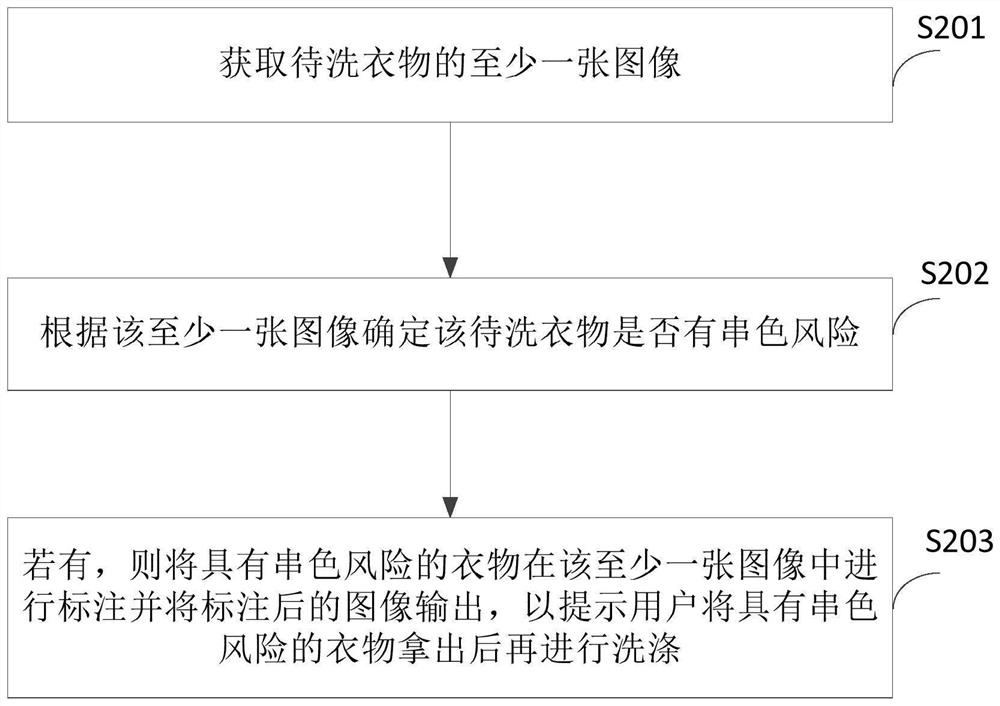

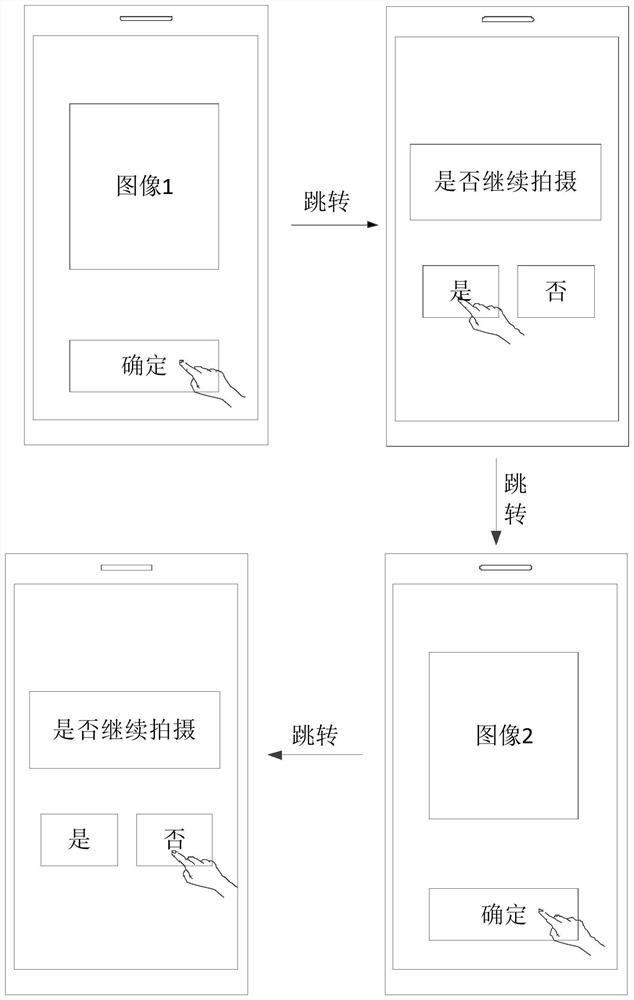

Clothes color crossing identification method and device, equipment and storage medium

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

Color-protection and color-absorption sheet

InactiveCN107476096APrevent discolorationColor crossing is convenient and easy to useFibre treatmentDyeing processWoven fabricHoneycomb

The invention discloses a color-protection and color-absorption sheet, which comprises a non-woven fabric layer, color absorption layers and color protection layers, wherein the color absorption layers coat the two sides of the non-woven fabric layer; the color protecting layers coat the outer sides of the color absorption layers. The non-woven fabric layer comprises a spunlace non-woven fabric; honeycomb holes are spread all over the spunlace non-woven fabric; the color absorption layers comprise active solid cationic etherifying agents and non-water-soluble adhesives; the color protecting layers comprise color protecting agents, film forming agents and water-soluble bonding agents. The color-protection and color-absorption sheet provided by the invention has the advantages that the decoloration and color staining during the clothes washing can be effectively prevented; in addition, convenience is realized; the use is easy.

Owner:诺圆环保科技(苏州)有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com