Transverse ink scrapping ink stack for improving printing quality

A technology of printing quality and ink stack, applied in printing and other directions, can solve problems such as unclean ink hanging, ink hanging, and color smearing, so as to shorten the ink scraping time, avoid color smearing, and improve the printing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

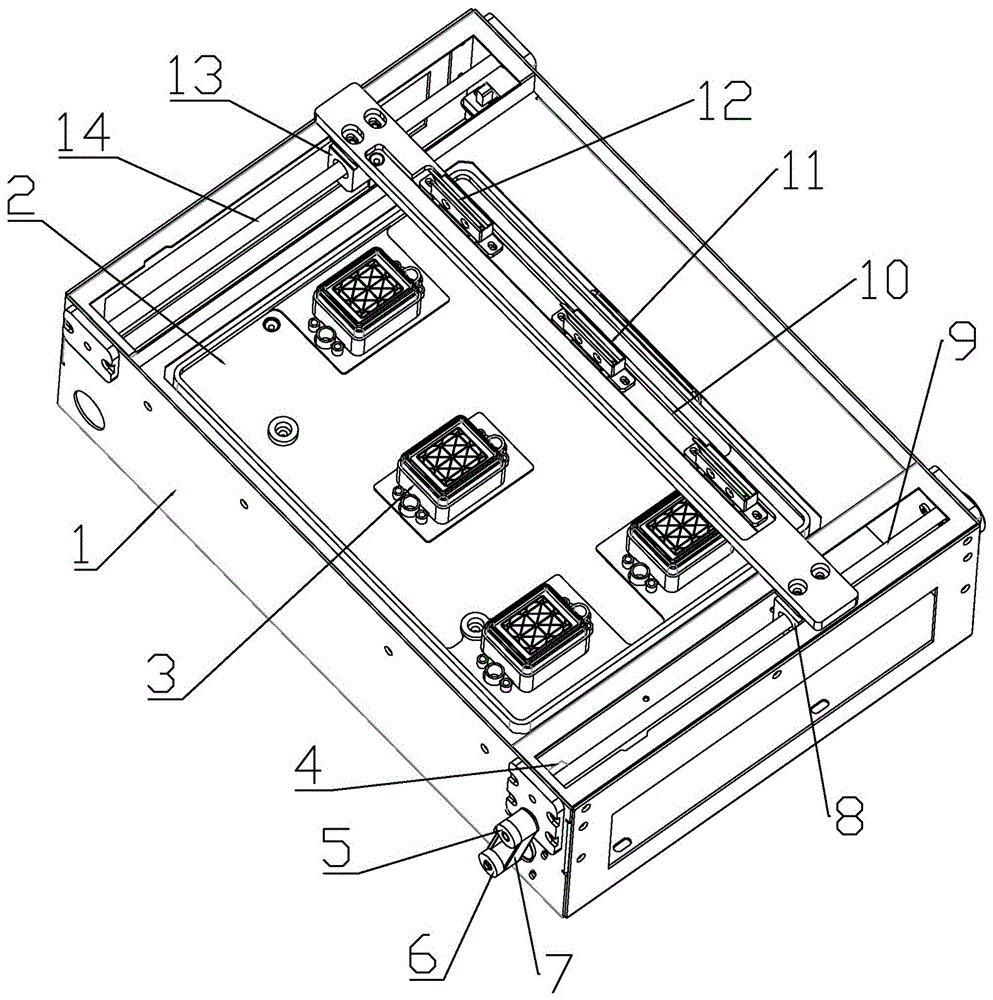

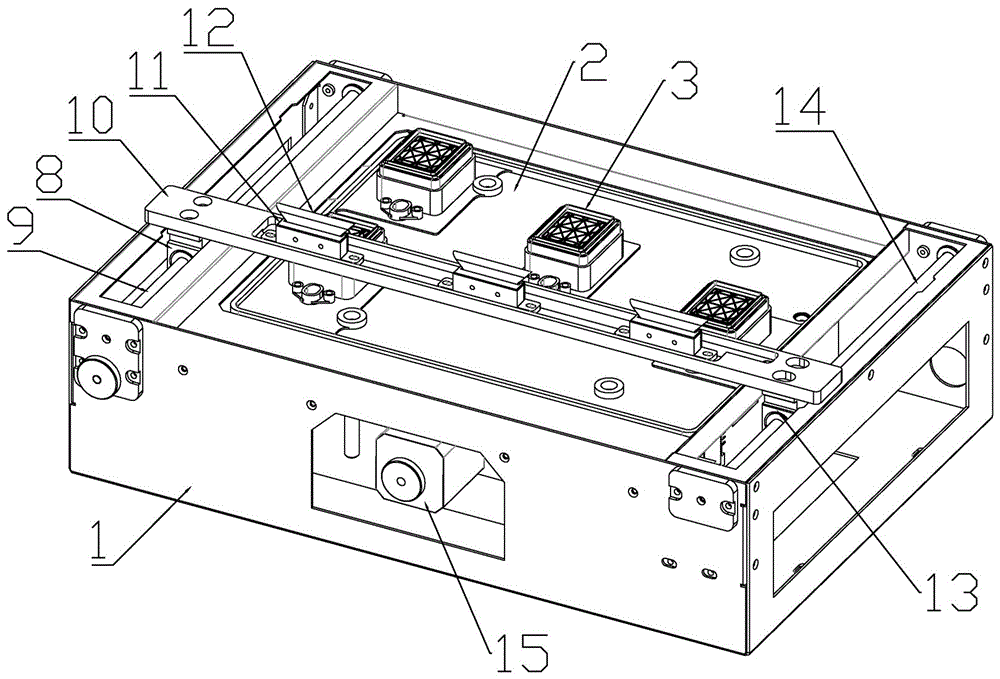

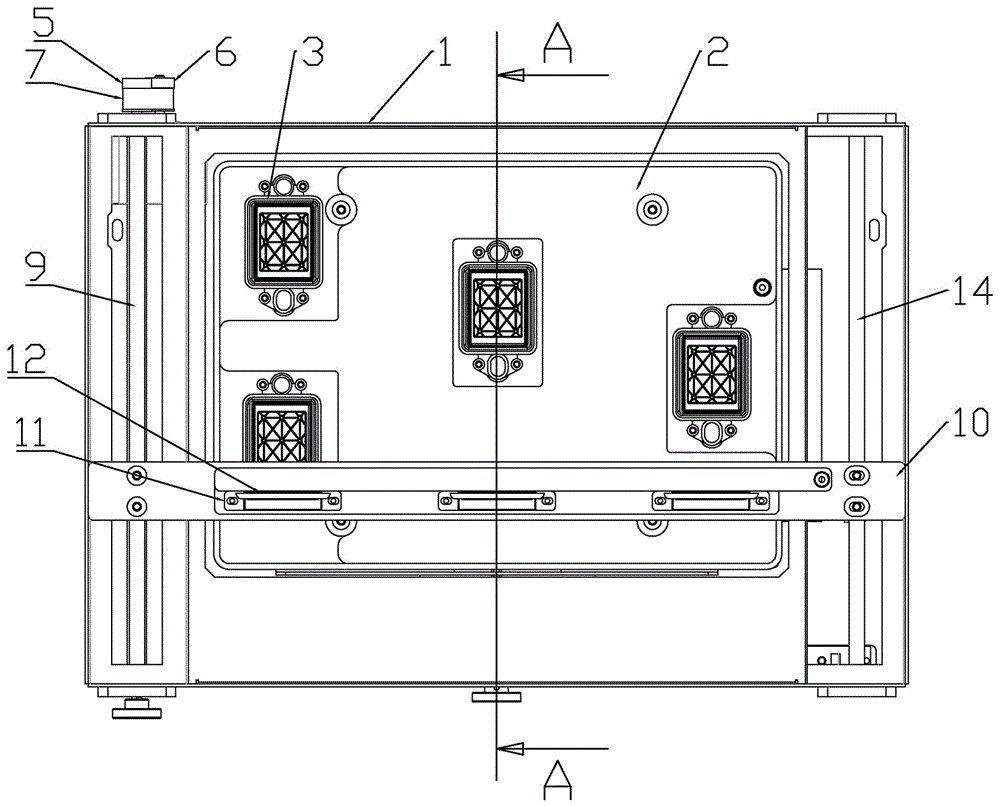

[0020] The specific embodiment of the present invention sees Figure 1-8 , a horizontal scraping ink stack for improving printing quality, including a bottom frame and a scraper base above the bottom frame, an ink stack base is provided on the upper end of the bottom frame, an ink stack is provided on the upper end of the ink stack base, and the ink stack base has two sides The side racks are respectively equipped with a scraper base driving screw and a scraper base slide rail. The scraper base driving screw is set with a scraper base drive nut, and the scraper base slide rail is set with a scraper base driven slider. One end of the scraper base is connected with the driving nut of the scraper base, the other end of the scraper base is connected with the driven slider of the scraper base, the upper end of the scraper base is provided with a scraper seat, and a scraper is arranged in the scraper seat, The scraper is perpendicular to the strip-shaped ink outlet at the bottom of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com